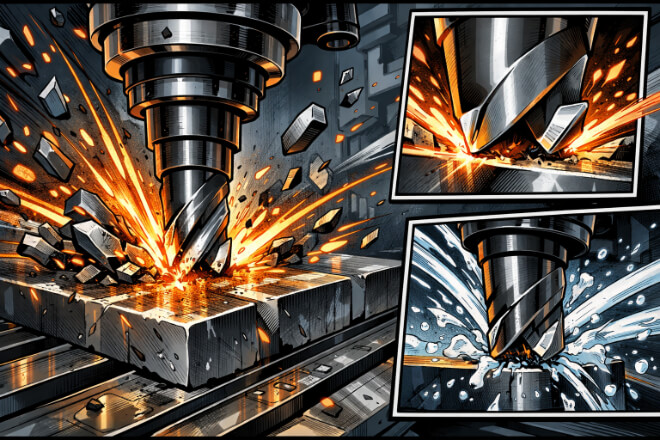

CNC (Computer Numerical Control) machinery plays a crucial role in modern manufacturing, providing high precision and automation for cutting, drilling, and shaping materials. The choice of cutting tools is critical to the overall performance and longevity of CNC machines.

Tungsten carbide tips are among the best tools for these machines due to their exceptional độ cứng, khả năng chống mài mòn, and ability to handle high cutting speeds.

In this blog, we will explore the key benefits of using tungsten carbide tips in CNC machinery and why they are the go-to choice for many industries.

Why Tungsten Carbide Tips Are Ideal for CNC Machinery

Tungsten carbide tips are widely recognized for their outstanding performance in CNC machining.

These tips are particularly beneficial in environments where high precision, durability, and longevity are essential. Here’s why they are ideal for CNC applications:

1). Độ cứng and Durability

Tungsten carbide is one of the hardest materials available, second only to diamond.

This hardness ensures that the tips stay sharp for a longer period, even when cutting through tough materials like steel, titanium, and composites.

In CNC machining, maintaining sharp edges is essential for producing accurate and consistent parts.

CNC machinery involves continuous cutting and shaping, which naturally leads to tool wear.

Tungsten carbide tips resist wear better than many other materials, reducing the frequency of tool replacements.

This extended tool life lowers operational costs and minimizes downtime, ultimately increasing productivity.

3). Heat Resistance

CNC machining often generates high temperatures due to friction. Tungsten carbide tips can withstand high heat without losing their hardness or performance.

This heat resistance ensures that the tool remains effective even in high-speed operations, contributing to consistent quality and precision.

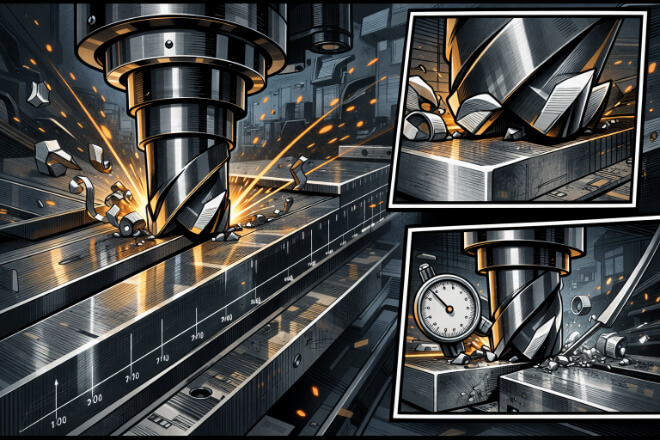

Improved Cutting Precision with Tungsten Carbide Tips

Precision is at the heart of CNC machining, and tungsten carbide tips are designed to deliver outstanding accuracy. Here’s how they contribute to improved cutting precision:

1). Maintaining Sharpness

The exceptional độ cứng of tungsten carbide allows the tips to maintain a sharp cutting edge over extended periods.

A sharp tool ensures smoother cuts and higher accuracy in parts, reducing the need for post-processing and improving the quality of the final product.

2). Consistent Performance

Tungsten carbide tips offer stable performance across different materials and cutting conditions.

Their ability to withstand wear and heat without losing precision makes them ideal for complex machining tasks that require consistent results.

3). Reduced Tool Deflection

Tool deflection occurs when the cutting tool bends under pressure, which can lead to inaccurate cuts.

Tungsten carbide tips, due to their rigidity, are less prone to deflection, ensuring that the cutting tool remains stable and the cuts stay precise.

Extended Tool Life with Tungsten Carbide Tips

Tool longevity is a key factor in reducing costs and improving productivity in CNC machining. Tungsten carbide tips are known for their long lifespan, which can provide several benefits:

1). Less Frequent Tool Changes

Bởi vì của họ độ cứng Và khả năng chống mài mòn, tungsten carbide tips last significantly longer than tools made from other materials.

