Carbide wear parts are essential in industries like mining, oil & gas, construction, and manufacturing.

These parts face constant friction, pressure, and chemical attack. Tungsten carbide is the most common material because it combines extreme hardness with good toughness.

For decision-makers, understanding the manufacturing processes of carbide wear parts is critical.

Each step—from raw powders to finished components—affects performance, reliability, and cost. This article explains these processes in simple terms and shows how they impact final quality.

Raw Material Selection

The process begins with tungsten carbide powder and a metallic binder, usually cobalt or nickel.

The quality of these powders determines the strength of the final part.

Tungsten carbide powder: Provides hardness.

Binder: Adds toughness and holds grains together.

Additives (chromium, vanadium, or tantalum carbides): Improve corrosion resistance and control grain growth.

Premium raw materials reduce weak spots and improve durability.

Powder Mixing and Spray Drying

Powders are blended with binders and additives to create the right grade for the application.

Ball milling: Powders are mixed with liquids and binding agents for uniform distribution.

Spray drying: Converts the slurry into spherical granules, making the powder ready for pressing.

Uniform granules are essential for stable density and consistent wear resistance.

Pressing and Forming

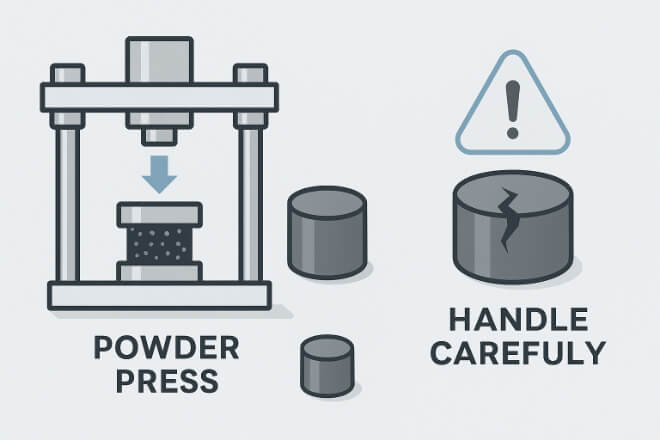

The prepared powders are pressed into “green compacts.” These are unsintered shapes that define the rough geometry of the part.

Main pressing methods:

Uniaxial pressing: For simple shapes like inserts or buttons.

Cold isostatic pressing (CIP): Applies equal pressure from all sides, ideal for large or complex parts.

Extrusion or molding: For special shapes like rods, bushings, or nozzles.

At this stage, the parts are fragile and must be handled carefully.

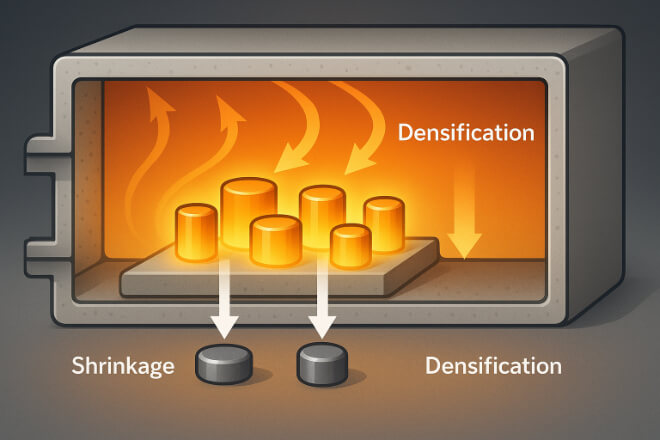

Sintering: Creating Strength

Sintering is the most important stage. Green compacts are heated in a furnace to 1400–1500°C. The binder melts, and the carbide grains bond tightly.

Hot isostatic pressing (HIP) may be added to remove pores and improve reliability.

Precision Grinding and Shaping

After sintering, carbide parts are very hard and require diamond tools for machining. Grinding ensures exact size and smooth surfaces.

Centerless grinding: Used for cylindrical parts such as rods and bushings.

Surface grinding: For flat wear plates and strips.

Lapping and polishing: For seals and high-precision components.

Proper grinding ensures tighter tolerances, lower friction, and better fit in machines.

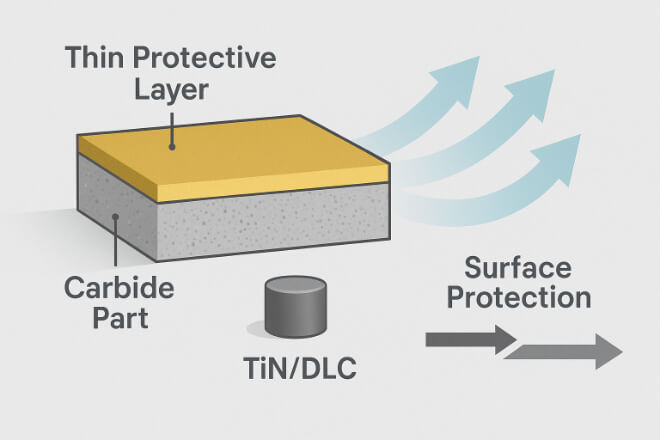

Coating and Surface Treatments

To extend service life, some carbide parts receive coatings:

CVD and PVD coatings: Titanium nitride (TiN), titanium carbonitride (TiCN), or aluminum titanium nitride (AlTiN).

Diamond-like carbon (DLC): Reduces friction in sliding parts.

Nickel plating: Protects against corrosion in aggressive environments.

Coatings help match the part to the specific service condition.

Quality Control and Testing

High-quality carbide wear parts must pass strict tests before shipment:

Hardness measurement (Rockwell or Vickers).

Microstructure analysis under microscopes.

Dimensional inspection with precision tools.

Inspection certificates ensure reliability and build trust with customers.

Packaging and Shipping

Even tough parts need protection during shipping. Common practices include:

Using trays, tubes, or foam to prevent chipping.

Adding desiccants to protect from moisture.

Labeling with batch numbers and certificates for traceability.

Good logistics reduce risk of damage and keep parts ready for use.

Why Manufacturing Process Matters for Decision-Makers

Every step in the process influences performance:

Poor powders → weaker wear parts.

Inconsistent pressing → uneven density.

Bad sintering → cracks or porosity.

Poor grinding → dimensional errors and high friction.

Missing QC → higher risk of early failure.

Decision-makers should always choose suppliers with advanced processes, strict QC, and proven industry certifications. This ensures better uptime, lower costs, and stronger ROI.

Key Takeaways

Carbide wear parts are built through a chain of controlled processes.

Raw material quality sets the foundation for durability.

Sintering defines strength, grinding defines precision.

Coatings extend life in special environments.

Strong QC and logistics ensure trust and reliability.

Conclusion

Carbide wear parts are not just strong materials; they are the result of carefully managed manufacturing processes.

By understanding how these parts are made, decision-makers can select the right suppliers, demand higher standards, and secure longer-lasting performance.

A reliable production process is the difference between frequent downtime and smooth, profitable operation.

If you want to know more details about any company, please feel free to contact us.