Tungsten Carbide Components for Sealing Equipment Applications

In sealing systems where precision, wear resistance, and reliability are critical, tungsten carbide components play an essential role. From mechanical seal faces to valve seats and shaft sleeves, these hardmetal parts ensure long-lasting operation under extreme pressure, temperature, and corrosive environments. They are widely used in mechanical seals, high-pressure valves, centrifugal pumps, and compressors.

The Common Tungsten Carbide Sealing Parts

In sealing equipment (such as mechanical seals, valve seals, pump sealing systems), the commonly used tungsten carbide tools or parts are mainly the following categories. They are widely used in key friction pairs of sealing systems due to their excellent wear resistance, corrosion resistance and high strength.

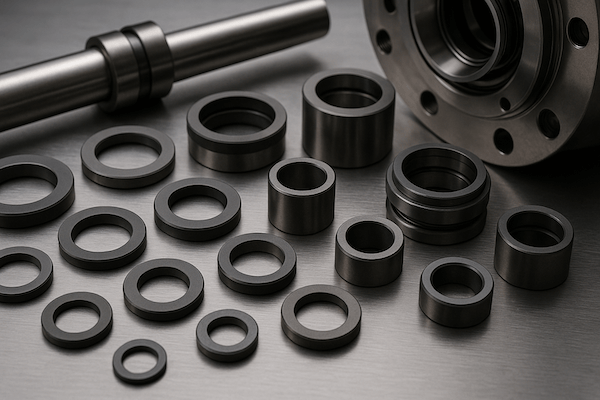

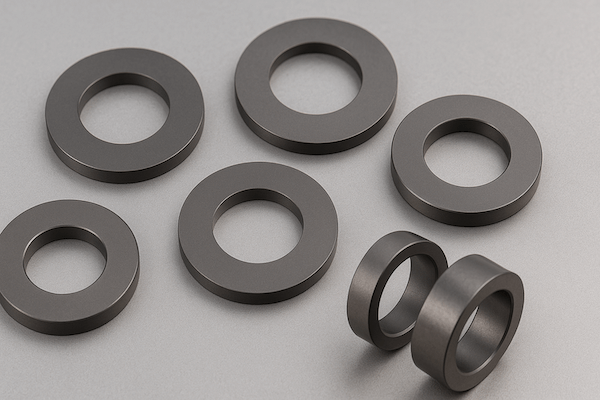

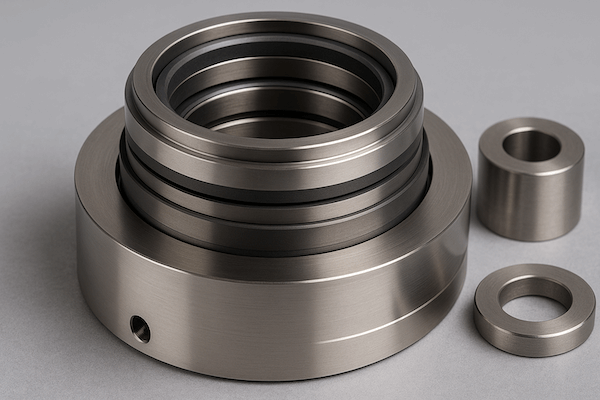

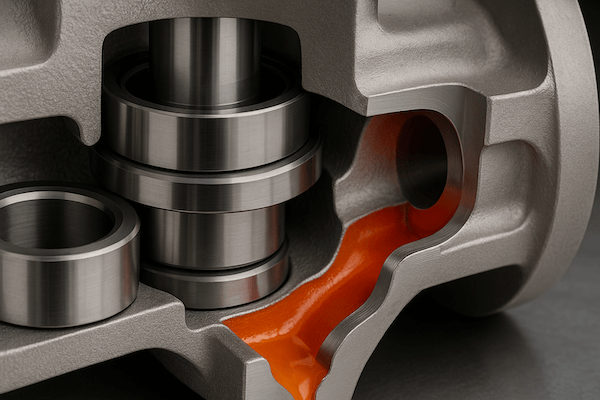

Tungsten Carbide Seal Ring

High-hardness sealing ring ensuring low friction and minimal wear in mechanical seal assemblies.

