Tungsten Carbide Cutting Tools for Precision and Durability

High-performance carbide tools engineered for metalworking, woodworking, aerospace, electronics, and more. Discover our industry-specific cutting solutions.

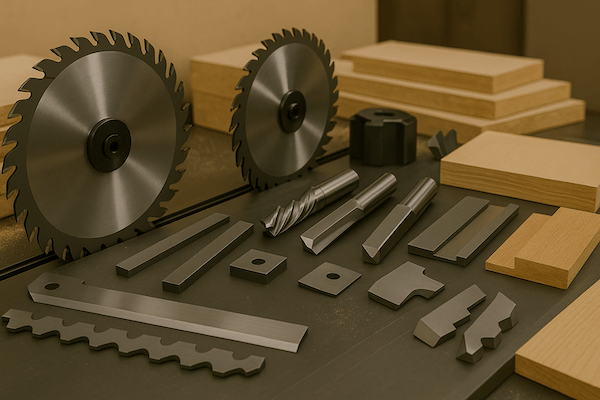

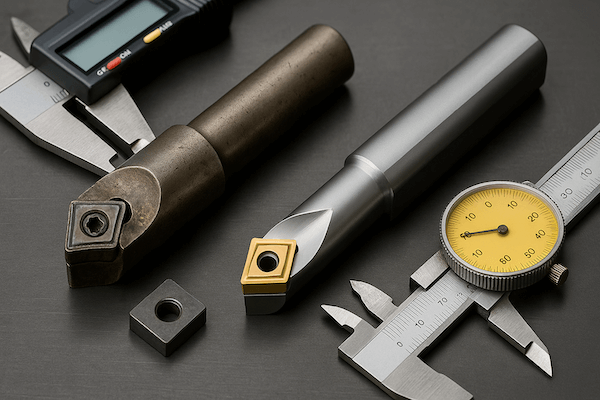

Types Of Tungsten Carbide Cutting Tools

Explore a wide variety of tungsten carbide cutting tools designed for turning, milling, drilling, grooving, trimming, and profiling—each optimized for specific materials, machining processes, and industrial applications.

Quick and easy: Enter your specifications and get a quote in one business day

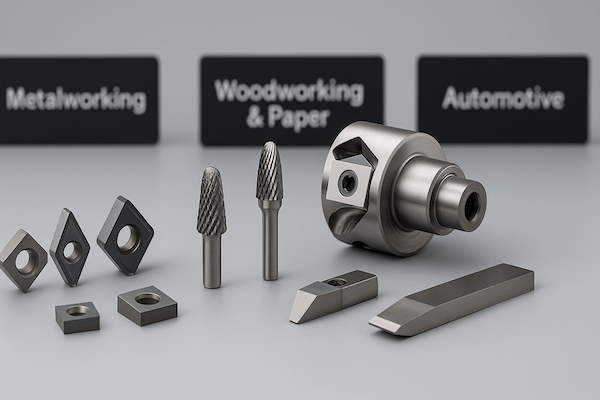

Industry-Specific Cutting Tool Solutions

Our carbide cutting tools are used across industries where precision and durability are essential. Explore specialized tools for your application.

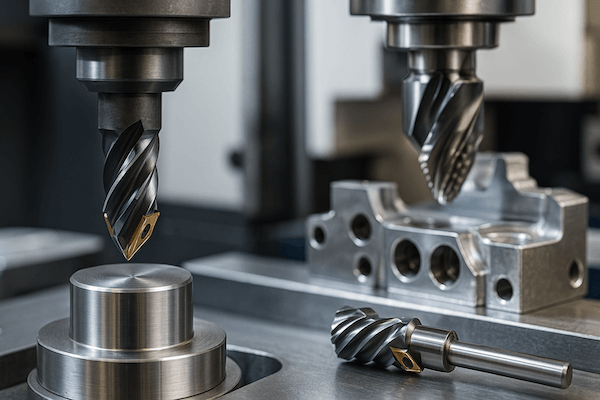

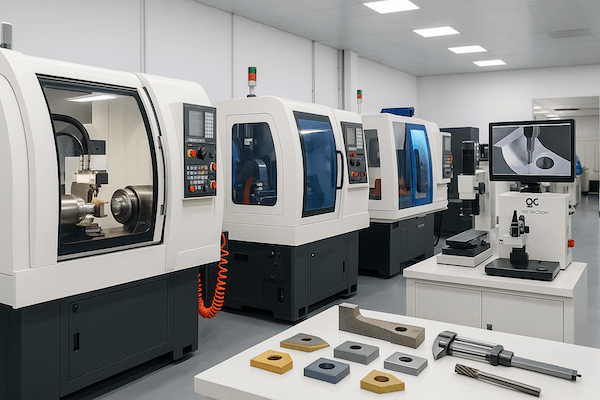

Metalworking

Carbide tools for turning, milling, and drilling steels, alloys, and cast iron in high-volume metal fabrication and precision machining operations.

