In machining, a clean and smooth surface finish is essential. It shows precision, saves post-processing time, and improves the overall quality of the part.

However, poor surface finish is a common problem—even when using high-performance tungsten carbide cutting tools.

This article will help you understand what causes poor surface finish, how to identify the root problem, and what steps you can take to fix it.

Whether you’re running a CNC shop or managing production quality, these tips are designed to keep your tools sharp and your parts clean.

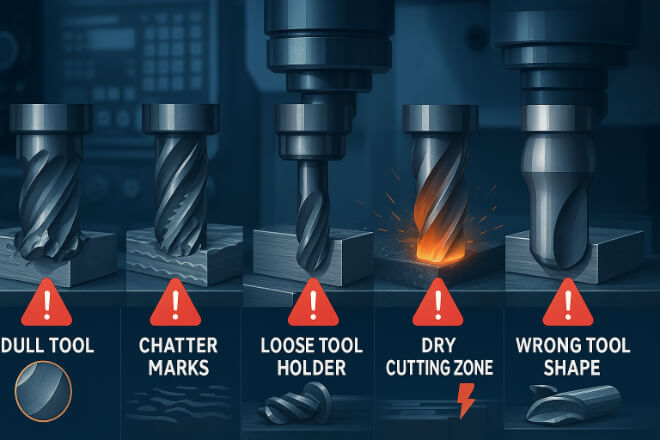

Common Causes of Poor Surface Finish

Many factors affect the surface finish of machined parts. Even with tungsten carbide cutting tools, if one element is off, your results can suffer. Below are some common causes:

Worn or damaged tools: When the cutting edge is dull or chipped, it tears the material instead of slicing it cleanly.

Incorrect speeds and feeds: Too fast or too slow can cause chatter or material smearing.

Improper tool holding: Loose tool holders or low rigidity can lead to vibration and movement.

Lack of coolant or lubrication: Without enough cooling, the tool overheats and affects the surface.

Wrong tool geometry: Tools that aren’t designed for the material or cut type can cause rubbing instead of cutting.

Fixing surface finish issues starts by checking all of the above one by one.

How to Inspect Tool Condition

If the surface finish starts to look poor, the first thing to check is the tool itself. Even tough tungsten carbide tools wear out with time.

Here’s what to inspect:

Look for visible wear: Rounded edges, chips, or dark spots mean the tool is worn.

Check tool edge sharpness: Use a microscope if needed to spot micro-chipping.

Measure tool runout: Use a dial indicator to make sure the tool spins straight.

Check coating condition: If the tool has lost its coating, friction and heat will increase.

Replace or regrind the tool if wear is significant. A dull or damaged tool is one of the top reasons for poor finish.

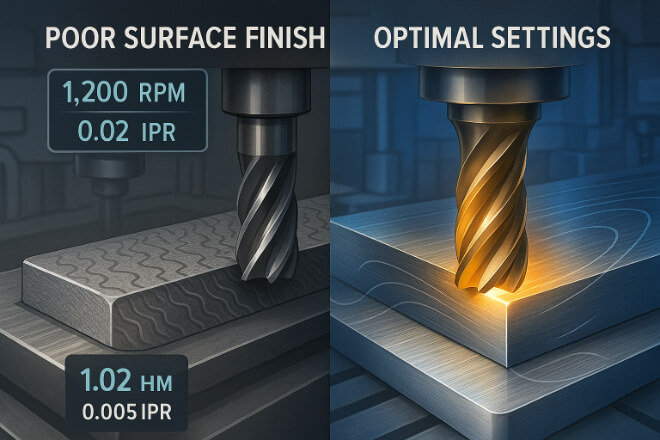

Optimize Cutting Speeds and Feeds

Tungsten carbide cutting tools are designed for high-speed machining, but each material requires a different setup.

To improve finish:

Reduce feed rate: Lower feed gives the tool more contact time for a cleaner cut.

Increase spindle speed: Higher RPM reduces chip thickness and smooths the surface.

Use finishing passes: A light final pass with slower feed and higher speed often improves surface quality.

Avoid aggressive cuts: Depth too high in one pass can overload the tool and cause chatter.

If you’re unsure about the best parameters, check the toolmaker’s recommendations or use a speed/feed calculator.

