In modern industrial machines, parts are often exposed to friction, pressure, and harsh materials that cause wear.

Once wear begins, efficiency drops, clearances increase, and failures become more frequent.

To prevent this, engineers use materials that can withstand these demanding conditions — one of the most successful being tungsten carbide.

Among its many uses, tungsten carbide bushings are essential in pumps, turbines, compressors, and other rotating systems.

Their outstanding wear resistance comes from a combination of material hardness, structure, and microchemical design.

This article explains the science behind this wear resistance — how tungsten carbide’s internal structure, bonding, and surface properties work together to deliver exceptional durability.

What Causes Wear in Bushings

Before understanding why tungsten carbide performs so well, it’s helpful to review what causes wear in the first place.

In mechanical systems, wear occurs through several mechanisms:

Abrasive wear – when hard particles or rough surfaces cut into softer materials.

Adhesive wear – when two surfaces stick and tear small fragments during sliding.

Erosive wear – when particles or fluids strike surfaces at high velocity.

Corrosive wear – when chemicals attack material surfaces, weakening them.

Most bushings in pumps, compressors, and turbines face combinations of these mechanisms — especially abrasive and erosive wear from solid particles in fluids.

What Makes Tungsten Carbide So Resistant

Tungsten carbide (WC) is a compound of tungsten (W) and carbon (C).

Its unique properties make it one of the hardest materials used in industry — second only to diamond.

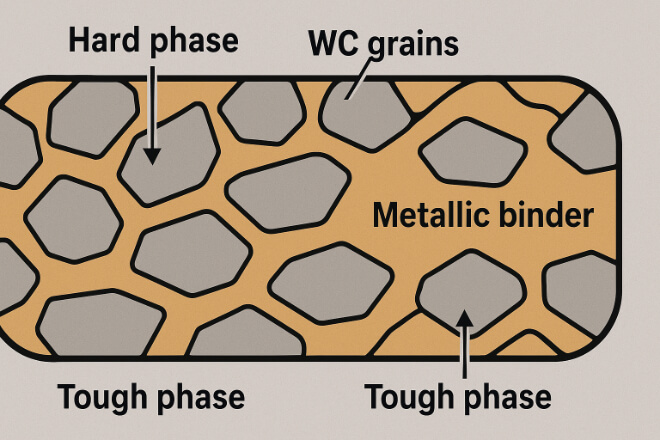

The hard WC grains resist cutting and scratching, while the metallic binder (usually cobalt or nickel) provides toughness and energy absorption.

Together, they form a microstructure that resists both abrasion and cracking.

The hardness of tungsten carbide typically falls between 88–92 HRA, several times harder than hardened steel.

Microstructure and Its Role in Wear Resistance

| Feature | Description | Effect on Wear Resistance |

|---|---|---|

| WC Grain Size | Fine grains (0.5–1.5 µm) provide smoother, denser structure | Higher hardness, better polishing ability |

| Binder Phase | Cobalt or Nickel binder between carbide grains | Improves toughness and prevents brittle failure |

| Porosity | Controlled low porosity (<1%) after sintering | Reduces crack initiation and erosion paths |

The tighter and more uniform the structure, the harder it is for wear to start. Fine-grain carbides are especially effective for precision bushings where surface finish and dimensional stability are critical.

The Hardness Advantage

Hardness is the main reason tungsten carbide resists wear. The higher the hardness, the more difficult it is for abrasive particles to cut or deform the surface.

Typical hardness comparison:

| Material | Hardness (HRA) | Relative Wear Life |

|---|---|---|

| Bronze | 45–60 | Low |

| Hardened Steel | 65–75 | Medium |

| Tungsten Carbide | 88–92 | Very High |

Because tungsten carbide is so hard, abrasive particles simply slide across its surface instead of embedding and cutting.

The Importance of the Binder Phase

The metal binder is what keeps tungsten carbide from being brittle. Without it, pure WC would be extremely hard but would crack easily.

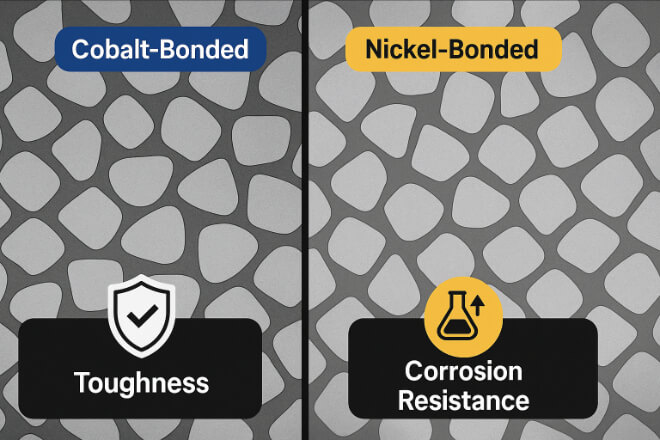

Cobalt binders give higher toughness and fatigue resistance.

Nickel binders add corrosion resistance, useful in seawater or chemical fluids.

Binder content typically ranges from 6% to 12% — less binder means more hardness, more binder means more toughness.

The key to wear resistance is maintaining the right hardness-to-toughness balance for the specific operating environment.

