Ngành công nghiệp bột giấy và giấy là một trong những môi trường công nghiệp có yêu cầu khắt khe nhất.

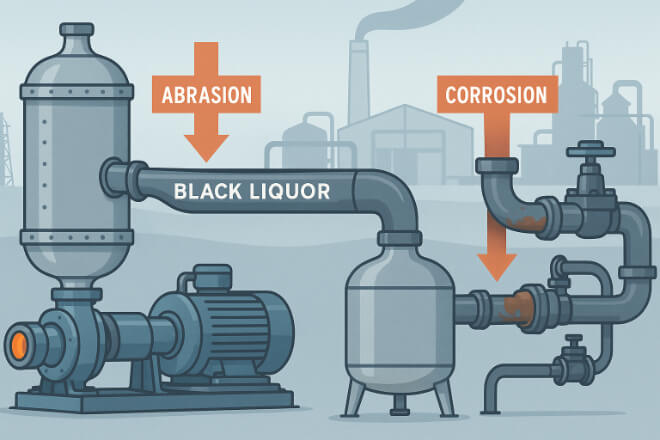

Máy bơm, máy trộn và đường ống trong các nhà máy này xử lý các sợi bột giấy mài mòn, hóa chất ăn mòn và nước đen áp suất cao.

Ngay cả những rò rỉ nhỏ cũng có thể làm gián đoạn sản xuất, làm hỏng thiết bị hoặc gây hại cho môi trường.

Vòng đệm cacbua đã trở thành giải pháp tối ưu cho lĩnh vực này. Họ cung cấp dịch vụ tuyệt vời độ cứng, khả năng chống ăn mònvà tuổi thọ cao.

Đối với những người ra quyết định, đầu tư vào phớt cacbua có nghĩa là ít hỏng hóc hơn, vận hành an toàn hơn và giảm chi phí.

Những thách thức trong dịch vụ bột giấy, giấy và rượu đen

Sợi bột mài mòn nhanh chóng làm mòn lớp niêm phong tiêu chuẩn.

Nước đen, một sản phẩm phụ của quá trình nghiền bột giấy, có tính kiềm cao và ăn mòn.

Nhiệt độ cao trong nồi hơi thu hồi hóa chất và thiết bị bay hơi gây áp lực cho thiết bị.

Hoạt động liên tục khiến thời gian ngừng hoạt động tốn kém và gây gián đoạn.

Gioăng bằng thép không gỉ hoặc than chì thường không đủ bền để chịu được những điều kiện này. Vòng đệm cacbua cung cấp sức mạnh và độ tin cậy cần thiết.

Tại sao vòng đệm cacbua là lựa chọn tốt nhất

1). Độ cứng Và Khả năng chống mài mòn

Cacbua cứng gần bằng kim cương. Nó chống trầy xước và mài mòn do sợi bột giấy và các hạt rắn trong dung dịch đen gây ra.

Cacbua liên kết niken có khả năng chống kiềm và hóa chất cao, rất lý tưởng cho hệ thống nước đen.

3). Độ bền và khả năng chống sốc

Cacbua liên kết coban xử lý được những thay đổi về áp suất và tải trọng va chạm cơ học trong máy trộn và máy bơm.

4). Độ ổn định nhiệt

Vòng cacbua vẫn duy trì hiệu suất ngay cả ở nhiệt độ cao trong quá trình tẩy trắng và phục hồi.

5). Tuổi thọ dài hơn

Giảm hao mòn và ăn mòn có nghĩa là ít phải thay thế hơn và chi phí bảo trì thấp hơn.

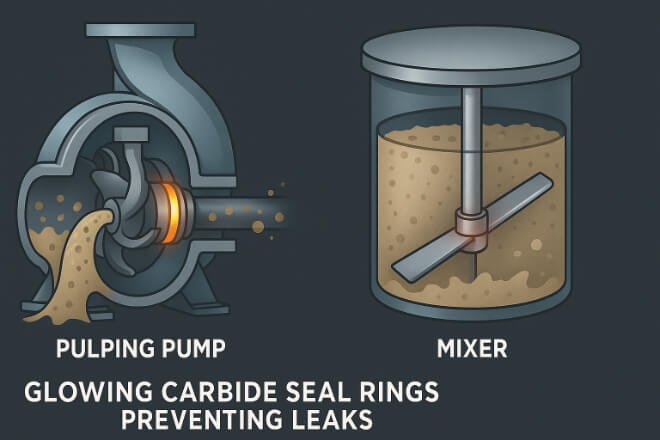

Ứng dụng trong chế biến bột giấy và giấy

1). Máy bơm nghiền bột

Vòng đệm cacbua ngăn ngừa rò rỉ trong các máy bơm chuyển hỗn hợp bột mài mòn.

2). Máy lọc và máy trộn

Việc trộn và tinh chế liên tục đòi hỏi phải có lớp đệm làm giảm ma sát và chống mài mòn.

3). Hệ thống tẩy trắng

Trong các hóa chất tẩy trắng ăn mòn, vòng cacbua duy trì độ kín đáng tin cậy.

Ứng dụng trong dịch vụ rượu đen

1). Máy bay hơi rượu đen

Phớt cacbua ngăn ngừa rò rỉ trong bộ phận bay hơi xử lý chất lỏng đen đậm đặc, ăn mòn.

