In the world of advanced materials, oxidation resistance is a critical property that defines how well a material can withstand chemical reactions with oxygen at elevated temperatures. For tungsten carbide (WC) tools, oxidation resistance plays a key role in determining tool life, surface stability, and suitability for high-temperature industrial applications. In this article, we’ll explore what oxidation resistance means, why it matters, and how it impacts the performance of tungsten carbide tools.

What Is Oxidation Resistance?

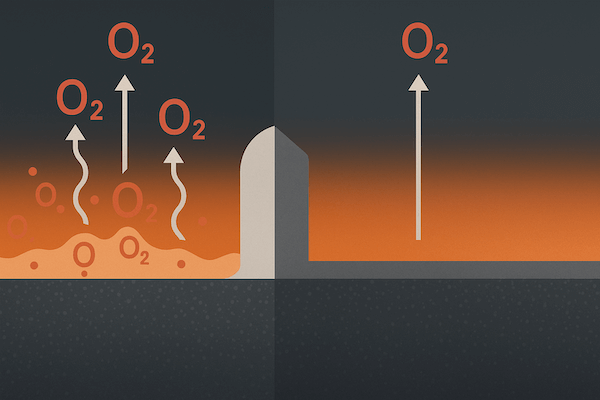

Oxidation resistance refers to a material’s ability to resist chemical degradation when exposed to oxygen, particularly at high temperatures. When oxidation occurs, the material surface reacts with oxygen in the air, forming oxides that can lead to:

Surface degradation

Loss of mechanical properties

Reduced hardness and wear resistance

Shortened service life

For tungsten carbide, this usually means the oxidation of both the tungsten carbide grains and the metallic binder (often cobalt or nickel) used in the composite.

Why Oxidation Resistance Matters in Carbide Tools

1. High-Temperature Applications

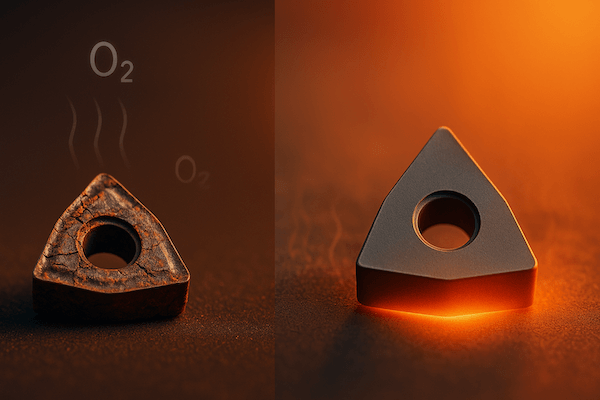

Tungsten carbide tools are widely used in cutting, drilling, mining, and forming operations, many of which generate extreme heat. Without good oxidation resistance, the tool surface may oxidize above 500–800°C, leading to:

Brittleness

Chipping or edge failure

Decline in dimensional accuracy

Improving oxidation resistance allows carbide tools to be used reliably in dry cutting, high-speed machining, and aerospace components.

2. Tool Surface Stability

The oxidation of carbide surfaces can cause roughness and chemical instability, which reduces tool life. A stable, oxidation-resistant surface:

Maintains cutting edge sharpness

Prevents micro-cracks

Reduces thermal degradation

This ensures consistent performance, especially in continuous operations.

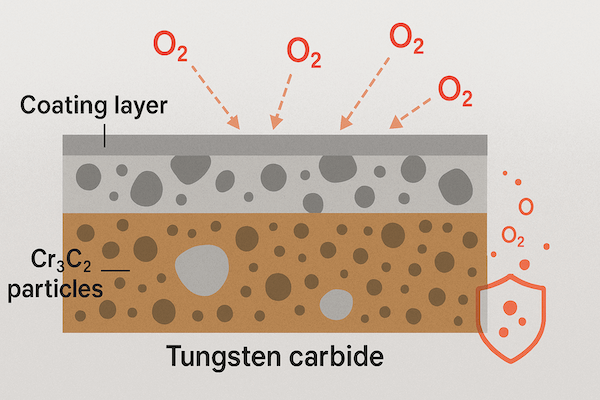

3. Coating and Alloy Enhancements

To enhance oxidation resistance, modern carbide tools are often coated with protective layers such as:

AlTiN (Aluminum Titanium Nitride)

TiAlCrN (Titanium-Aluminum-Chromium Nitride)

Cr₃C₂ Additions to the carbide matrix

These coatings and alloying elements act as thermal barriers, significantly increasing resistance to oxidation and extending tool life in aggressive environments.

How Tungsten Carbide Resists Oxidation

Pure tungsten carbide can begin oxidizing at around 500–600°C, and cobalt binders may oxidize even earlier. However, through:

Fine grain control

Addition of inhibitors (e.g., VC, Cr₃C₂)

Surface coatings

Vacuum or inert-atmosphere sintering

Manufacturers can greatly improve the oxidation resistance of the final tool product. This is crucial for maintaining hardness, chemical stability, and dimensional integrity during high-temperature operations.

Conclusion

Oxidation resistance is an essential property that enables tungsten carbide tools to perform in extreme thermal environments without significant degradation. Whether in metal cutting, aerospace manufacturing, or high-speed forming, enhanced oxidation resistance leads to longer tool life, better reliability, and lower maintenance costs. As material science advances, combining optimized tungsten carbide microstructures with cutting-edge coatings continues to push the limits of performance in demanding industries.