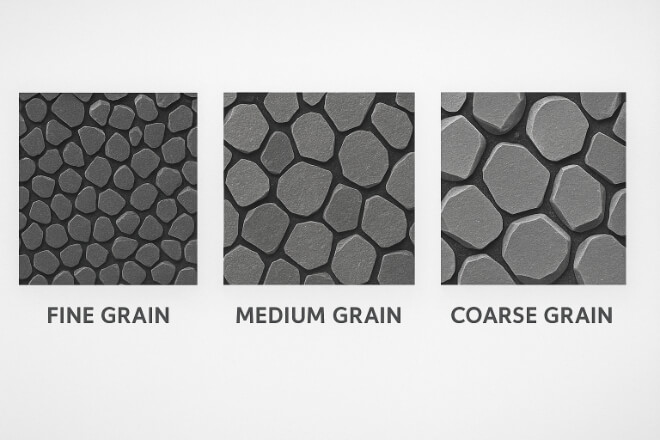

Ảnh hưởng của kích thước hạt đến hiệu suất mài mòn cacbua

When companies choose tungsten carbide wear parts, they often focus on hardness, toughness, and cost. But one factor is often overlooked: grain size. The size of the tungsten carbide grains in the microstructure has a direct effect on the wear resistance, toughness, and lifetime of the part. For decision-makers in industries like mining, oil and […]

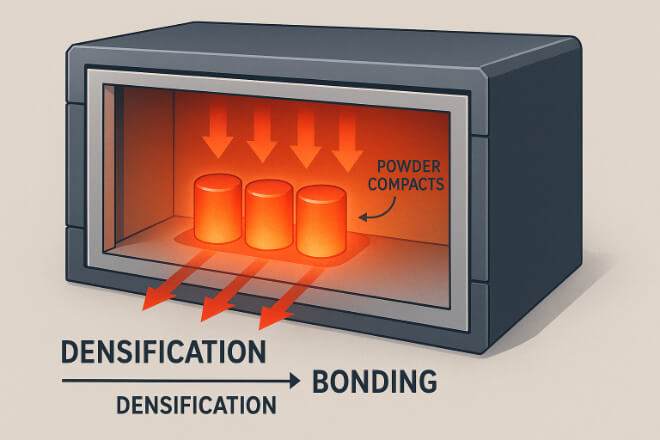

Thiêu kết, HIP và chế tạo các bộ phận chịu mài mòn bằng cacbua

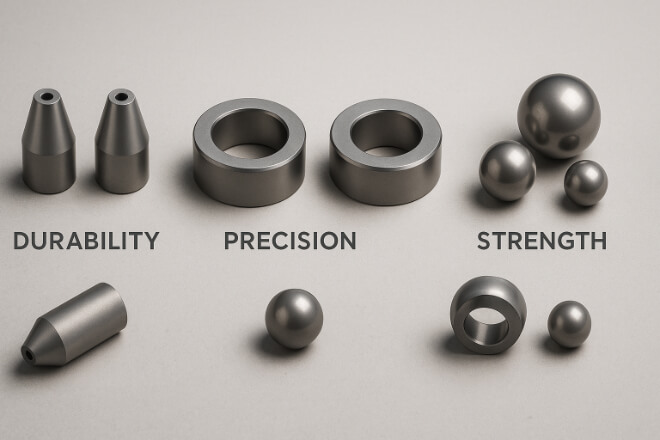

In industries such as mining, oil and gas, metalworking, and manufacturing, the performance of machines depends on the strength of their wear parts. These parts face high pressure, heat, and friction, so they must be made from materials that can last in tough environments. Tungsten carbide wear parts are among the most reliable solutions. But […]

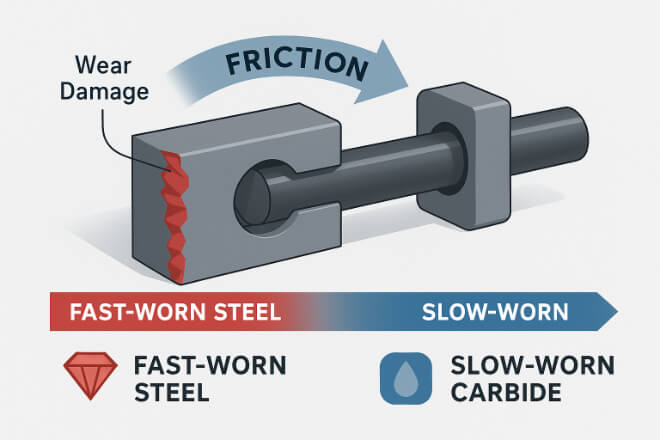

So sánh các thành phần chịu mài mòn của Carbide và HSS

In many industries, the performance of machines depends on the quality of their wear components. These are the parts exposed to high friction, pressure, or cutting forces. The most common materials used are carbide (tungsten carbide) and HSS (high-speed steel). Both have their place in modern production, but the choice between carbide and HSS can […]

Lợi ích về chi phí của các bộ phận mài mòn bằng cacbua vonfram

In today’s competitive industries, companies face growing pressure to lower costs while keeping machines running smoothly. Equipment downtime, frequent part replacements, and inefficient tools can quickly increase expenses. This is why many decision-makers are turning to tungsten carbide wear parts. Tungsten carbide, known for its extreme hardness and durability, is used to produce a wide […]

Khả năng chống mài mòn: Tại sao các bộ phận cacbua lại vượt trội hơn các bộ phận khác

In modern industries, machinery parts face constant wear. Friction, heat, and impact often damage critical components, leading to downtime and costly repairs. This is why wear resistance has become a key factor when choosing parts. Among the many materials available, carbide parts stand out as the most reliable option. Their ability to resist abrasion, maintain […]