When it comes to machining hard materials or running long production cycles, tungsten carbide cutting tools are often the first choice.

These tools are known for their exceptional wear resistance, but what exactly gives them that strength?

In this article, we’ll break down the science behind why tungsten carbide tools last longer, resist damage, and keep cutting cleanly—even under extreme conditions.

Whether you run a CNC shop or manage tool procurement, understanding wear resistance helps you choose better tools, reduce downtime, and lower your total machining costs.

What Is Wear Resistance and Why Does It Matter?

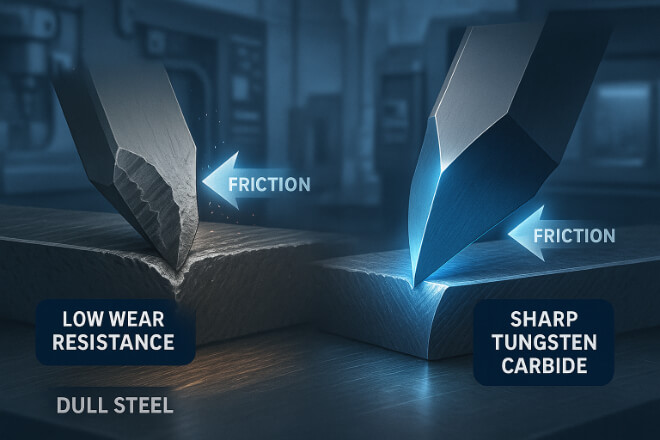

Wear resistance is the ability of a material to withstand gradual surface damage caused by use, friction, heat, and cutting forces.

For cutting tools, high wear resistance means the tool maintains its shape and sharpness longer—even in tough conditions.

Without good wear resistance:

Edges dull quickly

Tools break under pressure

Surface finish becomes poor

Tool life shortens, increasing costs

Tungsten carbide tools are specially made to resist these issues. But what gives them that edge?

The Structure of Tungsten Carbide: Hardness Meets Strength

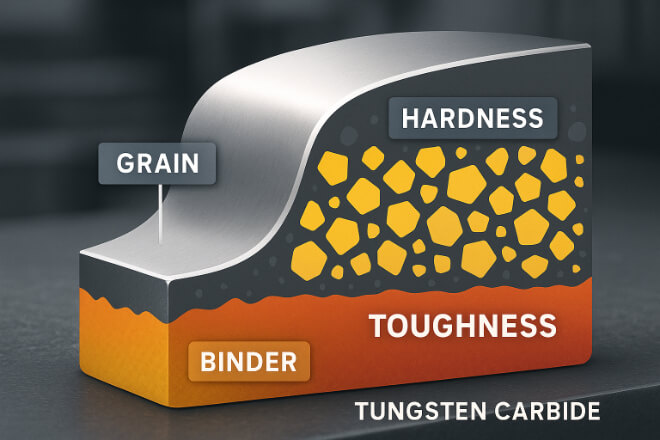

Tungsten carbide is not a single metal. It’s a composite material made from two key parts:

Tungsten carbide grains – extremely hard ceramic particles

Cobalt binder – a metal that holds the grains together and gives the material toughness

This structure offers a perfect balance:

Hard grains cut through tough materials and resist wear

Tough binder prevents cracking and absorbs shocks

The combination of hardness and toughness is what makes tungsten carbide ideal for cutting tools.

This structure outperforms traditional tool materials like high-speed steel in both tool life and cutting performance.

Types of Tool Wear and How Carbide Fights Them

There are different kinds of tool wear that happen during machining. Let’s look at them and see how tungsten carbide helps reduce damage:

| Type of Wear | What Happens | How Tungsten Carbide Helps |

|---|---|---|

| Abrasive Wear | Chips or dust grind away the tool surface | Hard tungsten grains resist grinding |

| Adhesive Wear | Workpiece material sticks and tears tool edges | Smooth carbide surface reduces sticking |

| Thermal Cracking | Heat cycles cause small cracks | Carbide handles high heat better than steel |

| Notching | Repeated impact at the cutting edge weakens the tool | Carbide’s toughness reduces edge chipping |

| Diffusion Wear | Material atoms move from tool to workpiece | Carbide resists chemical breakdown at high heat |

By resisting all these wear types, tungsten carbide tools last much longer in real-world machining.

