Wastewater treatment plants and chemical processing facilities work under harsh and corrosive conditions.

Pumps, mixers, compressors, and valves all face contact with dirty water, aggressive chemicals, and high pressure. In these systems, seal rings are vital for preventing leaks and protecting machines.

Among the many materials available, tungsten carbide seal rings have become a top choice.

Their hardness, toughness, and resistance to wear and corrosion make them ideal for wastewater and chemical equipment.

For decision-makers, investing in these rings means fewer breakdowns, lower costs, and safer operations.

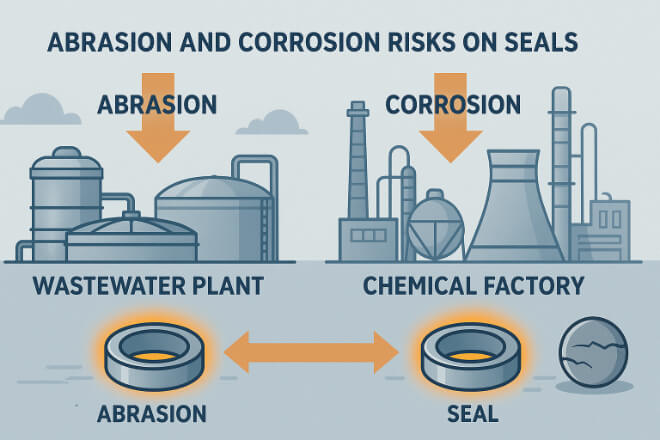

Challenges in Wastewater and Chemical Applications

1). Wastewater Systems

Abrasive solids such as sand, grit, and sludge damage seals

Variable pH levels cause corrosion

Continuous operation leads to wear and fatigue

2). Chemical Equipment

Pumps and mixers face acids, solvents, and alkalis

High temperatures speed up corrosion and wear

Safety demands leak-free performance in hazardous environments

Ordinary seal materials like stainless steel or carbon rings fail quickly.

Tungsten carbide provides the strength needed to survive these harsh environments.

Why Tungsten Carbide Seal Rings Are Ideal

1). Wear Resistance

Tungsten carbide is almost as hard as diamond. It resists scratches and abrasion from solid particles in wastewater.

Nickel-bonded tungsten carbide performs well against acids, alkalis, and seawater—perfect for chemical and wastewater applications.

3). Toughness and Strength

Cobalt-bonded tungsten carbide survives shock loads and pressure changes common in pumps and mixers.

4). Thermal Stability

Seal rings keep their hardness even in hot chemical processes.

5). Long Service Life

Fewer replacements and less downtime reduce long-term costs.

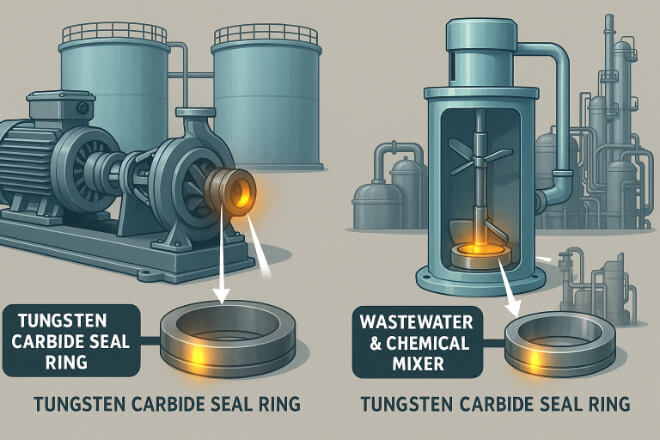

Applications in Wastewater Equipment

1). Pumps

Seal rings in wastewater pumps face sand, sludge, and grit. Tungsten carbide provides durability and leak protection.

2). Mixers

Mixers in treatment plants operate continuously. Polished tungsten carbide seal rings reduce friction and extend life.

3). Valves

Valves exposed to contaminated water rely on tungsten carbide rings to maintain tight sealing.

Applications in Chemical Equipment

1). Chemical Pumps

Seal rings resist acids and solvents that destroy weaker materials.

