Tungsten carbide bushings are known for their excellent hardness, wear resistance, and durability, making them ideal for harsh industrial applications.

However, adding TaC (Tantalum Carbide) and TiC (Titanium Carbide) to tungsten carbide further improves its abrasion resistance and performance.

This blog explores how these additions enhance the abrasion performance of tungsten carbide bushings.

And why they are becoming the material of choice for industries requiring superior durability in abrasive environments.

Understanding TaC and TiC Additions in Tungsten Carbide

Tungsten carbide (WC) is a composite material known for its hardness and wear resistance, making it ideal for use in bushings, bearings, and other industrial components.

However, in certain high-demand applications, additional carbides such as TaC (Tantalum Carbide) and TiC (Titanium Carbide) are added to further enhance the material’s properties.

What Are TaC and TiC?

TaC (Tantalum Carbide) is a carbide compound that enhances the toughness and high-temperature performance of tungsten carbide. It is known for its ability to increase wear resistance in highly abrasive environments.

TiC (Titanium Carbide) is another carbide that is added to tungsten carbide to increase its hardness and abrasion resistance. TiC helps improve the material’s resistance to thermal shock and deformation under high pressures.

These carbide additions create a stronger, more durable material that is highly resistant to wear, particularly in environments with heavy abrasion and extreme temperatures.

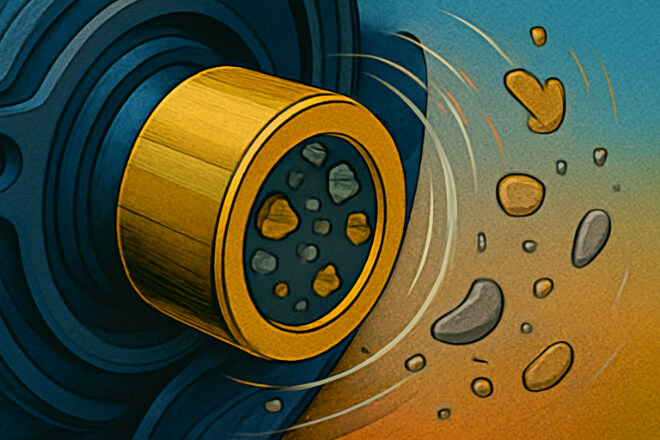

Abrasion Resistance in Tungsten Carbide Bushings

Abrasion resistance is one of the most critical factors in the performance of bushings.

In industrial applications, components like pumps, valves, and bearings are subject to constant wear from abrasive particles, chemicals, and high-pressure fluids.

If the bushing material can resist this abrasion, the equipment lasts longer, and maintenance costs are reduced.

How TaC/TiC Additions Improve Abrasion Resistance:

Increased hardness:

Both TaC and TiC are extremely hard materials that significantly improve the hardness of the tungsten carbide composite. Harder materials resist wear more effectively.

Better wear resistance:

TaC and TiC improve the wear resistance of tungsten carbide by creating a tougher material that can withstand the continuous friction and impact forces found in many industrial applications.

Enhanced performance in abrasive environments:

With the addition of TaC and TiC, the bushings can handle extreme conditions like mining, cement.

And slurry handling, where the material is exposed to constant abrasion from solid particles.

The combination of tungsten carbide with TaC and TiC offers unparalleled wear resistance, making it the best choice for highly abrasive environments.

TaC/TiC vs. Traditional Tungsten Carbide Bushings

While tungsten carbide is already known for its excellent wear resistance, the addition of TaC and TiC improves its properties even further.

Let’s compare traditional tungsten carbide bushings with TaC/TiC-coated tungsten carbide bushings in terms of abrasion resistance.

Comparison of Performance

| Property | Traditional Tungsten Carbide | Tungsten Carbide with TaC/TiC Additions |

|---|---|---|

| Hardness | High | Very High |

| Wear Resistance | Good | Excellent |

| Resistance to Thermal Shock | Moderate | High |

| Impact Resistance | Moderate | High |

| Chemical Resistance | High | High |

| Cost | Lower | Higher |

Key Points:

Hardness: The addition of TaC and TiC makes the composite significantly harder, improving its resistance to wear and tear.

Wear resistance: While traditional tungsten carbide offers good wear resistance, the addition of TaC/TiC provides excellent performance in abrasive conditions.

Thermal shock resistance: TaC and TiC are more resistant to thermal shock, making these bushings ideal for applications with fluctuating temperatures.

Impact resistance: TaC/TiC additions make the bushings more resistant to impact and sudden forces, which is critical in mining and other heavy-duty operations.

Applications of TaC/TiC Tungsten Carbide Bushings

Tungsten carbide bushings with TaC/TiC additions are suitable for a wide range of applications where abrasion, high pressure, and harsh environments are common.

