In many industries — from dầu khí to power generation and water treatment — pumps and compressors work non-stop under harsh conditions.

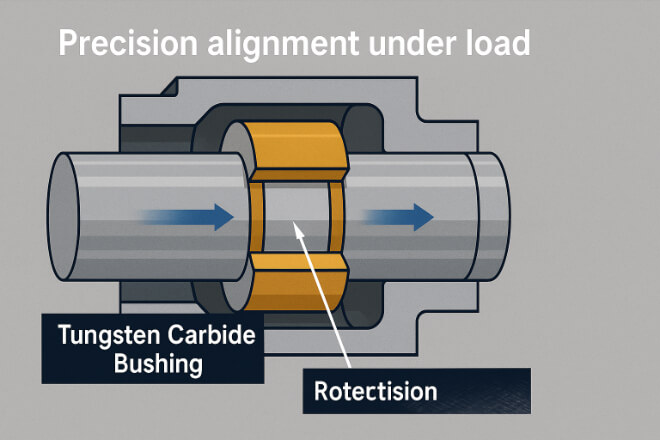

Inside these machines, bushings play a small but critical role: they support rotating shafts, reduce friction, and maintain alignment.

Among all materials used for bushings, tungsten carbide stands out for its exceptional khả năng chống mài mòn, độ cứng, and dimensional stability.

Its unique combination of mechanical and chemical properties allows pumps and compressors to run longer, with fewer breakdowns and lower maintenance costs.

This article explores the key applications of ống lót cacbua vonfram in pumps and compressors, explaining why this material is preferred for high-performance, high-reliability machinery.

Why Tungsten Carbide Bushings Are Used in Pumps and Compressors

Tungsten carbide (WC) is a compound made of tungsten and carbon atoms bonded together, usually with a small amount of metallic binder such as cobalt or nickel.

This material combines metallic strength with ceramic độ cứng, making it ideal for moving parts that face constant friction, pressure, and fluid flow.

In pumps and compressors, tungsten carbide bushings:

Support rotating shafts and impellers

Maintain precise alignment under load

Resist wear caused by sand, particles, or slurry

Withstand high pressures and temperatures

Prevent shaft vibration and leakage

In short, these bushings act as the foundation of reliability in rotating systems.

Key Performance Advantages

| Tài sản | Sự miêu tả | Impact on Equipment |

|---|---|---|

| Hardness (88–92 HRA) | Resists abrasive wear and scoring | Tuổi thọ dài hơn |

| Compressive Strength (>4000 MPa) | Maintains shape under heavy loads | Prevents shaft misalignment |

| Khả năng chống ăn mòn | Stable in chemical and wet environments | Reduced maintenance |

These properties make ống lót cacbua vonfram suitable for almost every type of pump or compressor — from high-speed chemical pumps to low-speed oilfield units.

Applications in Centrifugal Pumps

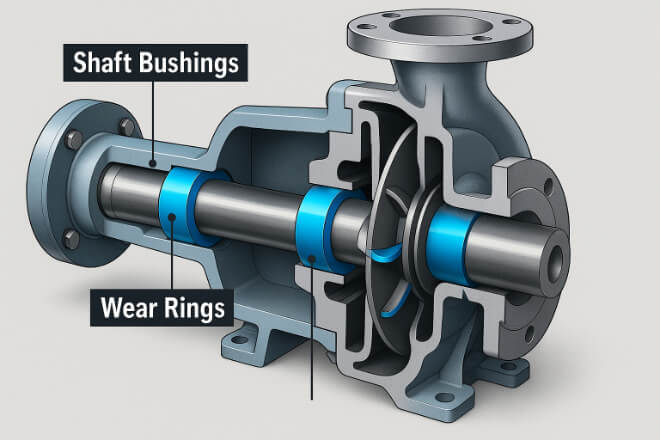

Centrifugal pumps are widely used in water systems, petrochemical plants, and power generation.

Their shafts rotate at high speed, often above 3,000 RPM, creating significant friction and heat at bearing surfaces.

Tungsten carbide bushings in centrifugal pumps serve as:

Journal bearings: Supporting the shaft to maintain alignment

Thrust sleeves: Absorbing axial loads from impeller rotation

Wear rings: Controlling clearance between impeller and casing

Because of their hard surface and low thermal expansion, carbide bushings maintain tight tolerances and prevent metal-to-metal contact — a common source of wear in conventional materials.

