Tungsten Carbide Tools for the Medical Industry

Tungsten carbide is widely used in the medical industry due to its exceptional hardness, dimensional stability, corrosion resistance, and ability to maintain cutting precision under demanding conditions. Whether for orthopedic implants, surgical equipment, or precision lab components, carbide tooling ensures repeatable, sterile, and ultra-precise manufacturing processes.

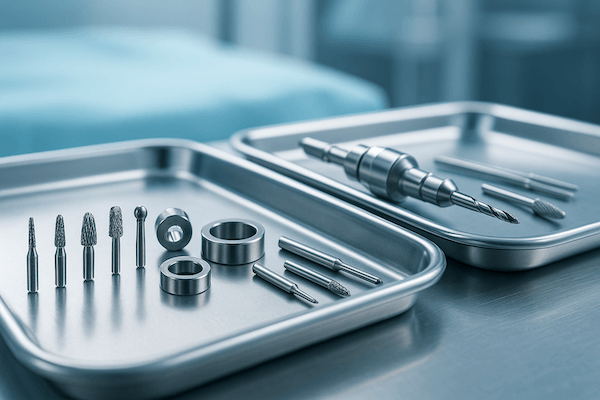

Key Tungsten Carbide Tools for Medical Applications

Below are the most commonly used tungsten carbide tools in the medical device industry, with a concise product description and a dedicated image generation prompt for each.

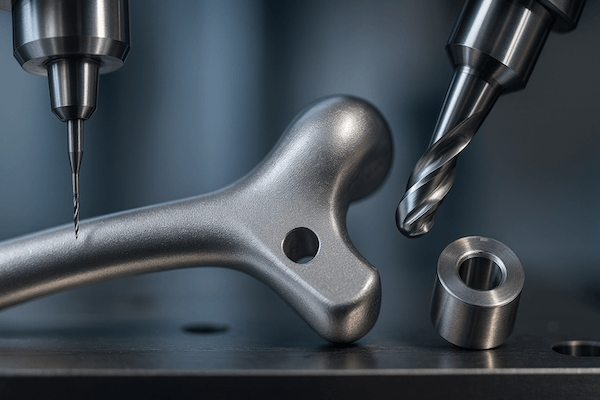

Tungsten Carbide Micro Drills

Micro-sized carbide drills for creating holes in titanium bone plates and dental components.

Tungsten Carbide Milling Cutters

Used for contouring surgical tools, bone screws, and joint implants with high accuracy.

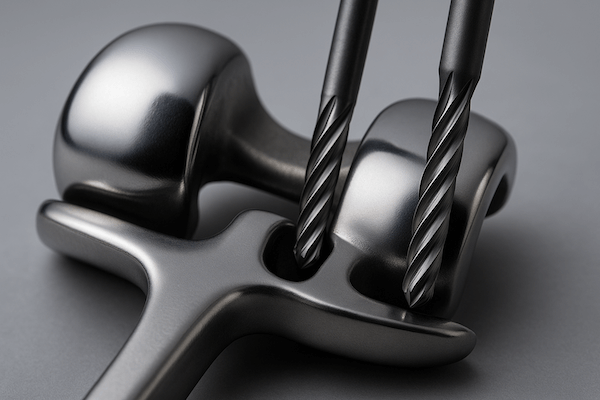

Tungsten Carbide Reamers

Precision reaming tools for expanding bores in implants or joint cavities.

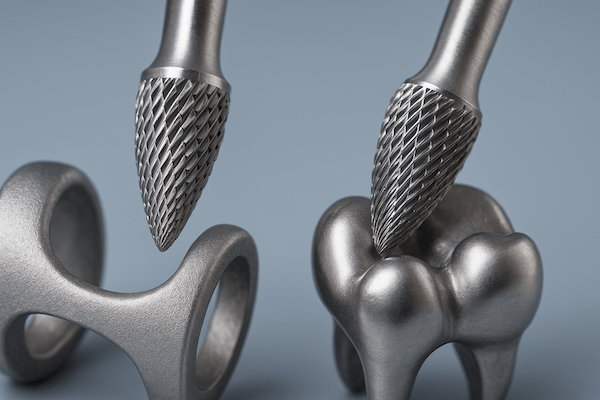

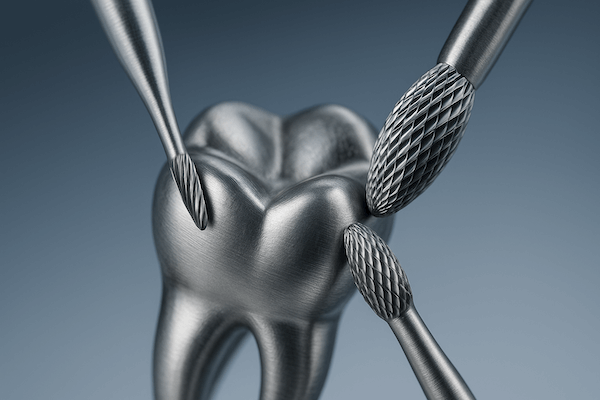

Tungsten Carbide Burrs & Rotary Files

Used for surface finishing and fine shaping of implants and dental tools.