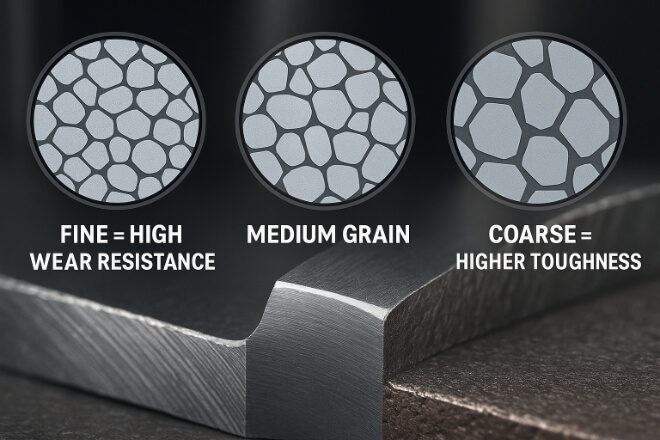

Grain Size and Wear Resistance: Bigger Isn’t Always Better

Did you know the size of the tungsten carbide grains affects tool performance?

Fine grains (nano or submicron): Better wear resistance, harder edges, great for precision work

Coarse grains: Higher toughness, good for heavy-duty roughing

Choosing the right grain size depends on your application. For example:

Fine grain carbide is perfect for aluminum, finishing, or tight tolerances

Medium/coarse grain carbide works well for steels and harder metals

Modern tools often use multi-layer grain structures to get the best of both worlds.

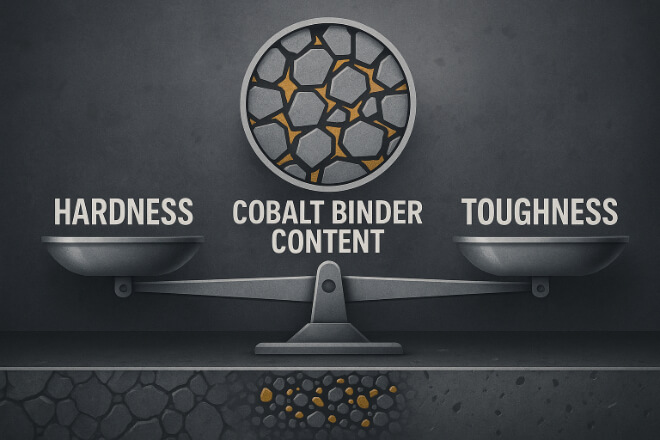

The Role of Cobalt Binder in Reducing Tool Wear

The cobalt binder in tungsten carbide plays a critical role in how the tool handles impact, vibration, and temperature.

Here’s how:

More cobalt = better toughness, less brittle

Less cobalt = more hardness, better wear resistance

Too much cobalt and the tool may deform. Too little and it may chip or crack. That’s why high-quality carbide grades carefully control cobalt levels to balance both properties.

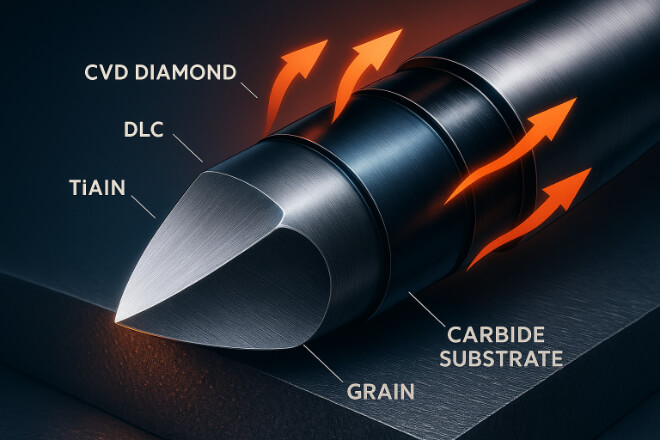

How Coatings Improve Wear Resistance Even Further

While tungsten carbide is already tough, adding a protective coating can make it even more wear-resistant.