Applications in Screw and Rotary Compressors

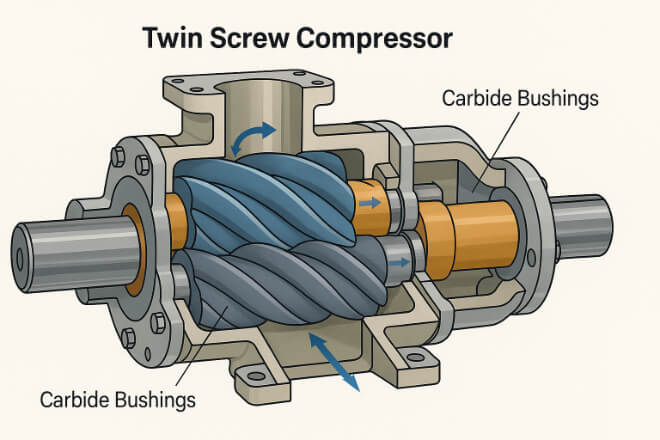

In rotary and screw compressors, the rotors or screws run at extremely high speeds under high internal pressure.

Any deformation or wear in the bushings can immediately affect sealing and compression efficiency.

Tungsten carbide bushings are used in:

Rotor support bearings

Timing gear bushings

Thrust ends and balance sleeves

Các độ cứng of carbide prevents wear caused by oil film breakdown, while its high stiffness ensures accurate rotor positioning.

This results in lower leakage, less vibration, and longer compressor life.

Applications in Multiphase and Slurry Pumps

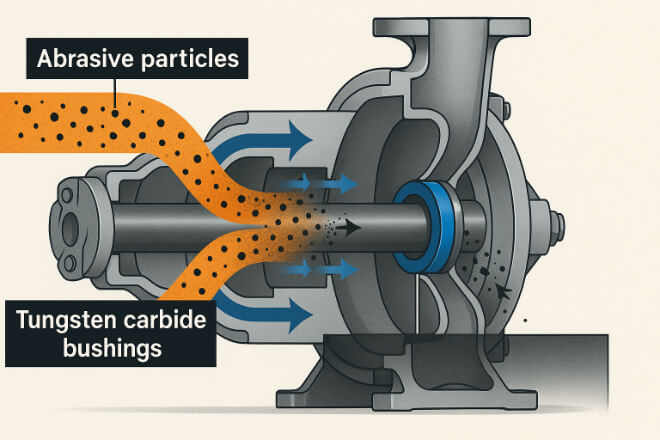

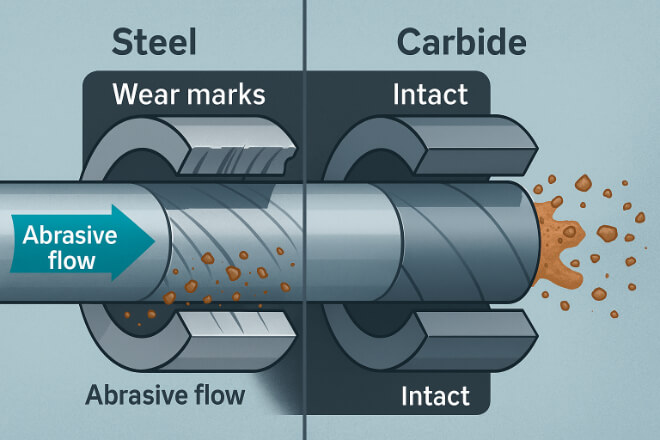

When handling slurry, mud, or multiphase mixtures, pumps face both abrasive and corrosive challenges.

Particles in the fluid act like sandpaper, eroding metal surfaces over time.

Nickel-bonded tungsten carbide bushings resist these conditions because they combine hardness with corrosion protection.

They are commonly used in:

Submersible slurry pumps

Dredge and mining pumps

Tailings transfer systems

These bushings maintain smooth surfaces, reducing friction and maintaining performance even when exposed to sand, silt, or chemical residues.