Key applications include:

Mining and dredging:

In mining, equipment is subjected to intense abrasive conditions from materials like sand, rocks, and slurry.

TaC/TiC tungsten carbide bushings offer superior wear resistance in these applications.

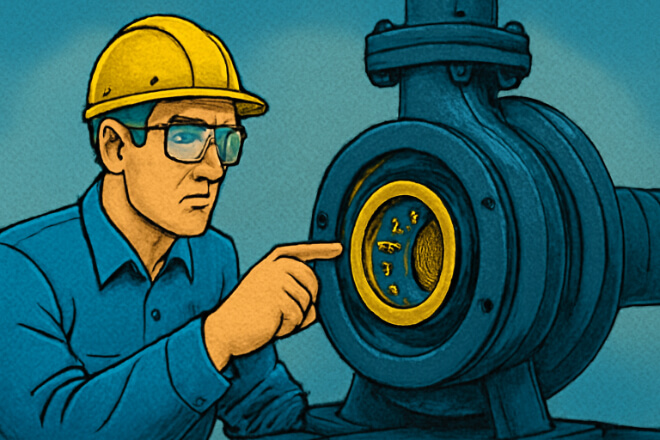

Equipment in the oil and gas industry often deals with high pressures and abrasive drilling fluids.

The enhanced properties of TaC/TiC tungsten carbide bushings help increase the service life of pumps and valves.

Chemical processing:

Chemical plants often deal with corrosive substances that can wear down equipment.

The addition of TaC/TiC to tungsten carbide ensures durability in these demanding environments.

Cement and slurry handling:

Cement plants and slurry pumps require components that can withstand heavy wear from abrasive materials.

TaC/TiC tungsten carbide bushings help reduce maintenance and downtime in these industries.

Benefits of TaC/TiC Tungsten Carbide Bushings in Industrial Applications

Using TaC/TiC tungsten carbide bushings provides multiple advantages that improve the overall performance of industrial systems.

Key Benefits:

Increased longevity:

Bushings made from TaC/TiC tungsten carbide last longer than traditional materials, reducing the need for frequent replacements and minimizing downtime.

Reduced maintenance costs:

With their superior wear resistance, TaC/TiC bushings can lower maintenance costs and extend the time between service intervals.

Improved system efficiency:

Reduced wear means that pumps, valves, and other equipment operate more efficiently, leading to lower energy consumption.

Better performance under extreme conditions:

TaC/TiC tungsten carbide bushings are ideal for high-pressure, high-abrasion, and high-temperature environments, making them versatile for a variety of industries.

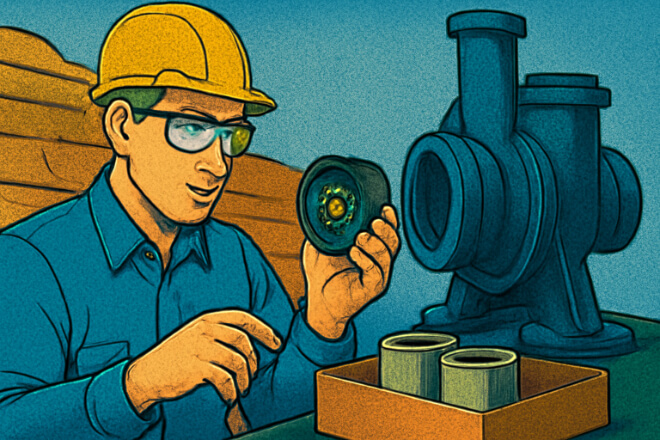

How to Choose the Right Bushing for Your Application

When choosing between traditional tungsten carbide bushings and those with TaC/TiC additions, it’s essential to consider the specific conditions of your application.

Factors to consider:

Abrasion levels:

If your equipment deals with highly abrasive materials, such as in mining or cement handling, TaC/TiC tungsten carbide bushings may be the better choice.

Pressure and temperature:

For high-pressure and high-temperature applications, TaC/TiC bushings offer improved resistance to these harsh conditions.

Corrosion resistance:

Both traditional tungsten carbide and TaC/TiC tungsten carbide offer high chemical resistance.

But the added benefits of wear resistance and thermal shock resistance in TaC/TiC bushings make them ideal for extreme environments.

Cost:

While TaC/TiC bushings are more expensive than traditional tungsten carbide, the long-term savings in maintenance and replacement costs can justify the investment.

Conclusion

Tungsten carbide bushings with TaC/TiC additions provide superior abrasion resistance and longer service life compared to traditional tungsten carbide bushings.

The combination of tungsten carbide with TaC and TiC improves wear resistance, reduces friction, and enhances performance in harsh industrial environments.

By carefully considering your application’s demands, you can choose the right bushing material to maximize equipment efficiency, reduce downtime, and lower maintenance costs.

If you want to know more details about any company, please feel free to contact us.