Cacbua Vonfram dùng để bảo vệ chống mài mòn cho bơm, van và phớt

In industries like oil & gas, chemical processing, mining, and power generation, pumps, valves, and seals face extreme conditions. They often operate under high pressure, with abrasive particles, and in corrosive fluids. This constant exposure leads to rapid wear and costly downtime. One solution trusted worldwide is tungsten carbide. Known for its hardness, wear resistance, […]

Linh kiện mài mòn cacbua cho ứng dụng chế biến gỗ và cắt

In the woodworking and cutting industry, efficiency, precision, and durability are key to staying competitive. Carbide wear components have become the preferred choice for companies that need high-performance tools. Made from tungsten carbide or other carbide materials, these components resist wear, maintain sharpness longer, and work well even under heavy use. This makes them essential […]

Tungsten Carbide in Paper, Textile, and Packaging Machinery

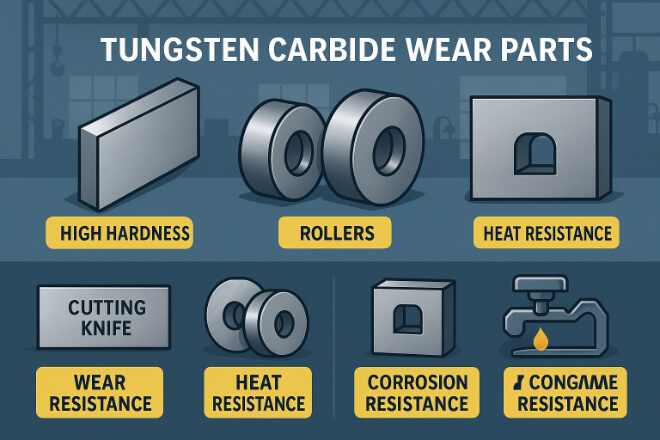

In today’s manufacturing world, companies in the paper, textile, and packaging industries face strong competition. They need machines that can run for long hours, produce high-quality products, and keep costs low. One of the biggest challenges is dealing with wear and tear on machine parts. This is where tungsten carbide wear parts play a key […]

Applications of Carbide Wear Parts in Metal Forming and Stamping

In the world of metal forming and stamping, equipment is pushed to extreme limits. High pressure, repetitive motion, and constant friction can quickly wear down ordinary tool materials. This is why carbide wear parts have become a trusted choice for many manufacturing companies. Known for their hardness, wear resistance, and long service life, carbide parts […]

How the Oil & Gas Sector Uses Tungsten Carbide Wear Components

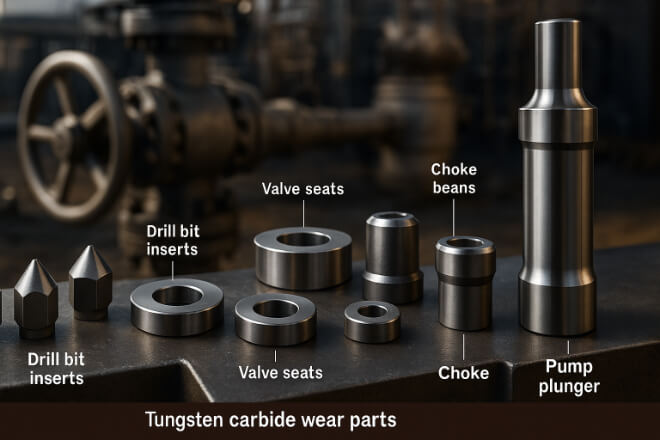

Tungsten carbide wear components are critical in the oil and gas sector. They keep drilling rigs, pumps, valves, and processing equipment running longer under extreme conditions. For decision-makers in this industry, knowing how and why these parts are used can help in selecting the right suppliers, improving equipment performance, and cutting maintenance costs. This article […]

