How Tungsten Carbide Tools Drive Reliability in the Oil & Gas Industry

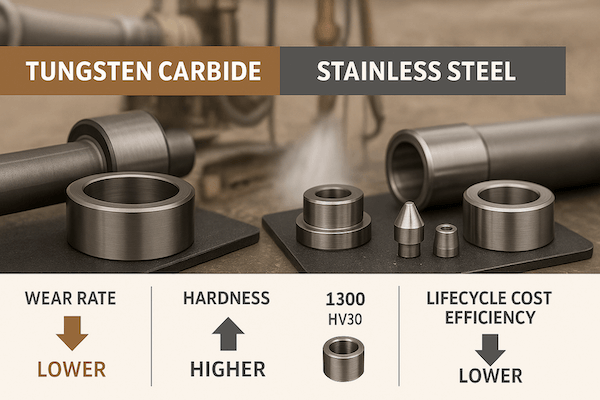

The oil and gas industry demands materials that can endure extreme pressure, corrosion, temperature, and abrasive media. Tungsten carbide (also known as cemented carbide) is the material of choice for mission-critical components used in exploration, drilling, pumping, and refining processes. Known for its unmatched wear resistance, hardness, and dimensional stability, tungsten carbide extends the life of tools and components under the harshest conditions—ensuring safe and efficient energy production.

The Main Types of Carbide Tools for Oil & Gas Industry

Discover four essential carbide components engineered for pressure, flow, and corrosion resistance in oilfield equipment.

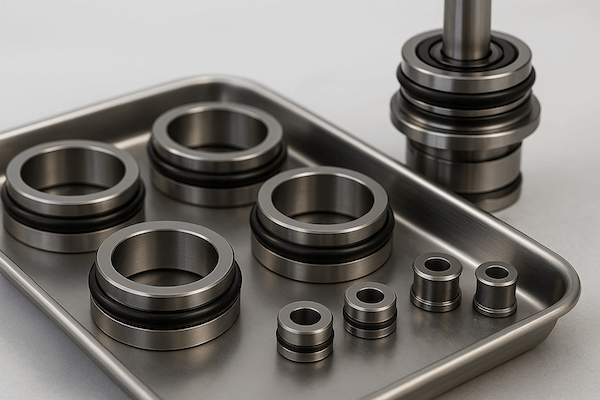

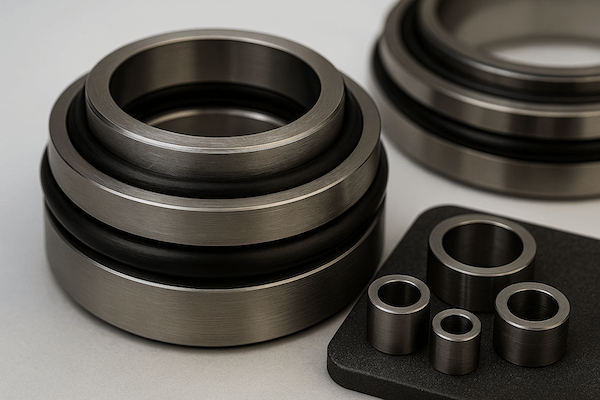

Tungsten Carbide Seal Rings

Used in mechanical seals to resist corrosion, heat, and abrasive slurries.

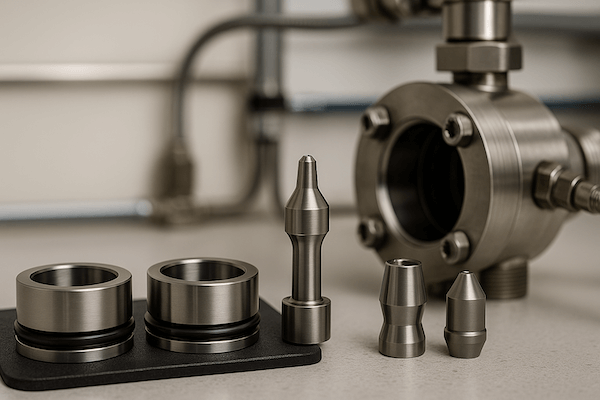

Valve Seats and Cores

Critical sealing components for flow control valves in high-pressure oilfield equipment.

Wear Sleeves

Protect rotating shafts in pumps and drilling equipment from abrasive wear.

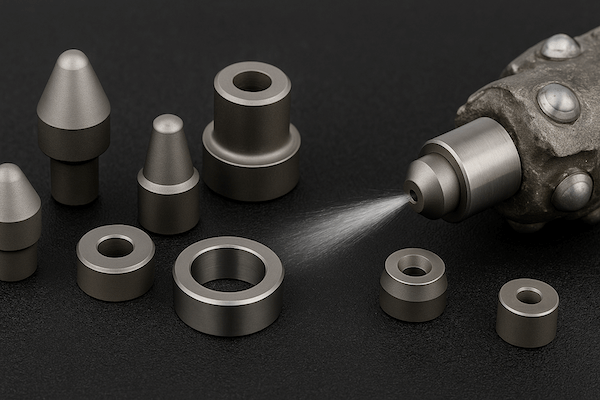

Flow Control Nozzles

Deliver accurate jet streams for downhole and surface mud circulation.