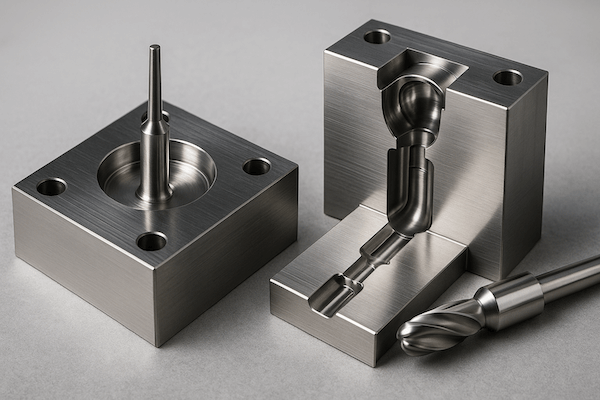

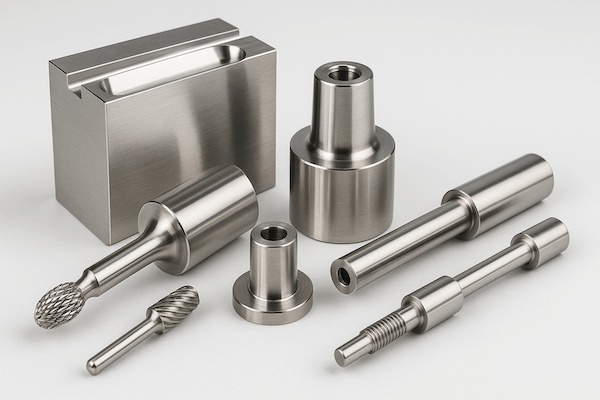

Tungsten Carbide Molds & Dies

High-durability molds for precision injection molding of plastic medical components.

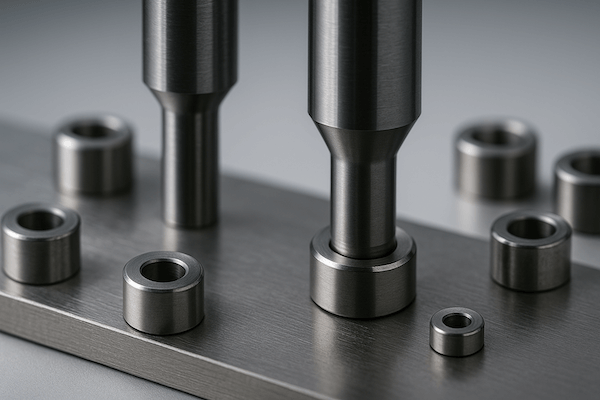

Tungsten Carbide Punches & Pins

Precision punches for compact medical metal or ceramic housings.

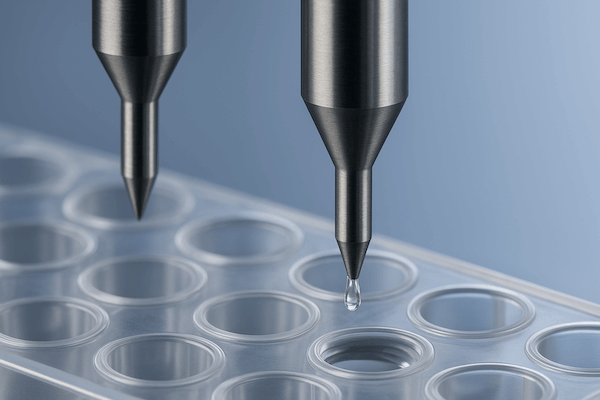

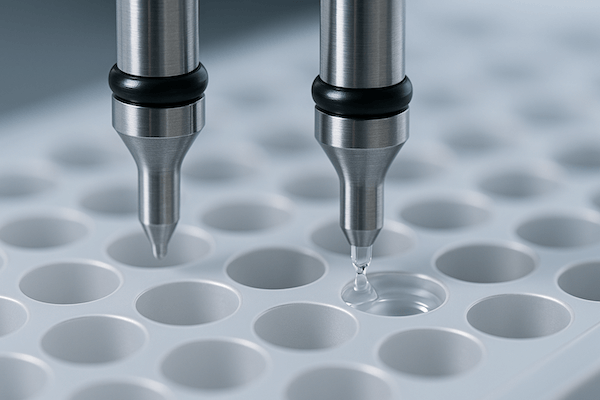

Tungsten Carbide Micro Nozzles

For precise microfluidic control in diagnostic and lab-on-chip systems.

