OEM Replacement Guide: Cross-Referencing Tungsten Carbide Bushing Part Numbers

Tungsten carbide bushings are critical components in many industrial applications, known for their exceptional hardness and wear resistance. When it’s time for a replacement, ensuring the correct part number is selected is crucial to maintain performance and avoid costly downtime. Cross-referencing tungsten carbide bushing part numbers can be a challenging task, especially with multiple manufacturers […]

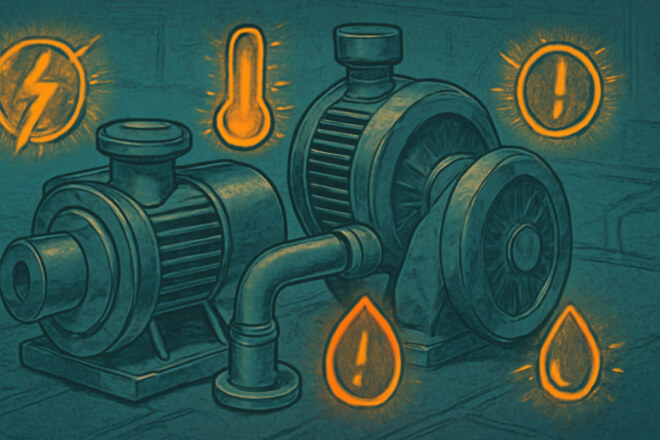

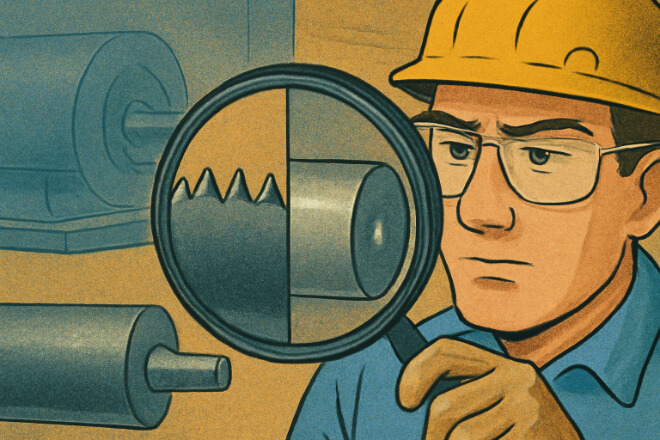

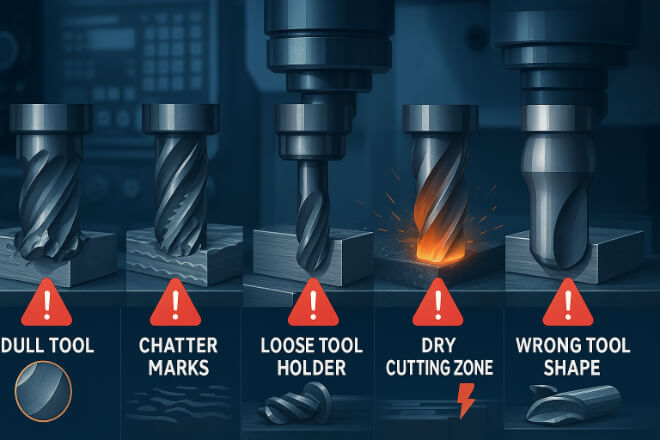

Field Checklist: Noise and Vibration Issues Affecting WC Bushings

Tungsten carbide (WC) bushings are essential components in machinery that require high strength and wear resistance. However, they are not immune to performance issues, particularly when noise and vibration arise. These problems can lead to early wear, reduced efficiency, and potential failure of the machinery. Identifying the root causes of noise and vibration is critical […]

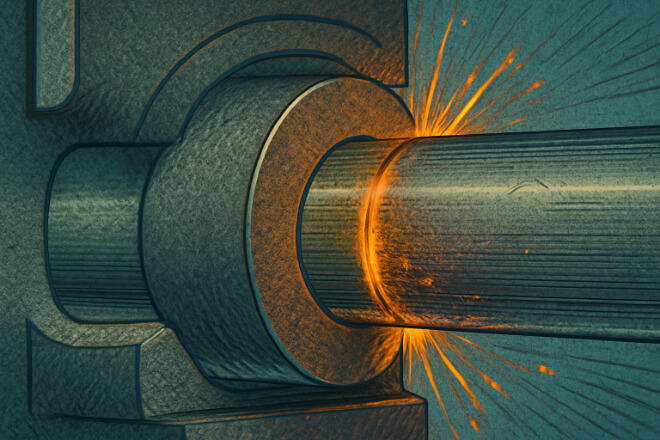

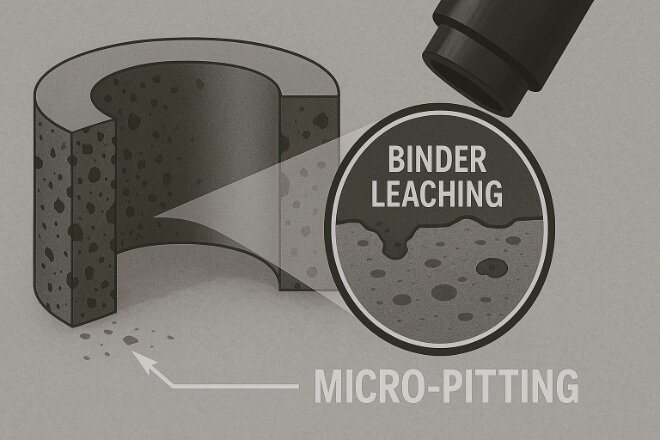

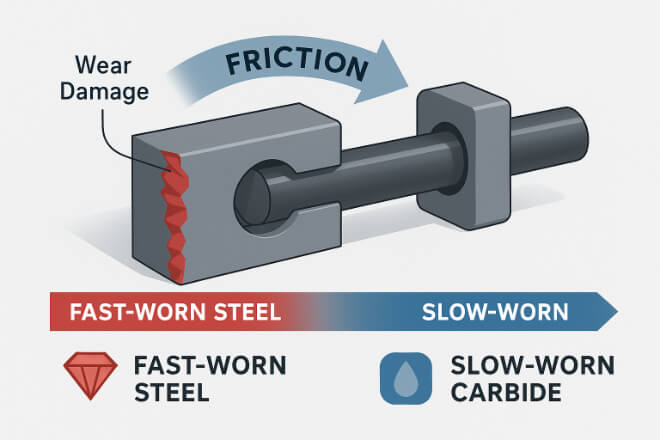

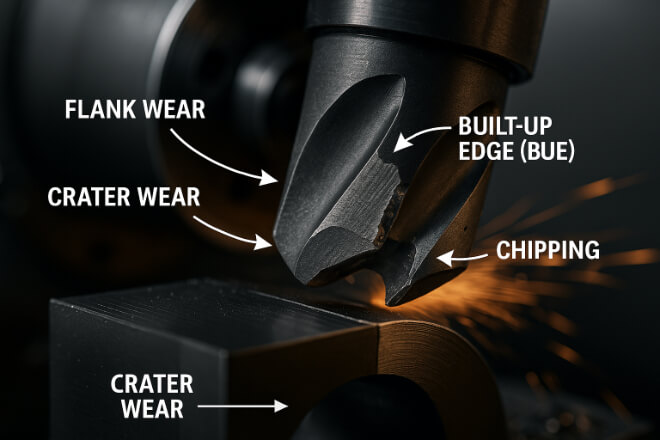

Counterface Damage Modes Against Tungsten Carbide Bushings Explained

Tungsten carbide (WC) bushings are highly durable components used in many industrial applications. They are designed to withstand high pressures, speeds, and harsh conditions. However, they can still experience damage, especially from the mating surface or counterface. Understanding the different damage modes that can occur between the bushing and its counterface is crucial for preventing […]

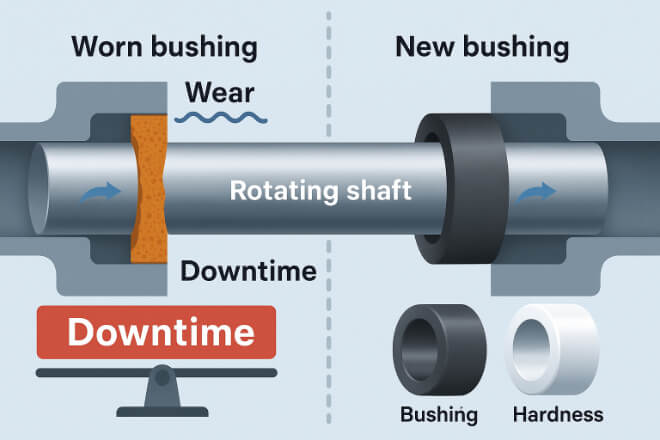

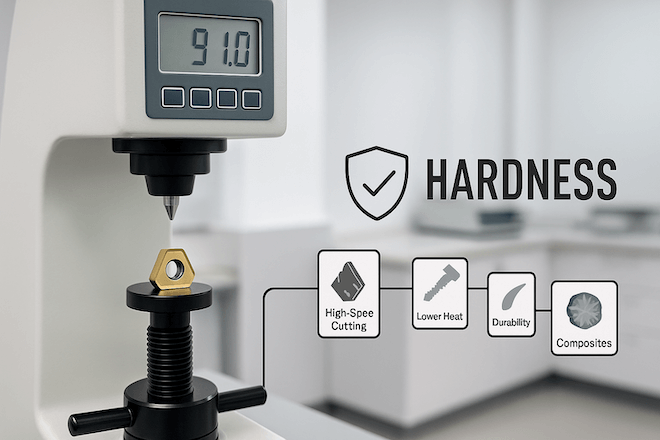

Shaft Hardness Requirements to Protect Tungsten Carbide Bushings

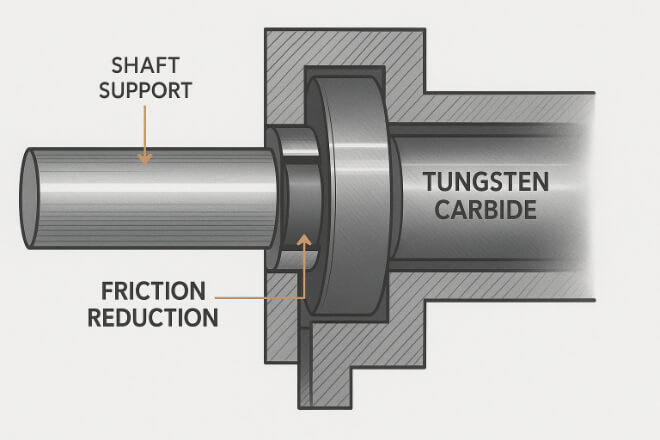

Tungsten carbide bushings are designed to handle tough industrial environments, but they can wear out prematurely if paired with shafts that don’t meet the right hardness requirements. The hardness of the shaft has a significant impact on the lifespan and performance of tungsten carbide bushings. In this article, we will explore the importance of shaft […]

Galling and Seizure in WC Bushings: How to Prevent It

Tungsten carbide (WC) bushings are commonly used in industrial applications for their durability and resistance to wear. However, even tungsten carbide can suffer from galling and seizure under certain conditions. These issues are costly and can lead to system failure. Understanding the causes of galling and seizure, and knowing how to prevent them, is essential […]