This means fewer tool changes are required, reducing downtime and ensuring that the CNC machinery operates continuously.

2). Lower Maintenance Costs

CNC machines require regular maintenance, and tools that wear out quickly can increase maintenance costs.

Tungsten carbide tips reduce the frequency of replacements, thereby lowering overall maintenance expenses. This also reduces the risk of machine failure due to worn-out tools.

3). Higher Return on Investment (ROI)

The extended tool life and reduced maintenance costs make tungsten carbide tips a cost-effective option in the long term.

Businesses can achieve a higher return on investment due to fewer replacements, less downtime, and more efficient operations.

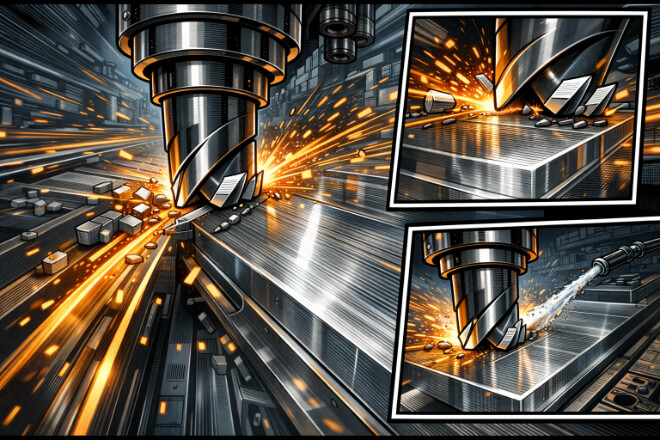

Increased Cutting Speeds and Efficiency

CNC machining often requires high cutting speeds for increased productivity. Tungsten carbide tips are ideal for high-speed operations due to their strength and heat resistance.

1). High-Speed Cutting

Tungsten carbide tips can handle higher cutting speeds compared to other materials, such as high-speed steel (HSS).

This capability allows CNC machines to operate faster, increasing material removal rates and improving production efficiency.

2). Enhanced Material Removal Rates (MRR)

By operating at higher cutting speeds without sacrificing accuracy, tungsten carbide tips help achieve greater material removal rates.

This leads to faster cycle times and higher throughput, which is crucial for industries that need to meet high production demands.

3). Smoother Surface Finish

The precision of tungsten carbide tips also results in smoother surface finishes.

This is particularly important in applications where the surface quality of the material is critical, such as in aerospace and automotive components.

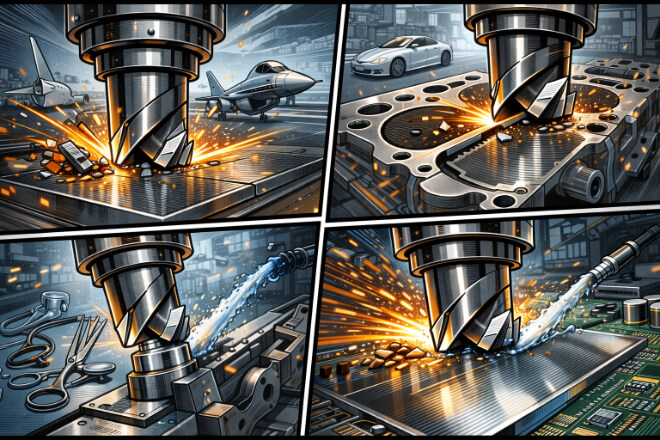

Applications of Tungsten Carbide Tips in CNC Machinery

Tungsten carbide tips are used in a variety of CNC machining applications across different industries. Some of the key applications include:

1). Hàng không vũ trụ Ngành công nghiệp

In aerospace manufacturing, precision is critical. Tungsten carbide tips are used for machining complex parts made from hard metals like titanium and high-strength alloys, ensuring accuracy and durability.

2). Ô tô Manufacturing

In automotive production, tungsten carbide tips are used for cutting engine components, gears, and body parts.

Their durability and precision ensure high-quality parts with tight tolerances, crucial for safety and performance.

3). Medical Device Production

The medical industry requires high-precision components that must meet strict standards.

Tungsten carbide tips are ideal for cutting and drilling parts made from materials like stainless steel and titanium, ensuring high-quality results.

4). Electronics Manufacturing

Tungsten carbide tips are used in the production of delicate electronic components, where precision and smooth finishes are essential.

Their hardness allows for clean cuts without damaging sensitive materials.

Phần kết luận

Tungsten carbide tips offer numerous benefits for CNC machinery, including improved cutting precision, extended tool life, and increased machining efficiency.

Their hardness, wear resistance, and heat resistance make them ideal for high-speed, high-precision applications.

By using tungsten carbide tips, businesses can reduce downtime, lower maintenance costs, and improve productivity, ultimately leading to significant cost savings and higher-quality results.

Investing in carbide tools for CNC machinery is a smart decision that yields long-term benefits in manufacturing operations.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.