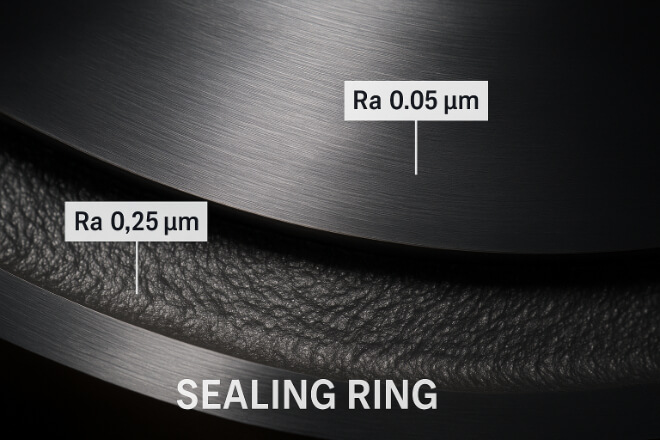

Địa hình bề mặt của vòng đệm kín: Ra 0,04–0,05 μm thực sự có nghĩa là gì

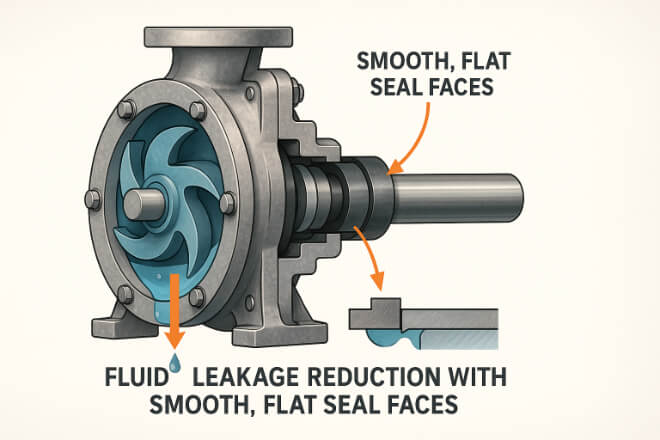

In mechanical seals, the surface topography of sealing rings directly affects leakage control, lubrication retention, and wear resistance. An Ra value between 0.04–0.05 μm is often specified for high-performance applications, but many decision-makers may wonder what this number truly represents and why it matters. This article explains Ra 0.04–0.05 μm in simple terms, its impact […]

Đạt được độ hoàn thiện như gương trên vòng đệm cacbua: Cửa sổ quy trình và những cạm bẫy

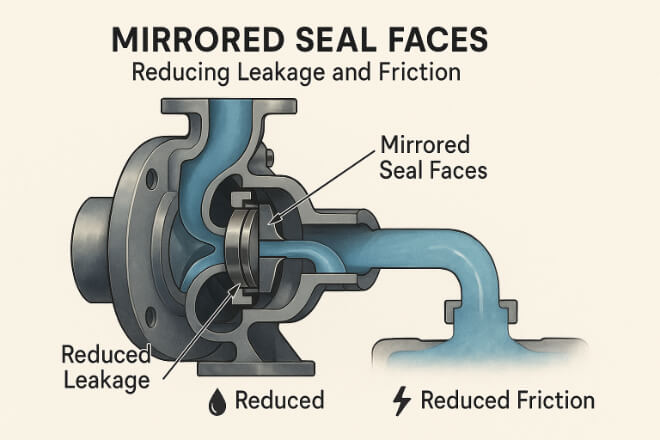

Carbide seal rings are critical components in pumps, compressors, and valves for industries such as oil & gas, chemical processing, power generation, and marine systems. Achieving a mirror-level finish on these rings ensures leakage control, low friction, and long equipment life. However, achieving a perfect mirror finish is not easy. It requires strict process windows, […]

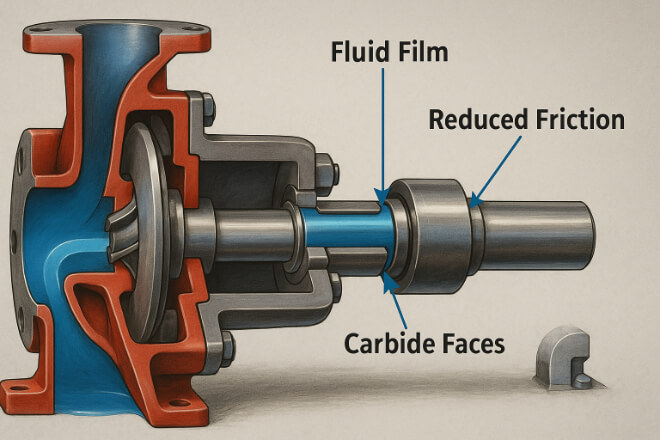

Hoàn thiện siêu mịn so với hoàn thiện dạng túi siêu nhỏ: Giữ độ bôi trơn trên bề mặt cacbua

In mechanical seals, the surface finish of carbide faces affects not only leakage control but also lubrication retention. Two popular finishing approaches—ultra-smooth finishes and micro-pocketed finishes—offer different advantages depending on the operating conditions. For decision-makers in industries like oil & gas, chemical processing, marine systems, and power generation, understanding these finishes helps improve seal performance, […]

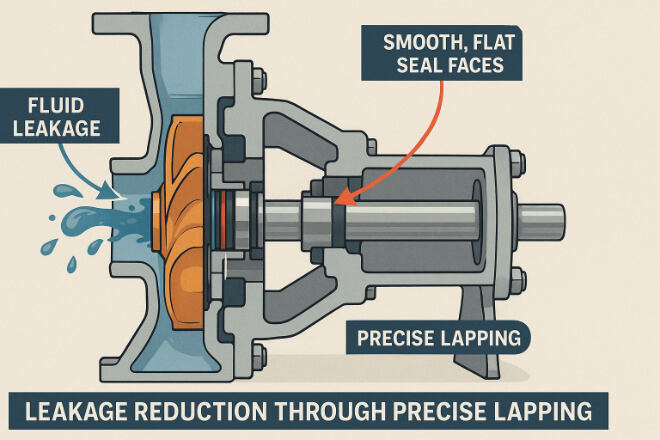

Vòng điều hòa, Lựa chọn tấm và Kiểm soát bùn cho quá trình mài mặt cacbua

In mechanical seal manufacturing and maintenance, carbide face lapping is a crucial finishing process. Proper lapping ensures surface flatness, low roughness (Ra), and tight sealing performance. Three key factors—conditioning rings, lapping plate selection, and slurry control—determine the quality and repeatability of the finish. This guide explains how these elements affect carbide face lapping and provides […]

Mục tiêu Ra và độ phẳng cho bề mặt phớt cacbua: Phương pháp mài và đánh bóng tốt nhất

Carbide seal faces are critical for pumps, compressors, and valves in industries like oil & gas, power generation, chemical processing, and water treatment. The surface roughness (Ra) and flatness of these seal faces directly affect leakage control, wear resistance, and equipment reliability. Lapping and polishing are two essential finishing processes that define the final Ra […]