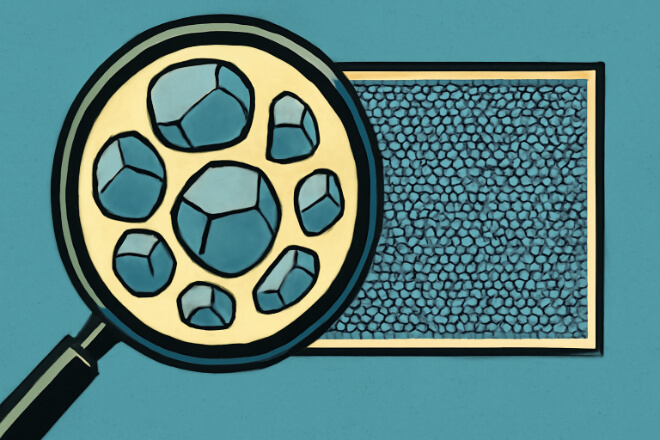

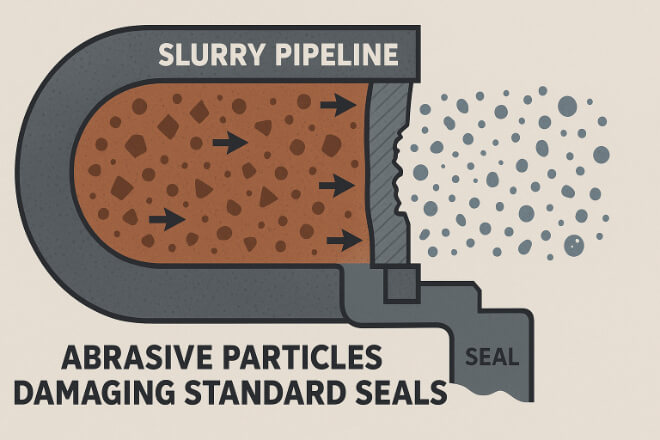

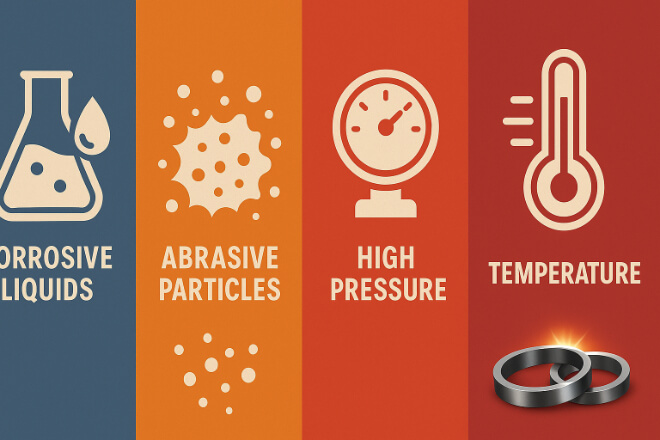

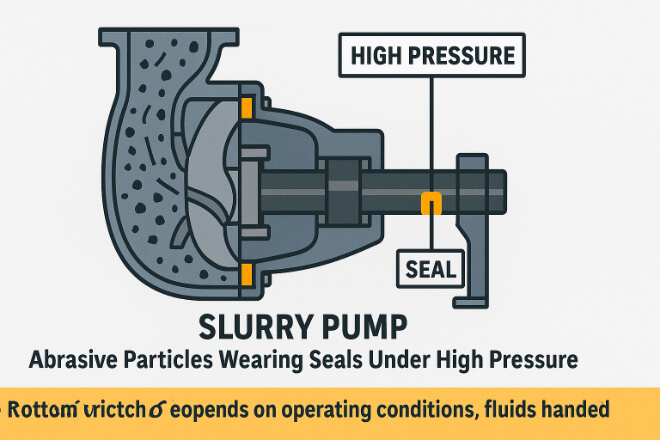

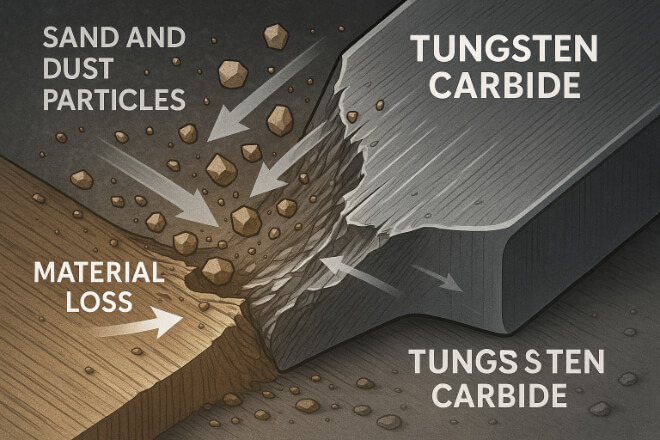

Abrasive Particle Size vs Bushing Lifespan: Practical Thresholds

Tungsten carbide bushings are widely used in pumps, compressors, and slurry systems because they resist wear better than most materials. But even tungsten carbide has limits when abrasive particles are present in the fluid. The size, hardness, and concentration of these particles have a major impact on bushing lifespan. This article explains how abrasive particle […]

Reading Wear Patterns on Tungsten Carbide Bushings: What They Tell You

Tungsten carbide bushings are used in pumps, compressors, mixers, and many rotating systems because they resist wear and last long under heavy load. But when a bushing begins to fail, the wear pattern on its surface tells a story. By reading these patterns, engineers can identify the real cause of failure and prevent the same […]

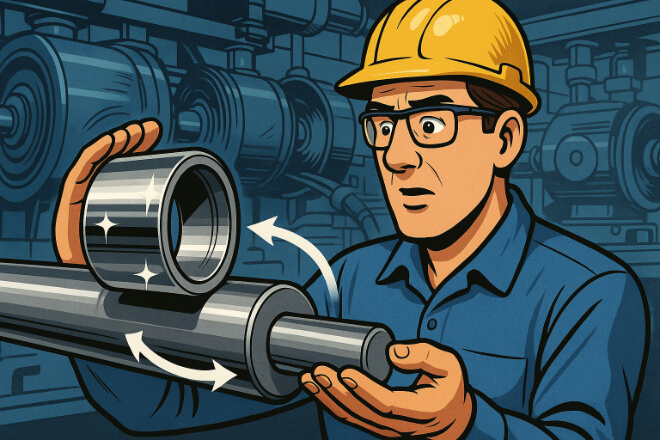

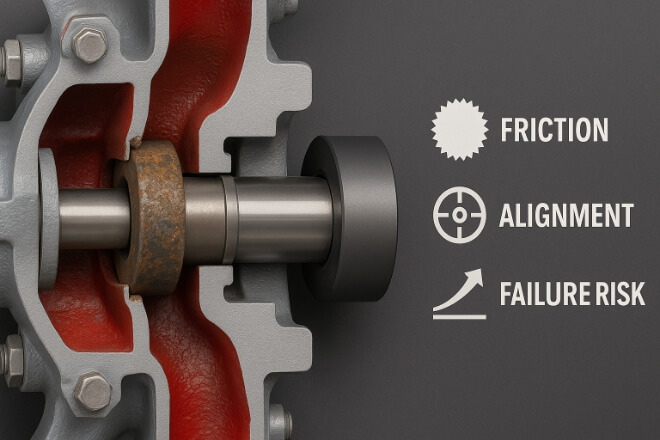

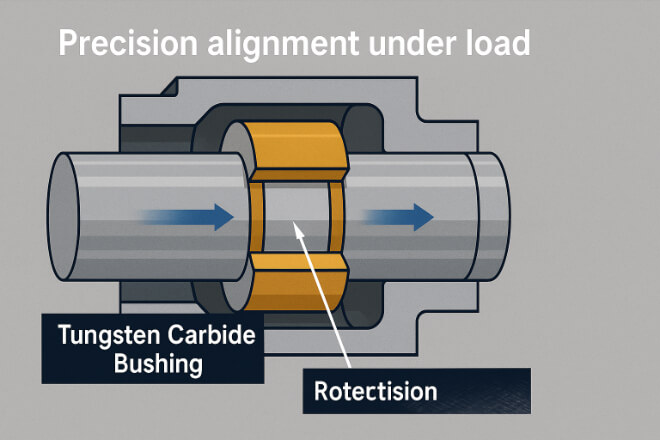

Detecting Misalignment vs Poor Clearance in WC Bushing Failures

Tungsten carbide (WC) bushings are used in pumps, compressors, and industrial machines because they resist wear and work well under heavy load. But they can still fail early when misalignment or poor clearance is present. These two problems look similar, but their causes and solutions are very different. This guide explains how to tell misalignment […]

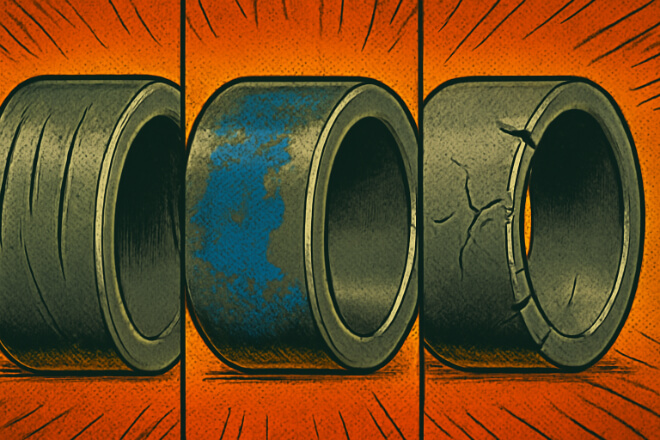

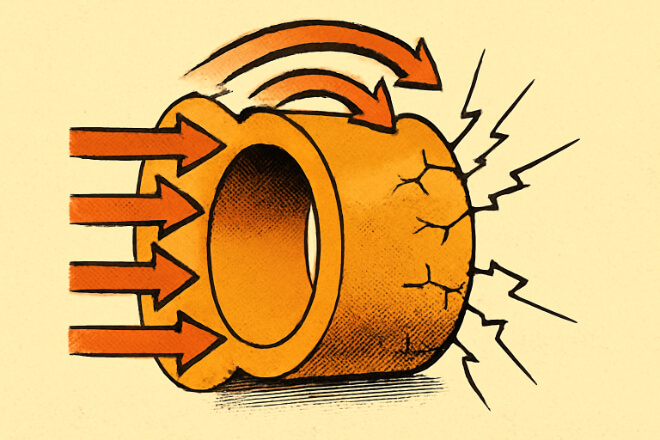

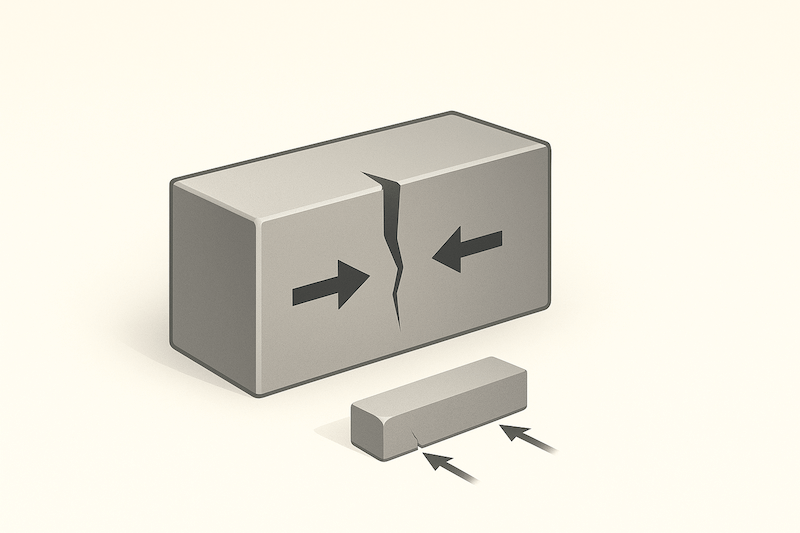

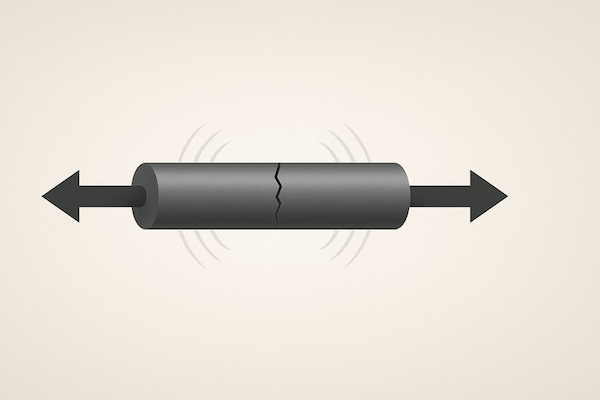

Why Tungsten Carbide Bushings Crack: Root Causes and Fixes

Tungsten carbide bushings are known for their high hardness and long life. But they can still crack when the working conditions or installation steps are not correct. Cracks reduce performance and may cause pump or machine failure. This guide explains the main reasons why these bushings crack and what you can do to avoid these […]

Storage and Packaging Best Practices for Tungsten Carbide Bushings

Tungsten carbide bushings are strong and wear-resistant, but they still need proper storage and packaging to stay in good condition. Poor handling can lead to corrosion, cracks, or size changes that affect pump or machine performance. This guide explains simple and reliable best practices for keeping your bushings safe before use. Why Proper Storage Matters […]