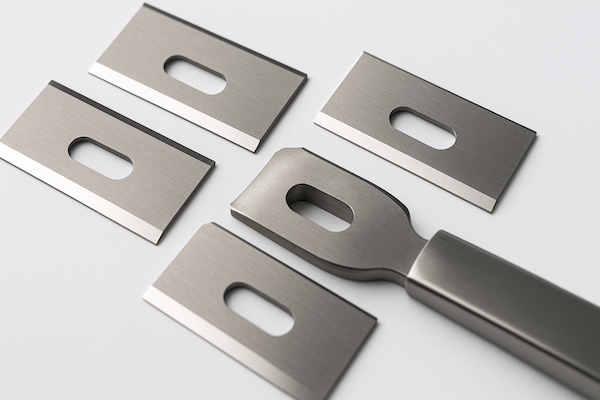

Tungsten Carbide Blades & Cutters

Used in tissue sample slicing and surgical sample preparation tools.

Tungsten Carbide Microprobes

High-precision probes for contact-based surface testing or micro-invasive procedures.

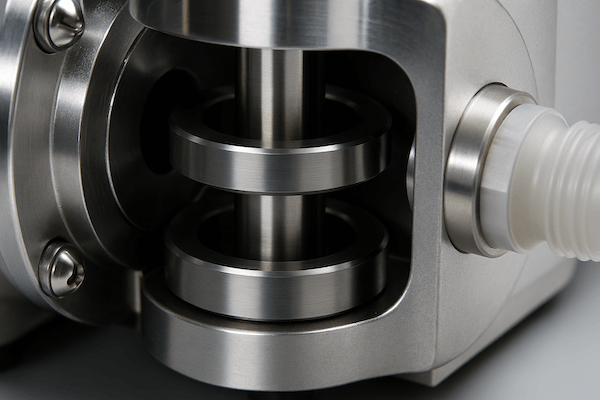

Tungsten Carbide Sealing Rings & Seats

Used in sterile fluid pumps, medical valves, and closed fluid transport systems.

Quick and easy: Enter your specifications and get a quote in one business day

Precision Machining for Surgical, Dental, and Diagnostic Applications

Tungsten carbide tools play a pivotal role in the high-precision manufacturing processes demanded by today’s medical industry. From orthopedic implant machining to diagnostic fluid systems, carbide tools deliver the hardness, durability, and geometric accuracy required to meet regulatory and performance standards.

Orthopedic & Surgical Implant Manufacturing

Typical Carbide Tools Used:

-

Tungsten Carbide Micro Drills – for bone plate hole creation

-

Ball Nose End Mills – for 3D contouring of joint implants

-

Carbide Reamers – for bore finishing in implant assemblies

Key Characteristics:

-

Exceptional dimensional accuracy (±0.01 mm)

-

High surface finish (Ra ≤ 0.2 μm)

-

Wear resistance under high-load surgical machining

Applications:

-

Machining femoral stems, hip cups, bone screws, trauma fixation plates

Dental Instrument Manufacturing

Typical Carbide Tools Used:

-

Dental Carbide Burrs – for shaping crowns and bridges

-

Micro Cutters – for high-speed polishing

-

Carbide Pins – for dental reamers and drills

Key Characteristics:

-

Micro-sized (0.3–2.5 mm)

-

Autoclavable and corrosion-resistant

-

Optimized for enamel, dentin, and zirconia shaping

Applications:

-

Manufacturing of dental rotary tools, surgical handpiece attachments, root canal files

Medical Injection Molds for Disposable Devices

Typical Carbide Tools Used:

-

Carbide Mold Inserts – for molding syringe barrels, inhaler nozzles

-

Sprue Bushings & Core Pins – for catheter hubs and connectors

Key Characteristics:

-

Highly polishable surfaces for mirror-finish plastics

-

Excellent dimensional stability in high-temperature injection cycles

-

High wear life in large-volume production runs

Applications:

-

Mold bases and inserts for syringes, IV connectors, infusion ports

Laboratory & Diagnostic Equipment Components

Typical Carbide Tools Used:

-

Tungsten Carbide Micro Nozzles – for fluid dispensing

-

Carbide Sealing Rings & Seats – for microfluidic pumps and diagnostic flow control systems

Key Characteristics:

-

Chemically inert under contact with reagents

-

Smooth internal channels for non-turbulent fluid transport

-

Long-lasting seal integrity for sterilized systems

Applications:

-

Cartridge-based test platforms, lab-on-chip dispensers, diagnostic fluid regulators

Conclusion: Why Application-Specific Carbide Tooling Matters

Each medical application has distinct material and performance demands—whether it’s the abrasive nature of zirconia in dental work, the precision of orthopedic screws, or the fluid integrity required in sealed diagnostic equipment. Tungsten carbide tools tailored for medical-grade work ensure:

Lower rejection rates

Longer tool life

Better compliance with medical manufacturing standards (ISO 13485, FDA, CE)

Quick and easy: Enter your specifications and get a quote in one business day