Tungsten carbide tips are highly valued in industries that require precision and durability, such as khai thác mỏ, manufacturing, and dầu khí.

While the initial cost of tungsten carbide tips is often higher than other materials, their long-term benefits can offer substantial savings.

Understanding the Total Cost of Ownership (TCO) for tungsten carbide tips is crucial for decision-makers to determine their value over time and ensure that they are making a cost-effective choice.

In this article, we will discuss how to calculate the TCO for tungsten carbide tips, taking into account all factors that influence their overall cost and performance.

What is Total Cost of Ownership (TCO)?

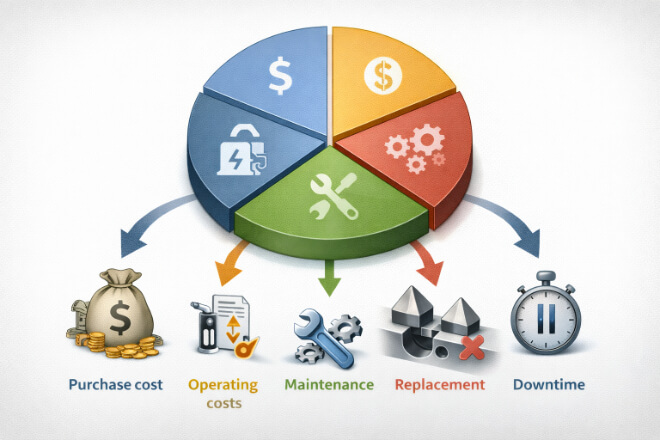

Total Cost of Ownership (TCO) refers to the comprehensive cost incurred by purchasing, using, and maintaining a product over its entire life cycle.

TCO is especially important when evaluating tools like tungsten carbide tips, where initial cost savings can be outweighed by high maintenance, repair, or replacement costs if the right product is not chosen.

The formula for calculating TCO includes several factors:

Initial Purchase Cost: The upfront cost of acquiring tungsten carbide tips.

Operating Costs: Costs related to the use of the tips, such as energy consumption and labor.

Maintenance and Repair Costs: Ongoing costs to maintain or repair the tips throughout their life.

Replacement Costs: Costs incurred when tips are no longer functional and need replacing.

Downtime Costs: The cost of equipment downtime due to worn-out or broken tips.

By calculating TCO, businesses can better assess the long-term benefits and costs associated with tungsten carbide tips.

Factors Affecting the TCO of Tungsten Carbide Tips

Several key factors influence the Total Cost of Ownership for tungsten carbide tips.

Understanding these factors can help companies make informed decisions about the best tips to purchase for their operations.

1). Initial Purchase Cost

The initial cost of tungsten carbide tips is often higher compared to other materials such as high-speed steel (HSS) or carbide-tipped tools.

However, the price varies depending on the size, quality, and material composition of the tip.

Example:

Tungsten carbide tips may have a higher upfront cost but can last much longer than HSS tips, resulting in fewer replacements and lower operational costs.

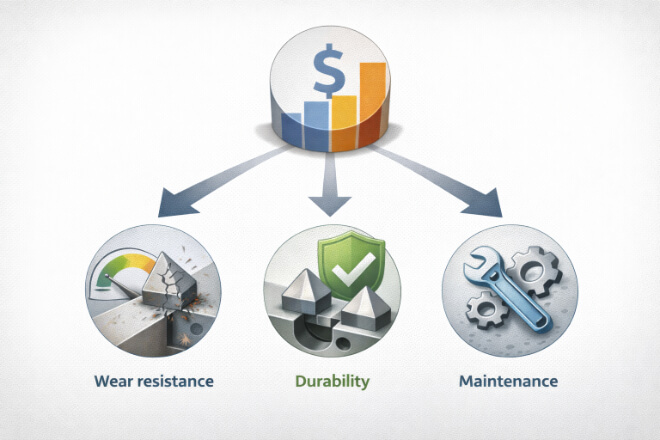

2). Durability and Khả năng chống mài mòn

One of the primary benefits of tungsten carbide tips is their exceptional durability and wear resistance.

Tips made from tungsten carbide are highly resistant to wear, reducing the frequency of replacements.

In applications with high abrasion or heavy cutting demands, the durability of tungsten carbide tips can significantly lower the cost of ownership.

Example:

Tungsten carbide tips in khai thác mỏ equipment or industrial cutting tools will require fewer replacements, leading to savings over time.

