Maintenance Tips for Extending the Life of Your Tungsten Carbide Cutting Tools

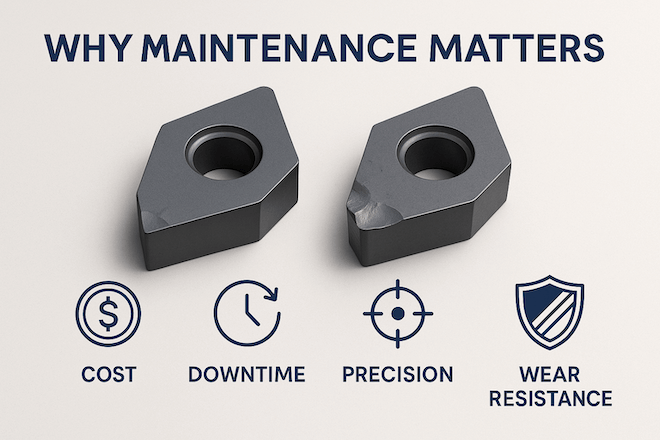

Tungsten carbide cutting tools are known for their hardness, strength, and wear resistance. But even the toughest tools need proper care to last longer and perform better. With good maintenance, you can reduce downtime, save money, and improve your production quality. In this article, we will share simple and effective maintenance tips to help extend […]

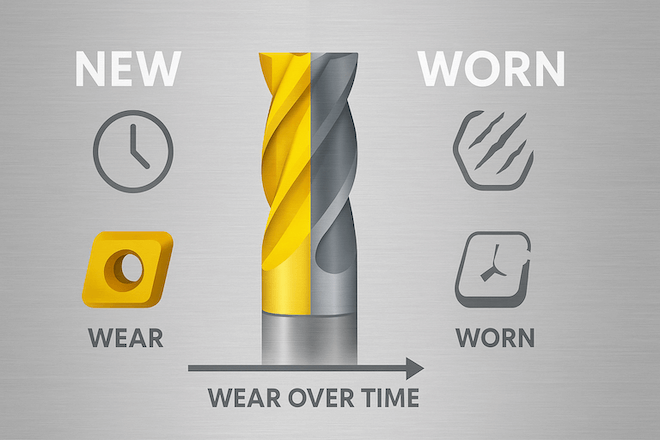

Why Tungsten Carbide Cutting Tools Have Superior Wear Resistance

In modern manufacturing, choosing the right cutting tool is very important. Tools must be strong, precise, and last a long time. Tungsten carbide cutting tools are trusted by industries because of one big reason — superior wear resistance. In this blog, we explain what makes tungsten carbide so tough, why it lasts longer than other […]

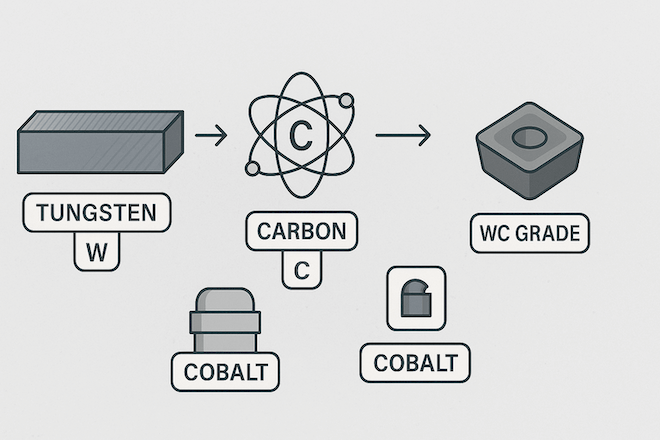

Understanding Tungsten Carbide Grades for Cutting Tool Applications

Introduction: Why Grades Matter in Tungsten Carbide Tools When using tungsten carbide cutting tools, understanding the grade is key. Grades define the tool’s hardness, toughness, and best use. This guide will help you understand what tungsten carbide grades are, why they matter, and how to choose the right one. What Are Tungsten Carbide Grades? A […]