Tungsten Carbide Tools for 3C Electronics & Semiconductors Industry

Tungsten carbide tools are essential in the production of 3C electronics and semiconductor components due to their precision, wear resistance, and performance under high-volume manufacturing. These tools are used in applications such as micro drilling, stamping, IC packaging, and dicing processes, where dimensional accuracy and tool longevity are critical.

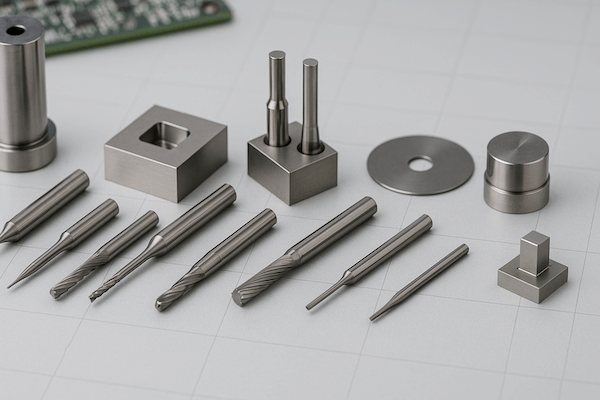

Typical Tool Types of Tungsten Carbide for 3C Electronics & Semiconductors Industry

Explore typical tungsten carbide tool types engineered for precision manufacturing in the 3C electronics and semiconductors industry, including drilling, stamping, molding, dicing, and micro-machining applications.

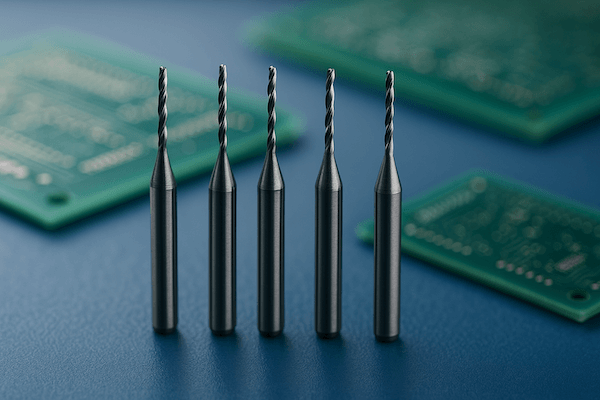

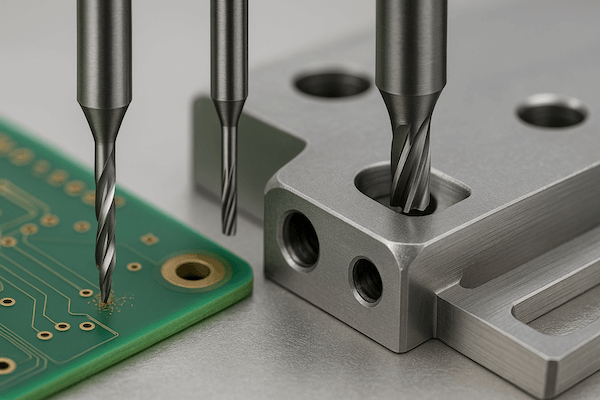

Carbide Micro Drills

Precision drills used for PCB and micro-component hole drilling in 3C electronic production lines.

Carbide Micro Reamers

Used for high-precision hole reaming in aluminum housings and sensor block components.

Carbide End Mills (Micro)

Ideal for micro slotting, contouring, and trimming of mobile phone casing components.

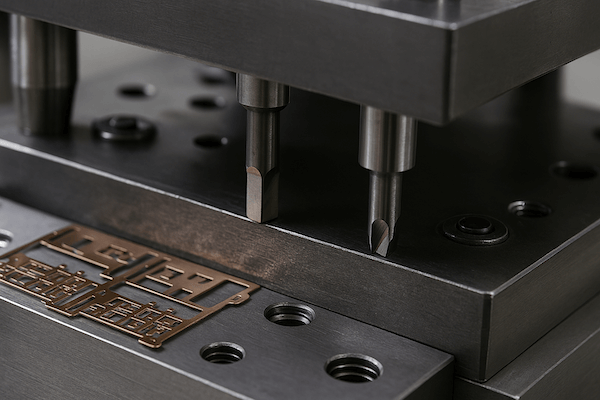

Carbide Punches & Dies

Used in high-speed stamping of connectors, lead frames, and battery metal shells.