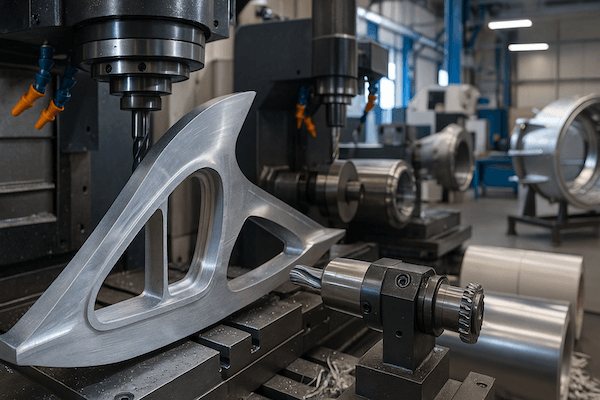

Aerospace

High-performance tools for machining titanium, Inconel, and carbon composites used in aircraft engine components and structural aerospace parts.

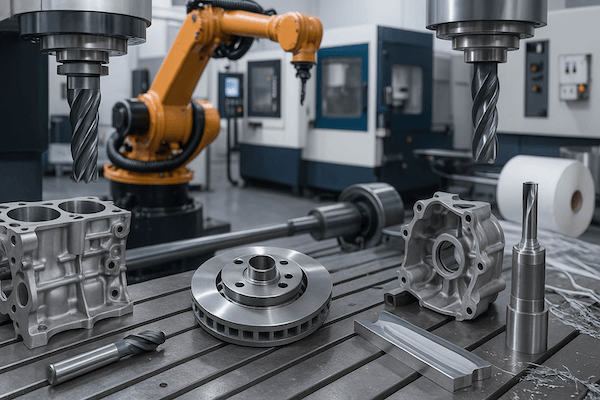

Automotive

Inserts and end mills for cutting engine blocks, transmission housings, brake systems, and forged drivetrain parts in auto part production.

Woodworking & Paper

Wood-grade carbide inserts and knives for cutting hardwood, MDF, laminated panels, and paper rolls in furniture and packaging industries.

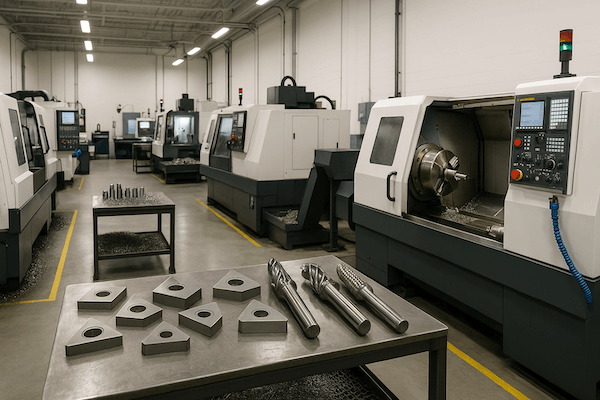

Built for Demanding Cutting Environments

Retop’s tungsten carbide cutting tools are engineered to deliver exceptional hardness, wear resistance, and dimensional stability. From CNC machining to precision edge trimming, our tools maintain consistent performance across harsh operating conditions. We offer standard and custom solutions with advanced coatings and micro-grain grades.Our tungsten carbide tools offer exceptional mechanical and thermal performance for oil and gas drilling, pumping, and sealing—ensuring maximum uptime in corrosive and high-pressure conditions.

| Feature | Description |

|---|---|

| High Hardness | Up to HRA 92 for cutting hardened steels and abrasive materials. |

| Wear & Heat Resistance | Maintains sharpness under high-speed, high-temperature conditions. |

| Versatile Material Use | Suitable for metals, wood, plastics, and composites. |

| Long Tool Life | Reduces downtime and tooling costs over extended use. |

| Precision Cutting | Ensures dimensional stability and consistent surface finish. |