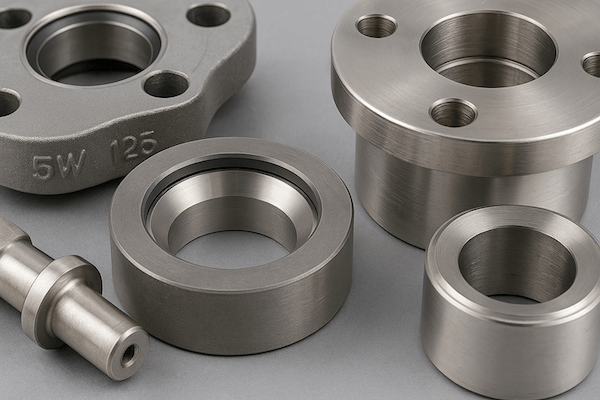

Tungsten Carbide Valve Seat

Precision-ground valve seat with high resistance to pressure erosion and chemical corrosion.

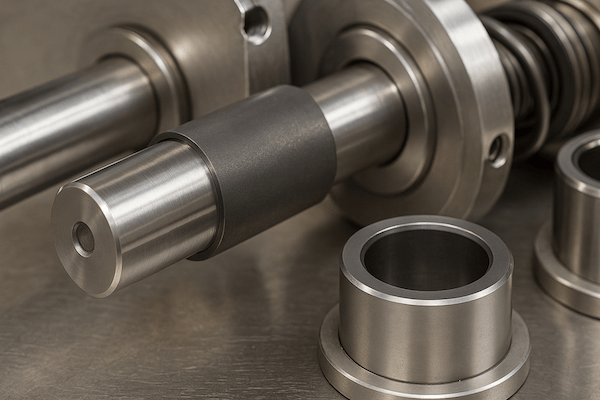

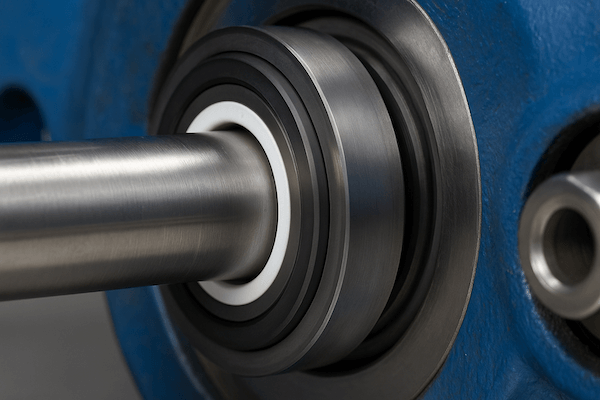

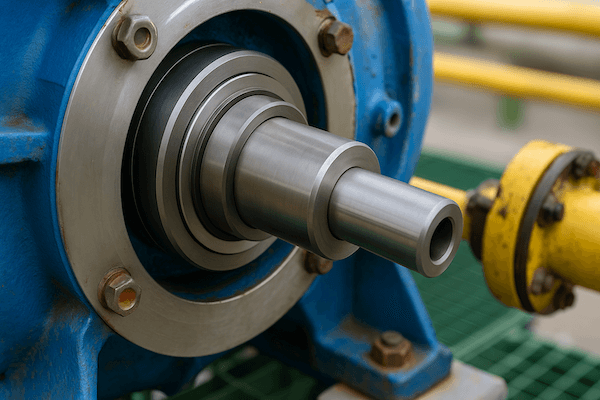

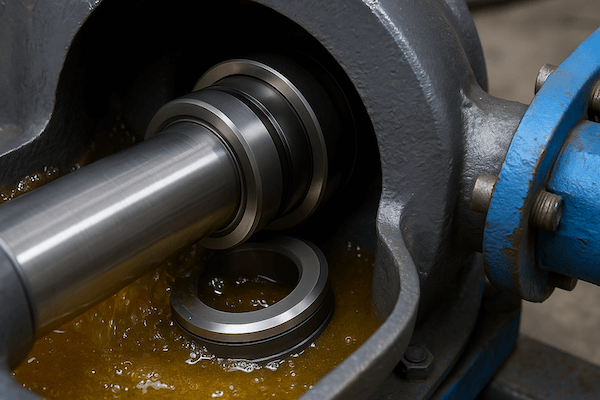

Tungsten Carbide Shaft Sleeve

Cylindrical sleeve protects pump shaft from wear and extends sealing performance.

