Tungsten carbide tips are renowned for their exceptional độ cứng Và khả năng chống mài mòn, making them indispensable in many industrial applications.

However, one of the major challenges when using tungsten carbide tips is preventing overheating, which can lead to tool failure, reduced performance, and increased operational costs.

Overheating can cause the carbide to soften, become brittle, or even crack.

This article will explore the causes of overheating in tungsten carbide tips and provide practical solutions to prevent it during operations, ensuring optimal performance and tool longevity.

Understanding the Risks of Overheating Tungsten Carbide Tips

Tungsten carbide tips are designed to withstand high levels of stress and heat. However, excessive heat can lead to several issues:

Loss of Hardness: Overheating can soften the carbide material, reducing its độ cứng Và khả năng chống mài mòn.

Cracking or Chipping: Sudden temperature changes or prolonged exposure to high heat can cause thermal shock, leading to cracks or chips in the tip.

Increased Wear: High temperatures increase friction, leading to faster wear of the tip.

Understanding the risks of overheating is the first step in preventing damage and ensuring that tungsten carbide tips continue to perform efficiently throughout their lifespan.

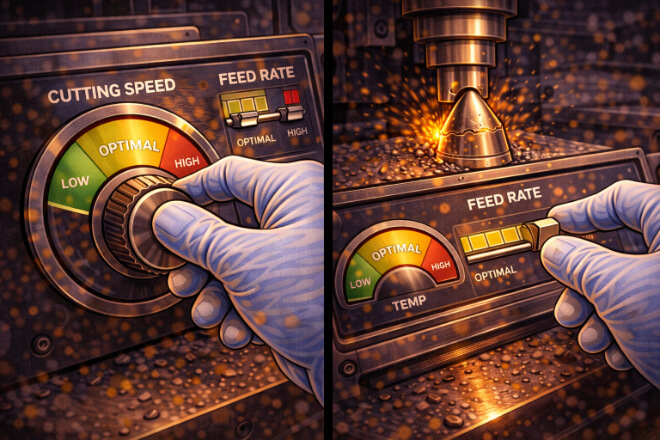

Controlling Cutting Speed and Feed Rate

One of the most common causes of overheating is operating at excessive cutting speeds.

While high cutting speeds can increase productivity, they also generate more heat, which can quickly cause carbide tips to overheat.

Tốc độ cắt: Tungsten carbide tips are designed to operate within a specific cutting speed range. Going beyond this range generates more heat, which can lead to the tool softening or cracking.

Feed Rate: A feed rate that is too high can also increase friction, which contributes to heat generation.

To prevent overheating, always adhere to the recommended cutting speed and feed rate for the material being processed.

Regularly monitor machine settings to ensure they remain within the optimal range.

Using the Right Coolant to Maintain Optimal Temperature

Coolants play a crucial role in reducing heat and maintaining the temperature of the carbide tips during machining.

Without proper coolant, the carbide tips can heat up rapidly, leading to overheating.

Choosing the Right Coolant: Not all coolants are suitable for tungsten carbide tools. It’s essential to use a coolant designed for high-performance machining, which will efficiently dissipate heat.

Correct Coolant Application: Ensure that the coolant is applied consistently throughout the cutting process to maintain optimal temperature control.

Insufficient or improper coolant can cause carbide tips to overheat, leading to tool failure.

Ensure that the coolant flow is adequate and that the system is functioning correctly during operations.

Ensuring Proper Tool Alignment and Machine Setup

Improper tool alignment or machine setup can lead to uneven stress on the tungsten carbide tips, causing excessive heat buildup.

Misalignment often results in increased friction, which directly contributes to overheating.

Tool Alignment: Ensure that the carbide tip is correctly aligned with the workpiece to prevent uneven pressure and unnecessary friction.

Machine Setup: Incorrect machine settings, such as improper depth of cut or incorrect tool angle, can lead to excessive heat generation.

By ensuring proper alignment and machine setup, you can reduce the friction and heat generated during operations, preventing overheating and tool failure.

Maintaining Optimal Cutting Conditions and Workpiece Material Compatibility

Another factor that contributes to overheating is the compatibility between the tungsten carbide tip and the workpiece material.

Some materials generate more heat than others, increasing the risk of overheating.

Vật liệu Độ cứng: Harder materials, like stainless steel or titanium, tend to generate more heat when cut, which can quickly raise the temperature of the carbide tip.

Workpiece Surface Condition: Materials with rough surfaces or high abrasiveness create more friction, leading to increased heat generation during the cutting process.

To avoid overheating, choose the right tungsten carbide tip grade for the material being processed.

Additionally, ensure the workpiece is properly prepared (e.g., cleaned and aligned) to reduce friction and heat buildup.

Implementing Regular Tool Maintenance and Monitoring

Routine maintenance and monitoring of tungsten carbide tips can help prevent overheating issues before they escalate.

Regular tool inspection ensures that any signs of wear, misalignment, or buildup are addressed promptly.

Tool Inspection: Check for signs of wear, such as dull edges or chips, which can increase friction and heat generation during operation.

Regular Cleaning: Build-up of material on the tip can increase friction, leading to overheating. Clean the tips regularly to prevent this issue.

By keeping your tools in optimal condition, you can maintain their performance and prevent overheating from excessive wear or misalignment.

Phần kết luận

Overheating is a major concern when working with tungsten carbide tips, as it can lead to tool failure, reduced performance, and increased operational costs.

By controlling cutting speed and feed rate, using the right coolant, ensuring proper tool alignment, and maintaining optimal conditions, you can significantly reduce the risk of overheating.

Regular maintenance and proper tool handling are also crucial in preventing excessive heat buildup.

By following these strategies, you can ensure that your tungsten carbide tips operate at their best, leading to longer tool life and improved efficiency.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.