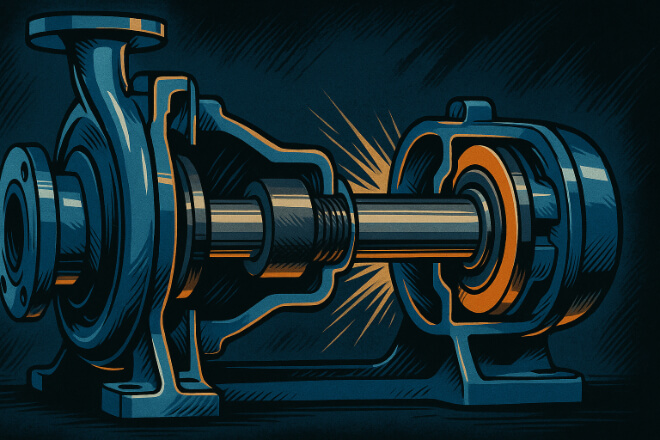

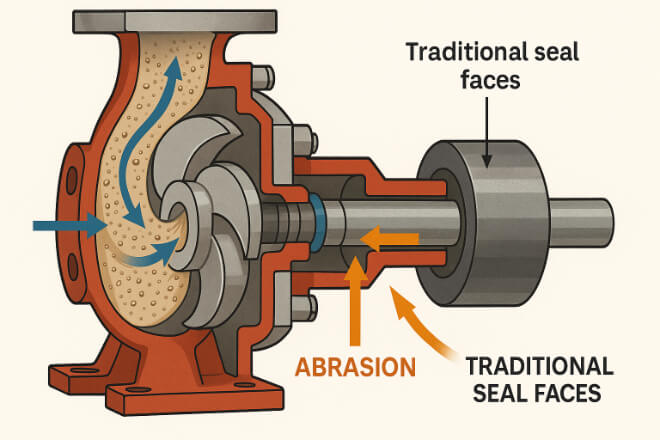

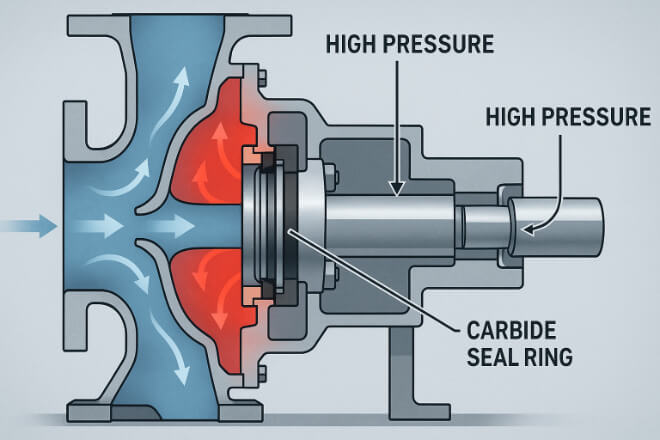

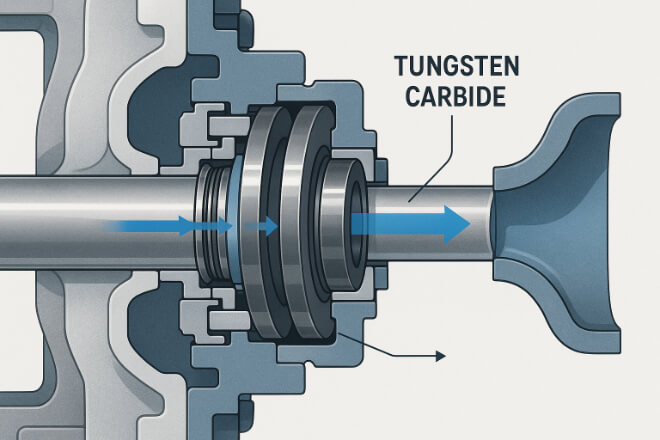

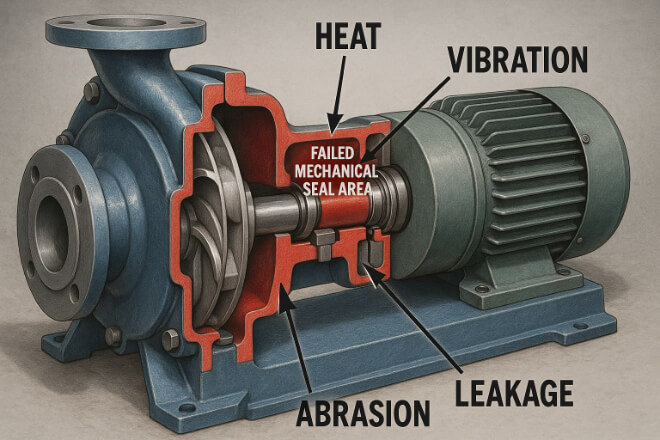

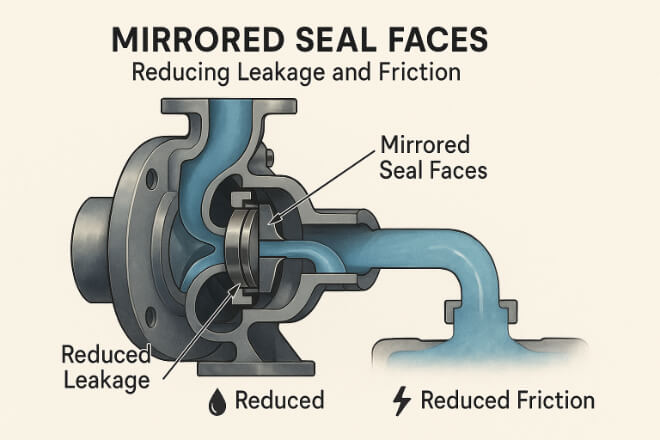

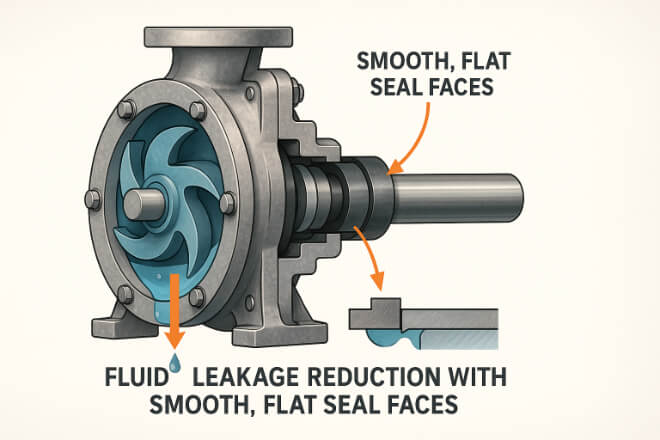

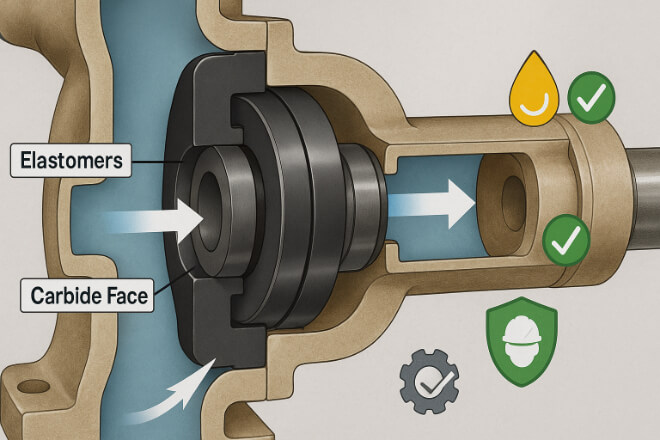

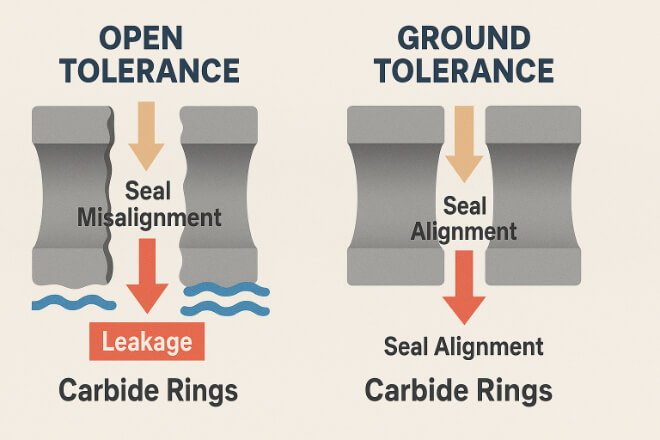

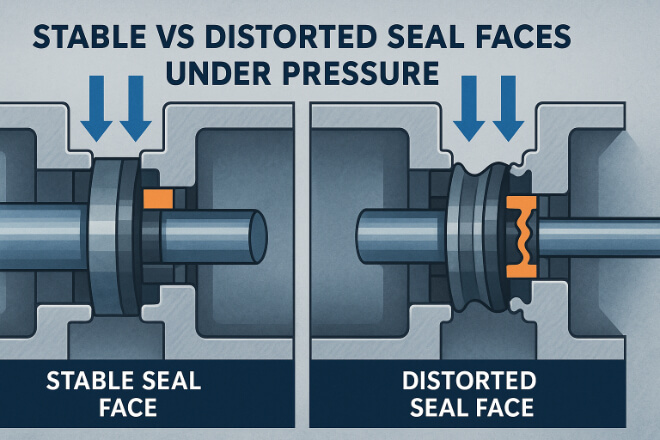

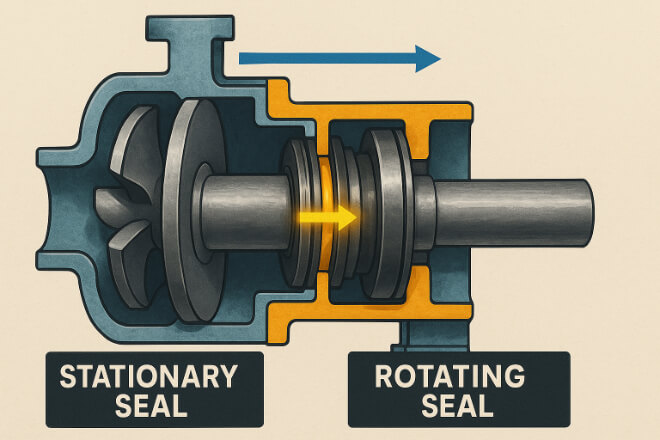

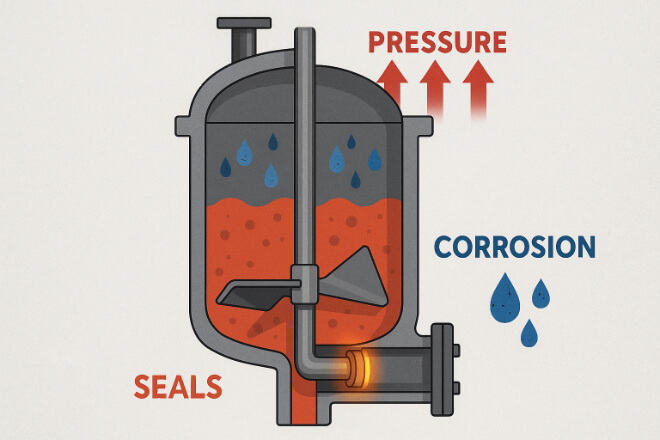

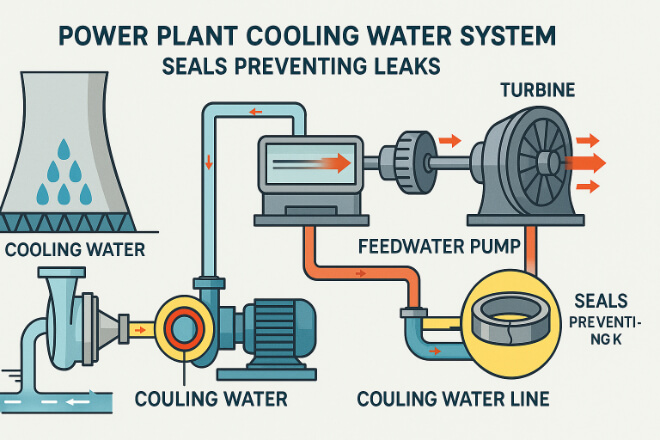

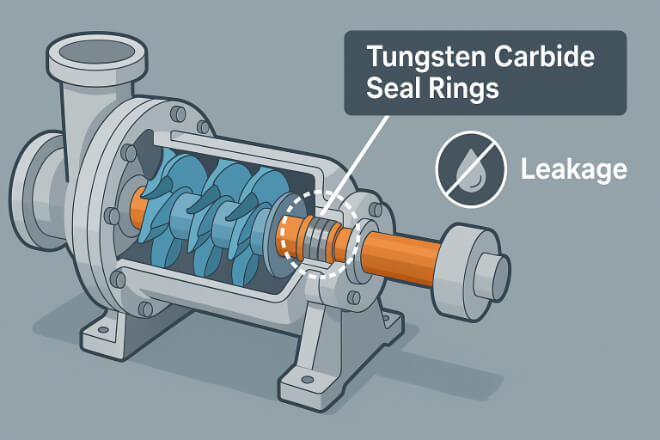

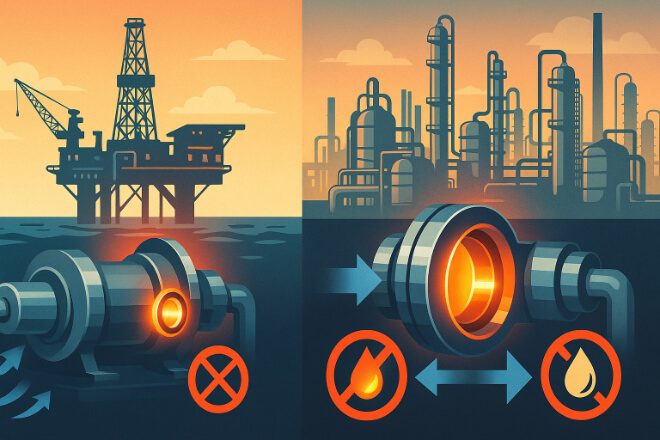

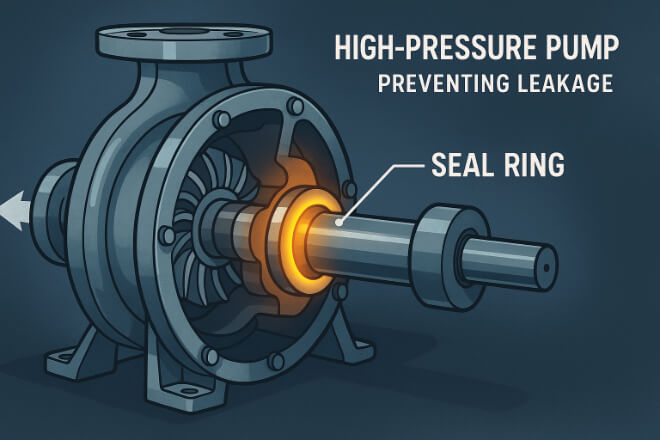

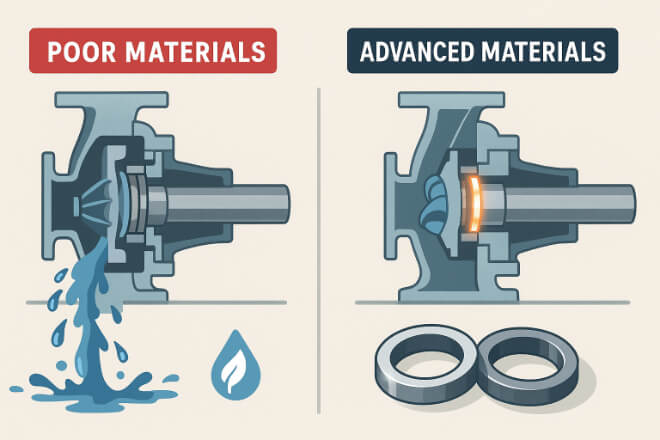

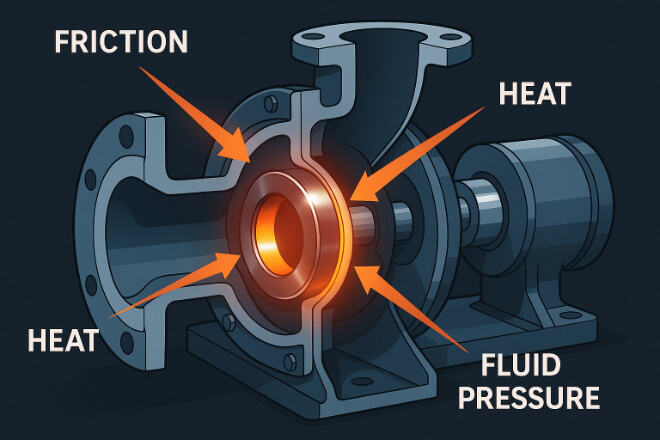

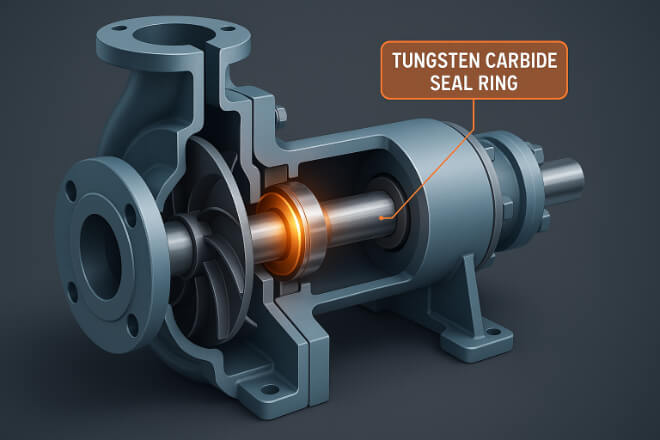

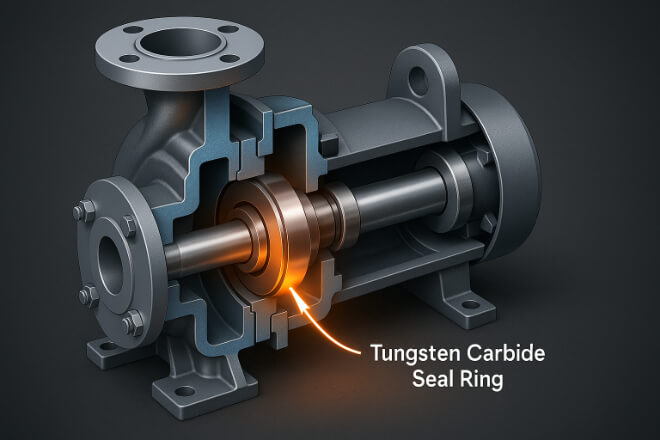

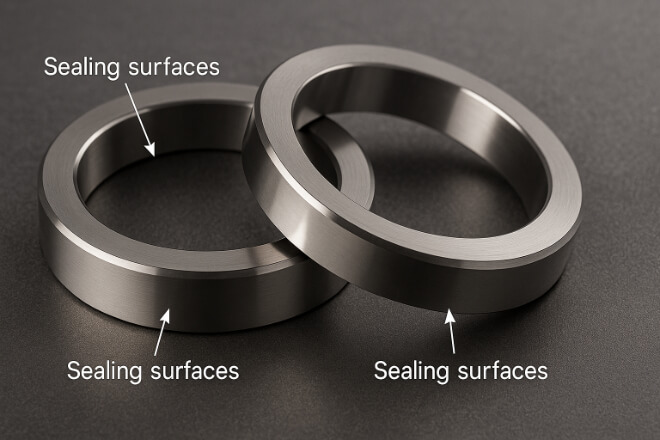

How to Pair Tungsten Carbide Bushings with Mechanical Seal Upgrades

Tungsten carbide bushings are crucial components in industrial applications, providing wear resistance and durability in harsh environments. Pairing them with the right mechanical seals is essential for ensuring system reliability and preventing leakage. Upgrading mechanical seals can significantly enhance the performance of tungsten carbide bushings, leading to longer operational lifespans and reduced maintenance costs. This […]