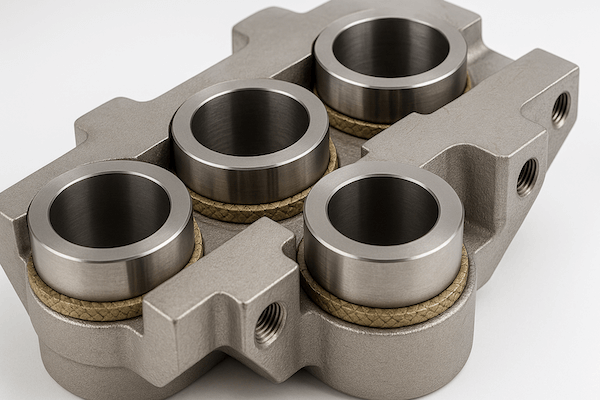

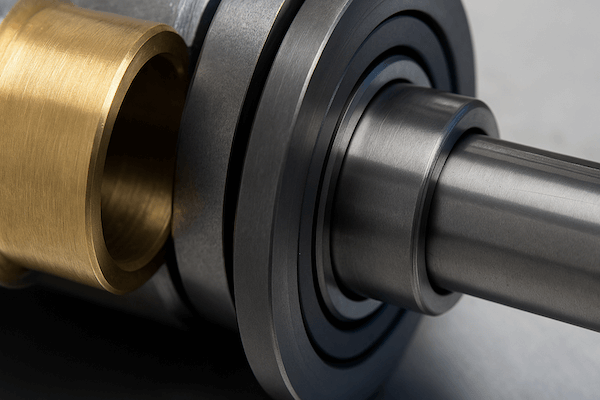

Tungsten Carbide Bushing

Wear-resistant guide bushing used to align and stabilize rotating shafts in seal units.

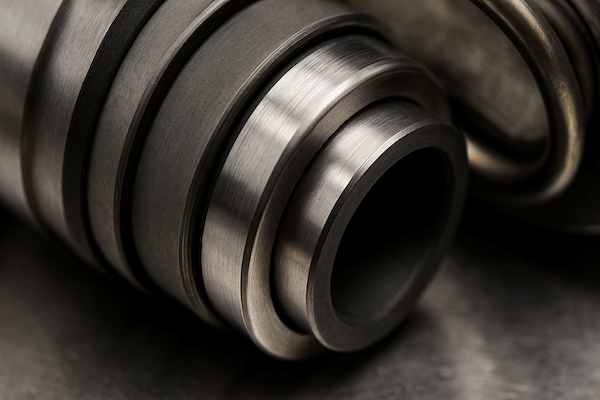

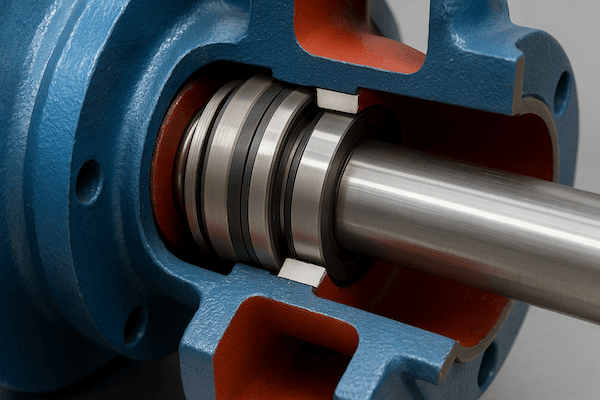

Tungsten Carbide Rotary Ring

Dynamic ring installed on rotating shafts forming a sealing interface with stationary rings.

Tungsten Carbide Thrust Washer

Flat disc-shaped washer handling axial loads in seal housings and rotating assemblies.

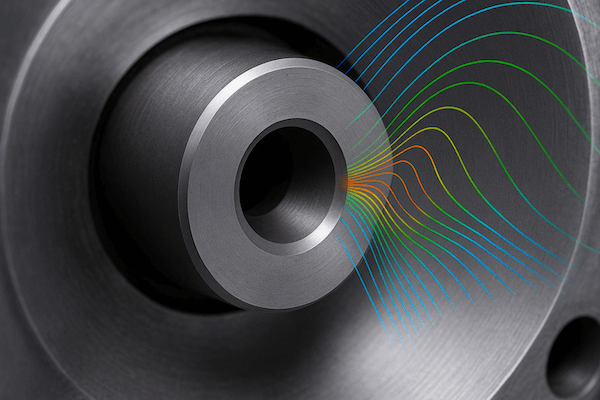

Tungsten Carbide Nozzle (for Sealing Systems)

Flow control nozzle that supports regulated fluid passage in high-pressure sealing environments.