Quick and easy: Enter your specifications and get a quote in one business day

Why Tungsten Carbide Is Essential in Oil & Gas Operations

✅ Superior wear and erosion resistance in abrasive and slurry-heavy conditions

✅ Excellent chemical and corrosion resistance for offshore, subsea, and sour gas service

✅ Longer service life = fewer replacements, reducing downtime and operating costs

✅ Dimensional stability at elevated temperatures and pressure

Applications of Tungsten Carbide Tools in the Oil & Gas Industry

Performance-critical components for drilling, sealing, and flow control in extreme oilfield environments.

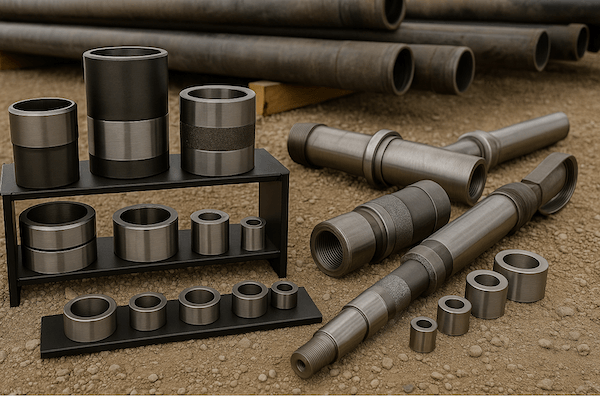

Downhole Drilling Components

Carbide inserts, sleeves, and nozzles are embedded in PDC bits, rotary steerable systems, and stabilizers. These components resist high-pressure, high-temperature (HPHT) and abrasive formations.

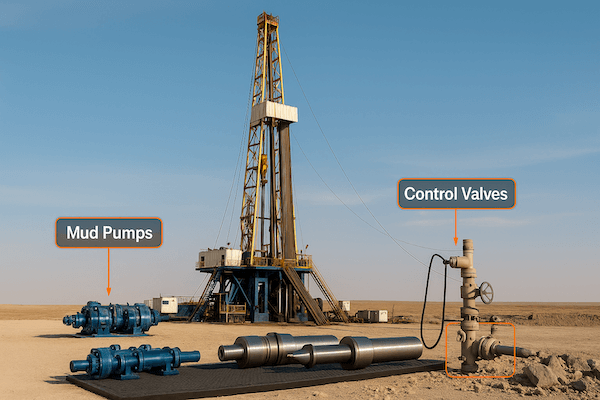

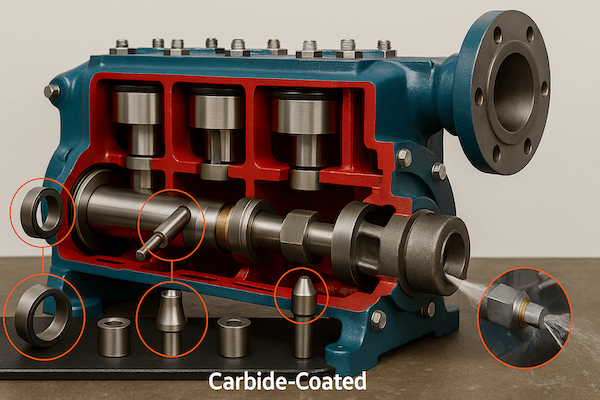

Pump and Valve Systems

Tungsten carbide valve seats, plungers, and seal rings are essential in mud pumps, cementing pumps, and choke/kill valves. They ensure longevity under slurry abrasion and corrosive brines.

Flow Restriction and Metering

Carbide flow control nozzles and orifices are used in flow restrictors, gas lift systems, and surface measurement devices for precise delivery and erosion resistance.

Mechanical Sealing Systems

Mechanical face seals using carbide rings operate in subsea pumps, compressors, and crude oil transfer systems. They prevent leakage under intense pressure, temperature, and chemical exposure.

Casing and Tubing Protection

Carbide wear sleeves and hardfacing parts are used in casing exit tools, liner hangers, and rotating tubing heads to extend operational life.

Partner with Us for Precision Carbide Components in Energy Operations

We specialize in custom manufacturing of tungsten carbide parts tailored for upstream and midstream applications. Whether you require seal rings for HPHT valves or nozzles for custom drill heads, we deliver ISO-quality precision and application-specific expertise. Contact us to discuss your engineering requirements or request a sample evaluation.

Quick and easy: Enter your specifications and get a quote in one business day