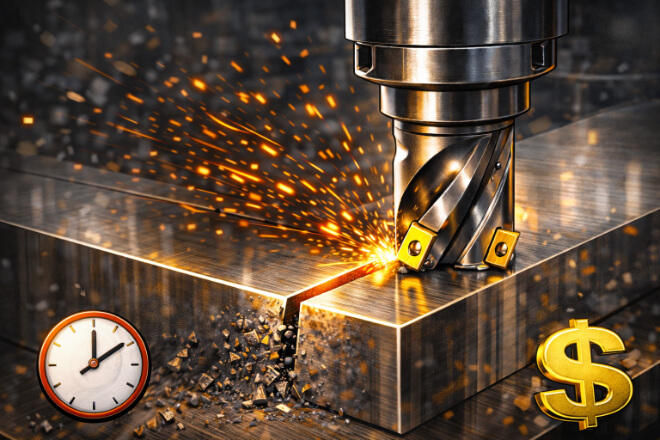

Cutting through tough materials like metal, stone, or high-Tỉ trọng plastics often leads to extremely high temperatures and friction.

These factors can cause rapid wear and tear on cutting tools, resulting in reduced performance and frequent tool changes.

Tungsten carbide tips are widely regarded as the ideal solution for high-heat and high-friction cutting jobs due to their độ cứng, heat resistance, and durability.

In this article, we will explore why tungsten carbide tips are superior in these demanding conditions and how they help improve efficiency, reduce downtime, and lower operational costs.

1. What Is Tungsten Carbide and Why Is It Ideal for High-Heat and High-Friction Cutting?

Tungsten carbide is a composite material made from tungsten and carbon. It is extremely hard and resistant to wear, making it one of the best materials for cutting tools in high-stress applications.

Key Benefits of Tungsten Carbide for High-Heat and High-Friction Cutting:

Độ cứng: Tungsten carbide is incredibly hard, which makes it ideal for cutting through tough materials without losing sharpness.

Khả năng chịu nhiệt: It can withstand extremely high temperatures, which prevents softening or degradation under high-heat conditions.

Khả năng chống mài mòn: Tungsten carbide’s resistance to abrasion ensures that the cutting tool can endure high friction without significant wear.

These properties make tungsten carbide an excellent material for cutting jobs that involve extreme heat and friction, where standard tools might fail.

2. How Tungsten Carbide Tips Handle High-Heat Environments

In many industrial cutting applications, heat is generated at the cutting edge due to the friction between the tool and the material being cut.

High temperatures can cause some materials to lose their độ cứng, leading to premature tool wear. Tungsten carbide tips, however, maintain their hardness even at elevated temperatures.

How Tungsten Carbide Stays Effective in High-Heat Conditions:

Retention of Hardness: Tungsten carbide retains its hardness up to temperatures of approximately 1,000°C (1,832°F), which is much higher than the operating temperatures of many other materials.

Prevention of Tool Deformation: Unlike softer materials, tungsten carbide does not deform or lose its shape when exposed to heat, maintaining cutting stability.

Minimized Heat Build-Up: Tungsten carbide tips also help reduce heat build-up, keeping the cutting area cooler and preventing damage to both the tool and the material.

This ability to handle heat makes tungsten carbide ideal for high-speed machining, metal cutting, and other high-heat applications.

3. Friction Resistance: How Tungsten Carbide Reduces Tool Wear

Friction between the cutting tool and the material is inevitable in most cutting operations.

Over time, this friction wears down the tool, reducing its effectiveness and causing frequent replacements.

Tungsten carbide tips are known for their exceptional resistance to friction, which extends the life of the tool and maintains cutting efficiency.

How Tungsten Carbide Reduces Friction:

Smooth Cutting Surface: The độ cứng of tungsten carbide creates a smooth cutting surface, which reduces the friction between the tool and the material being cut.

Minimized Edge Wear: Due to its resistance to friction, the cutting edge of a tungsten carbide tool stays sharp for longer, reducing the need for re-sharpening.

Fewer Tool Changes: The reduced friction means that tungsten carbide tips last longer, which reduces downtime for tool changes and increases overall productivity.

