Dụng cụ cắt cacbua đã trở nên thiết yếu trong các hoạt động tiện hiện đại. Những dụng cụ này được biết đến với độ cứng cao, tuổi thọ cao và khả năng cắt các vật liệu cứng như thép không gỉ, thép tôi và gang.

Đối với các công ty muốn tăng hiệu quả gia công và giảm thời gian chết máy, việc lựa chọn dụng cụ tiện cacbua là một bước đi thông minh và mang tính chiến lược.

Trong hướng dẫn này, chúng tôi sẽ giải thích cách thức hoạt động của dụng cụ cacbua trên máy tiện, khám phá các loại, ưu điểm, mẹo về hiệu suất và cách chọn dụng cụ cacbua phù hợp để cải thiện năng suất.

Dụng cụ cắt cacbua là gì?

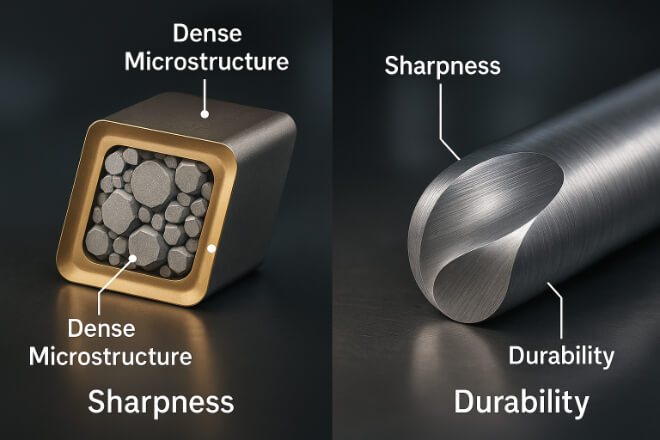

Dụng cụ cắt cacbua được làm từ cacbua vonfram, một vật liệu rất cứng có thể chịu được nhiệt độ và áp suất cao.

Chúng cứng hơn thép gió (HSS) và giữ được độ sắc bén lâu hơn. Điều này khiến chúng trở nên lý tưởng để cắt kim loại, nhựa và các vật liệu cứng khác trên máy tiện.

Dụng cụ cacbua có thể thực hiện các công việc cắt liên tục, hoạt động tốc độ cao và các vật liệu có thể làm mòn dụng cụ mềm nhanh chóng.

Tại sao nên sử dụng dụng cụ cắt cacbua trong máy tiện?

Máy tiện hoạt động bằng cách xoay phôi trong khi dụng cụ cắt gọt vật liệu. Trong quá trình này, độ bền và khả năng giữ cạnh của dụng cụ là rất quan trọng. Đó chính là điểm mạnh của dụng cụ cacbua.

Lợi ích chính của dụng cụ tiện cacbua:

Tuổi thọ dụng cụ dài hơn HSS

Tốc độ cắt cao hơn cho sản xuất nhanh hơn

Bề mặt hoàn thiện tốt hơn trên các bộ phận cuối cùng

Giảm thời gian chết nhờ ít thay đổi công cụ hơn

Hiệu suất ổn định ở nhiệt độ cao

Bằng cách giảm thiểu hao mòn và gia công lại dụng cụ, dụng cụ tiện cacbua giúp giảm tổng chi phí sản xuất.

Các loại dụng cụ cắt cacbua cho máy tiện

Các thao tác tiện khác nhau cần hình dạng dụng cụ khác nhau. Việc lựa chọn hình dạng phù hợp giúp cải thiện cả tuổi thọ dụng cụ và chất lượng chi tiết.

| Loại công cụ | Sử dụng chung |

|---|---|

| Chèn tiện | Tiện tổng quát và tạo hình đường viền |

| Dụng cụ chia tách và rãnh | Cắt bỏ các bộ phận hoặc tạo rãnh |

| Chèn ren | Tạo luồng bên trong hoặc bên ngoài |

| Quán bar nhàm chán | Mở rộng lỗ bên trong |

| Công cụ lập hồ sơ | Hình dạng và đường viền phức tạp |

Mỗi loại dụng cụ có nhiều loại cacbua và lớp phủ khác nhau, phù hợp với các vật liệu và nhu cầu hiệu suất khác nhau.

Chọn loại dụng cụ cacbua phù hợp

Cấp độ công cụ ảnh hưởng độ cứng, độ dẻo dai, Và khả năng chống mài mòn. Bạn phải chọn đúng loại cacbua phù hợp với công việc gia công của mình.

| Cấp độ cacbua | Tốt nhất cho | Đặc trưng |

|---|---|---|

| Thép loại P | Cắt thép và thép hợp kim | Độ bền và khả năng chịu nhiệt cao |

| K-grade (Gang) | Gang, vật liệu không chứa sắt | Cứng và chống mài mòn |

| Cấp M (Thép không gỉ) | Thép không gỉ và hợp kim | Độ bền và độ mài mòn cân bằng |

Nhà cung cấp dụng cụ cacbua sẽ hướng dẫn bạn lựa chọn loại tốt nhất cho nhu cầu của bạn.

