Tungsten carbide cutting tools are widely used in machining industries because they are hard, durable, and perform well under tough conditions.

But one important factor that often gets overlooked is the balance between hardness and toughness.

Getting this balance right can make the difference between a tool that breaks too easily and one that delivers long, efficient service.

In this blog, we’ll explain what hardness and toughness mean in the context of cutting tools, why they matter, and how to choose the right balance based on your machining needs.

1. What Is Hardness in Tungsten Carbide Tools?

Hardness is the ability of a material to resist wear and deformation. In cutting tools, it means how well the edge can stay sharp and resist scratching or dulling when in contact with hard materials.

Tungsten carbide is incredibly hard—second only to diamond. This makes it excellent for cutting through tough metals like stainless steel, cast iron, and aerospace alloys.

Benefits of high hardness in cutting tools:

Better wear resistance

Longer tool life

Cleaner cuts

Maintains sharp edges under heat and pressure

However, high hardness comes with a trade-off. As a tool becomes harder, it usually becomes more brittle—and that’s where toughness comes in.

2. What Is Toughness and Why Does It Matter?

Toughness is the ability of a tool to absorb impact or shocks without cracking or breaking. While hardness helps a tool stay sharp, toughness helps it survive harsh conditions, like:

Interrupted cuts

Heavy milling

Vibrations during machining

- Tool collisions with hard inclusions in the material

A tool that is too hard but not tough enough might chip or crack during cutting. On the other hand, a tough tool can resist breaking but might wear out faster if it’s not hard enough.

This is why it’s so important to find the right balance.

3. The Hardness-Toughness Trade-Off

You can’t maximize both hardness and toughness at the same time—they work like opposite ends of a scale. Increasing one often reduces the other.

| Property | High Hardness | High Toughness |

|---|---|---|

| Tool Wear | Very low | Moderate |

| Edge Durability | High | Moderate |

| Chipping Risk | High | Low |

| Best Use | Finishing, high-speed cuts | Roughing, interrupted cuts |

The right balance depends on what you’re cutting and how.

High hardness is best for fine, fast cuts in soft or uniform materials.

High toughness is better for interrupted cuts, hard spots, or rough operations.

4. What Affects the Hardness and Toughness of Carbide Tools?

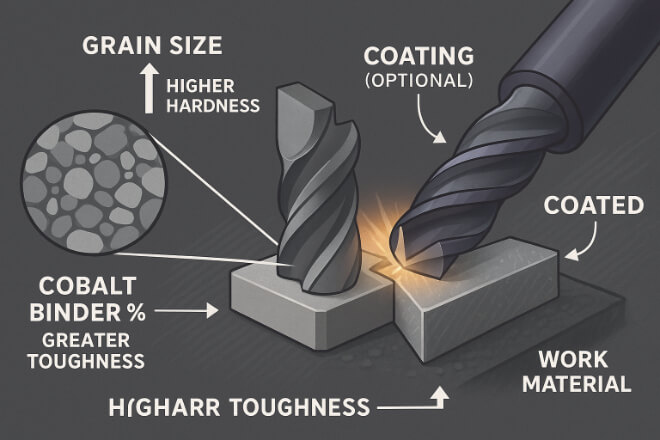

Several factors in tungsten carbide’s microstructure determine its hardness and toughness, including:

1). Grain Size

Fine grains = higher hardness, lower toughness

Coarse grains = more toughness, less hardness

2). Cobalt Binder Content

Less cobalt (4–6%) = harder, but more brittle

- More cobalt (10–15%) = tougher, but softer

3). Additives and Coatings

Additives can improve wear or shock resistance

- Coatings (like TiAlN or DLC) add surface hardness without making the core brittle

Tool designers adjust these variables to match your needs.

5. Common Use Cases: When to Favor Hardness vs. Toughness

Each application demands a different tool characteristic. Here’s a quick guide:

| Application | Recommended Balance |

|---|---|

| High-speed finishing | More hardness |

| Heavy-duty roughing | More toughness |

| Cutting cast iron | Medium toughness |

| Machining stainless steel | Balanced |

| Cutting aerospace alloys (e.g. Inconel) | High hardness with coating |

| Tooling with frequent interruptions | High toughness |

Knowing what your job demands will help you choose better tools—and avoid downtime.