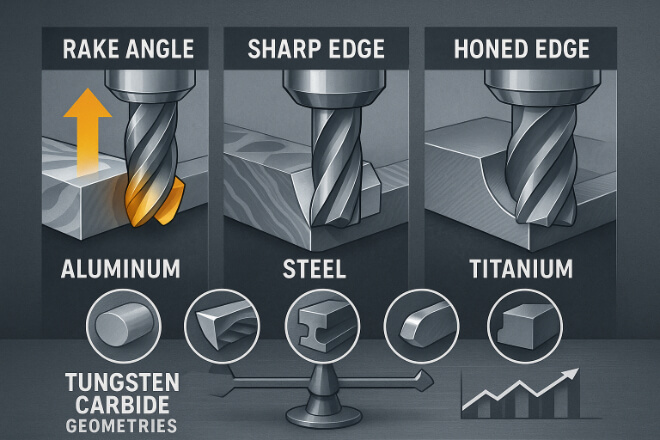

Use the Right Tool Geometry

Geometry matters—a lot. Choosing the right tool shape can improve both tool life and part finish.

Tips for choosing the right tool geometry:

High rake angles: These reduce cutting force and leave smoother finishes.

Sharp cutting edges: Great for soft materials like aluminum or brass.

Honed or chamfered edges: Better for harder materials and help reduce chipping.

Flat land or margin: Helps stabilize the tool during cut and avoid vibrations.

Tungsten carbide tools come in many shapes, so match geometry to material and application.

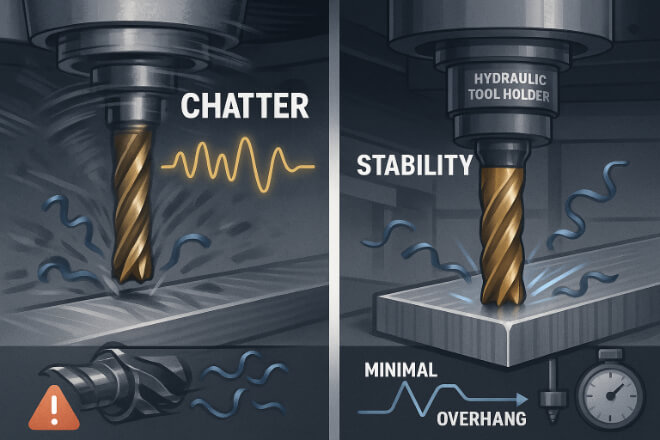

Control Vibration and Chatter

Vibration is a big enemy of surface finish. Even the best cutting tool can’t help if the setup vibrates during machining.

How to reduce it:

Use shorter tools: Reduce overhang length as much as possible.

Choose stable holders: Hydraulic or shrink-fit holders offer better grip.

Check machine alignment: Misaligned spindles or loose slides cause poor cutting.

Slow down feed if needed: Lighter cutting reduces tool deflection.

Also, look out for harmonic chatter—change spindle speed slightly to move away from vibration-prone ranges.

Apply Proper Coolant or Lubrication

Coolant doesn’t just cool. It reduces friction, clears chips, and helps with surface finish. Without it, tools heat up, chips stick, and surfaces get rough.

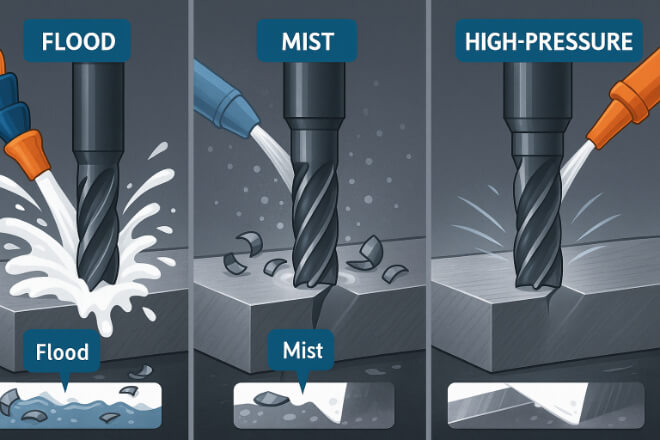

Choose the right fluid:

Flood coolant: Best for general machining.

Mist lubrication: Works well in high-speed, light cut operations.

High-pressure coolant (HPC): Needed when machining deep pockets or sticky materials.

Also, check the direction of coolant flow—it should hit the cutting zone directly to be effective.

