Submersible pumps are essential in industries like oil and gas, mining, and water treatment.

These pumps operate in extreme environments, submerged in harsh liquids under high pressure and temperatures.

Tungsten carbide bushings are ideal for such conditions due to their exceptional wear resistance, corrosion resistance, and heat stability.

This guide explains why tungsten carbide bushings are a perfect fit for submersible pumps and how to select the right one for your application.

Why Tungsten Carbide Bushings Are Ideal for Submersible Pumps

Submersible pumps face extreme conditions like high-pressure water, chemicals, and abrasives.

Tungsten carbide bushings are perfect for these demanding environments because of their:

High Hardness: Tungsten carbide is almost as hard as diamond, which helps resist wear and abrasion.

Corrosion Resistance: It performs well in aggressive liquids, preventing rust or chemical breakdown.

Heat Resistance: Tungsten carbide can handle high temperatures without weakening.

Long Life: These bushings last longer, reducing the need for frequent replacements.

These characteristics make tungsten carbide bushings an ideal solution for enhancing pump performance and longevity.

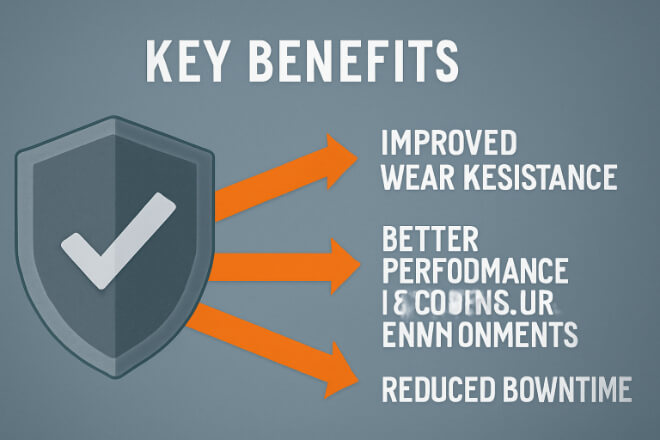

Key Benefits of Tungsten Carbide Bushings for Submersible Pumps

1). Improved Wear Resistance

Tungsten carbide’s hardness makes it resistant to abrasion, ensuring that the bushings remain intact and functional even in rough conditions. This results in fewer repairs and replacements.

2). Better Performance in Corrosive Environments

Submersible pumps often deal with chemicals and saltwater. Tungsten carbide’s corrosion resistance ensures that the bushings maintain their integrity and continue to perform efficiently.

3). Reduced Maintenance and Downtime

With their superior durability, tungsten carbide bushings minimize the frequency of failures and the need for maintenance, reducing costly downtime.

4). Superior Temperature Stability

These bushings can withstand high temperatures, which is essential for pumps operating in deep or heat-intensive environments.

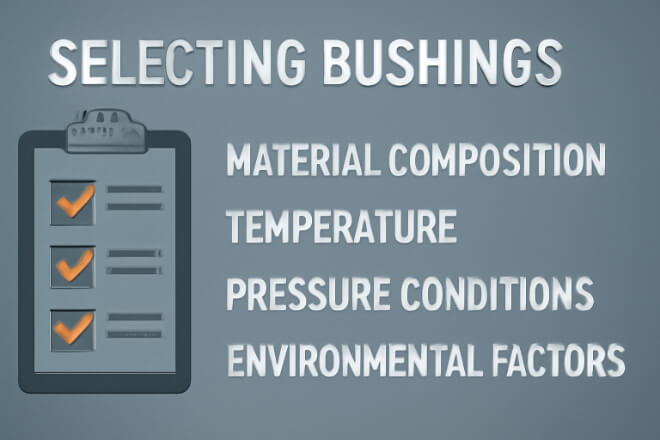

Key Considerations When Selecting Tungsten Carbide Bushings for Submersible Pumps

When choosing tungsten carbide bushings, several factors should be considered:

1). Material Composition

Tungsten carbide bushings are available with either cobalt or nickel binders:

WC-Co (Cobalt Binder): Offers excellent wear resistance and toughness.

WC-Ni (Nickel Binder): Ideal for corrosion-resistant applications.

2). Bushing Size and Fit

Ensure the bushing fits precisely within the pump’s components. Incorrect sizing can lead to misalignment and premature failure.

3). Temperature and Pressure Conditions

Select a tungsten carbide grade that suits the specific temperature and pressure conditions the pump will face.

4). Environmental Factors

Consider the type of liquid the pump will handle. Tungsten carbide bushings are available with enhanced resistance to chemicals, making them suitable for aggressive environments.

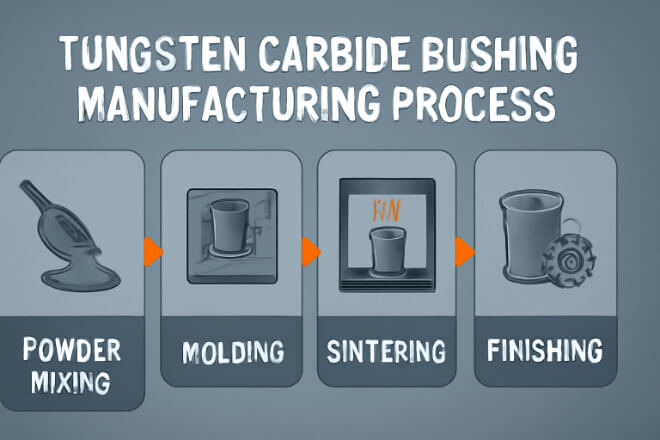

Manufacturing Process of Tungsten Carbide Bushings

Tungsten carbide bushings are manufactured through a careful process that includes:

Powder Mixing: Tungsten carbide powder is mixed with a binder (cobalt or nickel).

Molding: The slurry is pressed into molds to create the bushing shape.

Sintering: The molded bushings are sintered at high temperatures to bond the material.

Finishing: The sintered bushings are machined to achieve the required dimensions and surface finish.

Common Applications of Tungsten Carbide Bushings in Submersible Pumps

Tungsten carbide bushings are used in a variety of submersible pump applications, including:

Oil and Gas: Pumps used for fluid extraction in harsh conditions.

Mining: Pumps that handle abrasive slurries and chemicals.

Water Treatment: Pumps used in wastewater treatment processes.

Chemical Processing: Pumps exposed to aggressive chemicals and solvents.

Testing and Quality Control for Tungsten Carbide Bushings

Before being used in submersible pumps, tungsten carbide bushings undergo several quality control tests:

1). Dimensional Inspection

Ensures that the bushing fits correctly within the pump assembly and meets the required tolerances.

2). Hardness Testing

Verifies the bushing’s resistance to wear and its ability to withstand operational stress.

3). Density and Porosity Testing

Checks for voids and ensures the bushing is compact and free of defects that could weaken it.

4). Corrosion Resistance Testing

Tests how well the bushing resists corrosion when exposed to chemicals or saltwater.

5). Microstructure Examination

Evaluates the internal structure of the bushing to ensure uniform material distribution.

Conclusion

Tungsten carbide bushings are the ideal solution for submersible pumps, providing exceptional wear resistance, corrosion protection, and heat stability.

By choosing the right tungsten carbide bushing and ensuring proper quality control, industries can maximize the performance and lifespan of their pumps, leading to reduced maintenance costs and increased reliability.

If you want to know more details about any company, please feel free to contact us.