What is Toughness?

Toughness is the ability of a material to absorb energy and plastically deform without fracturing. It reflects a material’s resistance to impact, shock, and sudden failure. Unlike hardness, which resists surface indentation, toughness deals with the material’s internal ability to withstand crack propagation and sudden loads.

In simple terms, a tough material bends or deforms before breaking, whereas a brittle material cracks or shatters.

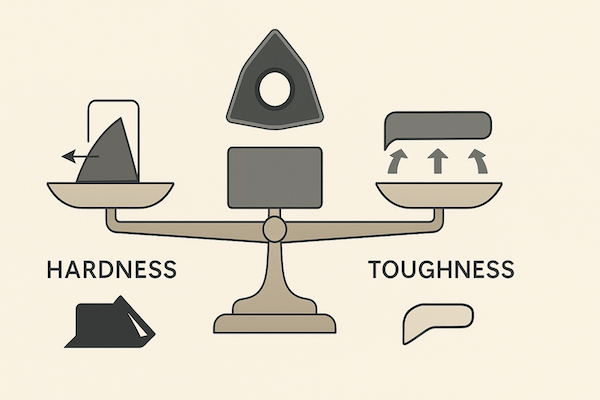

Toughness vs. Hardness – A Crucial Trade-off

In engineering materials, hardness and toughness are often inversely related. Increasing hardness usually reduces toughness, and vice versa. This trade-off becomes especially critical in tungsten carbide tools, which must strike a balance between:

Hardness – for wear resistance and precision cutting

Toughness – for shock absorption, impact resistance, and tool life

For example, a carbide cutting tool edge that is too hard may chip easily during interrupted cutting, while one that is too tough may wear faster.

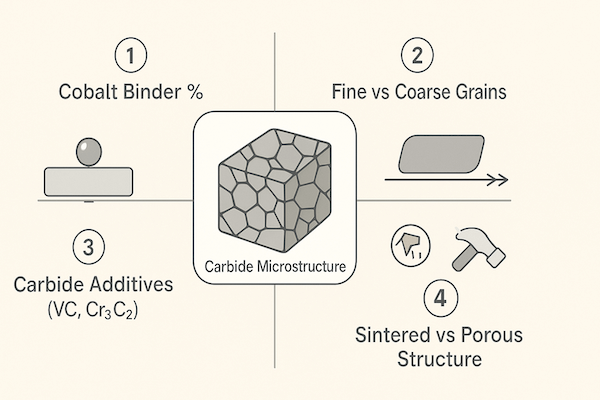

What Affects Toughness in Tungsten Carbide?

Tungsten carbide (WC) is inherently hard and brittle, but when combined with a metallic binder such as cobalt (Co), it becomes a cemented carbide. The toughness of cemented carbide depends on several factors:

1. Binder Content

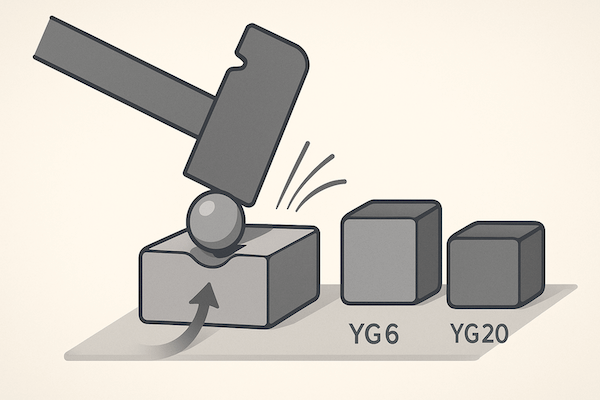

Higher cobalt content generally improves toughness but reduces hardness. For example:

YG20 (20% Co) has high toughness, suitable for impact tools.

YG6 (6% Co) has high hardness, better for wear applications.

2. Grain Size

Fine-grained WC offers better toughness than coarse grains due to a more uniform microstructure and better crack resistance.

3. Additives

Grain growth inhibitors such as VC, Cr₃C₂, or TaC are added to enhance both hardness and toughness simultaneously.

