Introduction

Tungsten carbide cutting tools are important in many industries. They help improve precision cutting, speed, and tool life in machining processes. Because of their wear resistance and hardness, carbide cutting tools are used in many sectors to increase productivity and reduce costs.

This guide will show you the top applications of tungsten carbide cutting tools across different industries, helping you understand why they are the first choice for many manufacturers.

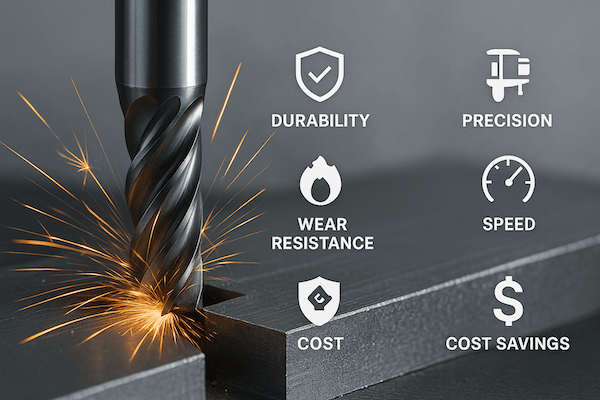

Why Tungsten Carbide Cutting Tools Are Important

Tungsten carbide cutting tools are made from a material that is much harder than steel. They can keep their sharp edges for a long time, even during high-speed machining. They also resist heat, making them ideal for many cutting applications.

Main benefits of tungsten carbide cutting tools:

✅ Long tool life

✅ High cutting speed

✅ Excellent surface finish

✅ Suitable for hard materials

✅ Reduced downtime in workshops

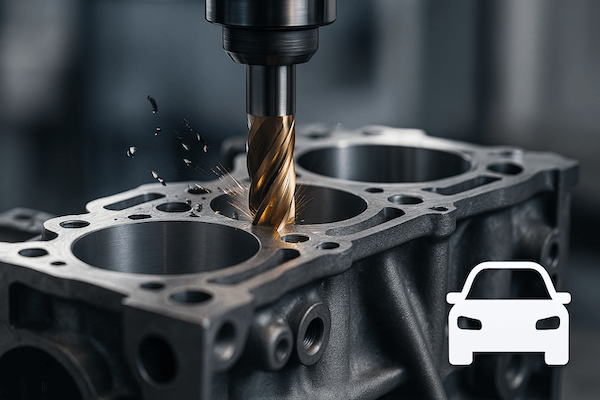

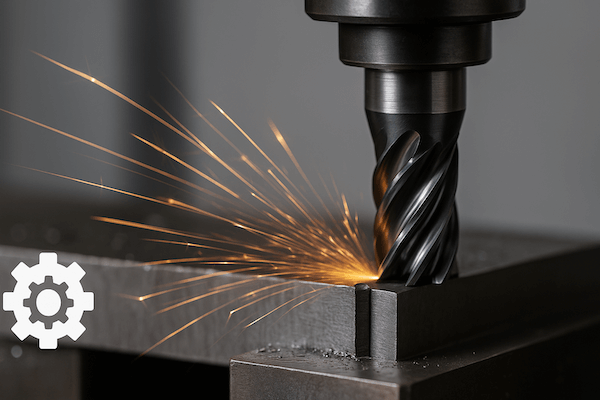

Automotive Industry

The automotive industry uses tungsten carbide cutting tools to machine parts like engine blocks, transmission parts, and brake systems. These parts need high precision, and carbide cutting tools help achieve tight tolerances.

Carbide cutting tools are used in:

Milling and drilling engine components

Cutting brake disc and drum surfaces

Precision boring and reaming

For high-precision automotive parts, tungsten carbide cutting tools help improve production speed and quality.

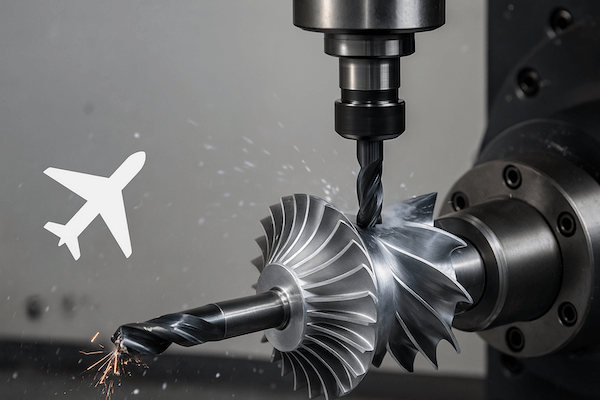

Aerospace Industry

In the aerospace industry, materials like titanium and nickel alloys are used. These materials are tough to machine, but tungsten carbide cutting tools can handle them effectively due to their hardness and heat resistance.

Applications include:

Cutting turbine blades

Machining landing gear parts

Creating precision holes in aircraft components

These tools help the aerospace industry achieve high precision and surface quality, critical for flight safety.

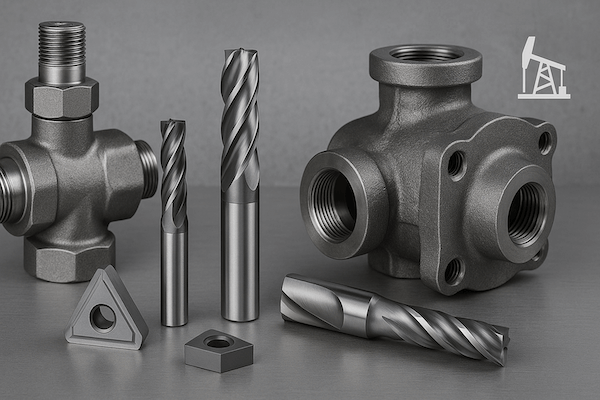

Oil and Gas Industry

The oil and gas industry uses tungsten carbide cutting tools to machine heavy-duty parts like valves, drilling components, and pump parts that operate in harsh environments.