Vibration Diagnostics: Saving Tungsten Carbide Bushings from Premature Failure

Tungsten carbide bushings are widely used in industries requiring high durability, wear resistance, and performance in harsh conditions. However, even the toughest materials can suffer from premature failure due to vibration. In industrial applications, vibration diagnostics play a critical role in identifying issues before they lead to costly repairs or replacements. This article explores the […]

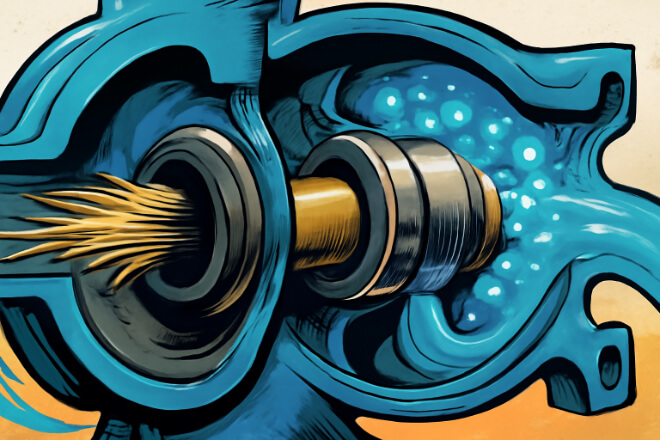

Preventing Cavitation and Erosion Damage to Tungsten Carbide Bushings

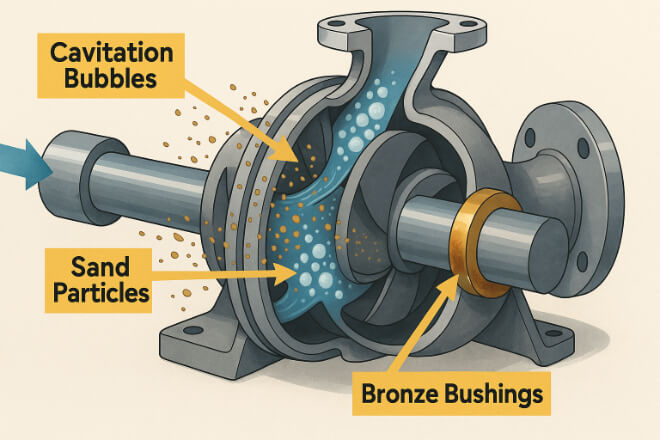

Tungsten carbide bushings are known for their durability, but they can still suffer from cavitation and erosion damage in high-demand environments. Cavitation occurs when pressure fluctuations cause bubbles to form and collapse, damaging the bushing surface. Erosion happens when abrasive particles wear down the bushing over time. This article will discuss how cavitation and erosion […]