Chemical Stability and Oxidation Resistance

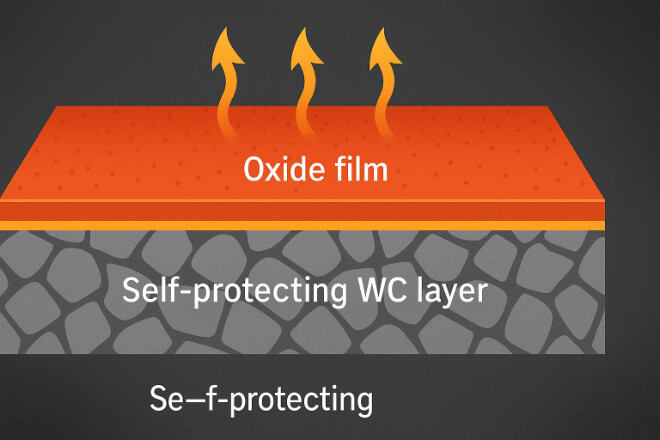

Wear isn’t only mechanical. High temperatures and reactive fluids can chemically attack surfaces.

Tungsten carbide has high chemical stability — the WC compound forms a protective oxide layer that resists further attack.

In addition, nickel-bonded carbides perform better in corrosive fluids such as acids or saltwater.

This combination of mechanical and chemical resistance gives tungsten carbide bushings their exceptional service life.

Friction, Surface Finish, and Polishing

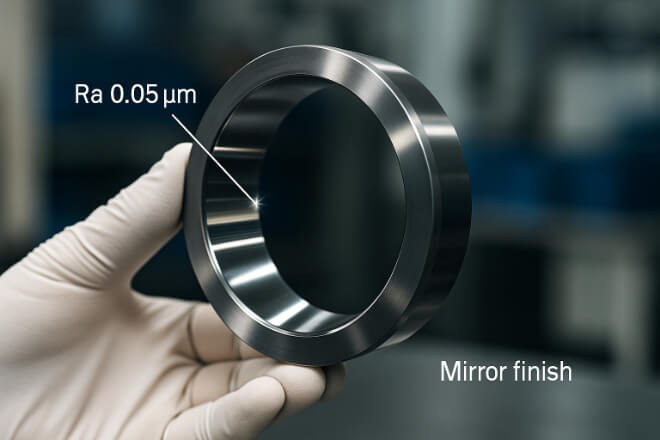

Another reason tungsten carbide bushings resist wear is the ability to achieve extremely fine surface finishes.

A properly lapped carbide bushing can reach Ra ≤ 0.05 μm, producing a mirror-like surface.

The smoother the surface, the lower the friction and the slower the wear process.

Smooth surfaces also minimize fluid turbulence and reduce heat generation — key factors for high-speed rotating equipment.

Thermal Conductivity and Heat Dissipation

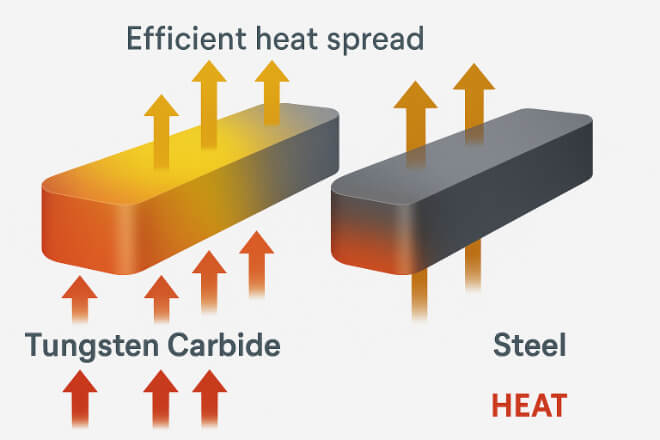

Tungsten carbide conducts heat well compared to ceramics or hardened steels. This helps distribute and remove the heat generated by friction.

Stable temperature means less thermal expansion and lower risk of distortion, keeping shaft alignment and clearance intact over long operating hours.

Practical Examples: Where Wear Resistance Matters Most

| Industry | Typical Operating Conditions | Why WC Bushings Are Preferred |

|---|---|---|

| Oil & Gas | High pressure, abrasive drilling fluids | High hardness prevents particle erosion |

| Mining & Slurry | Sand and solid-laden flow | Coarse-grain WC absorbs impacts and resists wear |

| Marine | Saltwater, variable load | Ni-bonded WC resists corrosion and pitting |

In all these industries, the wear resistance of tungsten carbide directly improves equipment reliability and lowers total ownership cost.

Summary of Key Factors

| Factor | Role in Wear Resistance |

|---|---|

| Hardness | Prevents abrasion and indentation |

| Toughness | Prevents cracking and chipping |

| Grain Size | Controls hardness and polishability |

| Binder Phase | Adds ductility and corrosion resistance |

| Surface Finish | Reduces friction and heat buildup |

| Chemical Stability | Prevents corrosion-related wear |

Conclusion

The wear resistance of tungsten carbide bushings is not accidental — it is the result of precise material engineering.

From the atomic bonding between tungsten and carbon to the careful choice of grain size and binder type, every detail is optimized for durability.

For decision-makers in manufacturing, chemical processing, or energy industries, using tungsten carbide bushings means reduced downtime, fewer replacements, and longer-lasting machines.

When operating conditions demand high reliability under pressure, the science of tungsten carbide wear resistance delivers performance that pays off over time.

If you want to know more details about any company, please feel free to contact us.