Lớp phủ cải thiện hiệu suất

Lớp phủ dụng cụ có thể cải thiện đáng kể tốc độ cắt, giảm mài mòn và giảm ma sát. Các lớp phủ phổ biến bao gồm:

| Lớp phủ | Lợi ích | Sử dụng điển hình |

|---|---|---|

| TiN (Titan Nitride) | Tăng độ cứng và khả năng chống mài mòn | Gia công chung |

| TiAlN (Titan nhôm nitride) | Khả năng chịu nhiệt cao | Cắt khô, thép cứng |

| AlTiN | Độ ổn định nhiệt và khả năng chống oxy hóa | Thép không gỉ, hợp kim chịu nhiệt độ cao |

| Lớp phủ kim cương | Tuyệt vời cho vật liệu không chứa sắt | Than chì, nhựa, nhôm |

Lớp phủ giúp lưỡi dao cacbua bền hơn và hoạt động tốt hơn, đặc biệt là ở tốc độ cao.

Dấu hiệu cho thấy đã đến lúc thay thế dụng cụ tiện cacbua của bạn

Ngay cả dụng cụ cacbua chất lượng cao cuối cùng cũng sẽ bị mòn. Sử dụng dụng cụ bị mòn sẽ ảnh hưởng đến độ hoàn thiện bề mặt và có thể làm hỏng cả máy và chi tiết.

Thay thế dụng cụ nếu bạn nhận thấy:

Các cạnh bị sứt mẻ hoặc gãy

Vết cháy hoặc đổi màu

Tăng độ rung hoặc tiếng ồn

Cần nhiều lực hơn khi cắt

Bề mặt hoàn thiện kém trên các bộ phận

Đừng đợi đến khi dụng cụ bị hỏng—việc thay thế theo kế hoạch sẽ tiết kiệm thời gian và bảo vệ thiết bị.

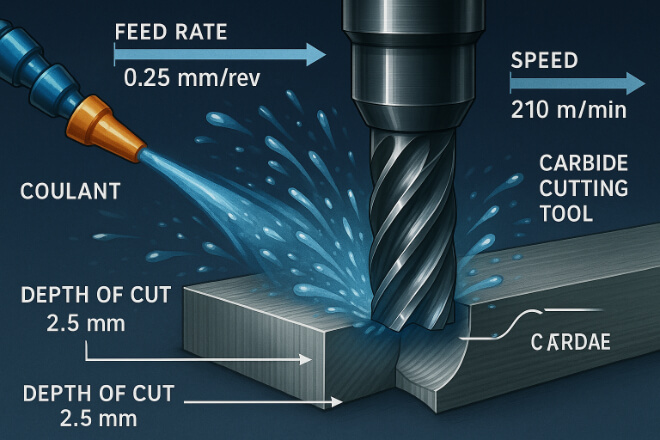

Chất làm mát và các thông số cắt quan trọng

Sử dụng dung dịch làm mát đúng cách giúp giảm tích tụ nhiệt và kéo dài tuổi thọ dụng cụ. Tương tự, việc lựa chọn tốc độ cắt, lượng chạy dao và độ sâu cắt phù hợp là rất quan trọng.

Mẹo:

Sử dụng chất làm mát gốc nước cho thép và thép không gỉ.

Sử dụng khí nén hoặc cắt khô cho nhôm (để tránh BUE—cạnh tích tụ).

Bắt đầu với các thông số cắt được nhà sản xuất khuyến nghị.

Điều chỉnh tốc độ/luồng dao dựa trên vật liệu và độ mòn của dụng cụ.

Chi phí so với hiệu suất: Carbide có đáng giá không?

Dụng cụ cacbua có giá ban đầu cao hơn—nhưng đó chỉ là một phần của câu chuyện. Điều quan trọng là chi phí cho mỗi bộ phận, chứ không phải chi phí cho mỗi dụng cụ.

| Nhân tố | Dụng cụ HSS | Dụng cụ cacbua |

|---|---|---|

| Tuổi thọ công cụ | Ngắn | Dài |

| Tốc độ cắt | Chậm hơn | Nhanh hơn |

| Hoàn thiện bề mặt | Trung bình | Xuất sắc |

| Tần suất thay đổi công cụ | Thường | Hiếm khi |

| Tổng chi phí theo thời gian | Cao hơn | Thấp hơn |

Với ít thay đổi công cụ hơn và chất lượng chi tiết tốt hơn, cacbua trở thành lựa chọn kinh tế hơn cho môi trường sản xuất cao.

Chọn nhà cung cấp phù hợp

Chất lượng dụng cụ cacbua của bạn cũng phụ thuộc vào nhà cung cấp. Một nhà cung cấp đáng tin cậy sẽ đảm bảo:

Nguyên liệu thô cao cấp

Hình dạng công cụ nhất quán

Dung sai chính xác

Hỗ trợ kỹ thuật

Giao hàng đúng hẹn

Việc lựa chọn nhà cung cấp đáng tin cậy giúp giảm thiểu tình trạng hỏng hóc dụng cụ, thời gian chết và lỗi linh kiện.

Suy nghĩ cuối cùng

Dụng cụ cắt cacbua là một khoản đầu tư mạnh mẽ cho gia công tiện. Từ gia công thô đến hoàn thiện chính xác, chúng vượt trội hơn các dụng cụ truyền thống về tốc độ, độ bền và độ chính xác.

Với hình dạng dụng cụ, lớp phủ và nhà cung cấp phù hợp, xưởng của bạn có thể sản xuất các bộ phận tốt hơn—nhanh hơn và rẻ hơn.

Nếu bạn muốn cải thiện tuổi thọ dụng cụ, tốc độ cắt và năng suất thì dụng cụ cacbua vonfram chính là giải pháp phù hợp.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.