Tungsten Carbide Wear Parts in the Mining Industry

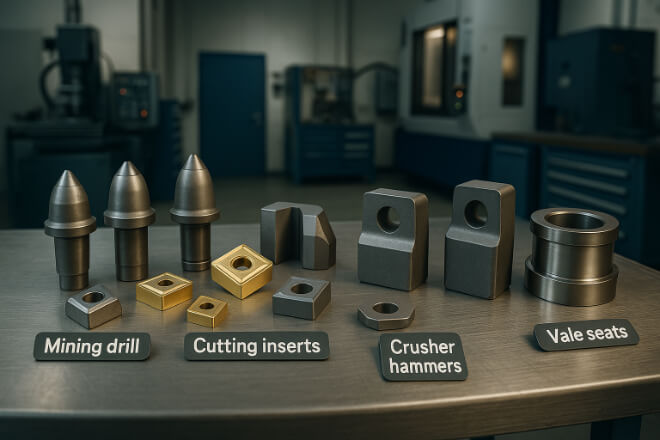

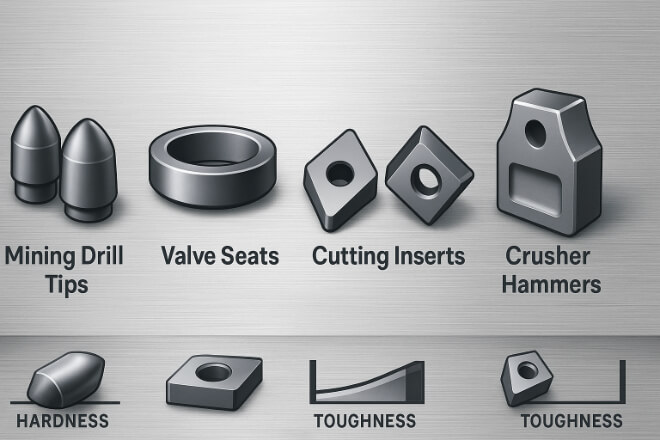

Mining is one of the toughest industries in the world. Equipment is pushed to its limits every day, working under high pressure, high heat, and in abrasive conditions. In such environments, tool failure can lead to costly downtime and reduced productivity. This is where tungsten carbide wear parts become essential. Tungsten carbide is a material […]

Precision Tolerances in Carbide Wear Part Manufacturing

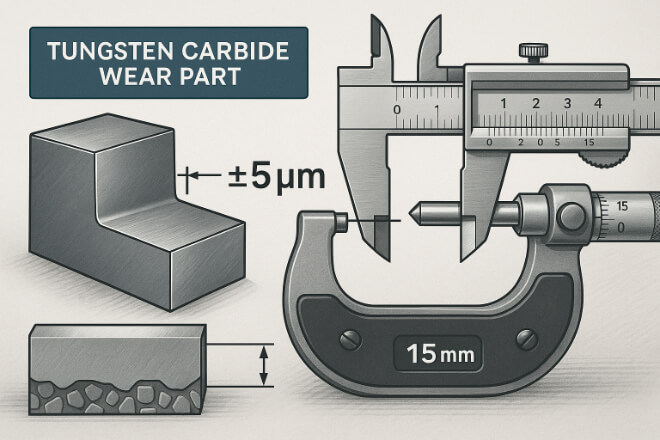

In modern manufacturing, precision tolerances are not just a technical detail—they are a business advantage. In industries where carbide wear parts are used, even the smallest dimensional error can lead to faster wear, higher downtime, and increased costs. Whether you are producing tools for mining, oil and gas, automotive, or aerospace, meeting strict tolerances ensures […]

Customizing Tungsten Carbide Wear Parts: Design Tips and Standards

In industries like mining, oil and gas, construction, and manufacturing, tungsten carbide wear parts are vital for keeping equipment running efficiently. These parts face extreme pressure, high temperatures, and constant friction. While standard parts are available, many companies require custom designs to meet unique operational needs. Customizing wear parts allows businesses to improve performance, reduce […]

Sintering, Grinding, and Coating: Inside the Production of Wear Parts

Wear parts are essential in industries like mining, oil and gas, metalworking, and construction. They face extreme heat, high pressure, and constant friction. To survive these harsh conditions, manufacturers use advanced processes like sintering, grinding, and coating to produce parts with the right balance of strength, toughness, and durability. This article explains each of these […]

Các bộ phận mài mòn cacbua vonfram được sản xuất như thế nào

Tungsten carbide wear parts are vital in industries like mining, oil and gas, metal cutting, and construction. These parts are chosen for their hardness, wear resistance, and long life under extreme working conditions. For decision-makers, understanding how tungsten carbide wear parts are manufactured helps in making better choices about suppliers, quality control, and costs. This […]