Carbide cutting tools help by:

Cutting hard and abrasive materials

Resisting corrosion in harsh environments

Providing longer tool life in tough drilling operations

Metalworking Industry

Tungsten carbide cutting tools are commonly used in metalworking for milling, turning, and drilling operations on various metals, including steel, stainless steel, and cast iron.

Applications:

Machining machine parts

Cutting dies and molds

Making precision components for different machinery

Because of their high cutting speeds and wear resistance, carbide cutting tools help reduce machining time and increase productivity in metal workshops.

Woodworking Industry

In the woodworking industry, tungsten carbide cutting tools are used to cut and shape wood, MDF, and composite materials.

Carbide-tipped saw blades and router bits are used for:

Cutting panels and boards

Shaping and profiling wood edges

Creating furniture parts with clean edges

These tools last longer than traditional steel tools and provide smoother cuts in woodworking applications.

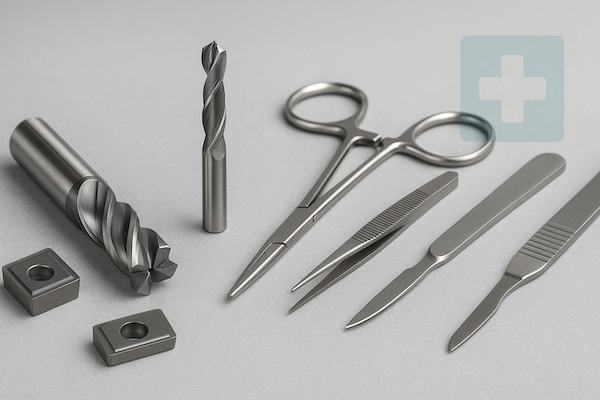

Medical Industry

The medical industry requires high-precision components for medical devices and surgical tools. Tungsten carbide cutting tools are used for machining:

Surgical instruments

Dental tools

Implant components

The tools help achieve the smooth surfaces and tight tolerances needed for medical devices.

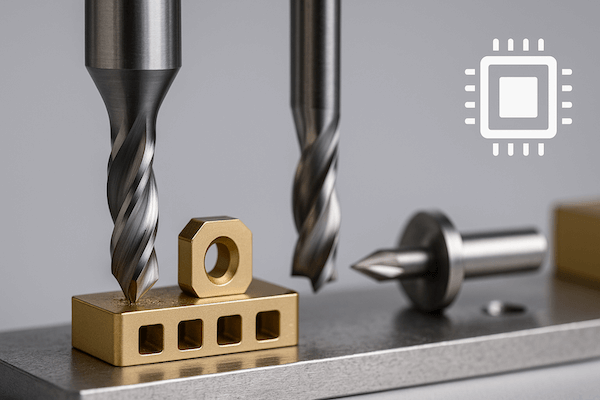

Electronics and Precision Parts Manufacturing

In electronics and precision parts manufacturing, small and complex components are made using tungsten carbide cutting tools.

Applications include:

Machining electronic connectors

Making small metal housings for devices

Cutting precision parts for microelectronics

Carbide cutting tools allow manufacturers to maintain tight tolerances and high-quality surface finishes.

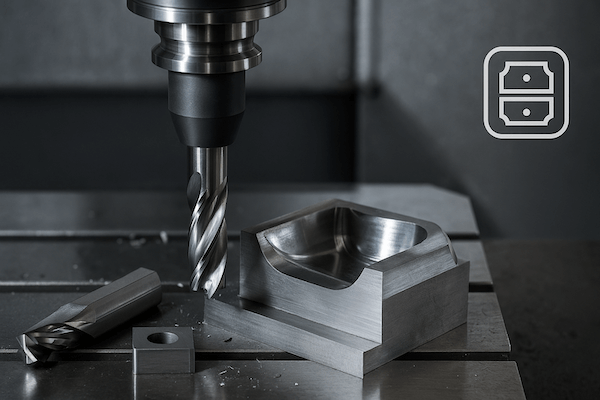

Mold and Die Industry

Tungsten carbide cutting tools are used to machine molds and dies, which require high hardness and precision.

Applications:

Machining injection molds

Cutting die surfaces

Creating precision cavities

These tools help achieve a high-quality surface finish and maintain dimensional accuracy in mold and die making.

Why Choose Retop for Tungsten Carbide Cutting Tools?

Retop offers high-quality tungsten carbide cutting tools designed to improve your machining processes. We provide:

✅ Tools with high hardness and wear resistance

✅ Customized carbide cutting tools for your needs

✅ Reliable and consistent quality

✅ Fast delivery and global service

To explore our carbide tool options, visit our Tungsten Carbide Cutting Tools page.

Conclusion

Tungsten carbide cutting tools play a crucial role in many industries, including automotive, aerospace, oil and gas, metalworking, woodworking, medical, electronics, and mold making.

By using carbide cutting tools, you can:

✅ Improve productivity

✅ Reduce machining time

✅ Achieve high precision and surface quality

✅ Save costs in the long run

If you want to enhance your CNC machining and manufacturing processes, tungsten carbide cutting tools are a smart investment.