In the world of metal forming and stamping, equipment is pushed to extreme limits.

High pressure, repetitive motion, and constant friction can quickly wear down ordinary tool materials. This is why carbide wear parts have become a trusted choice for many manufacturing companies.

Được biết đến với độ cứng, khả năng chống mài mòn, and long service life, carbide parts help industries reduce downtime and improve production efficiency.

This article will explain what carbide wear parts are, why they are ideal for metal forming and stamping, and where they are used in these processes.

What Are Carbide Wear Parts?

Carbide wear parts are components made from tungsten carbide, a material created by combining tungsten powder with a metal binder (usually cobalt). The result is a material that is:

Extremely hard (second only to diamond)

Resistant to wear and abrasion

Capable of holding its shape under high pressure and heat

Carbide wear parts are used in many industries, but they are especially valuable in metal forming and stamping because of their ability to maintain precision under heavy loads.

Why Carbide Is Ideal for Metal Forming and Stamping

Metal forming and stamping require tools to press, cut, and shape metal sheets with high force and speed.

This puts enormous stress on tool surfaces. Carbide wear parts are ideal for this work because they provide:

Thượng đẳng khả năng chống mài mòn – Withstands thousands of cycles without losing precision.

Heat resistance – Works well even in high-temperature forming processes.

Strength under pressure – Maintains shape and accuracy in heavy-duty operations.

Reduced downtime – Longer tool life means fewer replacements and less production stoppage.

Common Applications in Metal Forming and Stamping

| Carbide Wear Part | Function in Metal Forming & Stamping |

|---|---|

| Punches | Cut holes or shapes in metal sheets |

| Dies | Form metal into specific shapes or profiles |

| Rolls | Shape and flatten sheet metal during forming |

| Mặc tấm | Protect machine surfaces from abrasion |

| Forming tools | Shape and bend metal without cracking |

Benefits of Using Carbide Wear Parts in Stamping and Forming

Switching to carbide wear parts can transform manufacturing operations. Key benefits include:

Increased tool life – Reduces replacement costs.

Consistent product quality – Maintains accuracy over long production runs.

Better efficiency – Fewer production stops for tool changes.

Lower maintenance costs – Less frequent repairs and part replacements.

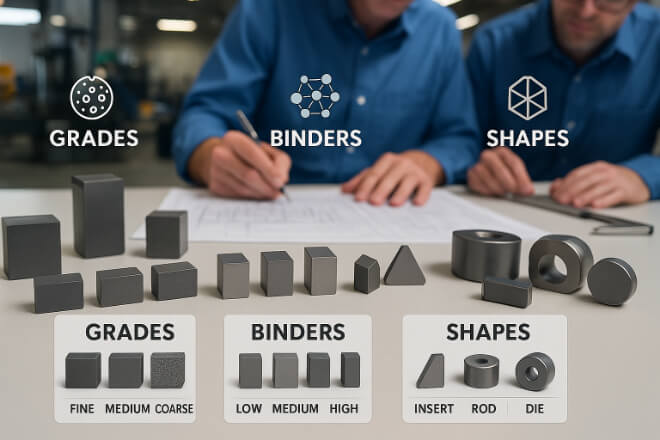

Selecting the Right Carbide Wear Parts

Choosing the right carbide wear part depends on several factors:

Material type – The metal being formed (e.g., stainless steel, aluminum).

Production volume – Higher volumes require higher wear resistance.

Forming temperature – High-heat processes need heat-resistant grades.

Precision requirements – Tighter tolerances need high-grade carbide.

Phần kết luận

Carbide wear parts play a critical role in the metal forming and stamping industry. They help manufacturers achieve high productivity, consistent quality, and cost savings.

For decision-makers, investing in high-quality carbide wear parts is not just about tool durability—it’s about keeping production efficient and competitive.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.