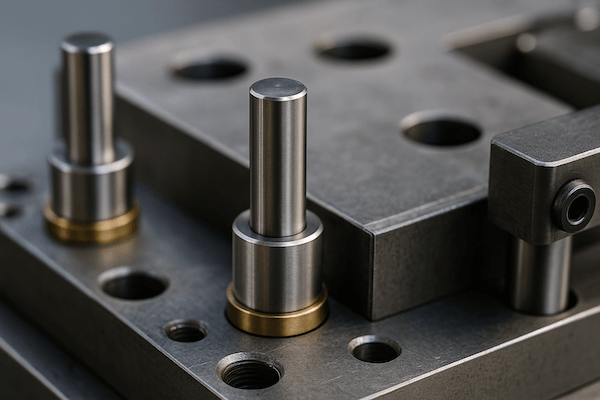

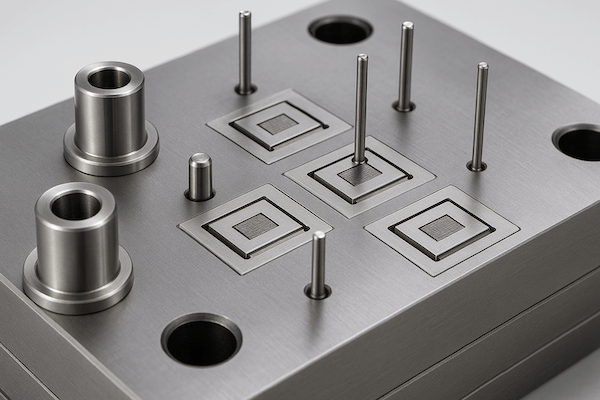

Carbide Guide Pins & Bushings

Ensure precision alignment and repeatability in fine-pitch stamping die operations.

Carbide Strip Dies

Applied in strip processing lines for battery shell and phone component cutting.

Carbide Cavity Inserts

Mold components for precision IC packaging and high-performance electronic connectors.

Carbide Sprue Bushings

Direct plastic flow in high-volume IC and sensor overmolding applications.

Carbide Ejector Pins

Maintain form accuracy and withstand repeated ejection in semiconductor packaging molds.

Carbide Scriber Blades

Dicing blades used to separate fragile substrates such as glass, ceramics, and silicon.