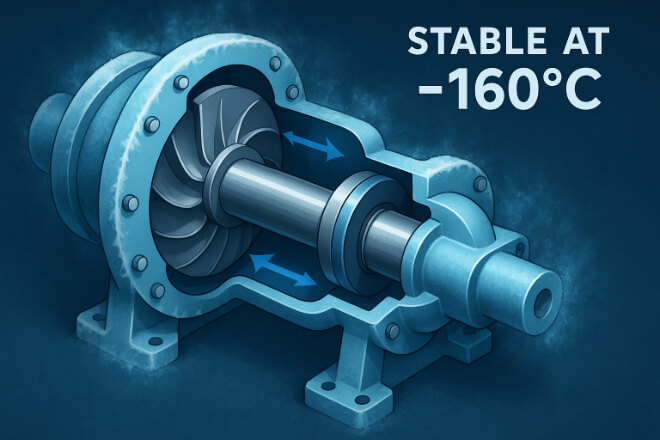

Applications in Cryogenic and LNG Compressors

In cryogenic systems and LNG (liquefied natural gas) compressors, temperatures can drop below -160°C.

At such low temperatures, many metals become brittle — but tungsten carbide remains dimensionally stable and strong.

Carbide bushings ensure that shaft alignment remains accurate even under extreme cold and pressure.

They are widely used in:

Cryogenic turbo expanders

Boil-off gas compressors

Refrigeration compressors for LNG terminals

The material’s resistance to thermal shock and low expansion rate makes it perfect for cold duty applications.

Binder Selection for Specific Applications

| Loại chất kết dính | Thuận lợi | Best Application Area |

|---|---|---|

| Coban (Co) | High toughness, excellent wear resistance | Oilfield, refinery, and general industrial pumps |

| Niken (Ni) | Better corrosion and chemical stability | Chemical and marine compressors |

Selecting the correct binder ensures both mechanical strength and khả năng chống ăn mòn for the intended application.

Common Failure Modes and How Carbide Solves Them

Traditional materials like bronze or hardened steel fail quickly in harsh environments due to wear, galling, or corrosion.

Tungsten carbide solves these problems through its hardness and chemical stability.

Common issues solved by carbide bushings:

Erosion from high-velocity particles

Misalignment wear due to shaft deflection

Thermal fatigue from temperature variation

Cavitation damage in liquid flow regions

Using carbide bushings reduces the frequency of part replacements and minimizes downtime — a key benefit for operators running continuous processes.

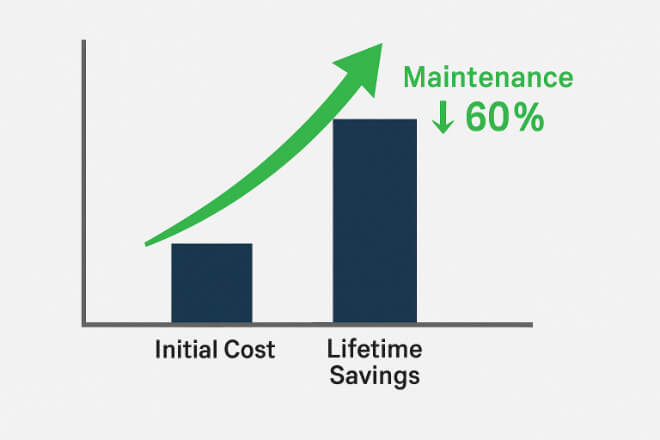

Cost and Life-Cycle Considerations

Although tungsten carbide bushings are more expensive upfront than bronze or steel, their total cost of ownership is significantly lower.

They last several times longer, require fewer replacements, and reduce shutdowns.

In critical systems such as offshore compressors or refinery pumps, this translates to substantial savings.

Example:

A chemical process pump that replaces steel bushings every 6 months can extend service intervals to 2–3 years with tungsten carbide, cutting maintenance costs by up to 60%.

Các ngành công nghiệp được hưởng lợi nhiều nhất

| Ngành công nghiệp | Typical Equipment | Performance Benefit |

|---|---|---|

| Dầu khí | Multiphase and booster pumps | High wear and pressure resistance |

| Chemical Processing | Centrifugal and metering pumps | Corrosion protection |

| Power Generation | Boiler feed and condensate pumps | Dimensional stability under heat |

| Marine | Cooling and ballast systems | Corrosion and cavitation resistance |

Phần kết luận

In pumps and compressors, tungsten carbide bushings are more than just mechanical components — they are the backbone of efficiency and reliability.

Their unique combination of hardness, strength, corrosion resistance, and precision helps operators minimize downtime, reduce energy loss, and achieve longer equipment life.

Whether in oil refineries, LNG plants, or chemical process systems, investing in tungsten carbide bushings ensures performance and protection for the most demanding applications.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.