Tungsten Carbide Tools in the Mold and Die Industry

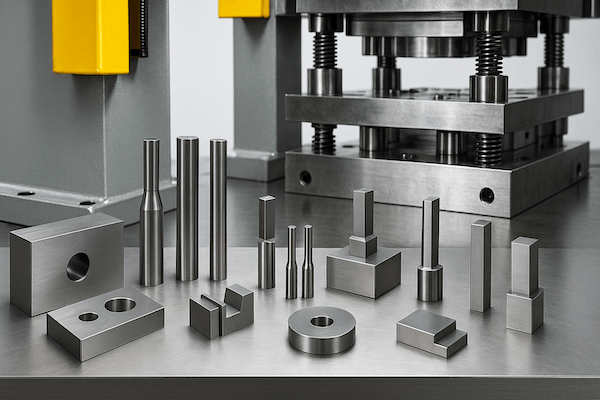

Tungsten carbide tools (also known as cemented carbide tools) play a critical role in the mold and die industry by offering extreme wear resistance, long service life, and precision under high pressure and repeated operation. These tools are essential for stamping dies, plastic injection molds, progressive dies, and forging molds, where tool longevity and dimensional accuracy are key. Carbide inserts, punches, dies, and core pins are commonly used to machine, shape, or form metals and plastics in high-speed production environments.

The Main Types of Carbide Tools for Mold and Die Industry

Key tungsten carbide products used in stamping, injection molding, and precision tooling for durability and dimensional control.

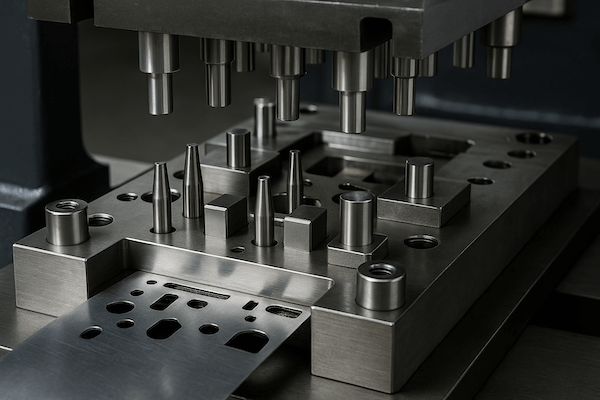

Carbide Punches

Precision carbide punches for progressive stamping dies

Carbide Die Inserts

Wear-resistant inserts for stamping and forming dies

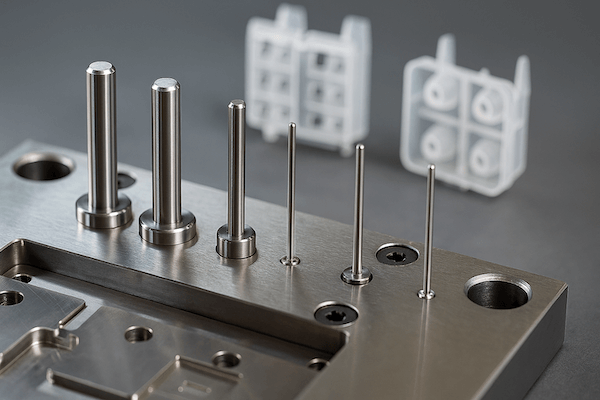

Carbide Core Pins

High-precision pins for plastic injection mold tooling

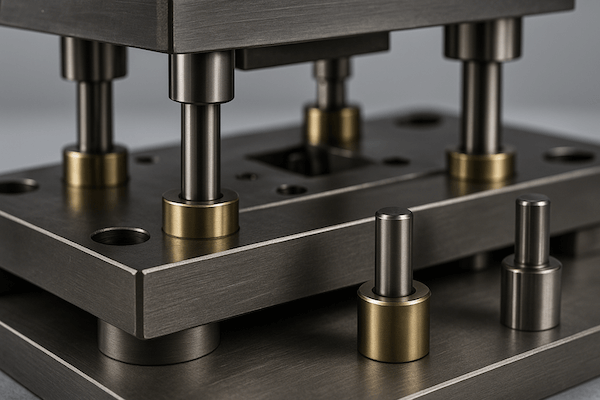

Carbide Guide Bushings

Alignment bushings for die sets and guide pillars

Quick and easy: Enter your specifications and get a quote in one business day

Applications of Tungsten Carbide Tools in Mold and Die Industry

Tungsten carbide tools enhance precision, wear resistance, and tool life in stamping, injection molding, and die-forming operations.

