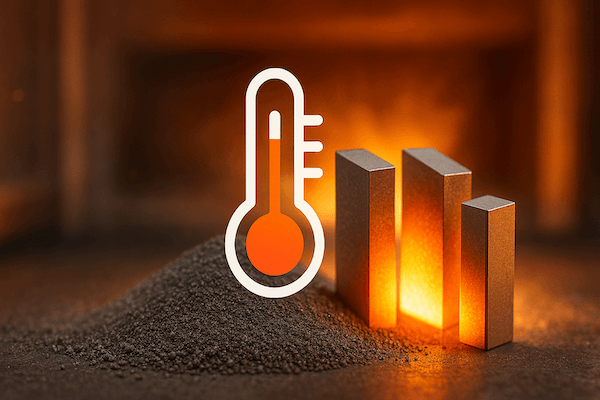

Sintering temperature is a critical factor in the production of tungsten carbide (WC) tools, directly influencing their hardness, strength, microstructure, and overall performance. In this article, we’ll explore what sintering temperature means, its role in hard alloy production, and why precise control is essential for producing high-quality carbide tools.

https://www.retopz.com/wp-content/uploads/2025/06/Understanding-Sintering-Temperature-in-Tungsten-Carbide-Tool-Manufacturing.png

What Is Sintering Temperature?

Sintering temperature refers to the high temperature at which powdered materials are compacted and fused together without reaching their melting point. In the case of tungsten carbide tools, the process typically involves heating a mixture of WC powder and a metallic binder—usually cobalt (Co) or nickel (Ni)—to a temperature range of 1350°C to 1500°C in a controlled atmosphere.

At this temperature, the metal binder melts and infiltrates the tungsten carbide particles, promoting densification and grain bonding. The end result is a solid, high-strength composite material.

Why Sintering Temperature Matters

1. Microstructure Formation

Sintering temperature controls the grain growth of WC particles and the distribution of the binder phase. Optimal temperature ensures:

Uniform grain size

High density

Strong metallurgical bonding

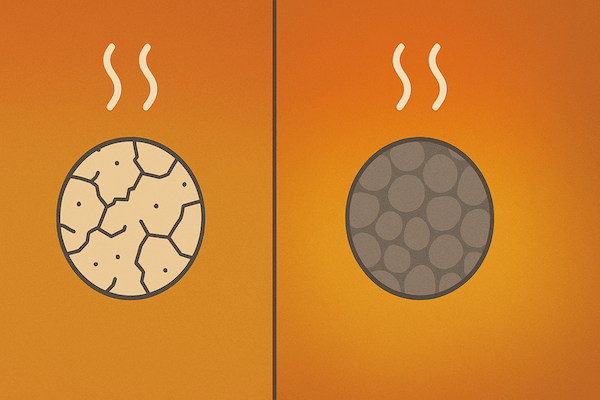

Improper sintering (too low or too high) can lead to porosity, weak bonding, or excessive grain growth, all of which reduce tool life and performance.

2. Mechanical Properties

The mechanical properties of tungsten carbide—such as hardness, toughness, and wear resistance—are closely tied to sintering temperature:

Higher temperatures can enhance grain bonding but may reduce toughness due to grain coarsening.

Lower temperatures may preserve fine grains but result in incomplete densification and brittleness.

Balancing these factors is key for applications ranging from mining and cutting tools to precision wear parts.

3. Phase Stability

At sintering temperatures, the WC-Co system can form unwanted phases like eta (η) phase or free graphite if not carefully controlled. Accurate sintering temperature helps:

Prevent formation of brittle phases

Maintain desired two-phase WC and binder microstructure

Sintering in Tungsten Carbide Tool Production

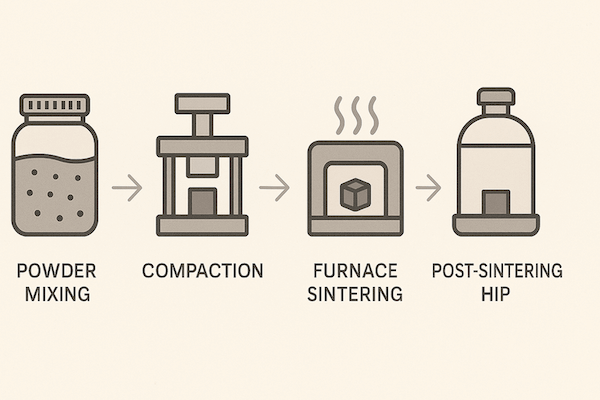

In modern tungsten carbide tool manufacturing, sintering is the final and most energy-intensive step. The key stages include:

Powder Mixing – WC powder is blended with cobalt or other binders, along with grain growth inhibitors like VC or Cr₃C₂.

Compaction – The mixture is pressed into a desired shape (e.g., blanks, inserts).

Sintering – The green compacts are sintered in a vacuum or hydrogen atmosphere at controlled temperatures.

Post-Sintering Treatments – Secondary processes like HIP (Hot Isostatic Pressing) may be applied to eliminate internal porosity.

Sintering temperature must be optimized based on material grade, tool geometry, and performance requirements.

Conclusion

Sintering temperature plays a foundational role in the manufacturing of high-performance tungsten carbide tools. It determines the physical properties, longevity, and consistency of the final product. Advanced carbide producers utilize strict temperature control systems, sophisticated furnaces, and real-time monitoring to achieve optimal sintering results. Understanding and managing this key parameter ensures that tungsten carbide tools meet the rigorous demands of modern industry—from metal cutting and mining to electronics and aerospace.