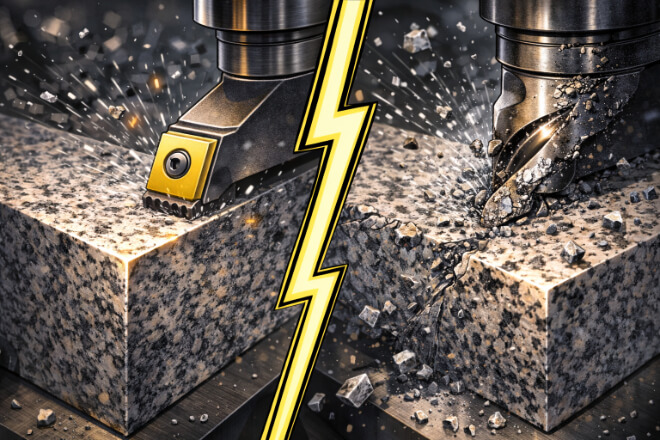

Cutting stone and granite can be a challenging task. These materials are tough, dense, and often abrasive, which means they can quickly wear out standard cutting tools.

Đây là nơi tungsten carbide tips come into play. Known for their độ cứng Và khả năng chống mài mòn, tungsten carbide tips help improve cutting performance, reduce tool wear, and enhance overall productivity.

In this blog, we will explore how tungsten carbide tips are used for stone and granite cutting, their benefits, and what you need to know before choosing the right tips for your cutting operations.

1. Why Tungsten Carbide Tips Are Ideal for Stone and Granite Cutting

Stone and granite are some of the hardest materials to cut, and using the right tool is essential for achieving precise, clean cuts.

Tungsten carbide tips are perfect for this type of work due to their combination of hardness, độ dẻo dai, and wear resistance.

Key Benefits of Tungsten Carbide for Stone and Granite Cutting:

Cao Độ cứng: Tungsten carbide is incredibly hard, making it ideal for cutting through tough, dense materials like granite and stone.

Khả năng chống mài mòn: Tungsten carbide tips resist abrasion, meaning they won’t wear down as quickly as standard steel or other materials.

Khả năng chịu nhiệt: These tips maintain their performance under the heat generated during cutting, preventing premature failure due to high friction.

Precision: Tungsten carbide tips allow for precise cuts in stone and granite, which is crucial in applications where accuracy is required.

For these reasons, tungsten carbide tips are the go-to choice for cutting tools used in stone and granite applications.

2. How Tungsten Carbide Tips Improve Cutting Performance

When working with stone and granite, cutting speed and precision are crucial.

Tungsten carbide tips improve cutting performance by maintaining sharpness and cutting efficiency over a long period of use.

How Tungsten Carbide Enhances Cutting Performance:

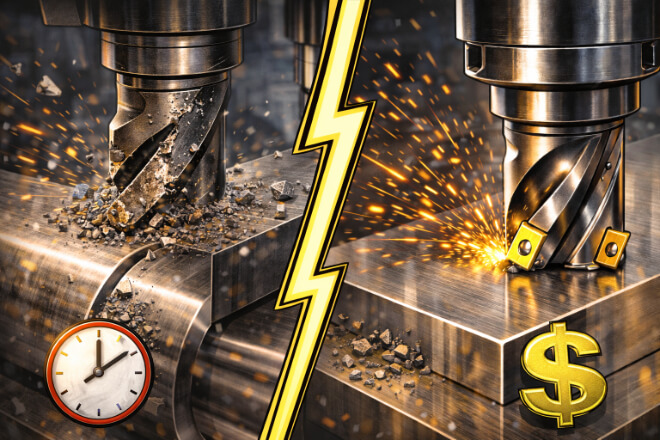

Faster Cutting Speeds: Tungsten carbide tips allow for faster cutting speeds, which helps reduce overall project time.

Clean Cuts: The sharpness and stability of tungsten carbide ensure that cuts are clean and precise, minimizing the need for rework or finishing.

Durability in Tough Conditions: The durability of carbide tips means they can withstand the constant stress and pressure of cutting through hard stone and granite without degrading.

These benefits help to improve productivity and reduce costs in the long run by decreasing downtime for tool replacements and increasing operational efficiency.

3. Choosing the Right Tungsten Carbide Tip for Stone and Granite

Selecting the right tungsten carbide tip for stone and granite cutting depends on several factors, including the type of material being cut, the cutting method, and the tool being used.

Factors to Consider When Choosing Tungsten Carbide Tips:

Stone Hardness: The độ cứng of the stone or granite determines the type of carbide tip required. Harder materials, such as granite, will require a tougher, more durable carbide tip.

Cutting Method: Different cutting methods (e.g., dry cutting, wet cutting, or drilling) may require different carbide tips for optimal performance.

