Tribology is the science of friction, wear, and lubrication, and it plays a crucial role in the performance of mechanical systems.

In applications where components are subjected to heavy loads and harsh conditions, understanding tribology is essential for improving the reliability and lifespan of the system. Tungsten carbide bushings are widely used in these applications due to their high wear resistance and toughness.

In this blog, we will explore the basics of tribology as it relates to tungsten carbide bushings and how engineers can apply tribological principles to enhance performance and prevent premature failure.

What is Tribology?

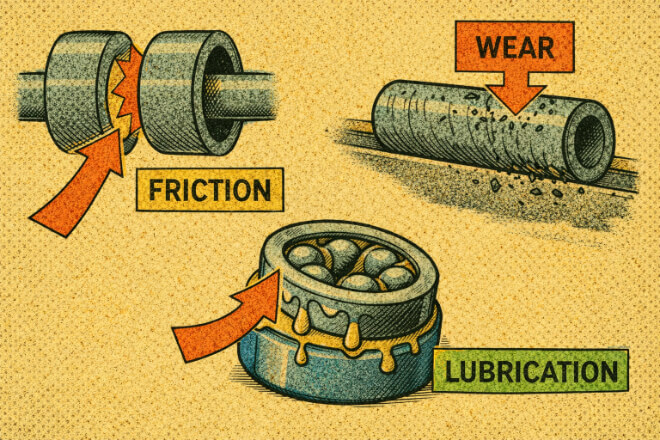

Tribology is the study of how surfaces interact in relative motion. It involves three main factors: friction, wear, and lubrication.

Understanding these factors is key to optimizing the performance of components like tungsten carbide bushings, which are frequently used in demanding industrial environments.

1). Key Tribological Factors

Friction: The resistance to motion that occurs when two surfaces move against each other.

Wear: The gradual loss of material from a surface due to mechanical action.

Lubrication: The process of reducing friction by introducing a substance, such as oil or grease, between the moving surfaces.

Why Tungsten Carbide Bushings?

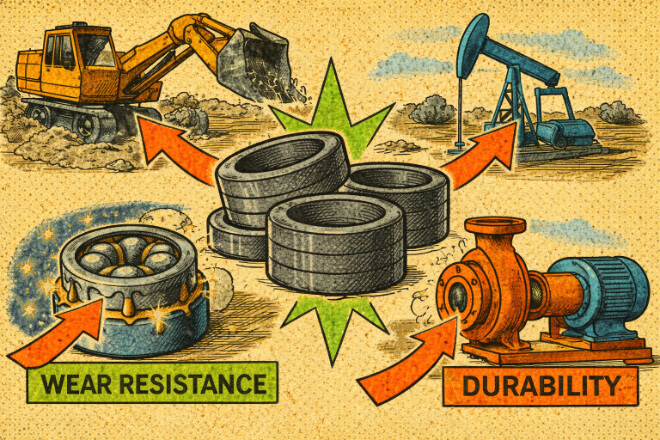

Tungsten carbide bushings are widely used in applications requiring high wear resistance and toughness.

Their tribological properties make them ideal for systems where durability is essential, such as pumps, turbines, and heavy machinery.

These bushings can withstand high temperatures, extreme pressure, and abrasive environments, making them a reliable choice for many industrial applications.

1). Advantages of Tungsten Carbide in Tribology

High Hardness: Tungsten carbide is one of the hardest materials, providing excellent wear resistance.

Low Friction: When properly lubricated, tungsten carbide bushings can reduce friction between moving parts, leading to smoother operation.

Heat Resistance: Tungsten carbide retains its strength and hardness even at high temperatures, making it ideal for challenging environments.

Friction and Wear in Tungsten Carbide Bushings

Friction and wear are key tribological factors affecting the performance of tungsten carbide bushings.

Understanding these elements can help engineers optimize designs and reduce maintenance costs.

1). How Friction Affects Tungsten Carbide Bushings

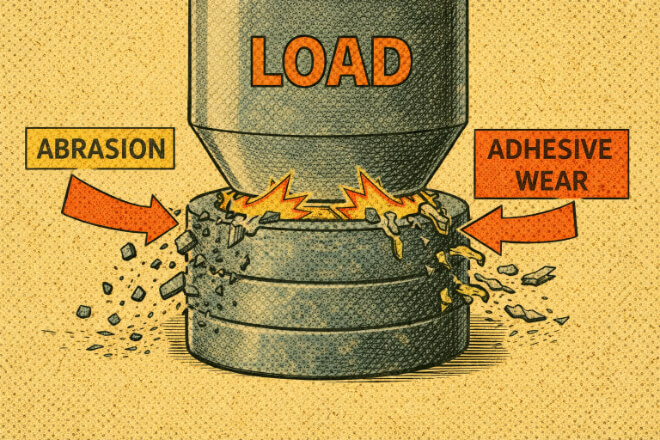

Friction can cause wear, heat generation, and eventual failure of the bushing.

Tungsten carbide bushings can handle high friction, but excessive friction without proper lubrication can lead to overheating and damage.

2). Wear Mechanisms in Tungsten Carbide

Abrasion: The wearing away of the bushing surface due to contact with hard particles or surfaces.

Adhesive Wear: Occurs when materials bond and tear away at the surface due to high friction.

Fatigue Wear: Caused by repeated stress and strain on the material, leading to cracks and fractures.

