Công nghệ mới nổi trong các bộ phận mài mòn cacbua vonfram

Cacbua vonfram đã là vật liệu đáng tin cậy cho các chi tiết chịu mài mòn trong nhiều thập kỷ. Độ cứng, độ dẻo dai và khả năng chống mài mòn của nó khiến nó trở thành lựa chọn hàng đầu trong các ngành công nghiệp như khai thác mỏ, dầu khí, gia công kim loại và sản xuất. Tuy nhiên, công nghệ đằng sau cacbua vonfram vẫn không ngừng phát triển. Những phát triển mới trong khoa học vật liệu, quy trình sản xuất và lớp phủ đang thay đổi […]

Cacbua vonfram có phủ và không phủ: Bạn nên sử dụng loại nào?

Cacbua vonfram là một trong những vật liệu phổ biến nhất được sử dụng cho dụng cụ cắt, chi tiết chịu mài mòn và các thành phần công nghiệp. Nó được đánh giá cao nhờ độ cứng, khả năng chống mài mòn và khả năng duy trì hiệu suất dưới tác động của nhiệt. Tuy nhiên, không phải tất cả các chi tiết cacbua vonfram đều giống nhau. Một số được phủ, một số khác thì không. Lớp phủ có thể thay đổi cách […]

So sánh các chi tiết mài mòn bằng cacbua vonfram với gốm và stellite

Trong các ngành công nghiệp đòi hỏi các bộ phận phải chịu được sự mài mòn, nhiệt độ cao và ăn mòn, việc lựa chọn vật liệu phù hợp là vô cùng quan trọng. Ba trong số những vật liệu phổ biến nhất cho các bộ phận chịu mài mòn là cacbua vonfram, gốm và Stellite. Mỗi vật liệu đều có những đặc tính, ưu điểm và nhược điểm riêng. Đối với những người ra quyết định trong lĩnh vực sản xuất, khai thác mỏ, dầu khí và các ngành công nghiệp nặng khác, việc lựa chọn giữa […]

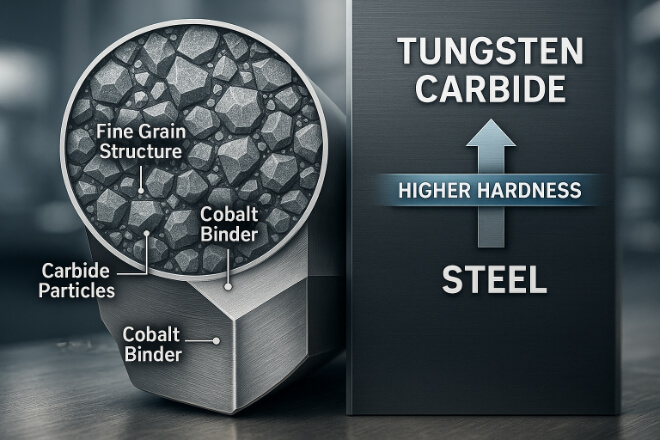

Cacbua vonfram so với thép: Vật liệu nào chịu mài mòn tốt hơn?

Trong các ngành công nghiệp như khai thác mỏ, dầu khí, gia công kim loại, chế biến gỗ và sản xuất, vật liệu chống mài mòn đóng vai trò vô cùng quan trọng. Khi thiết bị hoạt động trong môi trường khắc nghiệt, các bộ phận phải chịu được ma sát, áp suất, nhiệt độ và ăn mòn. Hai trong số những vật liệu phổ biến nhất cho các bộ phận chịu mài mòn là cacbua vonfram và thép. Việc lựa chọn đúng vật liệu có thể ảnh hưởng đến năng suất, chi phí và thời gian ngừng hoạt động. Điều này […]