Tungsten carbide bushings are well-known for their exceptional durability and wear resistance.

In high-temperature environments, where many materials fail to perform reliably, tungsten carbide stands out as a preferred material.

This blog will discuss why tungsten carbide bushings are an excellent choice for applications exposed to high heat.

The factors to consider when selecting them, and the benefits they provide to industries like aerospace, automotive, and chemical processing.

Why Tungsten Carbide is Ideal for High-Temperature Applications

Tungsten carbide is widely used in industries where high temperatures and wear-resistant components are crucial.

This is because tungsten carbide has a unique combination of properties that make it capable of withstanding extreme conditions:

High Melting Point:

Tungsten carbide has a high melting point of approximately 2870°C, which makes it suitable for high-temperature applications where other materials might degrade.

Thermal Conductivity:

It has excellent thermal conductivity, allowing it to dissipate heat quickly and maintain stable performance under thermal stress.

Tungsten carbide is one of the hardest materials available, which means it maintains its structural integrity even when subjected to extreme temperatures.

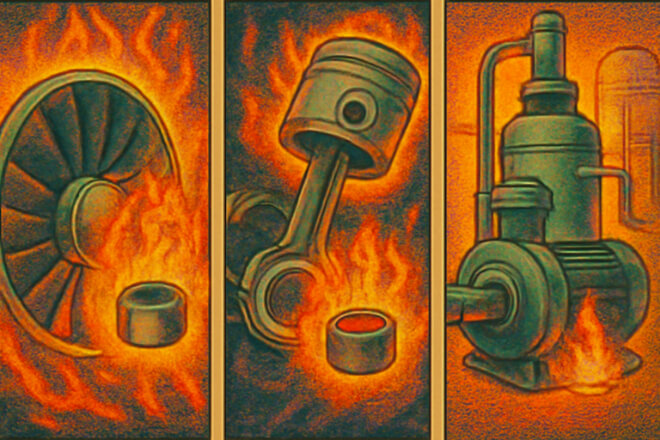

Applications of Tungsten Carbide Bushings in High-Temperature Environments

Tungsten carbide bushings are widely used in various industries that require reliable performance in high-temperature settings. Some key applications include:

In aerospace systems, components often operate under high heat, especially in engines and turbines.

Tungsten carbide bushings are used to support rotating parts, reducing friction and ensuring longevity under extreme temperatures.

High-performance engines require bushings that can withstand the heat produced during operation.

Tungsten carbide bushings in automotive engines provide long-lasting durability, reducing maintenance costs and increasing overall engine efficiency.

Chemical Processing:

In chemical plants, pumps and valves often handle corrosive fluids at high temperatures.

Tungsten carbide bushings provide protection against wear and corrosion, helping to extend the life of these critical components.

Key Benefits of Tungsten Carbide Bushings in High-Temperature Environments

Using tungsten carbide bushings offers several benefits when exposed to high temperatures:

At elevated temperatures, friction increases, which can wear down many materials.

Tungsten carbide’s exceptional hardness ensures that it maintains its shape and integrity, even under harsh conditions.

High temperatures often lead to the formation of aggressive chemical reactions.

Tungsten carbide’s ability to resist oxidation and chemical wear makes it highly effective in high-temperature environments, especially where other materials might corrode.

Longevity and Cost Savings:

Tungsten carbide bushings last longer than many alternatives, which leads to fewer replacements and lower maintenance costs. This makes it a cost-effective solution over time.

Improved Efficiency:

Because tungsten carbide reduces friction and wear, it improves the overall efficiency of machinery, ensuring smoother operations even at high temperatures.

Selecting the Right Tungsten Carbide Bushing for High-Temperature Applications

Choosing the correct tungsten carbide bushing for a high-temperature environment depends on several factors. Here are some considerations:

Tungsten carbide bushings are often combined with binders like cobalt (Co) or nickel (Ni).

Nickel-bonded tungsten carbide is better suited for high-temperature applications because it maintains its strength and durability even in extreme heat.

The grain size of tungsten carbide affects its wear resistance and toughness.

Fine-grain tungsten carbide is ideal for wear-resistant applications, while coarse-grain tungsten carbide is better for high-impact environments.

Temperature Range:

Ensure that the selected tungsten carbide can handle the specific temperature range of your application.

Some formulations are optimized for extreme heat, offering enhanced resistance to thermal stress.

Key Properties of Tungsten Carbide for High-Temperature Environments

| Property | Tungsten Carbide | Other Materials |

|---|---|---|

| Melting Point | 2870°C | Varies (typically lower than tungsten carbide) |

| Thermal Conductivity | High | Lower in many alternatives |

| Hardness | Excellent (higher than most materials) | Varies (often lower than tungsten carbide) |

Challenges and Considerations When Using Tungsten Carbide Bushings in High-Temperature Environments

While tungsten carbide bushings are ideal for high-temperature applications, there are a few considerations to keep in mind:

Brittleness:

Tungsten carbide is very hard but can be brittle, especially at extreme temperatures.

It is important to ensure that the bushing is designed to withstand the specific mechanical stresses of your application.

Cost:

Tungsten carbide is more expensive than other materials, but its long-lasting durability can make it more cost-effective over time due to reduced maintenance and replacement needs.

Conclusion

Tungsten carbide bushings are an excellent choice for high-temperature environments.

Their combination of high melting point, wear resistance, and corrosion protection makes them ideal for industries like aerospace, automotive, and chemical processing.

By selecting the right tungsten carbide bushing material, manufacturers can enhance the performance and longevity of their machinery, ultimately reducing costs and improving operational efficiency.

If you want to know more details about any company, please feel free to contact us.