Quick and easy: Enter your specifications and get a quote in one business day

Typical Applications of Tungsten Carbide Seal Components

Tungsten carbide is an essential material in high-performance sealing systems due to its superior wear resistance, chemical stability, and mechanical strength. Below are the most common industrial applications where tungsten carbide sealing components are indispensable. Each scenario demonstrates how carbide rings, sleeves, bushings, or valve seats function under demanding conditions while delivering long-term reliability.

Shaft Sealing in Chemical and Petrochemical Pumps

In chemical and petrochemical plants, pump systems often handle highly corrosive fluids at elevated temperatures and pressures. Tungsten carbide seal rings and sleeves are widely used in these environments due to their outstanding resistance to corrosion, thermal shock, and abrasive slurry.

Key Advantages:

-

Exceptional chemical resistance in acidic and alkaline media

-

Long operational life with minimal maintenance

-

Ideal for high-viscosity or particle-loaded fluids

Mechanical Seal Faces in Submersible and Deep-Well Pumps

Tungsten carbide mechanical seal faces are critical in deep-well and submersible pumps used in groundwater extraction and oilfield applications. These seals ensure durability at great depths under high pressure and flow turbulence.

Key Advantages:

-

High strength-to-weight ratio for deep submersion

-

Reliable sealing under high flow velocity

-

Resistance to sand, sediment, and scale deposits

High-Pressure Shaft Seals in Gas Compressors

Gas compressors in refineries and power stations operate at extremely high pressures. Tungsten carbide thrust washers and seal rings provide the abrasion and pressure resistance necessary for long life and leak-free performance.

Key Advantages:

-

Withstands high axial and radial loads

-

Maintains sealing integrity under pressure spikes

-

Superior dimensional stability at elevated temperatures

Rotary Joints and Vacuum Pump Seal Components

Rotary unions and vacuum pumps require tight seals for rotating elements. Tungsten carbide bushings and rotary rings reduce friction and ensure vacuum integrity under dynamic rotation.

Key Advantages:

-

Low friction and heat generation

-

High hardness for minimal wear under rotary motion

-

Suitable for cleanroom and inert gas applications

Sealing Elements in High-Pressure and Control Valves

Tungsten carbide valve seats and sleeves are used in high-pressure control valves, including those used in oil & gas, chemical injection, and process control. These components prevent erosion and fluid leakage over millions of cycles.

Key Advantages:

-

Excellent erosion resistance from high-speed fluid impact

-

Tight shut-off performance under pressure differentials

-

Long cycle life in automated flow control systems

Wear-Resistant Seal Parts in Fluid Transfer Systems

In water treatment, slurry handling, and industrial pipelines, tungsten carbide components provide protection against abrasive wear, prolonging the life of sealing interfaces and pump components.

Key Advantages:

-

Excellent abrasion and impact resistance

-

Optimal for slurry, sludge, or suspended particle fluids

-

Low maintenance and reduced operational downtime

Conclusion: The Value of Tungsten Carbide in Advanced Sealing Solutions

Tungsten carbide components have become the industry standard for sealing systems that demand extreme wear resistance, pressure tolerance, and chemical durability. From chemical process pumps and submersible systems to gas compressors and control valves, these precision-engineered parts deliver unmatched performance and service life. Whether you need seal rings, bushings, sleeves, or valve seats, tungsten carbide ensures optimal reliability across the most challenging environments.

By selecting high-quality tungsten carbide sealing components, manufacturers and system integrators benefit from reduced downtime, lower maintenance costs, and improved operational efficiency. As sealing applications evolve with increasing technical demands, tungsten carbide remains the trusted choice for critical performance under pressure.

If your industry requires long-lasting, precision-engineered sealing solutions, tungsten carbide is the material of choice—and Retop is your partner for excellence.

Quick and easy: Enter your specifications and get a quote in one business day