3). Maintenance and Repair Costs

Even though tungsten carbide tips are highly durable, they still require periodic maintenance to ensure they perform at optimal levels.

Maintenance costs include labor, servicing, and occasional repairs. The frequency and cost of maintenance depend on the application and operating conditions.

Example:

Regular inspection and cleaning of tungsten carbide tips can prevent premature wear and reduce the need for costly repairs.

4). Replacement Costs

Over time, tungsten carbide tips will eventually wear out and need to be replaced.

While these tips typically last longer than alternatives, the replacement cost is an important consideration.

Replacement costs should factor in not only the cost of new tips but also the time required to replace them and the potential downtime during the replacement process.

Example:

If tungsten carbide tips last for 1,000 hours before requiring replacement, compare that to other materials that may need replacement after only 500 hours.

The extended life of tungsten carbide tips means fewer replacements, which lowers overall costs.

5). Downtime Costs

Downtime is another significant factor when calculating TCO.

When tungsten carbide tips fail or need replacement, equipment may be idle, leading to lost production time.

Downtime costs include lost labor, reduced output, and the negative impact on overall operations.

Example:

If tungsten carbide tips experience minimal downtime due to their durability, this leads to better productivity and lower costs compared to frequent downtime caused by more fragile tips.

How to Calculate TCO for Tungsten Carbide Tips

To accurately calculate the Total Cost of Ownership for tungsten carbide tips, it is essential to consider all the factors discussed above. Here is a step-by-step guide to help you calculate TCO:

Step 1: Determine Initial Purchase Cost

Start by calculating the cost of purchasing the tungsten carbide tips. This includes the price per unit and the number of tips required.

Example: If each tungsten carbide tip costs $100 and you need 10 tips, the initial purchase cost is $1,000.

Step 2: Estimate Operational Costs

Calculate the ongoing costs of using the tips, including energy consumption and labor.

For example, if the tips are used in a production line, calculate the cost of the energy required to run the equipment and the labor involved in operating it.

Example: If operating the equipment with tungsten carbide tips costs $50 per hour and the equipment runs for 1,000 hours annually, the annual operational cost is $50,000.

Step 3: Account for Maintenance and Repair Costs

Estimate the costs of maintaining and repairing the tips. This includes routine inspections, servicing, and any repairs necessary to keep the tips performing well.

Example: If maintenance costs amount to $500 per year, add this to the TCO.

Step 4: Factor in Replacement Costs

Next, estimate how often the tungsten carbide tips will need to be replaced and the associated costs.

This includes both the cost of the tips themselves and any labor or downtime required for replacement.

Example: If the tips last for 1,000 hours before replacement and the cost to replace them is $1,000, the replacement cost per year would depend on how frequently the equipment is used.

Step 5: Consider Downtime Costs

Finally, estimate the downtime costs caused by replacing or maintaining the tips. This includes the loss of productivity and labor during any downtime.

Example: If replacing the tips causes 5 hours of downtime, and the average cost per hour of downtime is $500, the downtime cost per year would be $2,500.

6). Total Cost of Ownership Formula

The TCO formula is as follows:

TCO = Initial Purchase Cost + Operational Costs + Maintenance & Repair Costs + Replacement Costs + Downtime Costs

By adding these factors together, you can determine the true cost of owning and operating tungsten carbide tips over their lifetime.

Example of TCO Calculation

Let’s assume the following example for calculating TCO:

| Nhân tố | Amount |

|---|---|

| Initial Purchase Cost | $1,000 |

| Operational Costs (annually) | $50,000 |

| Maintenance & Repair Costs | $500 |

| Replacement Costs (annually) | $1,000 |

| Downtime Costs (annually) | $2,500 |

Total Annual TCO = $1,000 + $50,000 + $500 + $1,000 + $2,500 = $55,000

(The amounts used in the examples are hypothetical. For specific pricing information, please contact us.)

Key Takeaways from TCO Calculation

Tungsten carbide tips, while initially more expensive, provide long-term savings due to their durability, reducing maintenance, replacement, and downtime costs.

Regular maintenance and careful management of tungsten carbide tips can lower TCO even further, maximizing their benefits.

Phần kết luận

Understanding the Total Cost of Ownership for tungsten carbide tips is crucial for making informed decisions about their use in industrial applications.

By considering the initial purchase cost, operational costs, maintenance, replacement, and downtime, businesses can assess the long-term value of tungsten carbide tips and make cost-effective choices.

Proper management and regular maintenance of these tips can help to minimize TCO, resulting in significant savings and improved operational efficiency.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.