Tool Compatibility: Make sure the carbide tip is compatible with the tool being used, whether it’s a diamond blade, circular saw, or core drill.

Tip Shape: The shape of the carbide tip can influence cutting performance. For example, a sharp, pointed tip is often best for precision cutting, while flat tips work well for rough cuts.

Choosing the right carbide tip based on these factors will ensure that the tool performs optimally and lasts longer.

4. Improving Efficiency and Reducing Costs with Tungsten Carbide Tips

One of the primary benefits of using tungsten carbide tips is the increased efficiency they provide.

Tungsten carbide’s durability and resistance to wear reduce the need for frequent tool replacements, allowing businesses to save money on tool costs.

How Tungsten Carbide Improves Efficiency:

Longer Tool Life: Tungsten carbide tips last significantly longer than standard tips, reducing the need for constant tool changes.

Fewer Downtime Events: With longer-lasting tools, there is less downtime for tool maintenance or replacements, helping operations run smoothly.

Increased Cutting Speed: The ability to cut faster without compromising tool life means projects are completed more quickly, which boosts productivity and reduces labor costs.

Overall, the use of tungsten carbide tips helps improve the cost-effectiveness of stone and granite cutting by reducing operational costs and improving project turnaround times.

5. Managing Tool Wear in Stone and Granite Cutting

Even though tungsten carbide tips are more durable than other materials, they still face wear and tear during prolonged use.

Managing tool wear is essential for getting the most out of your carbide tips.

Ways to Manage Tool Wear:

Regular Maintenance: Regularly inspect and clean cutting tools to ensure that carbide tips maintain optimal performance.

Proper Speed and Feed Rates: Adjusting cutting speeds and feed rates can help prevent excess wear on the carbide tips. Cutting too fast can cause overheating, while cutting too slowly may result in unnecessary wear.

Proper Cooling: For wet cutting applications, using proper cooling methods can help maintain the carbide tip’s integrity and prevent premature wear due to heat buildup.

By properly managing tool wear, businesses can extend the life of their tungsten carbide tips and maintain consistent cutting performance.

6. Safety Considerations When Using Tungsten Carbide Tips for Cutting Stone and Granite

Safety is always a concern when working with power tools and cutting hard materials like stone and granite.

Tungsten carbide tips are no exception, and it’s important to follow safety guidelines to prevent accidents and ensure a safe working environment.

Safety Tips for Using Tungsten Carbide Tips:

Wear Protective Gear: Always wear appropriate personal protective equipment (PPE), such as goggles, gloves, and ear protection.

Proper Tool Handling: Ensure that tools are used correctly and that carbide-tipped blades are securely mounted to prevent accidents.

Dust Control: Cutting stone and granite can generate a lot of dust, which can be harmful if inhaled. Use dust extraction systems to keep the air clean.

By following proper safety procedures, workers can avoid injuries and maintain a safe working environment while using carbide-tipped tools for stone and granite cutting.

7. Applications of Tungsten Carbide Tips in Other Stone Cutting Tools

Tungsten carbide tips are not only used in saw blades but also in a wide range of other tools for stone cutting.

Other Applications for Tungsten Carbide Tips:

Diamond Blades: Tungsten carbide tips are often used in diamond blades for cutting granite and stone, providing improved wear resistance and cutting efficiency.

Drilling Tools: Carbide-tipped drill bits are used for drilling holes in stone and granite, offering precision and longevity.

Angle Grinders: Carbide tips are used in grinding wheels for polishing and shaping stone surfaces.

These various applications highlight the versatility of tungsten carbide tips in the stone cutting industry.

8. Cost-Effectiveness of Tungsten Carbide Tips for Stone Cutting

While tungsten carbide tips are more expensive initially than other materials, they offer significant cost savings over time.

By lasting longer and reducing downtime, carbide tips offer great value for stone and granite cutting businesses.

Long-Term Cost Benefits:

Fewer Tool Changes: Tungsten carbide tips last much longer than steel or other materials, reducing the need for frequent replacements.

Chi phí bảo trì thấp hơn: Carbide tools require less maintenance, as they don’t wear down as quickly as conventional tools.

Higher Productivity: Faster cutting speeds and less downtime mean higher productivity and reduced labor costs.

In the long run, the durability and performance of tungsten carbide tips make them a cost-effective investment for stone and granite cutting businesses.

Phần kết luận

Tungsten carbide tips are essential for efficient, precise, and durable stone and granite cutting.

With their hardness, wear resistance, and heat stability, carbide tips help improve cutting performance, reduce operational costs, and extend tool life.

Whether used in saw blades, drill bits, or grinding tools, tungsten carbide tips offer significant benefits for the stone cutting industry.

By choosing the right carbide tips and managing tool wear, businesses can achieve high-quality results while minimizing downtime and costs.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.