Cryogenic and extreme cold environments—such as liquefied natural gas (LNG) plants, hàng không vũ trụ testing facilities, scientific labs, and deep-sea systems—require sealing solutions that can perform reliably at very low temperatures.

In these environments, materials become brittle, fluids behave differently, and any failure can cause costly downtime or safety hazards.

Vòng đệm cacbua vonfram are a trusted choice for pumps, compressors, and turbines operating in these harsh conditions.

This article explains their properties, advantages, applications, and best practices for decision-makers.

Challenges of Cryogenic and Extreme Cold Conditions

Operating at temperatures as low as -196 °C (-320 °F) creates challenges:

Material brittleness → Metals and plastics can crack or deform.

Thermal contraction → Components shrink, causing misalignment.

Lubrication issues → Fluids thicken or freeze, increasing friction.

Seal failure risks → Even small leaks can cause dangerous situations.

Downtime costs → Repairs at cryogenic facilities are expensive.

Tính chất của vòng đệm cacbua vonfram

Tungsten carbide is a composite of tungsten and carbon, bonded with cobalt or nickel. Its properties make it ideal for extreme cold:

Cao độ cứng → Maintains strength and khả năng chống mài mòn.

Low thermal expansion → Reduces dimensional changes during cooling.

Độ dẻo dai → Resists cracking from thermal shock or vibration.

Khả năng chống ăn mòn → Performs well with cryogenic fluids like LNG or liquid oxygen.

Tuổi thọ dài → Reduces maintenance and replacements.

Cacbua vonfram liên kết coban so với liên kết niken

1). Cacbua vonfram liên kết coban

Greater impact resistance.

Suitable for pumps and compressors exposed to vibration.

2). Cacbua vonfram liên kết niken

Thượng đẳng corrosion resistance.

Best for cryogenic systems handling oxygen, hydrogen, or chemical-rich fluids.

Ưu điểm so với các vật liệu bịt kín khác

| Tính năng | Cacbua Vonfram | Gốm sứ | Thép |

|---|---|---|---|

| Low-Temperature Toughness | Xuất sắc | Thấp, giòn | Vừa phải |

| Khả năng chống mài mòn | Xuất sắc | Vừa phải | Nghèo |

| Khả năng chống ăn mòn | High (nickel grades) | Very Good | Thấp |

| Thermal Contraction | Thấp | Vừa phải | Cao |

| Service Life | Lâu dài | Vừa phải | Ngắn |

Applications in Cryogenic and Cold Environments

Vòng đệm cacbua vonfram được sử dụng rộng rãi trong:

LNG pumps and compressors → Ensure leak-free transfer of liquefied gases.

Aerospace cryogenic testing systems → Handle extreme cold during rocket or satellite testing.

Scientific laboratories → Maintain seal integrity in liquid nitrogen systems.

Marine deep-sea equipment → Resist high pressure and freezing seawater.

Hydrogen fuel systems → Provide safe sealing for clean energy applications.

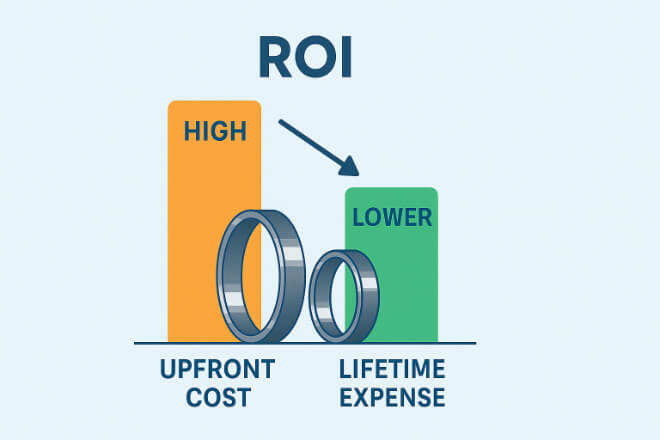

Chi phí so với Giá trị dài hạn

While tungsten carbide seal rings have a higher upfront price, they:

Giảm thời gian chết bằng cách kéo dài thời gian.

Chi phí bảo trì thấp hơn do ít phải thay thế hơn.

Protect critical equipment from leaks and damage.

Deliver better ROI in high-risk, cold environments.

Environmental and Safety Benefits

Leak prevention → Reduces risk of environmental contamination.

Recyclable material → Supports sustainability goals.

Improved efficiency → Leak-free systems consume less energy.

Thực hành tốt nhất để sử dụng vòng đệm cacbua vonfram

Match binder to environment → Nickel for corrosive cryogenic fluids, cobalt for high vibration.

Use proper installation techniques → Tránh trầy xước hoặc lệch trục.

Kiểm tra thường xuyên → Spot wear or contraction damage early.

Làm việc với các nhà cung cấp có kinh nghiệm → Ensure correct specifications for cryogenic conditions.

Plan maintenance schedules → Avoid unplanned shutdowns in critical systems.

Những điểm chính cần ghi nhớ cho người ra quyết định

Tungsten carbide seal rings are the best choice for cryogenic and extreme cold applications.

Their low thermal expansion, khả năng chống ăn mòn, Và độ dẻo dai prevent leaks and damage.

Correct binder selection (nickel or cobalt) maximizes reliability.

Investing in tungsten carbide reduces downtime, cost, and environmental risks.

Phần kết luận

In cryogenic and extreme cold systems, seal reliability is critical. Tungsten carbide seal rings provide unmatched performance, ensuring pumps, compressors, and turbines remain leak-free even under severe conditions.

For decision-makers, selecting tungsten carbide is a strategic investment in safety, efficiency, and sustainability.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.