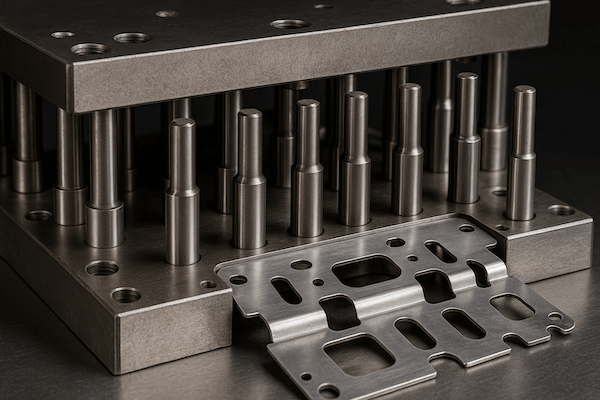

Stamping and Forming Tools

| Product Name | Tool Category | Application Area |

|---|---|---|

| Tungsten Carbide Punches | Stamping Die Tools | Progressive stamping, piercing holes in sheet metal |

| Tungsten Carbide Die Inserts | Wear Components for Dies | Blanking dies, forming dies, compound die inserts |

Injection Mold Tooling

| Product Name | Tool Category | Application Area |

|---|---|---|

| Tungsten Carbide Core Pins | Mold Forming Components | Shaping internal cavities in injection molds |

| Tungsten Carbide Ejector Pins | Mold Ejection Components | Ejecting plastic parts after molding |

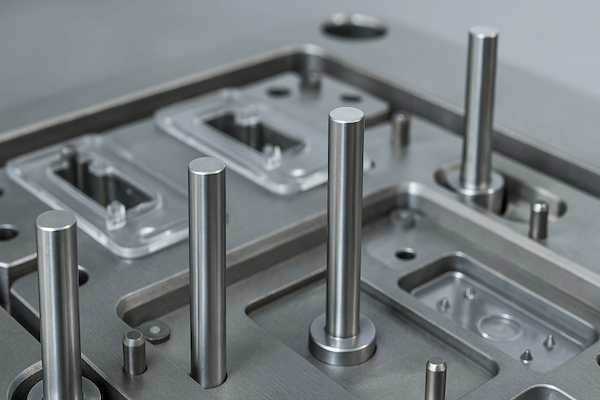

Alignment and Motion Components

| Product Name | Tool Category | Application Area |

|---|---|---|

| Tungsten Carbide Guide Bushings | Die Alignment Components | Guide alignment in progressive die sets |

| Tungsten Carbide Guide Pins | Linear Motion Components | Precision die opening and closing operations |

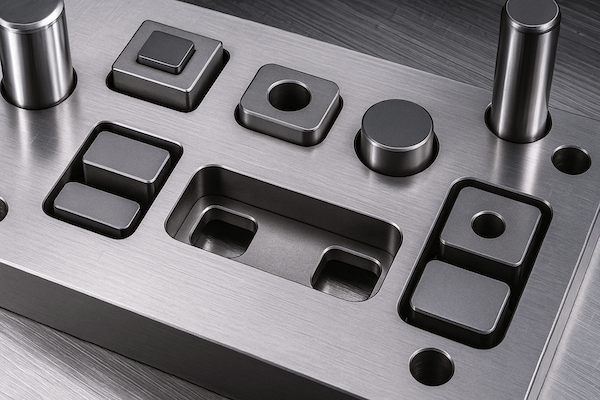

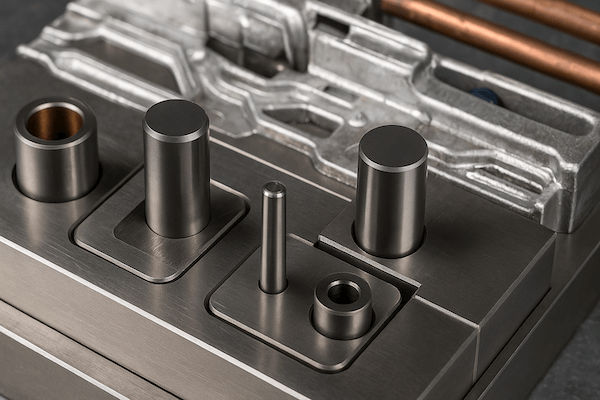

Die Casting Mold Inserts

| Product Name | Tool Category | Application Area |

|---|---|---|

| Tungsten Carbide Cavity Inserts | Die Casting Mold Inserts | High-wear zones in aluminum die casting molds |

| Tungsten Carbide Sprue Bushings | Injection Feed Components | Melt feed and gate sections in die casting molds |

Conclusion

With their outstanding hardness, wear resistance, and dimensional stability, tungsten carbide tools are indispensable to the mold and die industry. Whether in high-speed stamping, precision molding, or tool component alignment, carbide punches, dies, inserts, and guide components help manufacturers reduce downtime, enhance part quality, and extend tool service life. Investing in these tools leads to better ROI, fewer replacements, and superior performance across the production lifecycle.

Quick and easy: Enter your specifications and get a quote in one business day