4. Sintering Quality

Porosity and micro-cracks from poor sintering can significantly reduce toughness. High-density, flaw-free carbide offers superior fracture resistance.

Importance of Toughness in Carbide Tool Applications

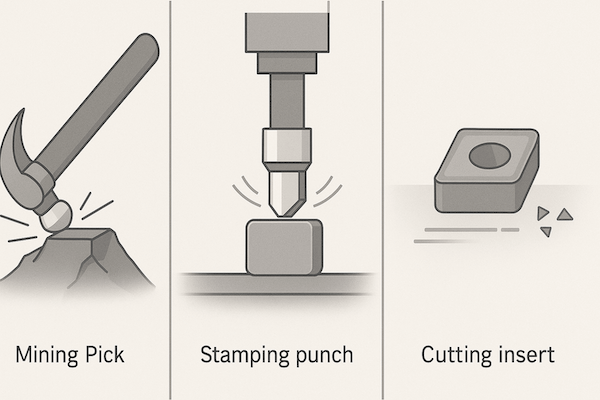

Toughness plays a critical role in tool performance, especially in dynamic or impact-heavy applications, such as:

Mining bits and tunnel boring tools – resist rock impact and vibration

Punch dies and stamping tools – survive repeated mechanical shock

Cutting inserts for cast iron – endure intermittent cutting loads

Woodworking and metal saw tips – prevent edge chipping during use

In these applications, tools must withstand high-stress environments without breaking or chipping, which makes toughness a key performance parameter.

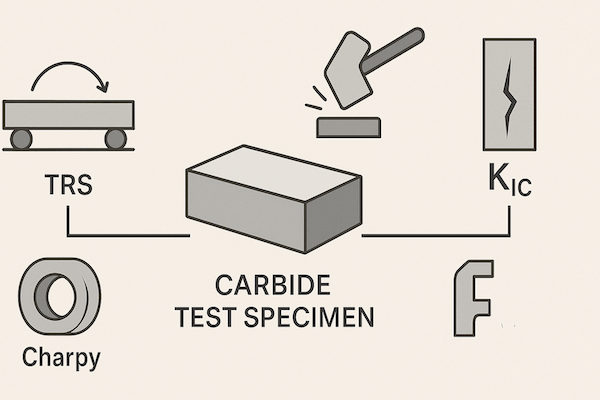

How Toughness is Measured

Toughness is not directly measured in units like hardness or density. Instead, it’s evaluated using tests such as:

Transverse rupture strength (TRS) – measures the force a sample can take before fracture

Charpy impact test – quantifies absorbed energy upon impact

Fracture toughness (K_IC) – reflects crack propagation resistance

These values help carbide manufacturers design grades tailored to specific demands.

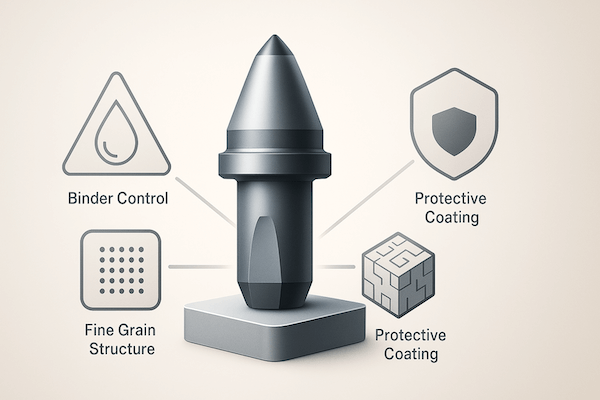

Balancing Toughness and Performance

Tool designers and carbide producers must carefully match the toughness of a tool to its intended use. Over designing for toughness can lead to excessive wear, while under designing leads to premature failure. Modern carbide technology focuses on:

Microstructure control

Binder phase optimization

Advanced coatings to maintain wear resistance while relying on core toughness

Conclusion

Toughness is a fundamental property that defines the durability and reliability of tungsten carbide tools. Especially in high-impact or cyclic-load environments, selecting the right grade with optimal toughness ensures longer tool life, reduced failure rates, and greater overall efficiency. Understanding how toughness interacts with binder content, grain size, and application demands is key to developing high-performance cemented carbide solutions.