Ống lót cacbua vonfram are widely used in applications that demand high khả năng chống mài mòn và độ bền.

One critical factor influencing their performance is grain size. The grain size of tungsten carbide directly impacts its strength, độ dẻo dai, and wear resistance.

In this article, we will explore how grain size affects the strength of tungsten carbide bushings.

How to control it during manufacturing, and how it influences bushing performance in various industrial applications.

What Is Grain Size in Tungsten Carbide?

Kích thước hạt refers to the size of the individual particles or grains that make up a material.

In tungsten carbide, the grains are composed of tungsten carbide (WC) particles bound together by a metallic binder, typically cobalt.

Why Grain Size Matters:

Smaller grains: A material with smaller grains tends to be harder and more wear-resistant because the smaller particles create a denser structure, making it more difficult for cracks to propagate.

Larger grains: Larger grains often result in a material that is more tough and resistant to cracking under impact, but it may be less wear-resistant.

By adjusting the grain size, manufacturers can tailor the material properties of tungsten carbide to suit specific applications.

The Effect of Grain Size on Strength

The strength of tungsten carbide bushings is directly affected by the size of the grains. Generally, smaller grain sizes lead to higher strength, but there are trade-offs depending on the application.

1). Small Grain Size:

Increased độ cứng: Smaller grains increase the hardness of the tungsten carbide, making it more resistant to wear and abrasion.

Đã cải thiện khả năng chống mài mòn: Due to the dense structure of small grains, the bushing can withstand harsh conditions, especially in high-speed, high-pressure environments like slurry pumps.

Thấp hơn độ dẻo dai: While small grains increase hardness, they can also make the material more brittle, leading to a greater risk of cracking under shock or impact.

2). Larger Grain Size:

Increased toughness: Larger grains typically result in a tougher material that can better absorb impacts and resist cracking.

Reduced hardness: Larger grains can reduce the overall hardness of the material, making it less resistant to wear, especially in applications involving abrasive materials.

More suitable for impact resistance: In applications where the bushing is subjected to sudden shocks or vibrations, larger grain sizes are often preferred.

Ultimately, the optimal grain size for tungsten carbide bushings depends on balancing hardness and toughness for the specific application.

Grain Size and Wear Resistance

Wear resistance is one of the primary factors influencing the choice of material for bushings. In tungsten carbide, wear resistance is directly related to the size of the grains.

1). Small Grains for Enhanced Khả năng chống mài mòn:

The smaller the grain size, the more resistant the tungsten carbide is to wear, as the material is denser and more homogeneous.

This is ideal for applications where the bushing will be in constant contact with abrasive materials, such as pumps handling slurries or grinders.

2). Larger Grains for Impact Resistance:

In applications where impact resistance is more critical than wear resistance, larger grains may be more effective.

Larger grains provide more resistance to cracking and failure under high stress, but at the cost of wear resistance.

Controlling Grain Size in Tungsten Carbide Bushings

The grain size of tungsten carbide can be controlled during the manufacturing process.

This control allows manufacturers to fine-tune the bushing’s properties based on the needs of the application.

Manufacturing Techniques:

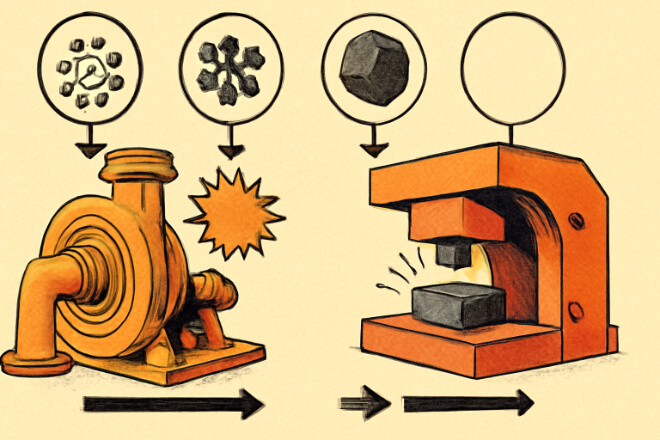

Powder Metallurgy:

The grain size of tungsten carbide is primarily controlled through powder metallurgy.

During the manufacturing process, tungsten carbide powders are mixed with a binder material (often cobalt) and sintered at high temperatures.

Higher sintering temperatures can lead to larger grain sizes, while lower temperatures help to maintain smaller grains.

Binder content:

The amount of binder used can also influence grain growth during the sintering process.

A higher binder content can sometimes lead to a more refined grain structure.

By adjusting these manufacturing parameters, manufacturers can produce tungsten carbide bushings with the desired grain size to optimize performance for a given application.

Applications of Tungsten Carbide Bushings with Different Grain Sizes

Different grain sizes are better suited for different applications. Below are some common uses for tungsten carbide bushings with varying grain sizes:

1). Applications for Small Grain Size Tungsten Carbide:

Slurry pumps: Small grains provide excellent wear resistance, making them ideal for pumps that handle abrasive slurries.

Precision machinery: Small grain size ensures tight tolerances and high khả năng chống mài mòn in precision applications like valves and seals.

2). Applications for Large Grain Size Tungsten Carbide:

Impact-resistant systems: In environments where shock loads are common, such as in mining or high-pressure hydraulic systems, larger grains provide improved toughness and resistance to cracking.

Heavy-duty pumps: Large grains are suitable for pumps that deal with high-pressure, non-abrasive fluids or where the bushing may face sudden impacts.

How to Choose the Right Grain Size for Your Application

Selecting the right grain size for tungsten carbide bushings depends on the specific demands of the application. Here are some key factors to consider:

Factors to Consider:

Wear vs. impact:

If wear resistance is critical, a small grain size is preferable. If the application involves frequent shocks or high-impact loads, a larger grain size will provide better performance.

Operating environment:

Consider whether the bushing will be exposed to high temperatures, abrasive materials, or high pressures, and select the grain size that offers the best balance between wear resistance and toughness.

Trị giá:

Smaller grains may require more precise manufacturing techniques, which can increase costs. Larger grains may be more cost-effective for less demanding applications.

Phần kết luận

The grain size of tungsten carbide plays a critical role in determining the strength, wear resistance, and impact resistance of bushings.

By carefully selecting the grain size based on the specific requirements of the application, manufacturers can optimize performance, reduce maintenance, and increase the lifespan of their systems.

Whether you need a high-wear-resistant bushing for slurry pumps or a tough, impact-resistant bushing for heavy-duty machinery, understanding how grain size affects tungsten carbide performance will help you make the right choice.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.