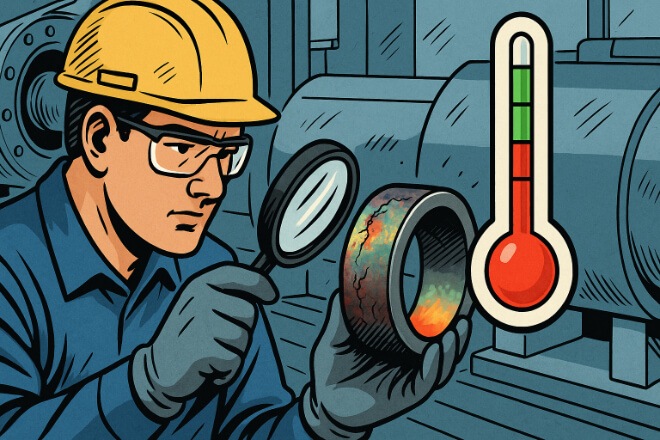

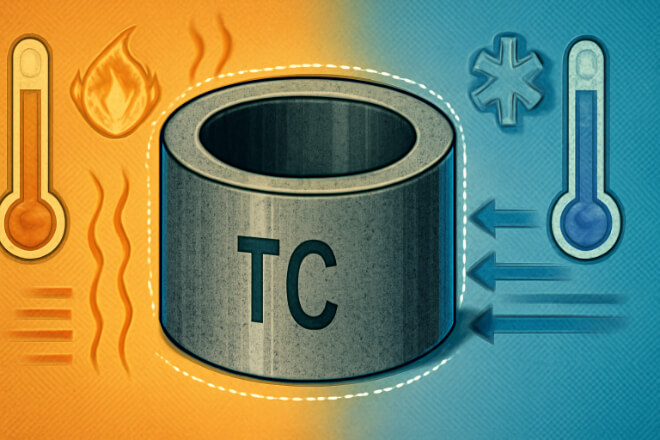

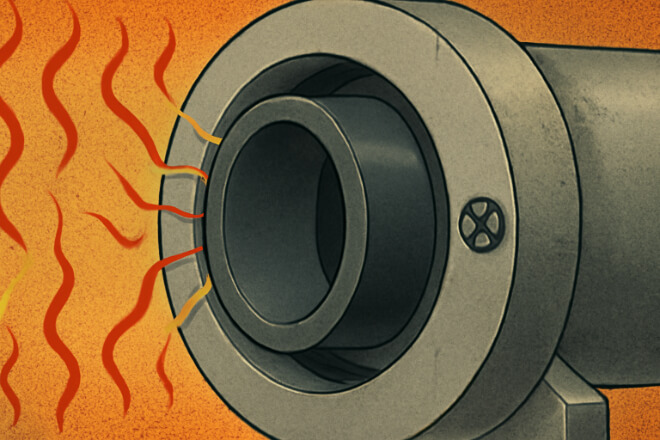

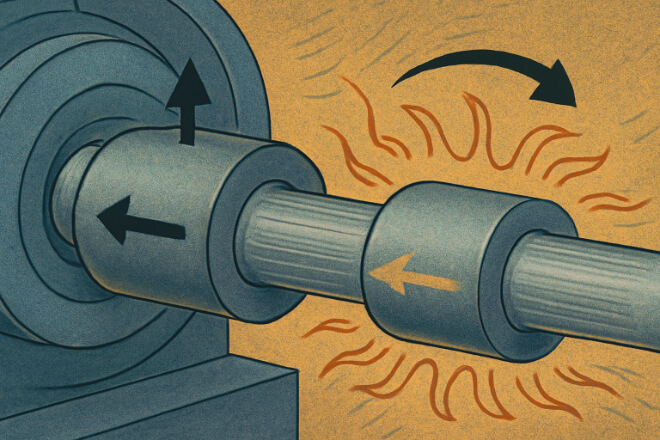

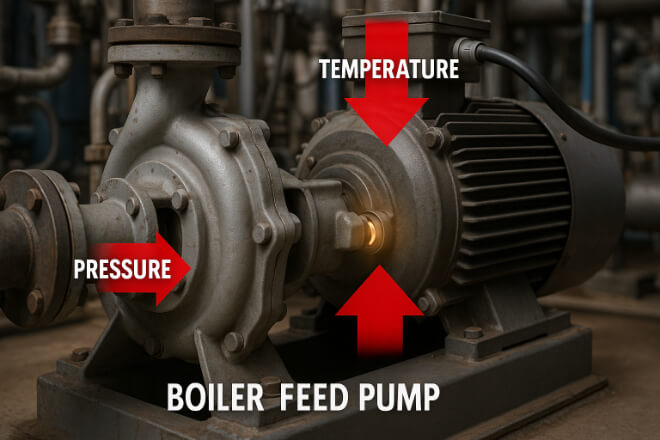

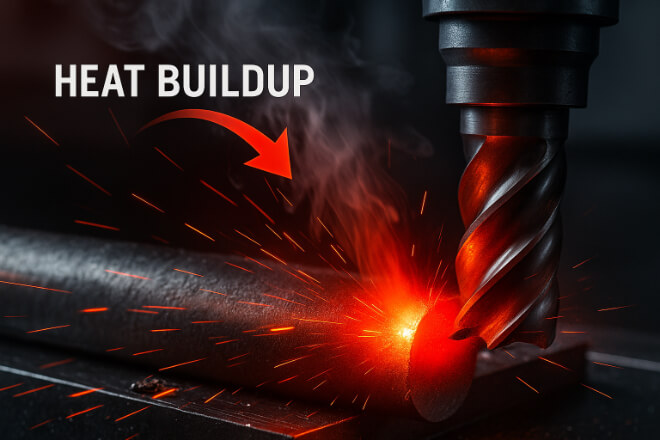

Temperature Limits and Cooling Strategies for WC Bushings in Service

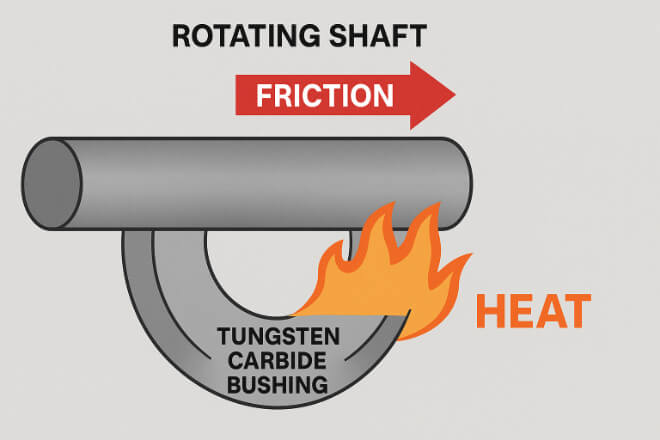

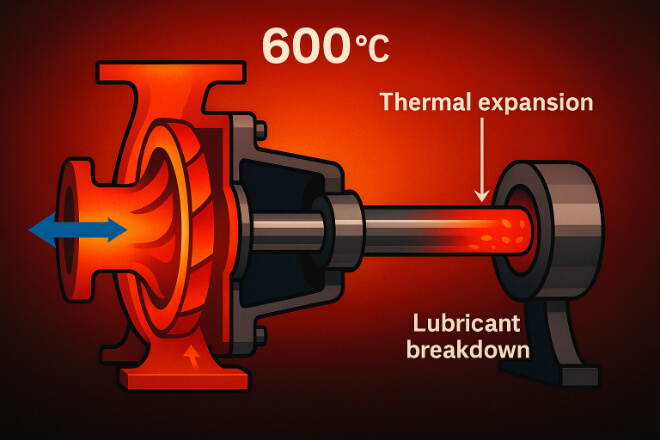

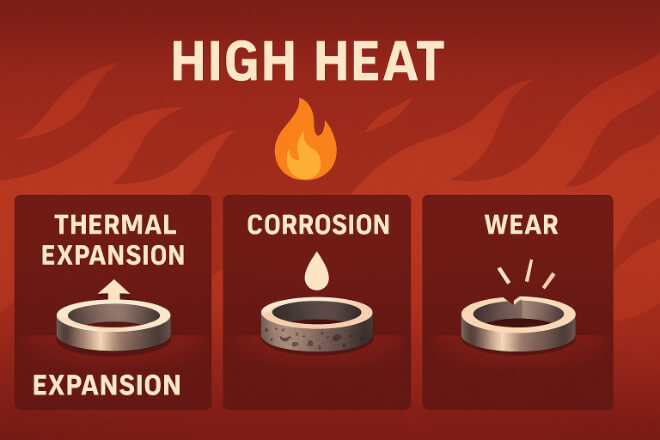

Tungsten carbide (WC) bushings are highly durable and capable of withstanding extreme conditions, making them ideal for heavy-duty applications. However, like any material, they have temperature limits that must be respected to ensure optimal performance and longevity. Excessive heat can cause thermal expansion, wear, and eventually premature failure of the bushing. This article will explore […]

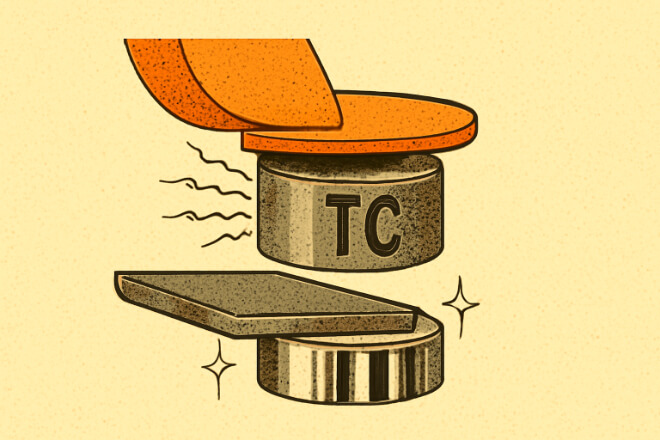

Field Guide: Removing and Replacing Tungsten Carbide Bushings Safely

Tungsten carbide bushings are essential for high-performance systems, but improper removal and replacement can cause damage. Ensuring safe and efficient procedures during bushing removal and installation is crucial to prevent wear or fractures. This guide provides a step-by-step approach to safely remove and replace tungsten carbide bushings, highlighting key tools and best practices for a […]

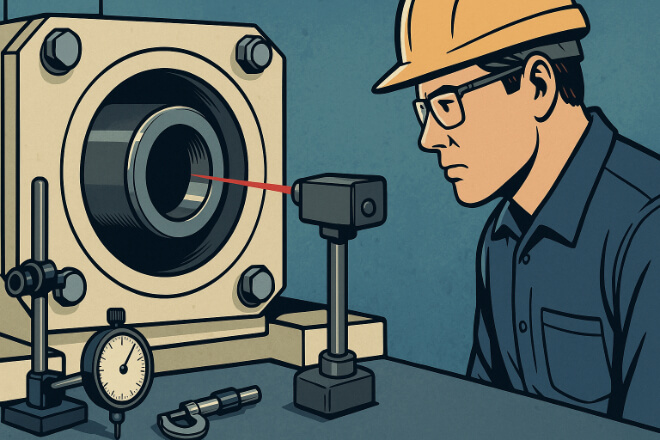

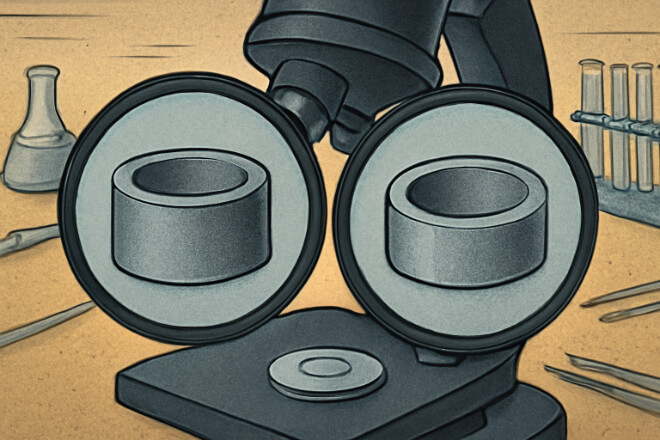

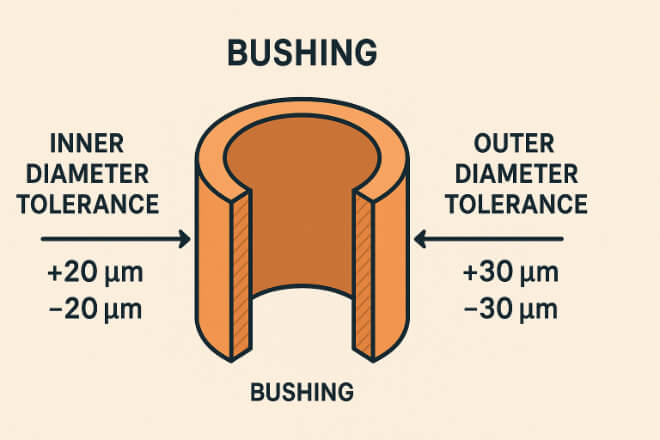

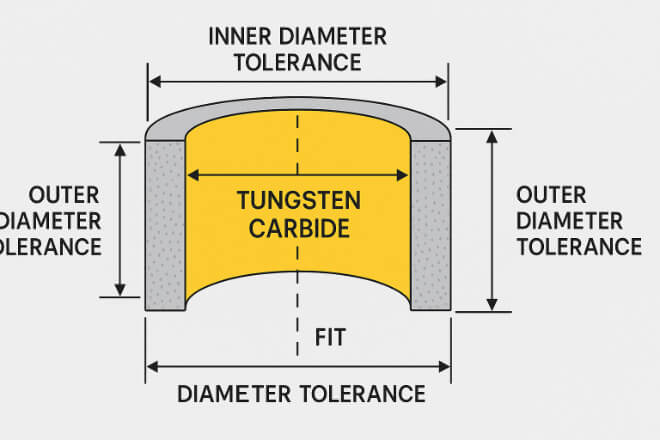

On-Site Inspection of Tungsten Carbide Bushings: ID, OD, and Roundness

Tungsten carbide bushings are essential for high-performance applications, but ensuring their quality requires accurate on-site inspection. Measuring critical dimensions like internal diameter (ID), outer diameter (OD), and roundness is vital for maintaining performance and preventing failure. This article discusses the importance of on-site inspection and best practices for ensuring the bushings meet the required specifications. […]

Alignment Checks to Prevent Out-of-Round Wear on WC Bushings

Tungsten carbide bushings are valued for their durability and wear resistance. However, if improperly aligned, they can suffer from out-of-round wear, which leads to uneven friction and premature failure. This article will explain the causes of out-of-round wear, how misalignment affects the bushing, and best practices for ensuring proper alignment to prevent these issues. What […]

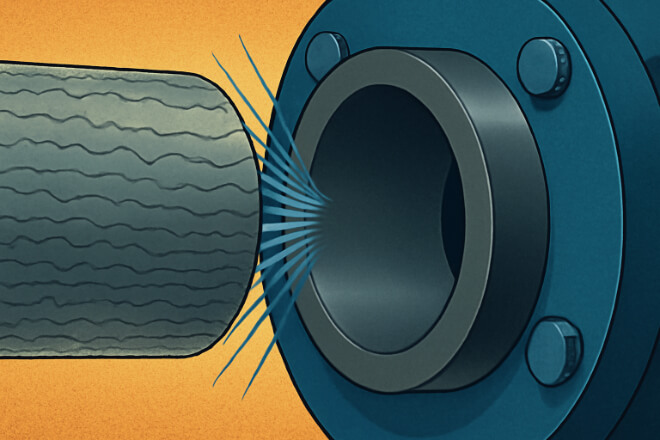

How to Press-Fit Tungsten Carbide Bushings Without Inducing Cracks

Tungsten carbide bushings are known for their exceptional durability, hardness, and wear resistance, making them ideal for high-performance applications. However, during installation, press-fitting tungsten carbide bushings into housings or shafts can sometimes lead to cracks or fractures, especially if the fit is too tight or improper installation techniques are used. This article will explore how […]

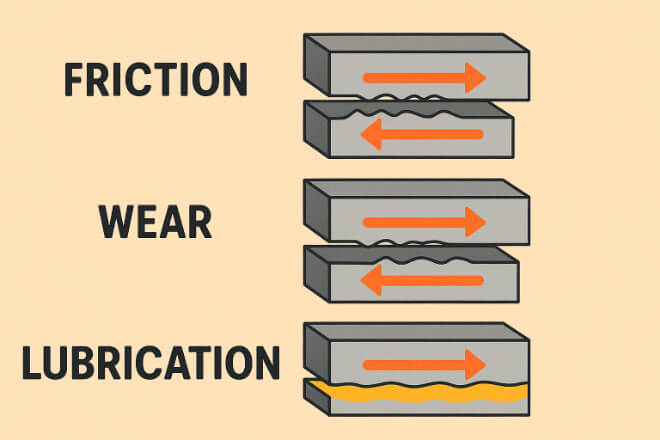

Lubrication Plans for Tungsten Carbide Bushings in Boundary Conditions

Tungsten carbide bushings are known for their durability and wear resistance. However, in boundary lubrication conditions, where the lubricant film is too thin to fully separate the bushing from the mating surface, ensuring proper lubrication is essential to prevent friction and wear. This article will discuss the role of lubrication in boundary conditions, the factors […]

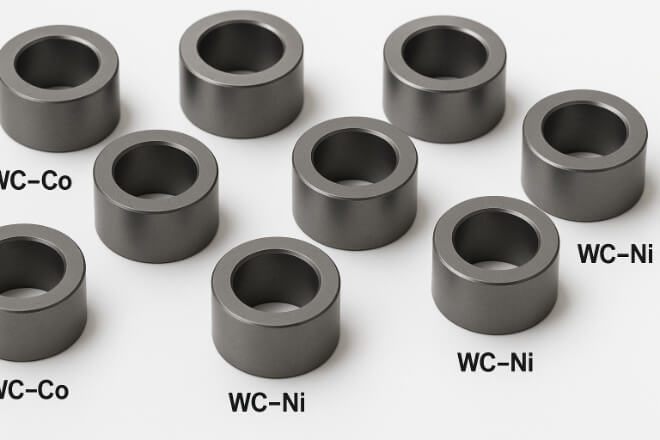

Non-Magnetic Requirements: When to Choose WC-Ni Bushings

When designing mechanical systems, non-magnetic materials are often a critical consideration. Whether in industries like electronics, medical equipment, or mining, certain applications require bushings that do not interfere with magnetic fields. In such cases, WC-Ni (Tungsten Carbide-Nickel) bushings become a key material choice. These bushings provide the strength and wear resistance of tungsten carbide while […]