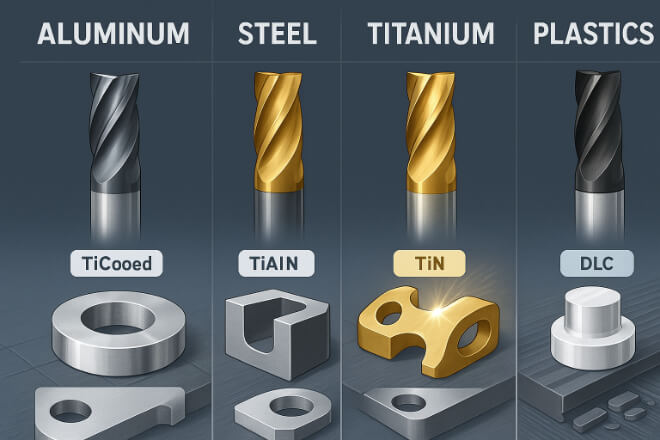

Choose Coated Carbide Tools for Better Finish

Tool coatings reduce friction and heat, which improves finish and tool life. For surface-sensitive jobs, coatings are a must.

Common coatings for better surface quality:

| Coating Type | Best For | Finish Benefits |

|---|---|---|

| TiAlN | Steel, stainless | Handles heat, reduces wear |

| DLC | Aluminum, plastics | Ultra-smooth surface, anti-stick |

| TiB2 | Non-ferrous metals | Low friction, prevents material buildup |

Use coated tungsten carbide cutting tools when you need high finish on tough materials.

Match Tool to Material

Not every carbide tool is ideal for every job. Some materials need special tool grades or designs to get the best finish.

Examples:

Aluminum: Needs polished flute tools and sharp edges.

Steel: Prefers TiAlN coated, honed edge tools.

Titanium: Requires tools with strong core strength and high heat resistance.

Plastics: Need very sharp, uncoated tools to avoid melting.

Choosing the wrong tool for the material can lead to rough, torn, or burned surfaces.

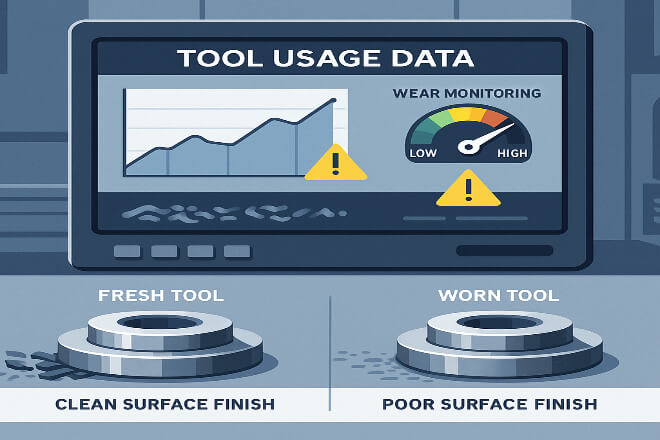

Track Tool Life and Performance

To maintain good surface finish, monitor tool life actively. Don’t wait for tools to fail.

Tips:

Use tool management software: Track how many parts each tool produces.

Set tool change alarms: Based on number of cuts, time, or condition.

Inspect parts regularly: If surface quality drops, it may be time to change tools.

Keep records: Know which tools and settings give the best finish.

Proactive maintenance keeps surface quality high and avoids costly scrap.

When to Replace or Regrind Tools

Not every surface issue can be fixed by changing speeds or checking coolant. Sometimes, the tool is simply at the end of its life.

Signs it’s time to change:

Surface finish keeps getting worse

Tool edge has visible damage

Cutting force feels higher

You see burn marks or discoloration

More chips stick to the tool

High-quality carbide tools can often be reconditioned. If your supplier offers regrinding, you can restore tool sharpness and save costs.

Final Thoughts

Poor surface finish can be frustrating, especially when you’re using tungsten carbide cutting tools.

But in most cases, it’s a sign that something else in the setup needs adjustment—tool condition, speeds and feeds, geometry, or coolant.

With regular inspections, optimized parameters, and the right tooling, you can achieve consistent, clean surfaces and avoid waste.

If you’re looking for premium-grade carbide tools that stay sharp and help you machine cleaner, check out Retopz—where precision meets performance.