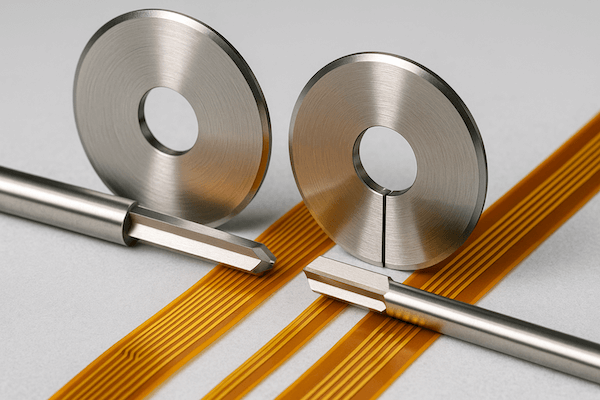

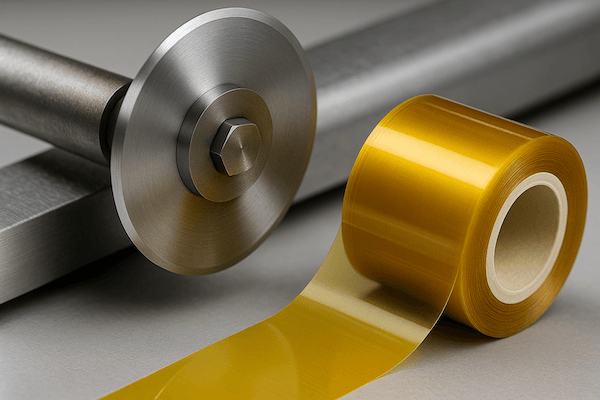

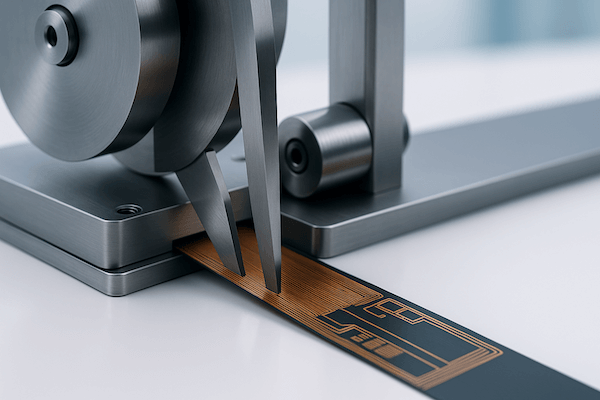

Carbide Slitting Blades

Precision cutting of thin battery foils, FPC boards, and laminated films.

Carbide Rotary Blades

Used in rotary systems for trimming composite 3C components with minimal burr.

Quick and easy: Enter your specifications and get a quote in one business day

Tungsten Carbide Tools for 3C Electronics & Semiconductors Industry

Tungsten carbide tools are essential in the production of 3C electronics and semiconductor components due to their precision, wear resistance, and performance under high-volume manufacturing. These tools are used in applications such as micro drilling, stamping, IC packaging, and dicing processes, where dimensional accuracy and tool longevity are critical.

Micro Machining for PCB and Sensor Components

Tungsten carbide tools play a vital role in high-precision micro machining processes for printed circuit boards (PCBs), sensor housings, and electronic modules.

- Carbide Micro Drills – Used for drilling vias and through-holes in PCB and IC substrates.

- Carbide Micro Reamers – Applied to ream precision holes in aluminum sensor housings.

- Carbide End Mills (Micro) – Create slots and profiles in mobile phone frames or ceramic housings.

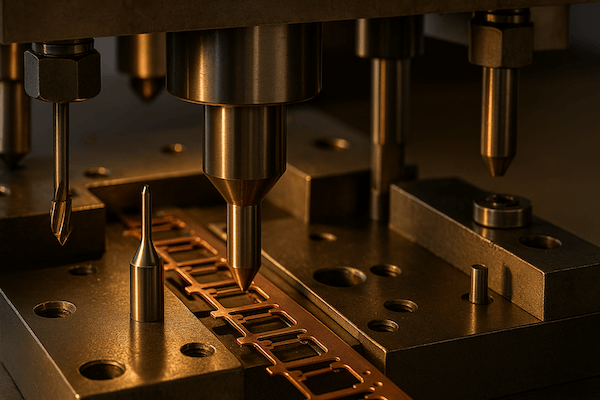

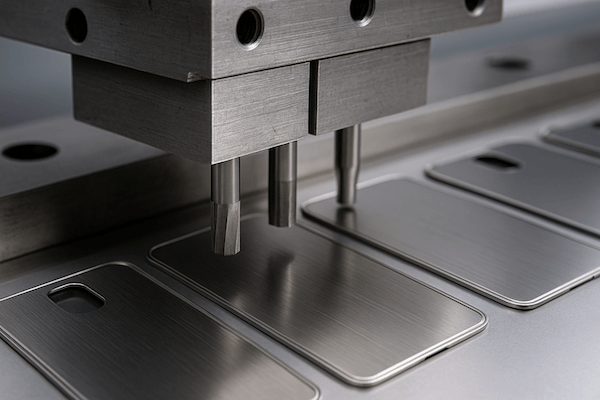

Precision Stamping for Connectors and Lead Frames

These tools ensure high-efficiency production of lead frames, smartphone shells, and battery cases using progressive stamping technology.

- Carbide Punches & Dies – High-speed punching of copper and stainless steel lead frames.

- Carbide Guide Pins & Bushings – Ensure tight alignment and positioning in stamping dies.

- Carbide Strip Dies – Ideal for continuous blanking of mobile phone metal cases.