Avoiding Edge Chipping on Thin-Wall Tungsten Carbide Bushings

Tungsten carbide bushings are known for their excellent hardness, wear resistance, and durability, making them ideal for demanding applications. However, when tungsten carbide bushings are designed with thin walls, they become more prone to edge chipping. This can negatively impact the bushing’s performance, causing premature wear, misalignment, or even failure. This article will explore the […]

Dimensional Stability of Tungsten Carbide Bushings at High Temperature

Tungsten carbide bushings are essential for high-temperature applications due to their excellent wear resistance and low coefficient of thermal expansion (CTE). Dimensional stability, or the ability to maintain size and shape under temperature fluctuations, is critical to ensure their performance in demanding environments. This article explores how high temperatures affect the dimensional stability of tungsten […]

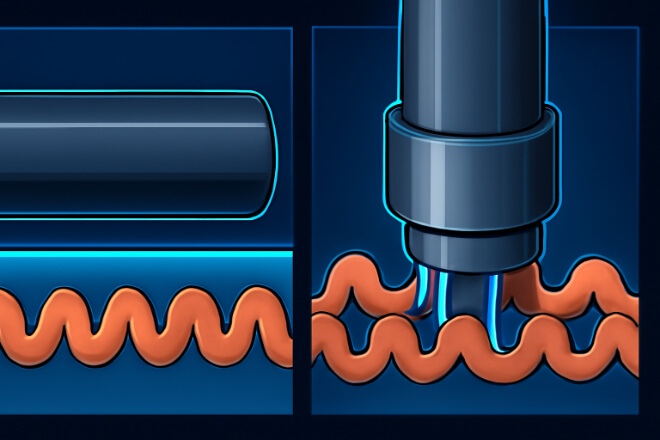

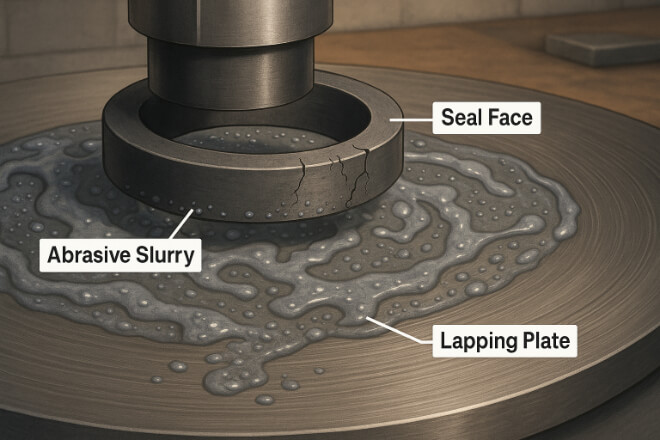

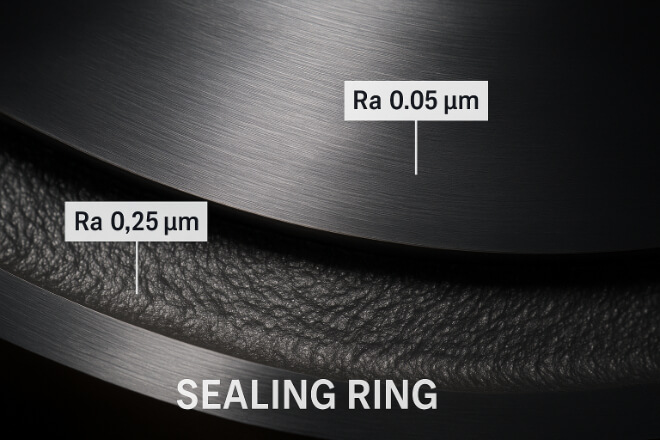

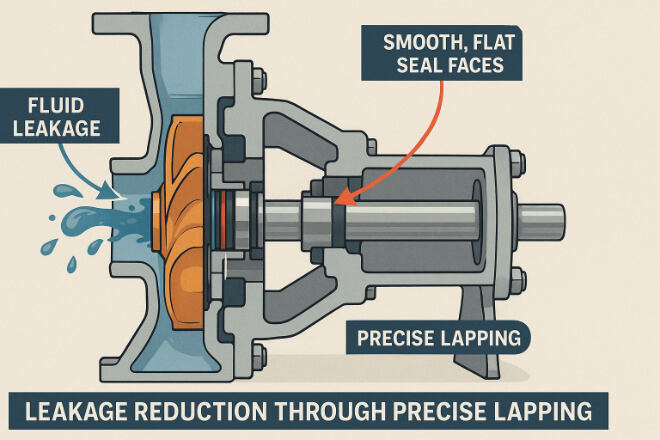

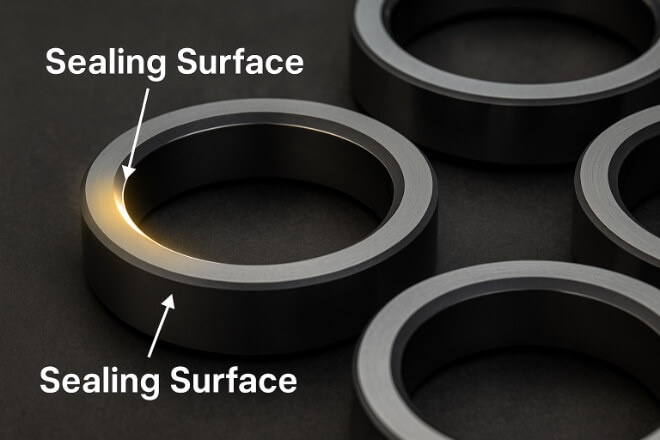

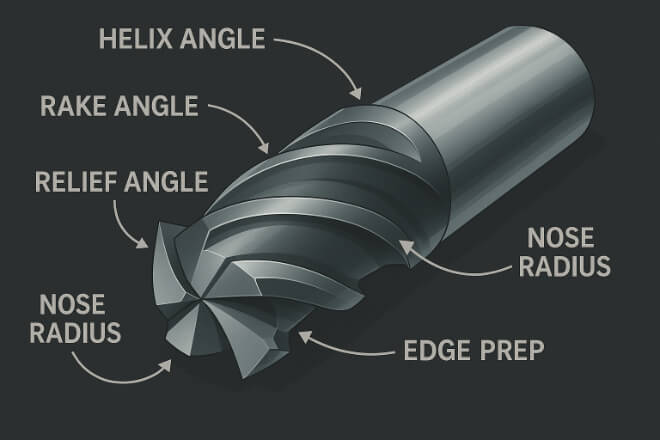

Lapping and Polishing Steps for Mirror-Finish Tungsten Carbide Bushings

Tungsten carbide bushings are known for their exceptional wear resistance, hardness, and durability. However, achieving a mirror-finish on the surface of these bushings is crucial for certain high-performance applications, where minimal friction, enhanced wear resistance, and smooth operation are required. The process of lapping and polishing is essential in achieving this mirror-finish. In this article, […]

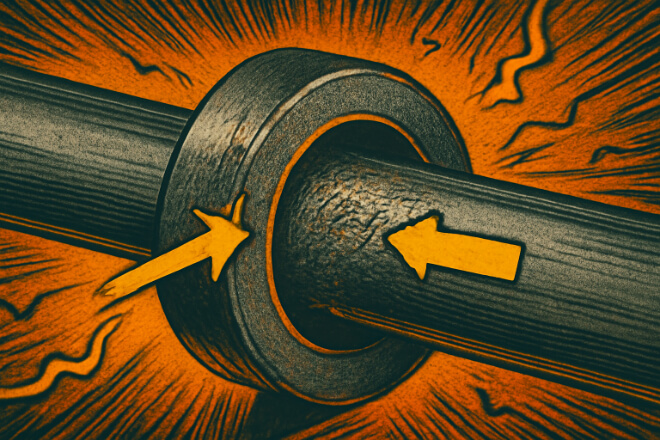

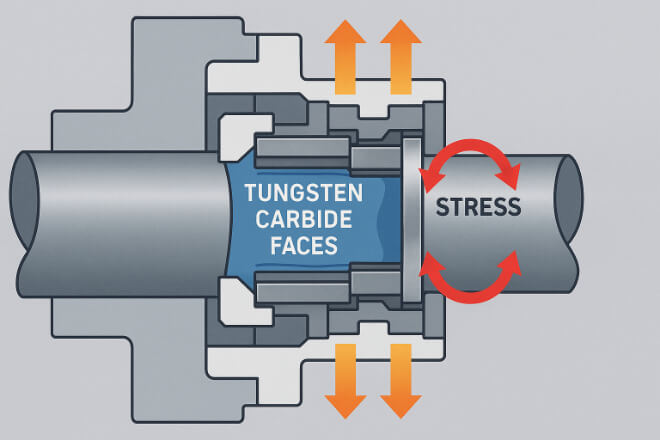

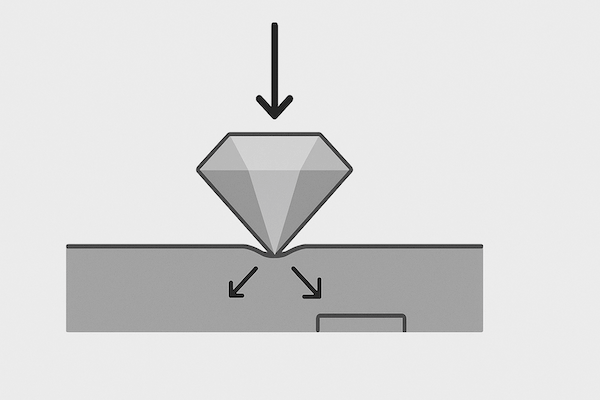

Hoop Stress and Press-Fit Calculations for Tungsten Carbide Bushings

When designing systems that use tungsten carbide bushings, understanding the behavior of materials under stress is essential for ensuring their durability and performance. Hoop stress and press-fit calculations are two critical factors in the design process. Hoop stress refers to the stress experienced by a material under pressure, while press-fit calculations help determine the interference […]