2). Lò hơi thu hồi

Vòng đệm chịu được sự kết hợp của nhiệt độ cao và sự tấn công của hóa chất.

3). Mạch thu hồi hóa chất

Vòng cacbua bền bỉ cải thiện độ tin cậy trong hệ thống tái chế nước đen.

Lợi ích cho ngành công nghiệp giấy và bột giấy

| Lợi ích | Sự miêu tả |

|---|---|

| Tuổi thọ kéo dài | Chống lại bột giấy mài mòn và dung dịch ăn mòn, giảm nhu cầu thay thế. |

| Giảm thời gian chết | Ít hỏng phớt hơn giúp thiết bị hoạt động liên tục và sản xuất ổn định. |

| Cải thiện an toàn | Ngăn chặn rò rỉ chất lỏng đen nóng, có tính ăn mòn có thể gây hại cho người lao động. |

| Hiệu quả chi phí | Ít bảo trì và thay thế hơn giúp giảm tổng chi phí sở hữu. |

| Độ tin cậy của quy trình | Độ kín ổn định hỗ trợ chất lượng sản xuất giấy và bột giấy đồng đều. |

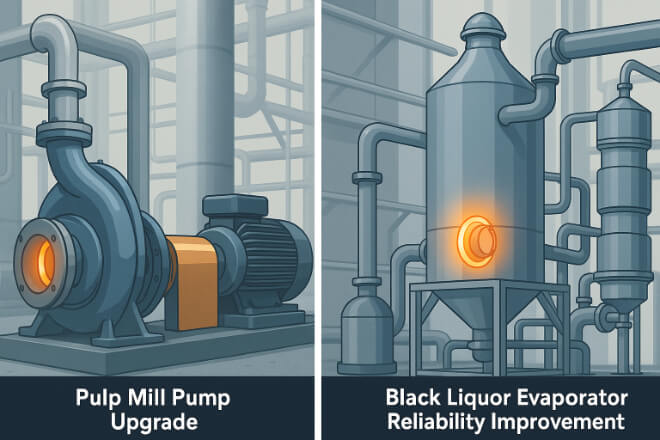

Nghiên cứu điển hình

1). Nâng cấp máy bơm nhà máy bột giấy

Một nhà máy bột giấy đã thay thế phớt thép không gỉ bằng vòng cacbua liên kết niken. Kết quả: tuổi thọ phớt tăng gấp đôi và giảm 40% chi phí bảo trì ngoài kế hoạch.

2). Độ tin cậy của thiết bị bay hơi dung dịch đen

Một nhà máy giấy đã sử dụng vòng cacbua trong thiết bị bay hơi nước đen. Kết quả: ít rò rỉ hơn, tuân thủ quy định về môi trường tốt hơn và chi phí vận hành thấp hơn.

Cách chọn vòng đệm cacbua phù hợp

1). Loại chất kết dính

Cacbua liên kết niken dùng cho chất lỏng đen ăn mòn và hóa chất tẩy trắng.

Cacbua liên kết coban dùng để chịu tải trọng va đập trong máy khuấy và máy bơm nghiền bột giấy.

2). Hoàn thiện bề mặt

Bề mặt cacbua đánh bóng giúp giảm ma sát và mài mòn trong thiết bị quay.

3). Điều kiện vận hành

Hãy cân nhắc đến nhiệt độ, áp suất và mức độ tiếp xúc với hóa chất khi lựa chọn cấp độ.

4). Chuyên môn của nhà cung cấp

Chọn nhà cung cấp có chứng chỉ ISO và có kinh nghiệm trong lĩnh vực bột giấy và giấy.

Chiến lược bảo trì và thay thế

Kiểm tra các vết nứt, rãnh hoặc hiện tượng ăn mòn ở phớt trong quá trình ngừng hoạt động theo kế hoạch.

Thay thế vòng bị mòn trước khi xảy ra rò rỉ để tránh tổn thất sản lượng.

Luôn dự trữ phớt cacbua dự phòng cho các máy bơm và máy trộn quan trọng.

Tái chế các thành phần cacbua đã qua sử dụng để giảm chi phí và tác động đến môi trường.

Cân nhắc về chi phí và ROI

Chi phí ban đầu: Cao hơn loại phớt tiêu chuẩn.

Tiết kiệm: Giảm rò rỉ và thời gian ngừng hoạt động giúp cải thiện lợi nhuận.

ROI: Tuổi thọ dài hơn và độ tin cậy được cải thiện là minh chứng cho khoản đầu tư xứng đáng.

Ưu điểm về môi trường và an toàn

Việc ngăn ngừa rò rỉ nước đen giúp bảo vệ sông ngòi, nước ngầm và công nhân nhà máy. Gioăng cacbua giúp nhà máy tuân thủ các quy định về môi trường và duy trì nơi làm việc an toàn.

Phần kết luận

Vòng đệm cacbua rất cần thiết cho các dịch vụ liên quan đến bột giấy, giấy và nước đen. Độ cứng, khả năng chống ăn mòn và độ bền của chúng khiến chúng trở thành lựa chọn tốt nhất cho những môi trường khắc nghiệt.

Đối với những người ra quyết định, phớt cacbua đảm bảo ít hỏng hóc hơn, chi phí bảo trì thấp hơn, cải thiện độ an toàn và chất lượng sản xuất ổn định - những yếu tố quan trọng để duy trì khả năng cạnh tranh trong ngành giấy và bột giấy.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.