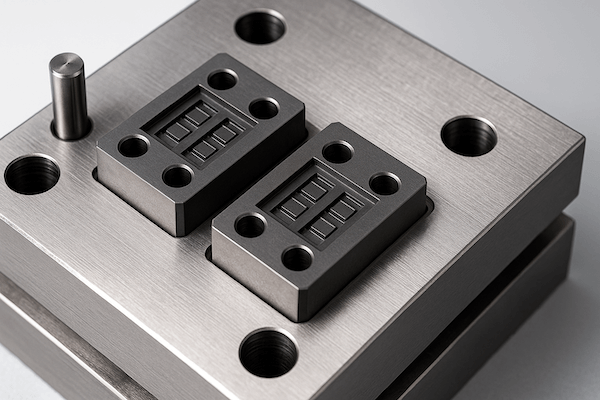

Semiconductor Packaging Mold Applications

Carbide tooling components are critical to IC molding, cavity inserts, and sprue systems for high-volume chip packaging.

- Carbide Cavity Inserts – Act as core mold components for IC package molding.

- Carbide Sprue Bushings – Provide durable flow channels for plastic injection in semiconductor molds.

- Carbide Ejector Pins – Ensure repeated precision ejection of molded chip units.

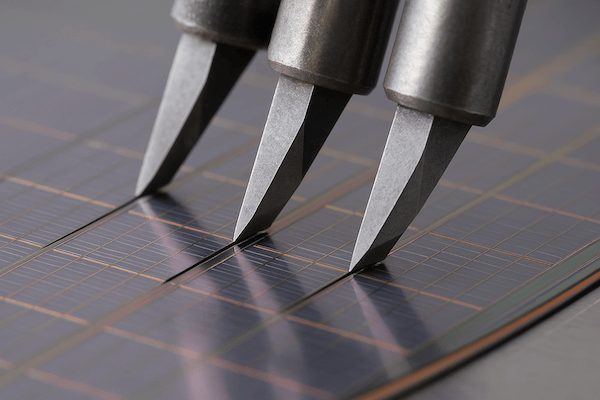

Dicing and Cutting of Hard-Brittle Substrates

Used to dice silicon wafers, ceramic substrates, and flexible circuits with extremely fine accuracy.

- Carbide Scriber Blades – Used for scribing and breaking semiconductor wafers.

- Carbide Slitting Blades – Cut battery foils and flexible printed circuit boards (FPCs).

- Carbide Rotary Blades – Trim adhesive tape and composite electronic films.

Conductive Material Processing for Connectors

Used in shaping and finishing electronic terminals, connectors, and precision metal parts.

- Carbide Forming Tools – Form USB contacts and mobile device terminal pins.

- Carbide EDM Electrodes – Shape micro cavities in connector molds through EDM.

- Carbide Facing Tools – Finish end faces of aluminum or copper connector shells.

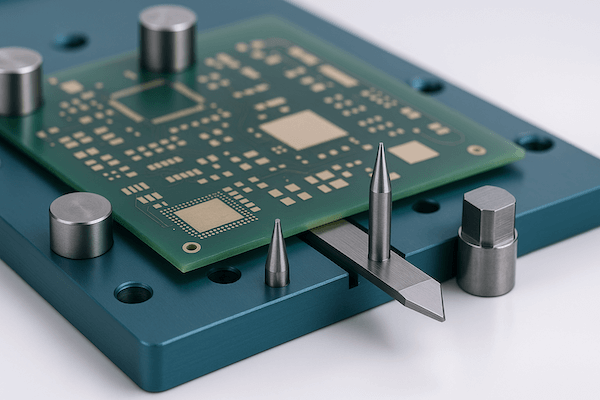

Assembly Fixtures and Precision Inspection Tools

Support the handling, clamping, and positioning of miniature parts during assembly and testing.

- Carbide Support Pins & Blocks – Secure FPCs and sensor components during testing.

- Carbide Alignment Pins – Provide accurate positioning in automated module assembly.

- Carbide Probe Tips – Perform signal and continuity testing on ICs and PCBs.

Summary

Tungsten carbide tools are indispensable in the 3C electronics and semiconductor industries, offering superior durability, micro-scale precision, and compatibility with mass production processes. From PCB drilling and sensor housing reaming to connector forming and chip packaging, carbide tools support every step of modern electronics manufacturing with unmatched performance.

Quick and easy: Enter your specifications and get a quote in one business day