When it comes to metal cutting, tungsten carbide cutting tools are one of the best choices in the market.

They are strong, durable, and can handle high-speed machining with ease. But for many manufacturers, one question often comes up: How much do tungsten carbide cutting tools cost?

The price of these tools can vary a lot depending on many factors. In this article, we’ll break down what affects the tungsten carbide cutting tools price, how to compare options, and tips to get the best value for your money.

Whether you are a production manager, purchasing officer, or business owner, understanding the price structure will help you make smarter buying decisions.

Why Tungsten Carbide Tools Are Not Cheap

Tungsten carbide is not a common material. It is a hard compound made from tungsten and carbon, and it is much harder than high-speed steel (HSS). Because of this, carbide tools last longer, resist wear, and provide cleaner cuts.

But this also means that making these tools takes more effort, higher-quality raw materials, and precise processes.

Compared to HSS tools, carbide tools are more expensive upfront. However, they often last much longer—making them a better long-term investment.

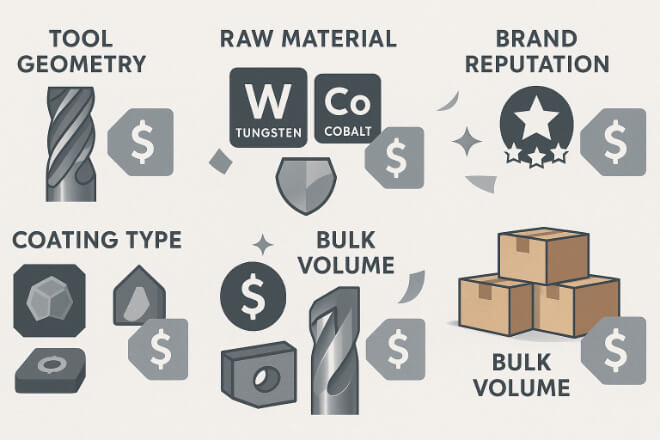

Factors That Affect Tungsten Carbide Tool Prices

There is no single fixed price for carbide tools. The final cost depends on a few key things:

1). Tool Type and Geometry

Different tools have different designs. A simple flat end mill will usually cost less than a complex step drill or custom-formed insert. Here’s a breakdown:

| Tool Type | Estimated Price Range |

|---|---|

| Standard End Mill | $10 – $50 |

| Drill Bit (solid carbide) | $15 – $70 |

| Turning Inserts | $3 – $20 each |

| Custom-Made Tools | $100 and above |

2). Raw Material Costs

Tungsten and cobalt—key ingredients in carbide—are global commodities.

Their prices can change based on supply, demand, and geopolitical issues. If raw material prices go up, so does the cost of the tool.

3). Coating Type

Some carbide tools come uncoated, while others have special coatings like TiN, TiAlN, DLC, or CVD diamond.

These coatings improve heat resistance and wear life but can add 10–30% to the price.

4). Brand and Supplier Reputation

Big global brands often charge more, not just for the tool but also for quality assurance, customer support, and delivery reliability.

A well-known supplier with ISO certifications may charge more, but you’re paying for consistency and support.

5). Order Volume

Buying in bulk will usually reduce your carbide tool cost per piece. Many suppliers offer discounts for large orders or recurring purchases.

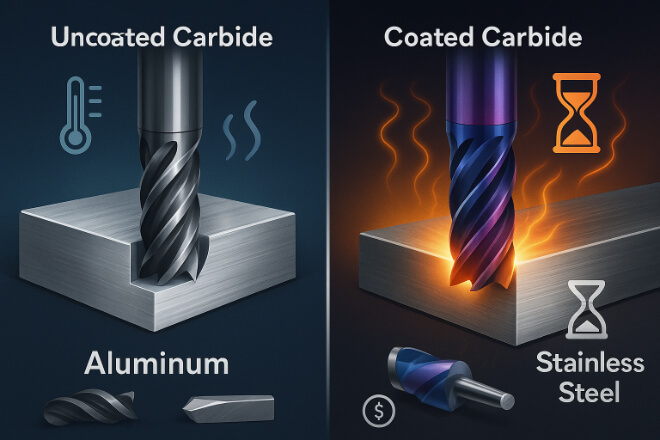

Uncoated vs Coated: Is the Extra Cost Worth It?

Many buyers wonder whether it’s worth paying more for coated tools. The answer depends on what you’re cutting.

Uncoated carbide tools are cheaper and suitable for softer materials like plastic, aluminum, or low-carbon steel.

Coated tools work better in high-speed or high-temperature applications and with harder materials like stainless steel or titanium.

If your goal is longer tool life and fewer tool changes, the extra cost for coating may be worth it.

Global Price Trends: What’s Happening Now?

In recent years, the tungsten carbide cutting tools price has been affected by several factors:

Rising raw material costs (especially tungsten and cobalt)

Supply chain disruptions post-COVID

Higher demand in automotive, aerospace, and energy sectors

Increased labor and energy costs in manufacturing countries

These pressures have caused a slight upward trend in pricing, especially for custom tools or tools with advanced coatings.

Tips to Get the Best Value

Here’s how to make sure you get the best value—not just the lowest price:

Focus on Cost per Part

Instead of looking at the price of the tool, consider how many parts it can cut before needing replacement.

A more expensive tool that lasts twice as long may actually save money.

Buy From a Trusted Supplier

Choose suppliers with strong quality control, technical support, and fast delivery.

Even if their price is slightly higher, you’re less likely to face problems like tool failure or downtime.

Ask for Volume Discounts

If you’re placing large or regular orders, don’t hesitate to ask your supplier for a bulk pricing plan. Some may also offer rebates or loyalty programs.

Regrinding and Recycling Programs

Some carbide tools can be reground and reused. Others can be returned to the supplier for recycling.

These services can lower your long-term tooling costs and support sustainability goals.

When Higher Price Means Better Value

Here are a few situations where paying a bit more is a smart move:

You need tight tolerances or a mirror finish

You’re machining hard materials like Inconel or titanium

Your machines run at high spindle speeds

You want to reduce tool change downtime

In these cases, premium carbide tools will deliver better results, lower scrap rates, and improve efficiency.

Comparing Prices: What to Watch For

If you’re comparing quotes from multiple suppliers, make sure you’re comparing the same specs:

| Specification | Why It Matters |

|---|---|

| Carbide Grade | Different grades affect hardness and wear |

| Tool Coating | Coated tools last longer in tough materials |

| Tolerance Level | Tight tolerance tools cost more but are more precise |

| Brand / Certification | Reputable brands often meet stricter QC standards |

Don’t just choose the cheapest tool on paper. Instead, compare the full tool specs, expected life, and the support behind it.

Final Thoughts

The price of tungsten carbide cutting tools depends on many factors—tool type, coating, material costs, brand, and more.

While it’s tempting to focus on the upfront price, decision-makers should think about the bigger picture.

Ask yourself:

How long will the tool last?

Will it reduce machine downtime?

Can it improve surface finish and part accuracy?

Is the supplier dependable?

A slightly higher investment in better tools can lead to better results and lower total cost.

If you’re ready to upgrade your tooling or compare options, check out Retopz for reliable tungsten carbide tools and expert support.