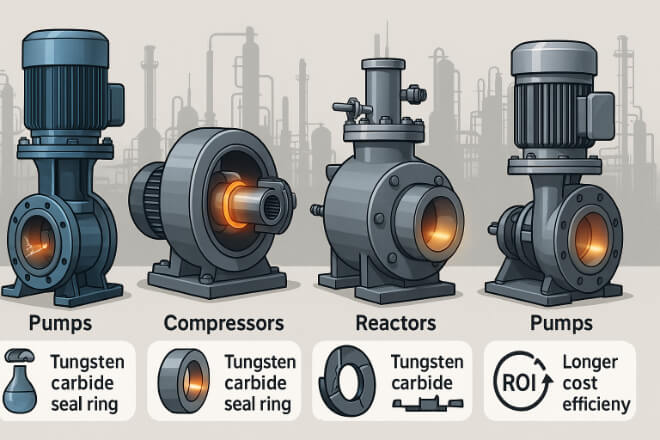

2). Compressors

Gas compressors in chemical plants run at high speed and heat. Tungsten carbide seal rings reduce friction and improve reliability.

3). Reactors and Agitators

Custom seal rings prevent leaks in reactors handling hazardous chemicals, protecting workers and equipment.

Benefits for Industry

Stronger Reliability: Survive both abrasion and corrosion

Improved Safety: Prevent leaks in hazardous systems

Cost Savings: Longer service life cuts maintenance costs

Efficiency: Machines run smoother with less friction

Compliance: Support environmental and safety regulations

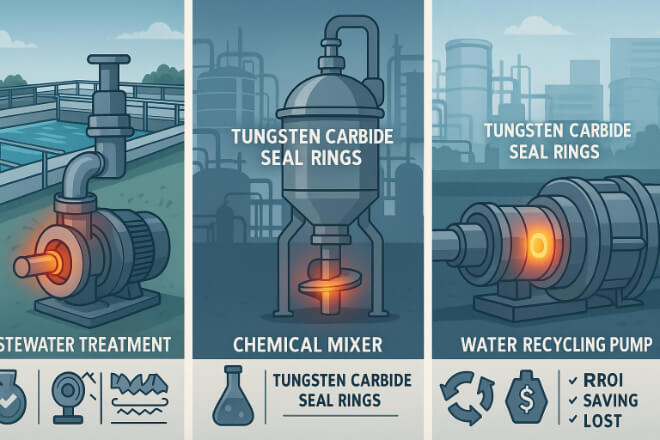

Case Studies

1). Wastewater Treatment Plant

Switching from stainless steel to tungsten carbide seal rings reduced failures by 60% in sludge pumps.

2). Chemical Refinery

Nickel-bonded tungsten carbide rings resisted acid attack, doubling service life in chemical mixers.

3). Industrial Water Recycling

Pumps with tungsten carbide rings lasted longer when handling abrasive sand in recycled water.

How to Select the Right Tungsten Carbide Seal Ring

1). Binder Choice:

Nickel for corrosive chemicals or seawater

Cobalt for heavy load and shock

2). Surface Finish:

Polished rings for high-speed systems

Coated rings for extra wear protection

3). Operating Conditions:

Consider pH level, temperature, and pressure

4). Supplier Quality:

Choose ISO-certified suppliers with proven experience

Maintenance and Replacement Strategy

Inspect regularly for cracks, scratches, or wear

Replace seals before total failure

Keep spare parts in stock for critical pumps

Recycle worn tungsten carbide to reduce costs

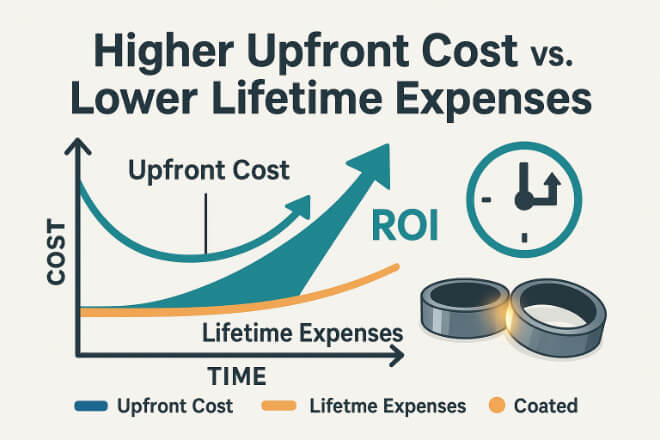

Cost and ROI Considerations

Higher initial cost than steel or graphite seals

Lower replacement frequency

Fewer shutdowns and repair costs

Safer and more reliable operations

Stronger long-term return on investment

Conclusion

In wastewater and chemical equipment, tungsten carbide seal rings provide the durability, safety, and efficiency needed to face abrasive and corrosive conditions.

For decision-makers, they are not just a technical upgrade but a smart business investment.

By reducing failures and extending service life, tungsten carbide seal rings help industries achieve both safety and profitability.

If you want to know more details about any company, please feel free to contact us.