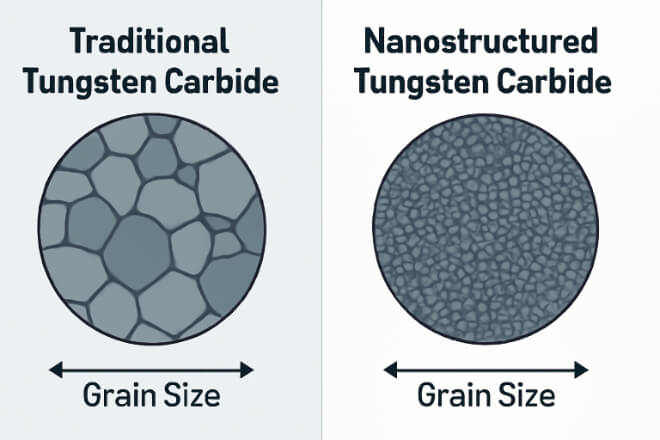

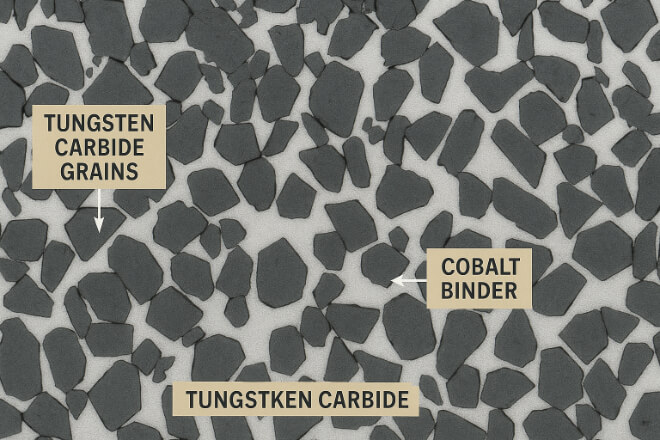

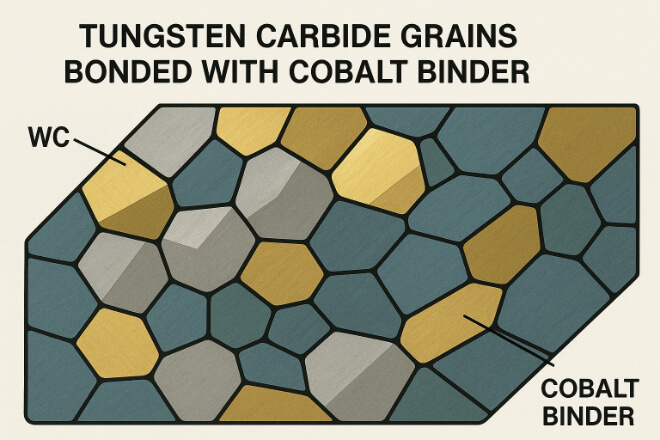

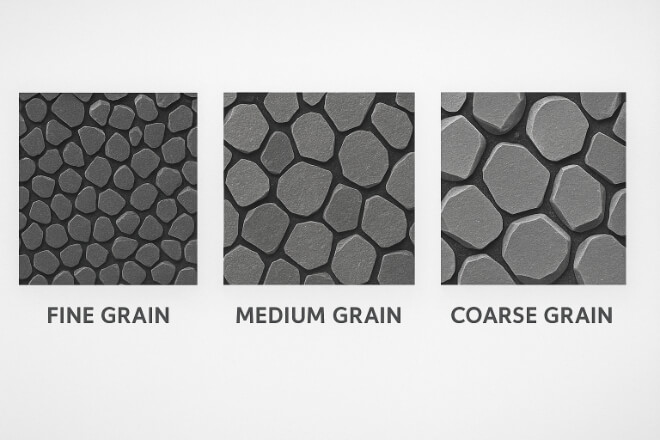

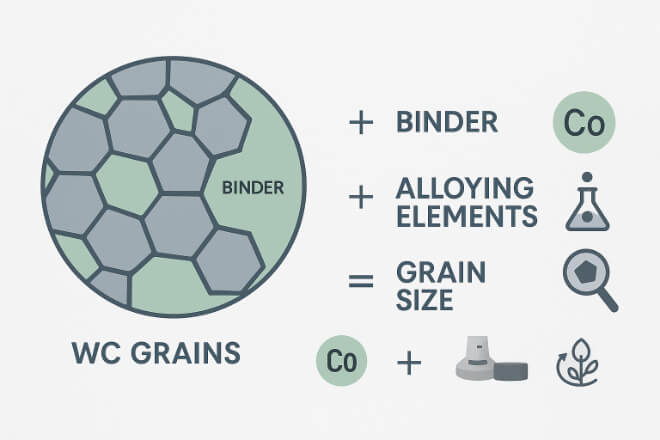

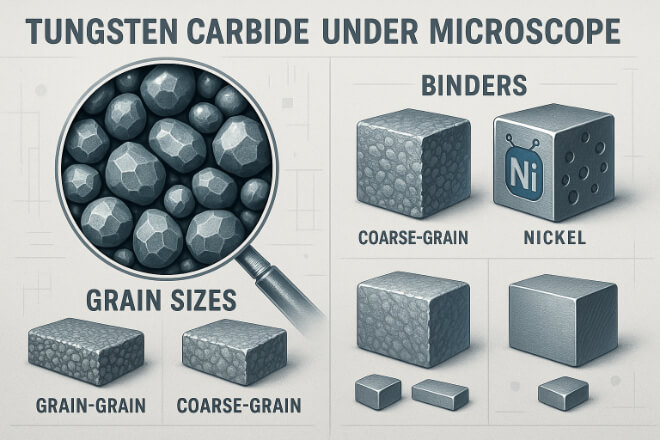

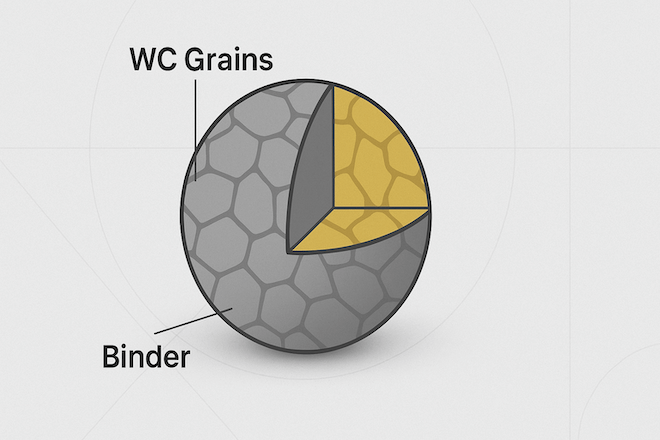

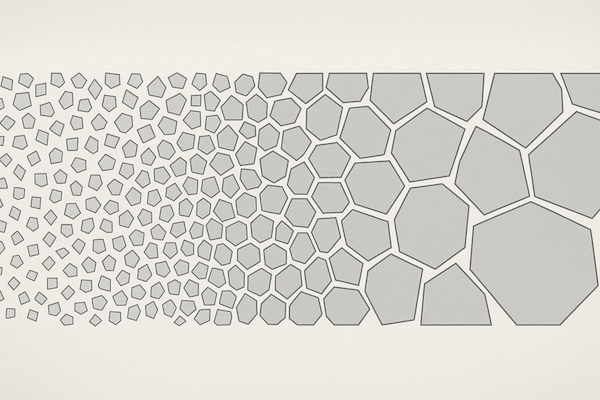

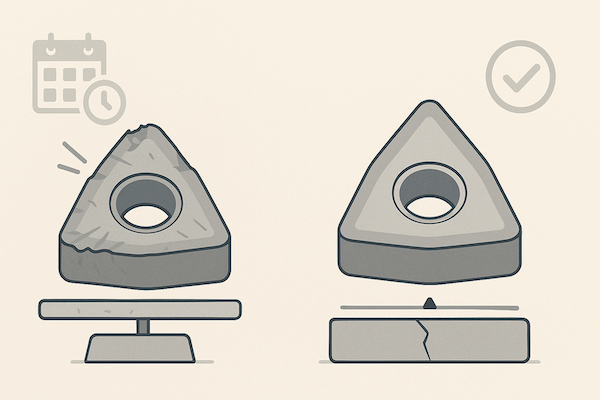

How Grain Size Affects Strength in Tungsten Carbide Bushings

Tungsten carbide bushings are widely used in applications that demand high wear resistance and durability. One critical factor influencing their performance is grain size. The grain size of tungsten carbide directly impacts its strength, toughness, and wear resistance. In this article, we will explore how grain size affects the strength of tungsten carbide bushings. How […]

Specifying Concentricity and Perpendicularity in Tungsten Carbide Bushing Drawings

Tungsten carbide bushings are known for their excellent durability and wear resistance. However, their performance largely depends on how well they are aligned within the housing, which is determined by two key factors: concentricity and perpendicularity. This article explores the importance of specifying these two factors in tungsten carbide bushing drawings and how they affect […]

Thermal Expansion Mismatch: Housing Design for Tungsten Carbide Bushings

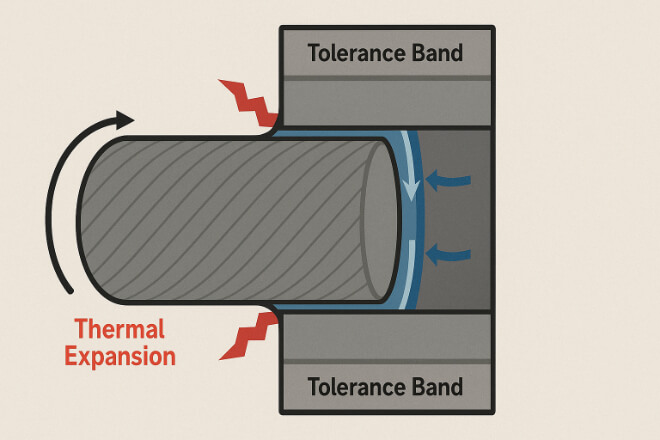

Tungsten carbide bushings are known for their wear resistance, but thermal expansion mismatch with the housing can affect their performance. Tungsten carbide has a low coefficient of thermal expansion (CTE), while materials like steel or aluminum expand more with temperature changes. This mismatch can lead to issues such as excessive wear or mechanical failure. This […]

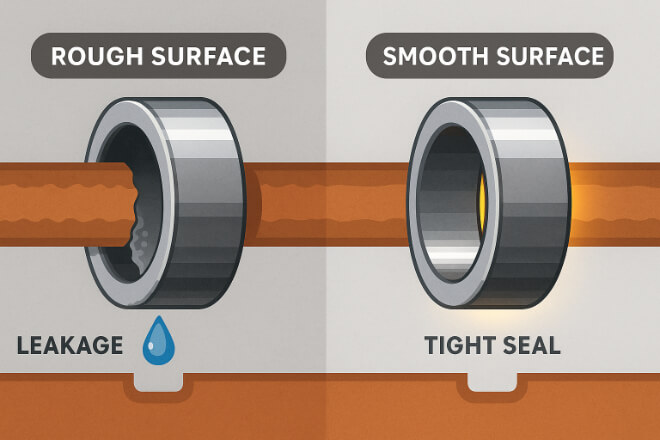

Recommended Surface Roughness for Tungsten Carbide Bushing Bores

Tungsten carbide bushings are known for their durability and wear resistance, making them essential for high-performance applications. One key factor that affects their performance is the surface roughness of the bushing bores. Proper surface roughness ensures reduced friction, better lubrication, and longer service life. This article will discuss the importance of surface roughness for tungsten […]

Clearance Fit Charts for Tungsten Carbide Bushings and Pump Shafts

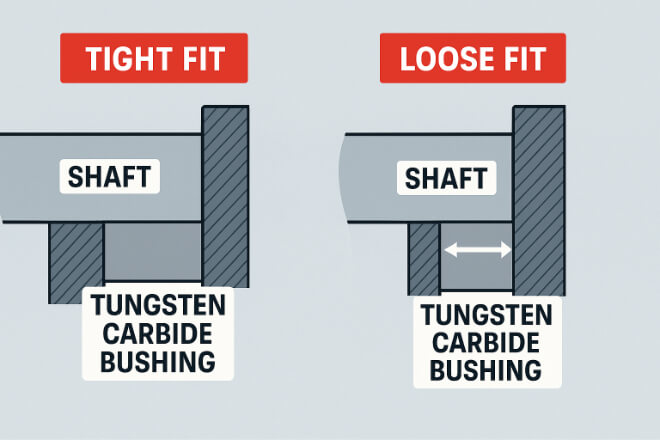

In mechanical systems, tungsten carbide bushings and pump shafts work together to ensure smooth, efficient performance. One critical factor in their compatibility is the clearance fit, which refers to the space or gap between the bushing and shaft. A proper clearance fit ensures that there is neither excessive friction nor too much movement, both of […]

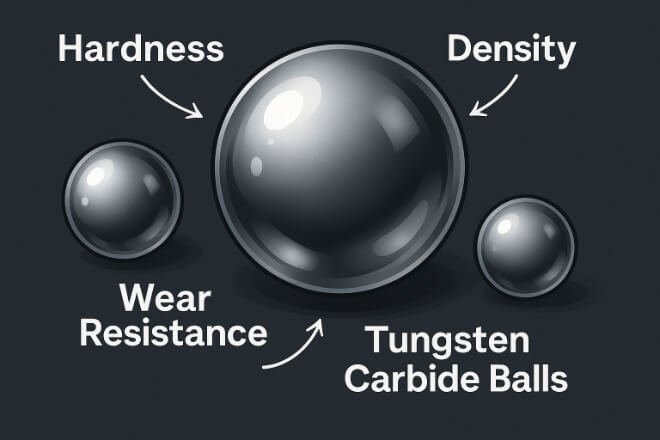

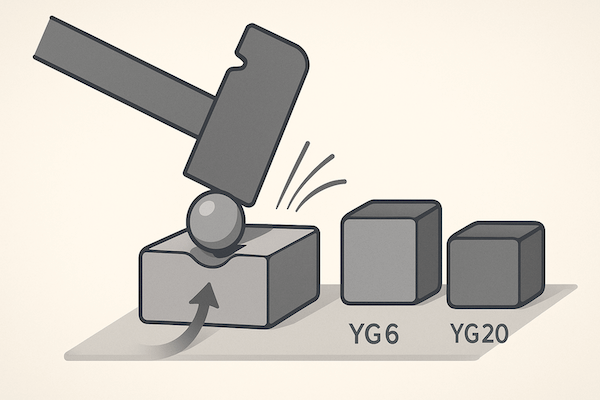

Density, Toughness, and Impact Resistance: What Sets WC Bushings Apart?

