Các bộ phận hao mòn cacbua vonfram được sử dụng trong các ngành công nghiệp mà dụng cụ phải chịu mài mòn, nhiệt độ cao hoặc va đập mạnh. Nhưng không phải tất cả cacbua vonfram đều giống nhau.

Mỗi loại thép được sản xuất để phù hợp với các điều kiện làm việc khác nhau. Chọn sai loại thép có thể dẫn đến hỏng hóc sớm, chi phí cao hơn và thời gian ngừng hoạt động. Chọn đúng loại thép sẽ đảm bảo tuổi thọ và hiệu suất tối đa cho dụng cụ.

Trong hướng dẫn này, chúng tôi sẽ giải thích ý nghĩa của điểm số, sự khác biệt giữa chúng và cách chọn điểm số phù hợp cho đơn đăng ký của bạn.

Mục tiêu là làm cho quá trình này trở nên đơn giản và rõ ràng, đặc biệt là đối với những người ra quyết định trong sản xuất, khai thác mỏ, dầu khí, gia công kim loại và các ngành công nghiệp nặng khác.

Hiểu về các loại cacbua vonfram

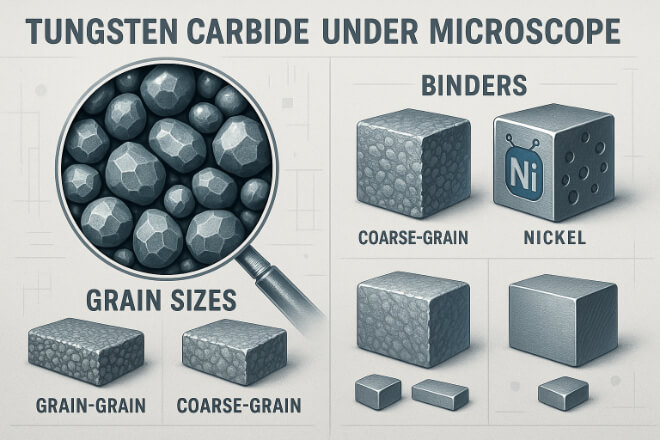

Cấp độ cacbua vonfram là sự kết hợp của hai thành phần chính:

Kích thước hạt của các hạt cacbua

Loại chất kết dính và tỷ lệ phần trăm (thường là coban hoặc niken)

Các hỗn hợp khác nhau thay đổi độ cứng, độ dẻo dai, Và khả năng chống mài mòn của một phần.

Sự cân bằng giữa độ cứng và độ dẻo dai

Độ cứng có nghĩa là khả năng chống mài mòn, trong khi độ dẻo dai có nghĩa là khả năng chống vỡ hoặc sứt mẻ.

Cao hơn độ cứng → khả năng chống mài mòn tốt hơn, nhưng khả năng chống va đập kém hơn.

Cao hơn độ dẻo dai → khả năng chống va đập tốt hơn, nhưng khả năng chống mài mòn kém hơn một chút.

Đây là lý do tại sao mũi khoan khai thác và khuôn cắt chính xác sử dụng các loại vật liệu rất khác nhau.

Các loại cacbua vonfram phổ biến và công dụng của chúng

| Loại lớp | Thuộc tính chính | Tốt nhất cho |

|---|---|---|

| Cacbua hạt mịn | Độ cứng cao, khả năng chống mài mòn tuyệt vời | Dụng cụ cắt chính xác, khuôn mẫu, vòi phun chống mài mòn |

| Cacbua hạt thô | Độ bền cao hơn, khả năng chống va đập | Công cụ khai thác, mũi khoan, bộ phận chịu mài mòn nặng |

| Cacbua dưới micron | Độ cứng cực cao, bề mặt mịn | Dụng cụ y tế, gia công tinh xảo, linh kiện chính xác |

| Cacbua liên kết niken | Khả năng chống ăn mòn | Van dầu khí, bơm hóa chất, ứng dụng hàng hải |

