In high-volume production runs, the efficiency and cost-effectiveness of manufacturing tools are critical to ensuring profitability and competitiveness.

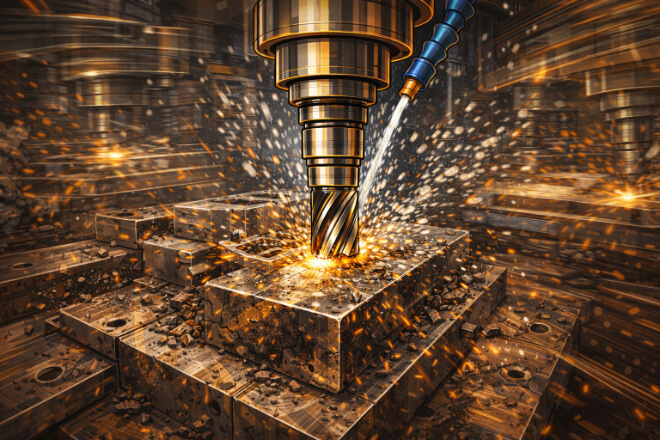

Tungsten carbide tips have gained popularity in industries that require rapid, precise, and durable cutting solutions, including automotive manufacturing, metalworking, and machining.

Their superior độ cứng, khả năng chống mài mòn, and durability make them the perfect choice for high-volume applications.

This blog will explore why tungsten carbide tips are cost-effective in high-volume production runs, helping companies achieve lower operational costs, fewer tool replacements, and improved production efficiency.

Why Tungsten Carbide Tips Are Ideal for High-Volume Production

High-volume production runs require cutting tools that can handle the demands of continuous operation while maintaining high precision.

Tungsten carbide tips are the ideal choice for such applications due to their exceptional properties.

1). Exceptional Độ cứng and Durability

Tungsten carbide is one of the hardest materials available, second only to diamond.

This hardness enables carbide tips to maintain their cutting edge for longer periods, even when exposed to high speeds and abrasive materials.

In high-volume production, tools are often subjected to constant wear, but tungsten carbide tips can withstand this stress without losing their cutting ability, reducing the need for frequent tool changes.

In high-volume production runs, the wear on cutting tools is a significant concern.

Tungsten carbide tips offer outstanding wear resistance, allowing them to endure prolonged contact with hard materials like steel, composites, and plastics.

The durability of carbide tips ensures that manufacturers experience fewer tool replacements and reduced downtime, which leads to cost savings and higher efficiency.

3). Heat Resistance

High-speed cutting often generates significant heat, which can degrade tool performance.

Tungsten carbide tips have excellent heat resistance, ensuring they maintain their sharpness and performance even in heat-intensive applications.

This ability to withstand high temperatures ensures that carbide tips remain effective in high-speed, high-pressure production environments.

How Tungsten Carbide Tips Contribute to Cost-Effectiveness in High-Volume Production

Tungsten carbide tips are not only durable but also cost-effective in high-volume production runs. Here’s how they contribute to lowering operational costs:

1). Extended Tool Life

One of the main cost benefits of using tungsten carbide tips is their extended tool life.

Unlike other materials, carbide tips last significantly longer before they need to be replaced. This results in fewer tool changes, lower material costs, and less frequent tool maintenance.

With carbide tips, manufacturers can run production lines for longer periods without the need for constant tool replacements, ultimately reducing overall production costs.

2). Reduced Downtime

In high-volume production, downtime can be costly. If tools need to be replaced frequently, the equipment experiences more interruptions, leading to lower production output.

Tungsten carbide tips reduce downtime by offering long-lasting performance, which keeps production running smoothly without unnecessary stoppages. This results in higher throughput and improved productivity.

3). Lower Maintenance Costs

Tools made from softer materials wear out quickly and require frequent maintenance to keep them operating at optimal levels.

Tungsten carbide tips, on the other hand, require less maintenance due to their exceptional wear and heat resistance.

