Compressors and turbo machinery are essential in industries such as oil and gas, chemical processing, marine, and power generation.

These machines operate under high pressure, heat, and vibration, and even a small seal failure can lead to expensive downtime and safety risks.

To ensure reliable performance, many companies choose tungsten carbide seal rings.

This article explains why tungsten carbide is the preferred choice, its advantages over other materials, and best practices for decision-makers.

Why Seal Rings Matter in Compressors and Turbo Machinery

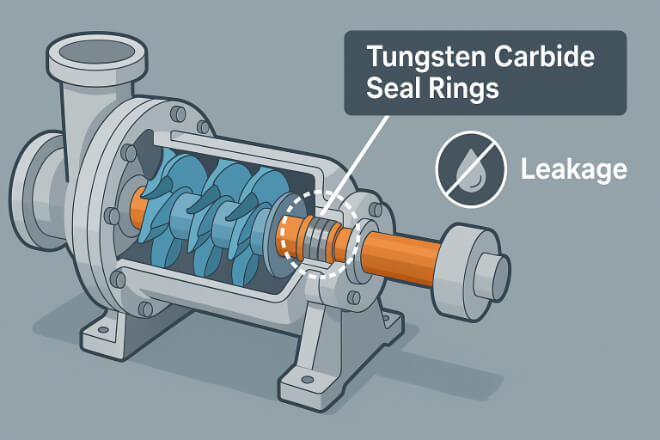

Seal rings in compressors and turbines perform critical tasks:

Prevent leaks of gas, air, or fluids.

Protect bearings and rotors from contamination.

Reduce friction and wear inside high-speed equipment.

Maintain efficiency under pressure and temperature changes.

A strong, durable seal ring ensures safe, reliable, and energy-efficient machinery.

Key Properties of Tungsten Carbide Seal Rings

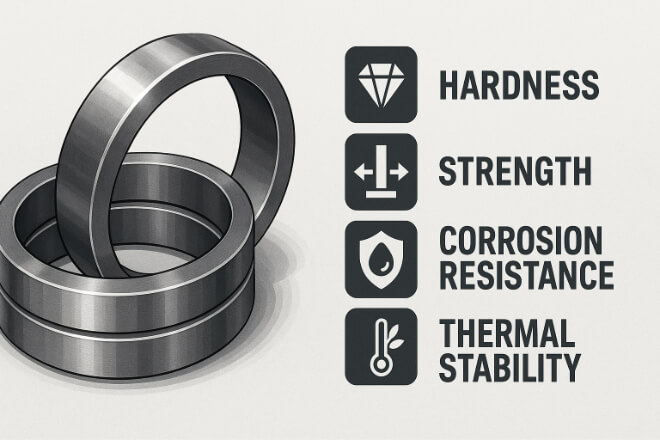

Tungsten carbide is a compound of tungsten and carbon, often bonded with cobalt or nickel. Its properties include:

Extreme hardness → Resists wear from friction and particles.

High compressive strength → Handles heavy loads and high pressure.

Thermal stability → Performs reliably under high temperatures.

Corrosion resistance → Protects against chemicals and gases.

Dimensional stability → Maintains accurate sealing surfaces.

These properties make tungsten carbide ideal for compressors and turbo machinery operating in harsh conditions.

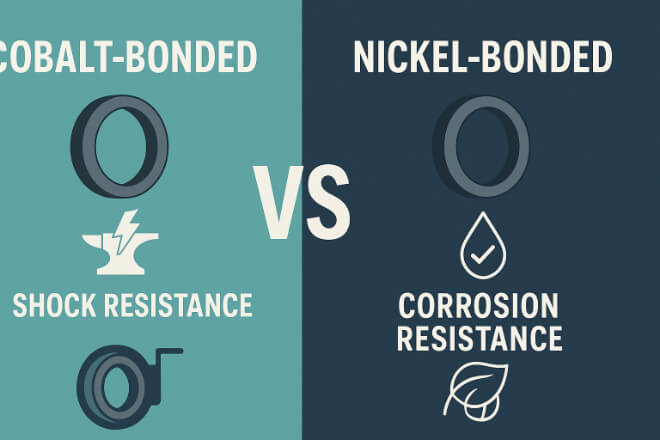

Cobalt-Bonded vs Nickel-Bonded Tungsten Carbide

1). Cobalt-bonded tungsten carbide

Greater toughness and shock resistance.

Best for compressors in oilfield, mining, or vibration-heavy environments.

2). Nickel-bonded tungsten carbide

Superior corrosion resistance.

Ideal for chemical plants, marine systems, and gas compressors.