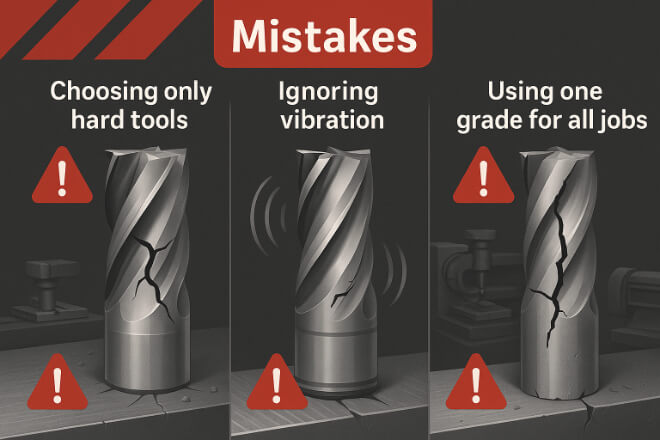

6. Mistakes to Avoid When Selecting Cutting Tools

Some common mistakes decision-makers make:

1). Choosing the Hardest Tool Always

Harder doesn’t always mean better. If the cut is rough or interrupted, too much hardness can lead to cracks.

2). Ignoring Machine Conditions

Old or unstable machines may vibrate. If the tool isn’t tough enough, it will break early.

3). Using One Grade for Everything

Different materials and operations need different carbide grades. Using the same tool for everything shortens tool life.

7. How to Check Tool Performance in Real Life

Don’t just rely on lab specs. Monitor your tool’s real-world performance using metrics like:

Tool life (time or parts per tool)

Surface finish quality

Number of tool changes per shift

Chip formation and color

Signs of chipping or micro-cracks

If your tools are wearing out too fast or breaking, you may need a tougher grade.

If they’re dulling too quickly, consider harder material or a better coating.

8. Choosing the Right Carbide Grade for Your Shop

Not every cutting job is the same, and not every tungsten carbide grade fits all needs. Here’s a simple table:

| Cutting Condition | Recommended Carbide Grade | Why? |

|---|---|---|

| High-speed, smooth cutting | Fine-grain, low cobalt | Maximum wear resistance |

| Interrupted or heavy cuts | Coarse-grain, high cobalt | Improved shock resistance |

| Mixed materials | Medium-grain, balanced cobalt | Good general-purpose solution |

| Superalloys or titanium | Fine-grain with advanced coating | Withstands heat and wear |

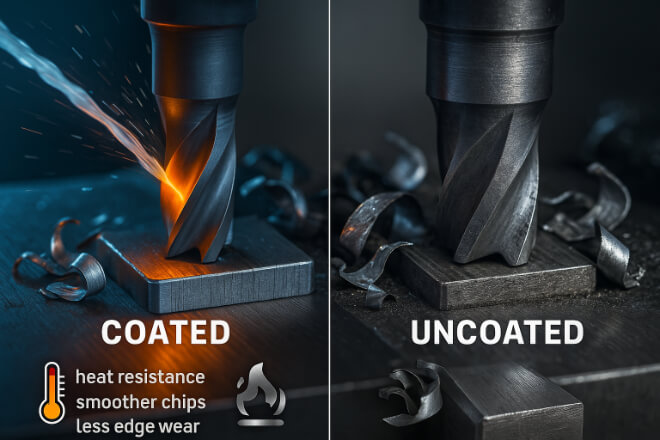

9. The Role of Coatings in Balancing Hardness and Toughness

Coatings help reduce the hardness-toughness trade-off. For example:

TiAlN: adds heat resistance and wear strength

DLC: reduces friction and built-up edge

CVD Diamond: ideal for cutting non-metallics or abrasive composites

A coated tool can have a hard surface for wear resistance and a tough core to absorb shocks.

If your tools are wearing too quickly or chipping too often, coating options can make a big difference.

Final Thoughts

Choosing tungsten carbide cutting tools is not just about picking the hardest material or the cheapest option.

It’s about selecting the right balance between hardness and toughness based on your application, machine setup, and cutting parameters.

Getting this balance right means:

Longer tool life

Better part quality

Less downtime and tool changes

More value from every tool purchase

If you’re not sure what grade or coating works best for your operation, talk to a trusted supplier like Retopz.

The right support can save you money and improve your machining results over the long term.