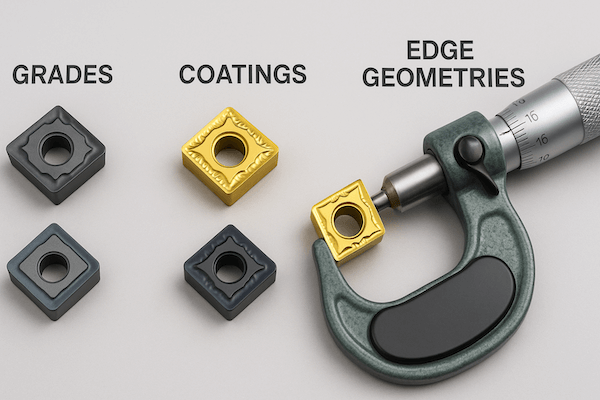

Precision Materials, Coatings & Carbide Customization Options

We offer a wide range of carbide grades, coating types, and precision tolerances to meet demanding performance and application-specific requirements.

Technical Specifications Table

| Category | Details |

|---|---|

| Carbide Grades | K10, K20, P25, micro-grain options for fine finishing and heavy-duty cutting |

| Coating Options | TiN (Titanium Nitride), TiAlN (Aluminum Titanium Nitride), TiCN (Titanium Carbonitride), or uncoated |

| Geometry Customization | Tailored chipbreaker shapes, rake angles, corner radius, and relief angles |

| Dimensional Tolerance | Up to ±0.01 mm for diameter, thickness, and edge precision |

| Application Match | Materials and coatings are selected based on cutting speed, material type, and surface requirements |

| Customization Availability | Full OEM/ODM support for custom specs, sample replication, and drawing-based production |

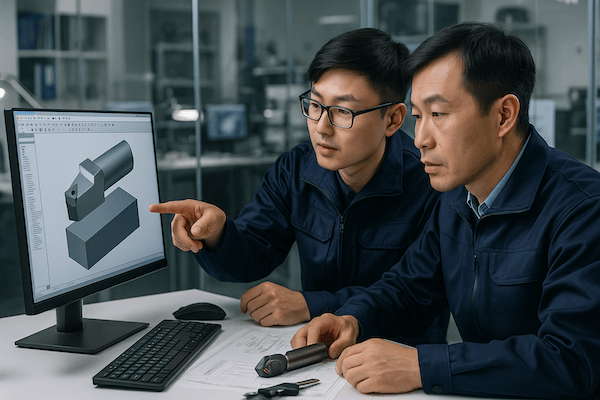

Custom Carbide Cutting Tools Built to Your Drawings

Upload your part drawing or tell us your application requirements—Retop engineers will design and manufacture precision carbide cutting tools optimized for your material, process, and tolerance needs.

Application-Driven Design

Every custom tool is engineered based on your workpiece material, cutting process, and toolpath conditions to maximize cutting efficiency and tool life.

Fast Prototyping & Replication

We provide rapid prototyping based on drawings, samples, or worn parts—ensuring fast lead time for urgent or replacement tools.

In-House Tool Manufacturing

From raw powder to sintering, grinding, and final inspection—every tool is made in our own plant under strict quality control.

Custom Carbide Cutting Tools Built to Your Drawings

Submit your tool drawing or sample and let us produce a high-performance, tolerance-specific carbide solution for your process.

Frequently Asked Questions (FAQ)

Find quick answers to common questions about carbide tool customization, material compatibility, tolerances, coatings, lead times, and ordering—helping you make informed decisions with confidence and clarity.

What materials can your carbide tools cut?

Our tools are suitable for a wide range of materials including steel, stainless steel, cast iron, aluminum, titanium, wood, plastics, and composites.

Can you produce tools based on my custom drawing or sample?

Yes. We specialize in custom carbide cutting tools based on your drawings, 3D models, or physical samples. OEM/ODM service is fully supported.

What carbide grades and coatings do you offer?

We offer grades like K10, K20, P25 and coatings such as TiN, TiAlN, TiCN, and uncoated options based on your cutting application.

Do you have a minimum order quantity (MOQ)?

For standard products, low MOQ is acceptable. For custom tools, MOQ may vary depending on complexity and production setup.

What tolerances can you achieve for custom carbide tools?

We maintain dimensional tolerances up to ±0.01 mm, depending on the tool geometry and specifications.

What is your typical lead time for production?

For standard tools, 3–7 working days. For custom tools, lead time ranges from 10–20 days depending on design complexity.

Do you offer inspection reports or quality certificates?

Yes. All tools undergo 100% inspection and we can provide dimension reports, material test reports, and hardness certification upon request.

Can you recommend the right tool based on my application?

Absolutely. Just tell us your material, machining method, and tool holding system—we will recommend or design the optimal tool solution.

Quick and easy: Enter your specifications and get a quote in one business day