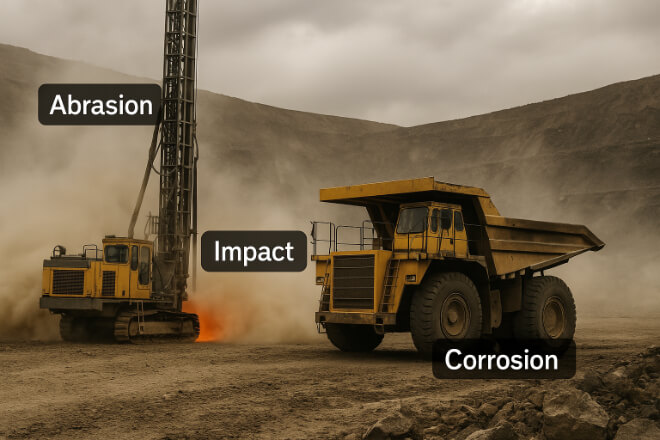

Mining and drilling are some of the toughest working environments in the world. Equipment used in these industries must endure abrasion, impact, vibration, and extreme pressure—often in dirty, wet, and dusty conditions.

Every part of a machine that moves or rotates is under constant stress. Bearings, seals, and bushings face heavy wear from rock particles, slurry, and drilling fluids.

To keep operations running safely and efficiently, equipment must be built with materials that can survive these harsh conditions. That’s where tungsten carbide bushings make a major difference.

This article explains why tungsten carbide bushings are ideal for mining and drilling applications, their key advantages over standard metals, and how they extend equipment life and reliability.

The Harsh Working Conditions in Mining and Drilling

Mining and drilling environments expose components to intense mechanical wear and abrasive materials.

From open-pit mining trucks to oil and gas drilling rigs, every rotating shaft is under pressure.

Common challenges include:

Abrasive wear from sand, mud, and rock fragments.

Corrosion from water, chemicals, and drilling fluids.

High temperature and pressure deep underground.

Shock loads and vibration from drilling tools and crushers.

Limited maintenance opportunities in remote operations.

Under such conditions, standard bronze or steel bushings fail quickly—causing downtime and high repair costs.

Tungsten carbide bushings are engineered to handle these challenges with outstanding durability.

Why Tungsten Carbide Performs Better

Tungsten carbide is a compound of tungsten and carbon, often bonded with cobalt or nickel. It combines metallic strength with ceramic-like hardness.

Key properties include:

Extremely high hardness (88–92 HRA).

Excellent resistance to abrasion and erosion.

High compressive strength (>4000 MPa).

Low coefficient of thermal expansion.

Strong resistance to corrosion in fluids and slurry.

Because of these features, tungsten carbide bushings last many times longer than steel ones in the same working environment.

Comparison with Other Bushing Materials

| Material | Abrasion Resistance | Impact Strength | Corrosion Resistance | Service Life |

|---|---|---|---|---|

| Bronze | Low | Moderate | Poor | Short |

| Hardened Steel | Medium | High | Moderate | Medium |

| Tungsten Carbide | Excellent | High | Excellent | Very Long |

This comparison clearly shows that tungsten carbide bushings provide the best protection in extreme abrasion and pressure conditions.

Applications in Mining Equipment

| Equipment | Operating Condition | Function of Bushing |

|---|---|---|

| Slurry Pumps | Abrasive slurry, high pressure | Supports rotating shaft and prevents wear |

| Crusher Bearings | Heavy impact and shock load | Provides alignment and wear resistance |

| Drilling Motors | Rotational friction in mud and grit | Maintains smooth rotation and stability |

| Hydraulic Cylinders | High pressure and heat | Reduces metal contact and leakage |

Tungsten carbide bushings are used across the mining sector, from excavation equipment to ore transport and drilling rigs.

Their main role is to protect rotating and sliding parts against wear, friction, and misalignment.

Applications in Drilling Systems

| Drilling Equipment | Environment | Benefit of Using Carbide Bushing |

|---|---|---|

| Downhole Motors | High pressure, abrasive mud | Improves wear life and reliability |

| Drill Bits | Hard rock drilling | Reduces vibration and mechanical wear |

| Mud Pumps | Corrosive fluids and solids | Provides sealing and shaft protection |

In both surface and underground drilling, tungsten carbide bushings play a vital role in maintaining operational stability and minimizing downtime.

Binder Selection: Cobalt vs Nickel

| Binder Type | Corrosion Resistance | Toughness | Recommended Use |

|---|---|---|---|

| Cobalt (Co) | Moderate | Excellent | Shock-loaded mining equipment |

| Nickel (Ni) | Excellent | Good | Wet drilling and corrosive mud systems |

Cobalt-bonded carbide offers higher impact resistance, making it perfect for rock crushing and impact-heavy applications.

Nickel-bonded carbide provides better corrosion resistance, ideal for drilling in wet or chemical environments.

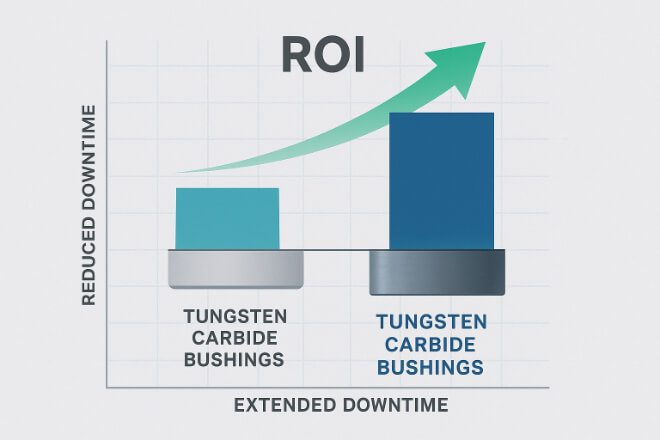

Advantages for Mining and Drilling Operators

Using tungsten carbide bushings offers multiple long-term benefits:

Extended equipment life and reduced downtime.

Lower maintenance and replacement frequency.

Improved machine alignment and stability.

Higher operational efficiency in harsh environments.

Better ROI through longer service intervals.

Many companies report up to 4–5 times longer service life compared to conventional metal bushings.

Real-World Case Study

| Equipment | Previous Material | Old Service Life | New Service Life (WC) | Downtime Reduction |

|---|---|---|---|---|

| Slurry Pump Shaft | Steel | 8 months | 3 years | 75% |

| Drilling Mud Pump | Bronze | 6 months | 2.5 years | 80% |

The case study clearly shows how tungsten carbide bushings greatly reduce downtime and improve reliability in real mining operations.

Conclusion

In mining and drilling, reliability means productivity. Equipment failure can cost thousands of dollars per hour in lost output and repairs.

Tungsten carbide bushings are proven to handle the toughest environments—resisting abrasion, corrosion, and pressure better than any other material.

For decision-makers, choosing carbide bushings means longer equipment life, fewer shutdowns, and a better return on investment.

In the demanding world of mining and drilling, they are not just a component—they are a critical performance upgrade.

If you want to know more details about any company, please feel free to contact us.