Choosing the right binder ensures long service life and optimal performance.

Advantages Over Other Seal Materials

| Feature | Tungsten Carbide | Ceramic | Steel |

|---|---|---|---|

| Wear resistance | Excellent for abrasives | Moderate | Poor in slurry |

| Toughness | High, resists shock | Low, brittle under impact | Moderate |

| Corrosion resistance | Good, nickel grades excel | Excellent in acids | Poor in chemicals |

| Thermal performance | Excellent at high heat | Good | Moderate |

| Service life | Long-lasting | Moderate | Short |

Applications in Compressors and Turbo Machinery

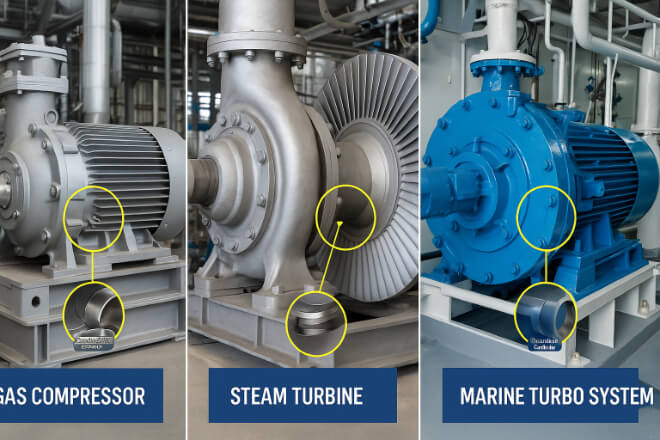

Tungsten carbide seal rings are widely used in:

Gas compressors → Prevent leaks under high pressure.

Steam turbines → Maintain tight seals during temperature changes.

Marine turbo systems → Resist seawater corrosion and vibration.

Chemical processing compressors → Handle aggressive chemicals without failure.

Power generation turbines → Improve energy efficiency and reduce maintenance.

Cost vs Long-Term Value

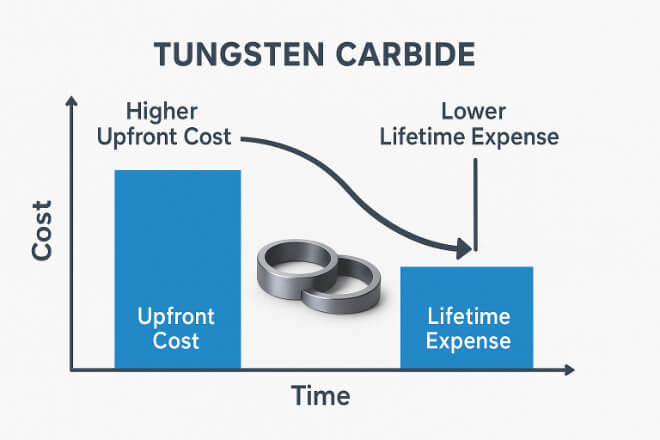

While tungsten carbide seal rings may cost more initially, they:

Last longer than steel or ceramic alternatives.

Require fewer replacements, lowering spare part costs.

Reduce downtime, improving productivity.

Protect equipment, extending compressor or turbine life.

For decision-makers, the life cycle cost is often lower with tungsten carbide despite its higher upfront price.

Environmental Benefits

Tungsten carbide is recyclable, reducing material waste. Reusing tungsten reduces mining demand and supports sustainability goals.

Fewer replacements also mean fewer seals in landfills and less manufacturing energy used over time.

Best Practices for Using Tungsten Carbide Seal Rings

Select the right binder → Nickel for corrosion, cobalt for shock.

Install carefully → Avoid scratches or misalignment that cause leaks.

Ensure proper lubrication → Reduces heat and friction.

Inspect regularly → Spot wear early to prevent costly downtime.

Work with trusted suppliers → Ensure material quality and proper specifications.

Key Takeaways for Decision-Makers

Tungsten carbide seal rings are essential for compressors and turbo machinery under high pressure, heat, and vibration.

Nickel-bonded grades excel in corrosive environments, while cobalt-bonded grades handle shock better.

Their durability, recyclability, and efficiency offer better ROI compared to other materials.

Choosing tungsten carbide reduces downtime, maintenance, and environmental impact.

Conclusion

In compressors and turbo machinery, seal reliability is critical. Tungsten carbide seal rings provide the hardness, strength, and corrosion resistance required for long-term performance in demanding industries.

For decision-makers, using tungsten carbide is a smart investment that balances cost, sustainability, and operational efficiency.

If you want to know more details about any company, please feel free to contact us.