Common coatings include:

TiAlN (Titanium Aluminum Nitride) – great for heat and oxidation resistance

AlTiN – provides a hard outer shell, ideal for dry machining

DLC (Diamond-Like Carbon) – low friction, perfect for aluminum

CVD Diamond – for extremely abrasive materials like composites or graphite

Coatings:

Reduce heat buildup

Prevent material sticking

Increase surface hardness

Help chips flow smoothly

That’s why most premium carbide tools today are coated using PVD or CVD technology.

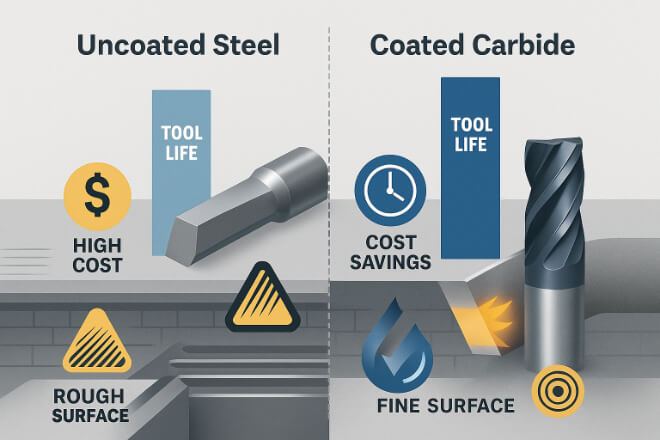

Real-World Results: Longer Tool Life, Lower Costs

The science is clear—but how does this help your shop?

When you use wear-resistant carbide tools, you get:

Fewer tool changes

Less downtime

Better surface finish

Higher machining speeds

Longer tool life

That means:

Lower total tool cost over time

Better quality parts

More jobs completed without delay

In fact, shops switching from uncoated steel tools to coated tungsten carbide often see tool life improve by 3x or more.

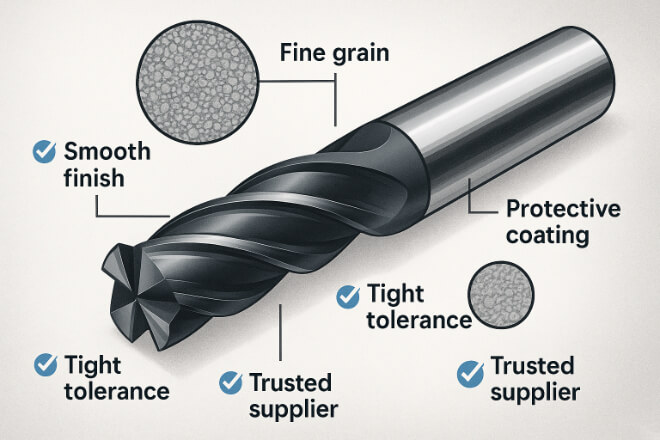

What to Look for in a Wear-Resistant Carbide Tool

If you want better wear resistance, here are key things to check:

Fine grain structure for precise work

Cobalt content that matches your material

High-quality coatings

Tight tolerances and smooth finishes

Supplier reputation (not all carbide is equal)

Avoid cheap tools with inconsistent materials or poor coatings—they wear out fast and end up costing more.

How to Get the Most from Your Carbide Tools

Even with the best material, tool wear can still happen if:

Speeds and feeds are too aggressive

Tools aren’t stored properly

Chips aren’t cleared quickly

Workpieces are not clamped tightly

Simple steps like proper setup, coolant use, and regular inspection help protect your tools—and your investment.

Final Thoughts: The Science Delivers Real Value

The wear resistance of tungsten carbide cutting tools is not magic—it’s materials science at work.

From hard carbide grains to cobalt binders and advanced coatings, every part is designed to make the tool last longer and cut cleaner.

For decision-makers, the takeaway is simple: wear resistance = cost savings. Investing in high-quality carbide tools reduces tool replacements, improves part quality, and boosts machine uptime.

If you’re serious about better machining results, switch to tools built on real science. Start with trusted suppliers who understand your needs—and can deliver tools that perform.

Need help choosing the right grade? Visit Retopz or contact our support team for expert guidance.