This reduces the need for regular servicing and the associated costs, contributing to overall savings in maintenance expenses.

Tungsten Carbide Tips in High-Speed, High-Precision Applications

High-volume production often requires both speed and precision, and tungsten carbide tips excel in both areas.

Their performance in high-speed, high-precision cutting makes them a valuable tool in various industries.

1). High-Speed Cutting Performance

In industries like automotive manufacturing and metalworking, high-speed cutting is essential for increasing throughput and reducing production times.

Tungsten carbide tips allow CNC machines and other automated tools to operate at faster speeds without compromising cutting quality.

The tips remain sharp and efficient during extended high-speed runs, making them ideal for mass production operations.

2). Precision in High-Volume Runs

Maintaining cutting precision over large production volumes is essential to meeting quality standards.

Tungsten carbide tips maintain their sharpness and geometry for longer periods, allowing manufacturers to produce components with consistent accuracy.

This consistency in cutting quality leads to fewer defects, less rework, and higher-quality products.

3). Increased Productivity

By reducing the frequency of tool changes and minimizing downtime, tungsten carbide tips contribute to increased productivity.

High-speed and precision cutting capabilities allow manufacturers to complete more parts in less time, improving efficiency and helping meet tight production schedules.

Applications of Tungsten Carbide Tips in High-Volume Production

Tungsten carbide tips are used in a wide variety of industries where high-volume production is essential. Their durability and efficiency make them a preferred choice for numerous applications.

1). Ô tô Manufacturing

In the automotive industry, tungsten carbide tips are used for cutting, shaping, and machining engine components, transmission parts, and chassis components.

The tips offer high performance and precision, ensuring that automotive parts meet strict quality standards while reducing manufacturing costs.

2). Hàng không vũ trụ Manufacturing

The aerospace industry requires tools that can handle the rigorous demands of high-speed and high-precision cutting.

Tungsten carbide tips are ideal for machining aerospace components, such as turbine blades, landing gear parts, and structural components, which require both durability and accuracy.

3). Gia công kim loại and Tooling

Tungsten carbide tips are commonly used in metalworking and tooling applications, where materials like steel and aluminum need to be shaped or cut with high precision.

The wear resistance of carbide tips ensures that these tools remain effective over extended production runs, making them perfect for creating high-quality metal products.

4). Plastic and Composite Machining

In addition to metals, tungsten carbide tips are also effective for cutting and shaping plastics and composites.

The heat resistance and sharpness of carbide tips make them suitable for high-speed machining of materials used in industries such as electronics, automotive, and construction.

Maximizing the Cost-Effectiveness of Tungsten Carbide Tips

To ensure that tungsten carbide tips remain cost-effective in high-volume production runs, certain best practices should be followed to maximize their performance.

1). Regular Tool Maintenance and Inspections

Regular inspections help identify wear and tear on carbide tips before they affect performance.

Reconditioning or sharpening carbide tips can extend their lifespan and improve cutting efficiency, further reducing replacement costs and extending tool life.

2). Optimizing Cutting Parameters

Adjusting cutting speed, feed rate, and depth of cut to match the material being processed helps maximize the performance of tungsten carbide tips.

Properly optimized cutting conditions ensure that tools last longer and operate more efficiently, reducing wear and improving overall production efficiency.

3). Selecting the Right Carbide Grade

Different grades of tungsten carbide are suitable for different materials and applications.

Choosing the appropriate grade based on the material being cut ensures that the carbide tips perform optimally, delivering maximum value and performance for high-volume production runs.

Phần kết luận

Tungsten carbide tips are a cost-effective solution for high-volume production runs due to their hardness, wear resistance, and performance in high-speed, high-precision applications.

By using carbide tips, manufacturers can extend tool life, reduce downtime, and increase productivity.

The efficiency and durability of tungsten carbide tips make them an invaluable investment for companies seeking to optimize their manufacturing processes and improve overall profitability.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.