Tungsten carbide bushings are critical components used in industries requiring high wear resistance, such as in pumps, compressors, and machinery.

To ensure optimal performance, these bushings must be made from high-quality materials, specifically tungsten carbide with Co (Cobalt) or Ni (Nickel) binders.

Verifying material certificates is essential in confirming the material’s composition and ensuring that the bushing will meet the necessary specifications.

In this article, we’ll explore why verifying material certificates is crucial for tungsten carbide bushings, what to look for, and how it impacts the final product.

Why Verifying Material Certificates Is Essential

The performance and longevity of tungsten carbide bushings depend largely on the materials used to manufacture them.

Material certificates provide crucial information about the composition and properties of the material, ensuring that the bushings will meet specific industry standards and customer requirements.

Benefits of Verifying Material Certificates:

Quality Assurance: Verifying the material ensures that the bushing is made from high-quality tungsten carbide that meets the necessary hardness, toughness, and wear resistance.

Compliance with Industry Standards: Certifying the material confirms compliance with international standards such as ISO, ASTM, or API, which is crucial in many industries.

Performance Reliability: A certified material guarantees that the bushing will perform optimally under the specific operational conditions of your machinery or equipment.

Avoiding Costly Failures: Proper material verification helps avoid premature wear, failure, or damage to machinery due to the use of substandard materials.

What Information to Look for in Material Certificates

When reviewing material certificates for tungsten carbide bushings, there are several key pieces of information to look for:

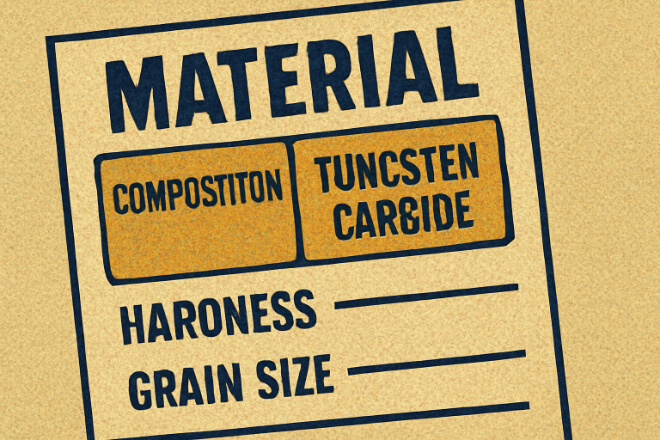

1). Material Composition

The certificate should clearly specify the tungsten carbide (WC) content, as well as the binder used (Co or Ni). These components impact the bushing’s properties:

WC provides the hardness and wear resistance.

Co (Cobalt) binders improve toughness and impact resistance.

Ni (Nickel) binders are often chosen for applications requiring corrosion resistance.

Ensure that the binder type and the ratio of binder to tungsten carbide match your requirements.

2). Hardness and Density Values

The material certificate should provide the hardness (measured in HV or Rockwell) and density of the tungsten carbide.

Hardness affects the bushing’s wear resistance, while density impacts the strength and durability under pressure.

Hardness (HV): Typically, tungsten carbide with Co binder will have a hardness of 1500-1800 HV, while WC-Ni alloys can be slightly lower but offer better corrosion resistance.

Density: The density should generally fall between 14.5-15.0 g/cm³ for tungsten carbide bushings.

3). Grain Size

Grain size is an important factor influencing the mechanical properties of the tungsten carbide bushing.

Finer grains result in a harder material, while coarser grains may offer better toughness.

The certificate should specify whether the bushing is made from fine or coarse grain tungsten carbide.

4). Porosity Levels

Material certificates should also indicate the porosity levels of the tungsten carbide.

Excessive porosity can weaken the material, making it more susceptible to failure.

Look for low porosity levels (less than 1%) for optimal durability.

5). Metallurgical Properties

Metallurgical properties such as binder phase distribution and microstructure should be included in the material certificate.

A uniform binder distribution and fine microstructure are essential for achieving high performance and longevity.

How to Verify Material Certificates

Verifying material certificates involves several steps to ensure the authenticity and quality of the tungsten carbide bushings:

1). Cross-Check with the Manufacturer

The first step in verification is to ensure the material certificate matches the manufacturer’s claims.

Cross-reference the certificate with the specifications provided by the manufacturer to confirm that the material composition, hardness, density, and other properties meet the required standards.

2). Review Testing Reports

The material certificate should be supported by testing reports, including hardness tests (e.g., Vickers or Rockwell), density measurements, and microstructure analysis.

These tests should be performed by accredited laboratories to ensure reliability.

3). Check for Compliance with Standards

Ensure that the material certificate references the relevant international standards such as ASTM, ISO, or API, which are widely accepted in industries such as oil and gas, mining, and manufacturing.

4). Verify Traceability

Material certificates should provide traceability to the batch or lot from which the tungsten carbide was sourced.

This ensures that the material used in the bushings can be traced back to its original source, improving transparency and accountability.

Common Issues with Material Certificates and How to Address Them

While material certificates are essential for ensuring quality, there are some common issues to watch out for during the verification process:

1). Inaccurate Information

Sometimes, the information on material certificates may be incorrect or outdated. Always double-check with the manufacturer and request updated certificates if necessary.

2). Lack of Detail

Some certificates may lack detailed information on grain size, binder content, or metallurgical properties.

If this information is missing, request further details or alternative documentation to ensure the material meets your specifications.

3). Incomplete or Missing Tests

Material certificates should be supported by appropriate testing reports.

If tests for hardness, density, or microstructure are missing, ask the supplier for the necessary data or request a re-test before proceeding.

Conclusion

Verifying material certificates for tungsten carbide bushings is crucial to ensuring that your bushings meet the necessary quality standards and perform reliably in your applications.

By reviewing key information such as material composition, hardness, density, and grain size, you can ensure that the tungsten carbide bushings you purchase will offer optimal performance, durability, and cost-effectiveness.

Regularly verifying these certificates and ensuring compliance with industry standards helps avoid costly failures and ensures that your machinery operates smoothly and efficiently.

If you want to know more details about any company, please feel free to contact us.