By reducing friction, tungsten carbide tips help maintain cutting speed and precision while minimizing the cost of tool replacements.

4. Tungsten Carbide’s Impact Resistance for Heavy-Duty Cutting Jobs

In high-friction environments, cutting tools are often subjected to sudden shocks or heavy impacts.

Tungsten carbide tips can withstand these forces without breaking or chipping, making them ideal for heavy-duty cutting tasks.

How Tungsten Carbide Handles Impact:

Độ dẻo dai: While tungsten carbide is hard, it is also tough enough to absorb the impact from heavy cutting loads, making it resistant to cracking or chipping.

Impact Resistance: Tungsten carbide tips are designed to endure the repeated stress and impact that occurs in cutting operations such as khai thác mỏ or machining of tough alloys.

Stable Performance: The toughness of tungsten carbide ensures that the tips maintain stable cutting performance, even under high-impact conditions.

This combination of hardness and toughness makes tungsten carbide tips suitable for demanding applications, where impact resistance is just as important as wear resistance.

5. Improved Cutting Efficiency and Productivity

Tungsten carbide tips help improve the overall efficiency and productivity of cutting operations by maintaining sharpness, speed, and precision.

With the ability to withstand both high heat and friction, tungsten carbide tips allow operators to push the limits of cutting performance.

Benefits to Cutting Efficiency:

Higher Cutting Speeds: Tungsten carbide allows for faster cutting speeds without compromising tool life or cutting quality.

Reduced Tool Maintenance: Tools with carbide tips require less frequent maintenance and fewer tool changes, resulting in less downtime.

Cleaner Cuts: The smooth and sharp edge of tungsten carbide tips provides cleaner, more precise cuts, reducing the need for post-processing and improving the quality of the workpiece.

These improvements in cutting efficiency help manufacturers increase throughput, lower operational costs, and achieve better results in less time.

6. Cost Benefits of Tungsten Carbide Tips in High-Heat and High-Friction Cutting Jobs

While tungsten carbide tips can have a higher upfront cost than other materials, they offer significant cost savings in the long run.

The durability, wear resistance, and heat resistance of tungsten carbide tips lead to fewer tool changes and reduced downtime, resulting in lower total cost of ownership.

Cost Advantages of Tungsten Carbide Tips:

Longer Tool Life: Tungsten carbide tips last much longer than standard tools, reducing the need for replacements.

Chi phí bảo trì thấp hơn: With their resistance to wear, carbide-tipped tools require less maintenance and fewer repairs.

Increased Productivity: Faster cutting speeds and longer-lasting tools help improve productivity, reducing labor and downtime costs.

In high-heat and high-friction cutting jobs, tungsten carbide tips provide a clear return on investment by reducing overall operational costs and increasing productivity.

7. Applications of Tungsten Carbide Tips in High-Heat and High-Friction Cutting Jobs

Tungsten carbide tips are used in a wide variety of applications where heat and friction are a significant factor. These include:

Common Applications Include:

Cắt kim loại: Tungsten carbide tips are used in tools that cut through metals like steel, aluminum, and titanium, where high friction and heat are generated.

Khai thác mỏ: Carbide tips are used in tools for cutting through hard rock and earth, where high impact and wear resistance are crucial.

Hàng không vũ trụ: Cutting aerospace alloys requires tools that can handle extreme temperatures and high-speed operations.

Chế biến gỗ: Tungsten carbide is also used in cutting tools for woodworking, where friction and heat can cause rapid tool wear.

These applications show the versatility and performance of tungsten carbide in various industries.

Phần kết luận

Tungsten carbide tips are the ideal solution for cutting jobs that involve high heat and high friction.

Their hardness, heat resistance, and wear resistance make them perfect for cutting through tough materials while maintaining performance and tool life.

By investing in tungsten carbide tips, businesses can improve cutting efficiency, reduce tool replacement costs, and increase productivity.

Whether you’re in metal cutting, mining, or aerospace, tungsten carbide tips offer unmatched performance in high-heat and high-friction environments.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.