Lubrication and Its Role in Tungsten Carbide Bushings

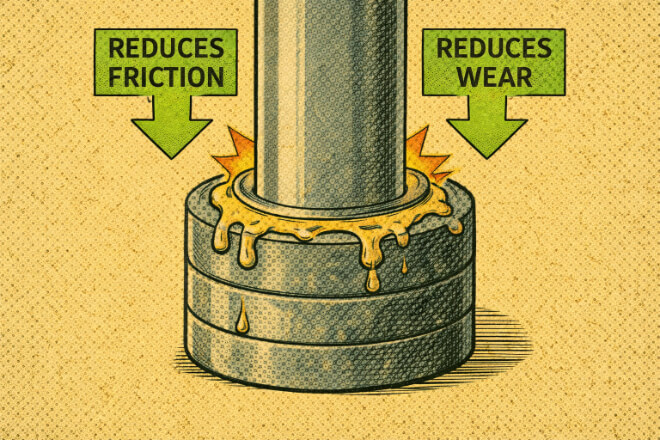

Lubrication is a critical factor in reducing friction and wear, especially in high-load applications.

Proper lubrication helps tungsten carbide bushings perform optimally, extending their lifespan and ensuring smooth operation.

1). Types of Lubrication

Boundary Lubrication: Occurs when a thin layer of lubricant separates the surfaces, reducing direct contact and minimizing friction.

Hydrodynamic Lubrication: Achieved when there is enough lubricant between the surfaces to fully separate them, resulting in very low friction.

Solid Lubrication: Used in high-temperature environments, solid lubricants can reduce wear even when liquid lubricants are ineffective.

2). Selecting the Right Lubricant for Tungsten Carbide

Oil-based Lubricants: Provide excellent lubrication under normal operating conditions.

Grease: Often used for slower-moving components or where lubrication retention is critical.

Dry Lubricants: Used in high-temperature environments where liquid lubricants would evaporate or degrade.

Factors Influencing the Tribological Performance of Tungsten Carbide Bushings

Several factors influence the tribological performance of tungsten carbide bushings, including the material properties, the operating environment, and the lubrication system used.

1). Material Properties

The hardness, toughness, and surface finish of tungsten carbide bushings directly affect their wear resistance and friction behavior.

High-quality tungsten carbide with proper sintering methods will provide the best tribological performance.

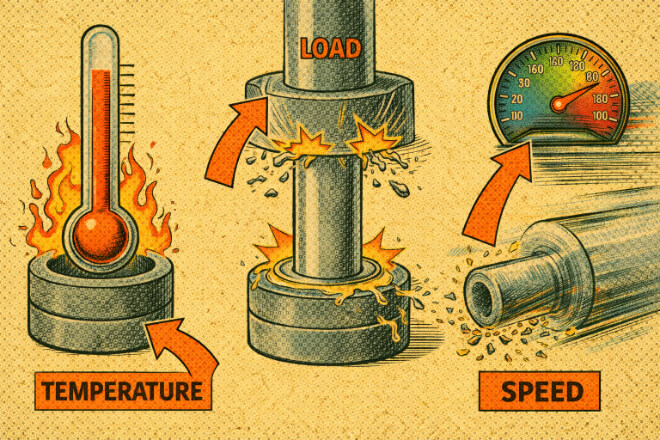

2). Operating Conditions

Temperature: High temperatures can alter the material’s properties, affecting friction and wear resistance.

Load: High loads increase friction and wear, leading to faster degradation if not properly managed.

Speed: Faster moving components may increase wear if insufficient lubrication is provided.

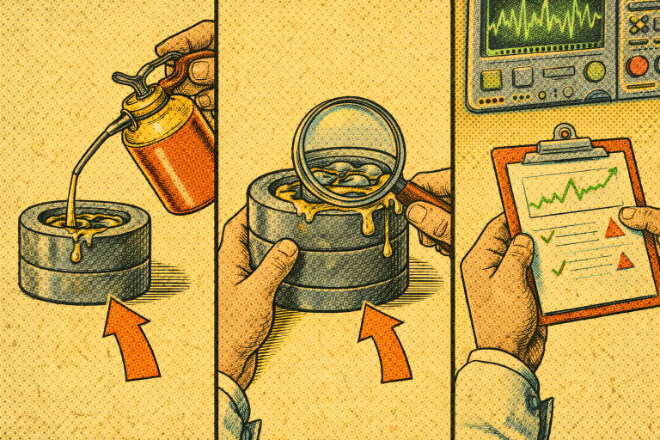

3). Lubrication and Maintenance

Proper lubrication reduces friction and wear. Regular maintenance, including checking lubrication levels and cleaning components, ensures optimal performance and prevents premature failure.

Best Practices for Tribological Optimization of Tungsten Carbide Bushings

To optimize the performance of tungsten carbide bushings, engineers should follow these best practices:

1). Selecting the Right Bushing Material

Ensure that the tungsten carbide bushing is designed with the appropriate binder material (such as cobalt or nickel) to meet the required mechanical and tribological performance standards.

2). Maintaining Proper Lubrication

Choose the right lubricant based on operating conditions and ensure it is applied consistently to reduce friction and wear.

3). Regular Inspections and Monitoring

Implement a regular inspection schedule to detect early signs of wear or lubrication failure. Monitoring factors like temperature, vibration, and noise can help identify issues before they lead to significant damage.

Conclusion

Tribology is a fundamental aspect of the performance and longevity of tungsten carbide bushings.

By understanding friction, wear, and lubrication principles, engineers can optimize the use of tungsten carbide bushings in demanding applications.

Implementing the right materials, lubrication systems, and regular maintenance practices ensures that tungsten carbide bushings perform optimally, reducing downtime and maintenance costs in the long run.

If you want to know more details about any company, please feel free to contact us.