Ống lót cacbua vonfram are crucial in many industrial applications due to their superior độ cứng and abrasion resistance.

However, even the best materials require additional protection. Advanced coating technologies can significantly improve the performance, service life, and resilience of these bushings under harsh conditions.

In this article, we will explore how coatings improve tungsten carbide bushings and the benefits they bring to various industries.

The Importance of Coatings for Tungsten Carbide Bushings

Tungsten carbide is renowned for its durability, and coatings provide an extra layer of protection, enabling it to withstand abrasion, corrosion, and other challenges.

Coated tungsten carbide bushings have a longer service life, reducing the need for maintenance and replacement.

Trong các ngành công nghiệp như dầu khí, coatings prevent corrosion and abrasion in high-pressure, abrasive environments, thereby reducing downtime and lowering operating costs.

For example, in the khai thác mỏ industry, tungsten carbide bushings with ceramic coatings have a longer service life when in contact with abrasive materials, thus improving mechanical efficiency and reducing maintenance costs.

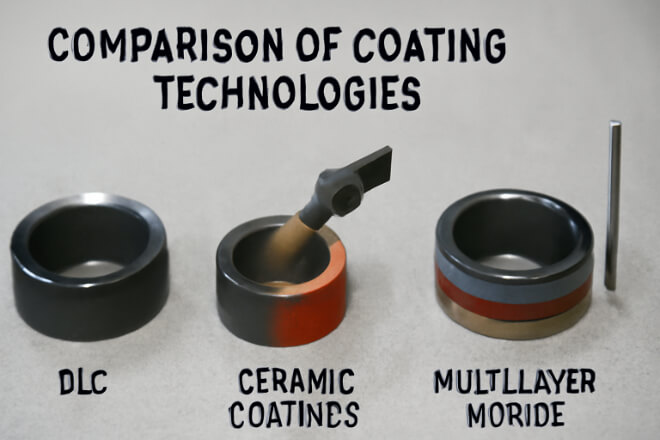

Advanced Coating Technology Types

A variety of coatings are available, each suited to specific application needs:

Hard Ceramic Coatings: These coatings are ideal for abrasive environments and offer excellent wear resistance.

Diamond-Like Carbon (DLC) Coatings: DLC coatings reduce friction, making them ideal for sliding applications.

Multilayer Nitride Coatings (e.g., TiN, TiCN): These coatings are prepared using PVD/CVD methods and offer wear resistance, corrosion resistance, and high-temperature stability.

Thermal Spray Coatings: These coatings are suitable for complex shapes and offer excellent heat and corrosion resistance.

Each coating provides specific advantages based on application requirements.

Key Performance Advantages of Coated Tungsten Carbide Bushings

Coating technology enhances the performance of tungsten carbide bushings in several key ways:

Extended Service Life: Choosing the right coating can double the service life of the bushing, reducing replacement costs.

Reduced Maintenance and Downtime: Coatings reduce wear, meaning less maintenance and less downtime.

Improved Efficiency: Low-friction coatings reduce energy consumption and heat generation in mechanical equipment.

Enhanced Resistance to Harsh Environments: Coatings protect against corrosion, high temperatures, and wear, making bushings more durable in extreme environments.

Market Trends and Technology Drivers

As the demand for high-performance components continues to grow across industries, the application of advanced coatings is becoming increasingly widespread. Key drivers include:

Demand for More Durable Components: The demand for long-life components is growing as industries such as hàng không vũ trụ Và khai thác mỏ face increasingly severe challenges.

Cost Saving Pressures: Coated bushings reduce maintenance costs and increase equipment uptime, which is crucial for industries with high operating costs.

Sustainability Goals: Longer-life components reduce waste and align with sustainability initiatives.

As in the dầu khí industry, for example, coated bushings help reduce maintenance downtime, thereby improving operational efficiency and reducing overall costs.

Challenges and Considerations When Choosing a Coating

While coatings offer significant advantages, some challenges also exist:

Upfront Costs: Coated bushings have a higher initial cost, but the long-term savings from reduced downtime and maintenance often outweigh these costs.

Compatibility with Operating Conditions: Selecting the appropriate coating based on the specific environment is crucial, such as high-temperature, chemically corrosive, or abrasive environments.

Quality Control: The coating process must be precise to ensure uniform application and good adhesion to the substrate.

For bushings in high-temperature engine applications, nitride coatings may be ideal.

But improperly applied coatings may fail to provide the necessary protection, leading to premature bushing wear.

Phần kết luận

Advanced coating technologies are transforming the performance of tungsten carbide bushings.

By improving their wear resistance, corrosion resistance, and resistance to extreme environments, coatings help extend bushing service life, reduce maintenance costs, and improve operational efficiency.

With increasing durability and performance requirements across industries, investing in coated tungsten carbide bushings is a wise choice for achieving long-term cost savings and reliability.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.