Các yếu tố cần xem xét khi chọn điểm

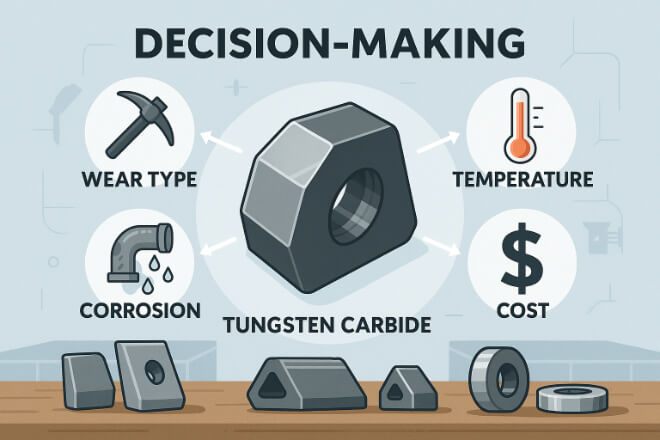

Khi lựa chọn loại cacbua vonfram, người ra quyết định nên xem xét:

Loại mài mòn – Là mài mòn do mài mòn, mài mòn do va chạm hay kết hợp cả hai?

Nhiệt độ hoạt động – Một số chất kết dính hoạt động tốt hơn ở nhiệt độ cao.

Rủi ro ăn mòn – Nếu bộ phận ở trong môi trường hóa chất hoặc ẩm ướt, lớp phủ niken sẽ hữu ích.

Chi phí so với Hiệu suất – Loại cao cấp hơn có thể đắt hơn nhưng có thể bền hơn nhiều.

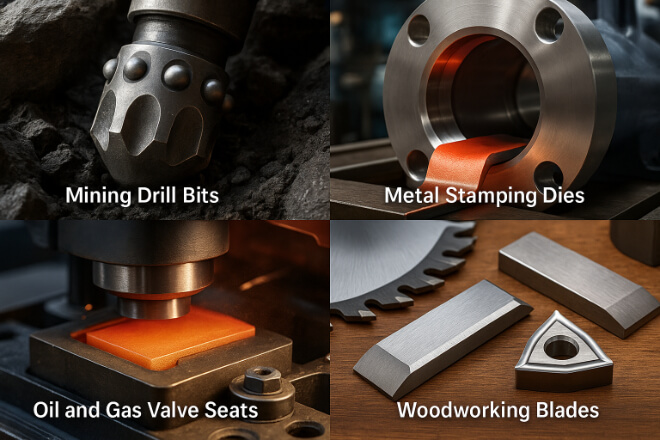

Ví dụ về ngành

Khai thác mỏ: Cacbua hạt thô có khả năng chống va đập khi khoan và nghiền.

Tạo hình kim loại: Cacbua hạt mịn dùng cho khuôn và đầu đột để chịu được sự mài mòn.

Dầu khí: Cacbua liên kết niken dùng cho đế van tiếp xúc với chất lỏng ăn mòn.

Chế biến gỗ: Cacbua hạt trung bình tạo sự cân bằng giữa độ sắc bén và độ bền.

Mẹo cho người ra quyết định

Làm việc với nhà cung cấp có thể thử nghiệm mẫu cho công việc cụ thể của bạn.

Theo dõi tình trạng hao mòn của các công cụ hiện có để hiểu rõ bộ phận nào bị hỏng trước.

Tránh chỉ định quá mức — cấp độ đắt tiền hơn không phải lúc nào cũng cải thiện hiệu suất.

Phần kết luận

Việc lựa chọn loại cacbua vonfram phù hợp cần cân bằng giữa độ cứng, độ dẻo dai và nhu cầu về môi trường.

Bằng cách hiểu rõ cách thức hoạt động của các cấp độ, người ra quyết định có thể kéo dài tuổi thọ dụng cụ, giảm thời gian chết và cải thiện hiệu quả. Lựa chọn đúng đắn giúp tiết kiệm chi phí và tăng độ tin cậy về lâu dài.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.