Tungsten carbide (WC) bushings are known for their exceptional hardness and wear resistance, making them ideal for heavy-duty applications. However, what truly sets WC bushings apart is their density, toughness, and impact resistance. These three key properties make WC bushings suitable for demanding environments where wear, shock, and pressure are constant challenges. This article explores […]

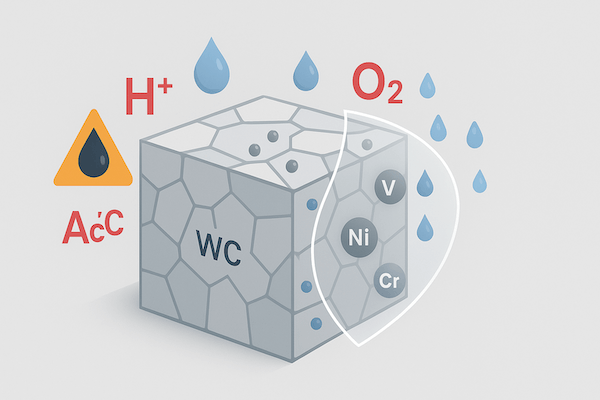

Corrosion Behavior of WC-Ni Bushings in Chloride-Rich Water

WC-Ni (tungsten carbide–nickel) bushings are widely used in pumps, valves, and rotating equipment because they offer strong wear resistance and good toughness. But in chloride-rich water, such as seawater or chemical process fluids, corrosion becomes a major concern. This article explains how WC-Ni bushings behave in chloride environments, what factors drive corrosion, and how to […]

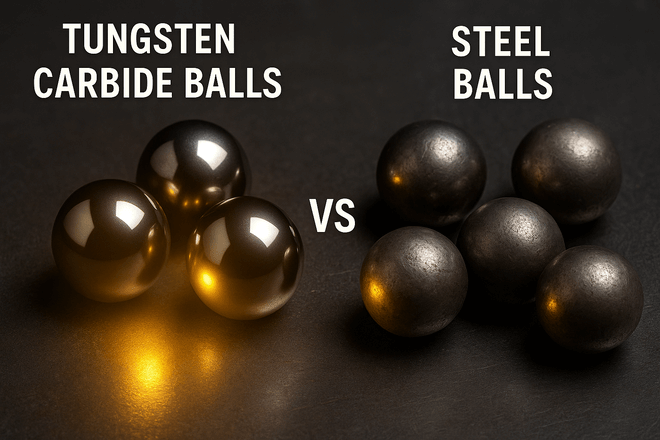

Selecting Shaft Counterface Materials for Tungsten Carbide Bushings

Tungsten carbide bushings are widely used in applications where durability and wear resistance are critical. These bushings are often paired with a shaft, which provides a counterface against which the bushing operates. Selecting the right shaft counterface material is crucial to ensure optimal performance, reduce wear, and extend the service life of both the bushing […]

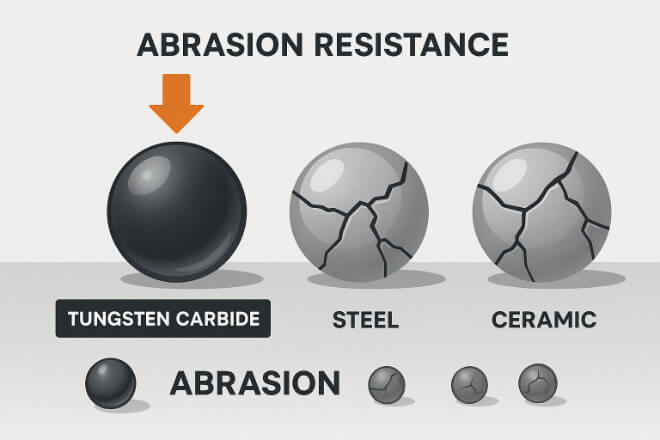

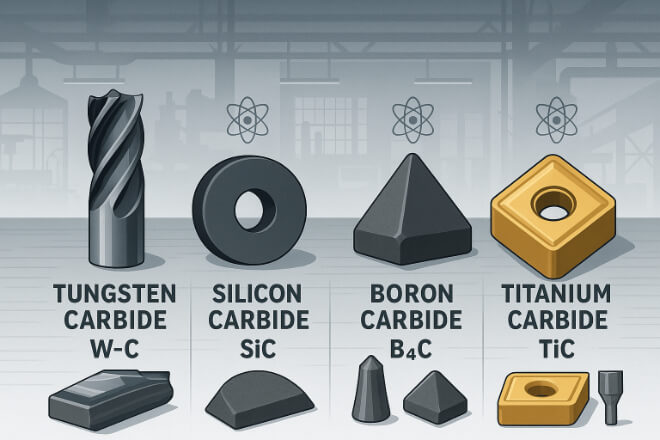

Silicon Carbide vs Tungsten Carbide Bushings in Abrasive Slurry Duty

In industries like mining, chemical processing, and wastewater treatment, pumps often handle abrasive slurries with solid particles and high pressures. To minimize wear and failure, bushings made from durable materials are essential. Silicon carbide (SiC) and tungsten carbide (WC) bushings are popular choices for these demanding applications. Both materials offer excellent wear resistance, but they […]

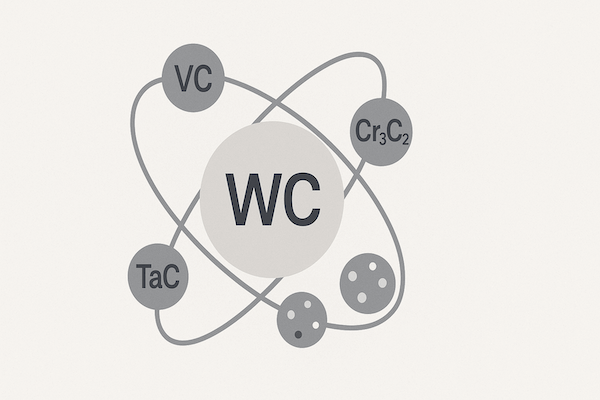

Tungsten Carbide Bushings with TaC/TiC Additions: Abrasion Performance

Tungsten carbide bushings are known for their excellent hardness, wear resistance, and durability, making them ideal for harsh industrial applications. However, adding TaC (Tantalum Carbide) and TiC (Titanium Carbide) to tungsten carbide further improves its abrasion resistance and performance. This blog explores how these additions enhance the abrasion performance of tungsten carbide bushings. And why […]

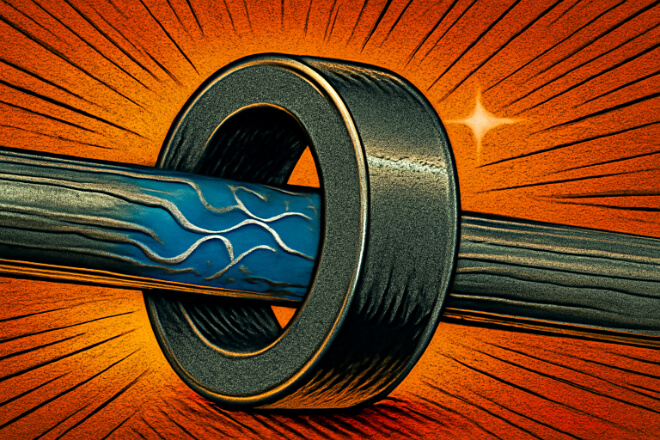

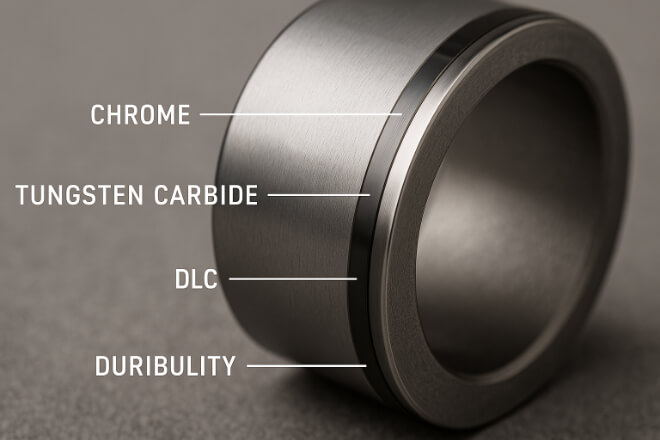

DLC and TiN Coated Tungsten Carbide Bushings: Friction and Wear Benefits

Tungsten carbide bushings are known for their outstanding hardness, wear resistance, and ability to handle extreme conditions. However, even these durable materials can benefit from additional surface treatments. DLC (Diamond-Like Carbon) and TiN (Titanium Nitride) coatings are commonly applied to tungsten carbide bushings to improve their performance by reducing friction and enhancing wear resistance. In […]

Binderless Tungsten Carbide Bushings: When Do They Make Sense?

Tungsten carbide bushings are widely used in industries like mining, chemical processing, and oil & gas due to their outstanding hardness, wear resistance, and durability. Traditionally, tungsten carbide bushings are produced with a binder material, such as cobalt or nickel, to provide toughness and help hold the carbide grains together. However, binderless tungsten carbide bushings […]

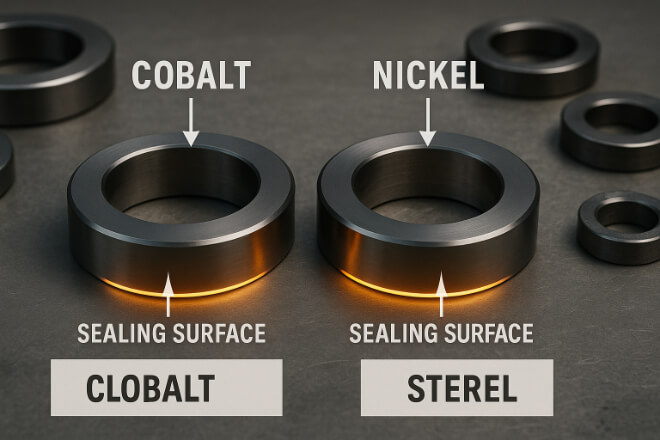

WC-Co vs WC-Ni Tungsten Carbide Bushings: Which Binder for Your Fluid?

In industries such as mining, oil and gas, and chemical processing, pumps are subjected to harsh conditions, including abrasive solids, high pressure, and aggressive fluids. Tungsten carbide bushings are often used to protect pump shafts and bearings in these demanding environments. However, the choice of binder in tungsten carbide, particularly WC-Co (cobalt binder) and WC-Ni […]

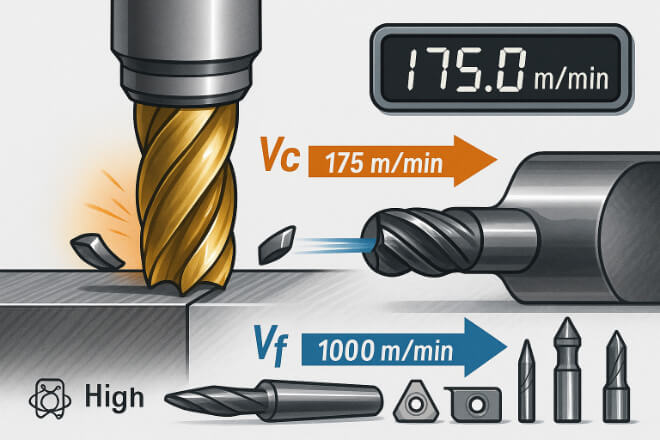

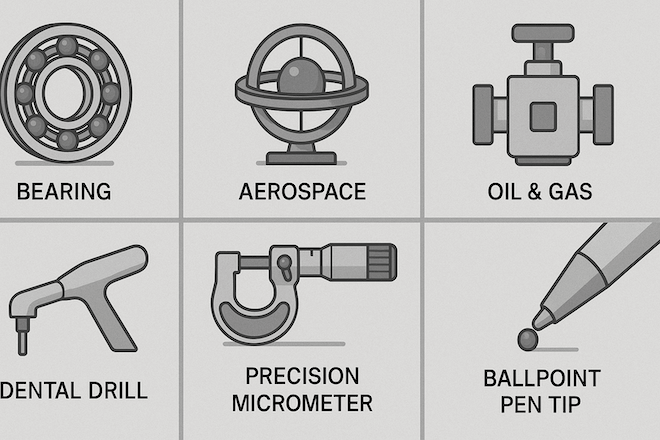

Tungsten Carbide Bushings for High-RPM Compressor Guide Supports

High-RPM compressors are essential components in a variety of industrial applications, including oil and gas, refrigeration, and air compression systems. These compressors operate at high speeds and often handle abrasive, corrosive, and high-pressure fluids. The guide supports in these compressors are key to maintaining stable operations, and their performance is heavily dependent on the materials […]

Tungsten Carbide Bushings in Mining Dewatering and Tailings Pumps

Mining dewatering and tailings pumps play a crucial role in the mining industry. These pumps are responsible for moving water, slurry, and tailings away from the mining site, often in harsh, abrasive, and corrosive environments. To ensure optimal performance and longevity, many mining operations use tungsten carbide bushings in their dewatering and tailings pumps. These […]

How Tungsten Carbide Bushings Improve Fertilizer and Acid Transfer Pumps

Fertilizer and acid transfer pumps are essential components in industries such as agriculture and chemical manufacturing. These pumps handle highly corrosive and abrasive substances like concentrated acids, fertilizers, and slurry, often under challenging conditions. To ensure reliability and reduce downtime, many plants use tungsten carbide bushings in their pumps. This article explores how tungsten carbide […]

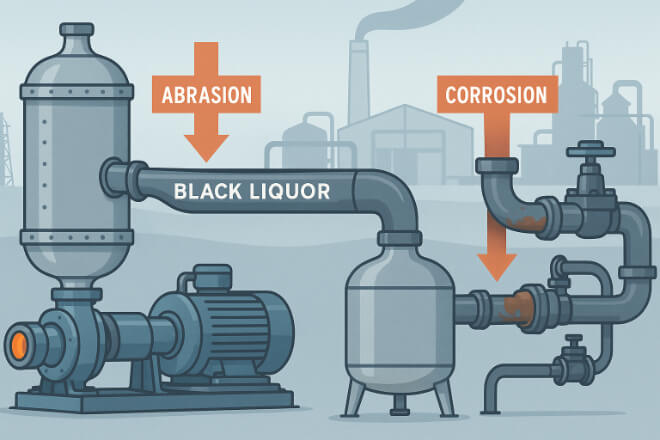

Tungsten Carbide Bushings for Pulp and Paper Process Pumps

Pulp and paper plants rely on process pumps to move fiber slurry, chemicals, and treated water through different stages of production. These pumps operate under tough conditions, with high solids, chemicals, and continuous wear. To improve pump reliability and reduce downtime, many mills are now switching to tungsten carbide bushings. These bushings provide long service […]

Using Tungsten Carbide Bushings in Geothermal Brine Pumps

Geothermal brine pumps operate in extremely harsh underground environments where heat, minerals, and corrosion combine to create rapid wear. To keep these pumps running safely and reliably, many engineers and OEMs now specify tungsten carbide bushings. This article explains why tungsten carbide is suitable for geothermal brine service, which grades to choose, what failure risks […]

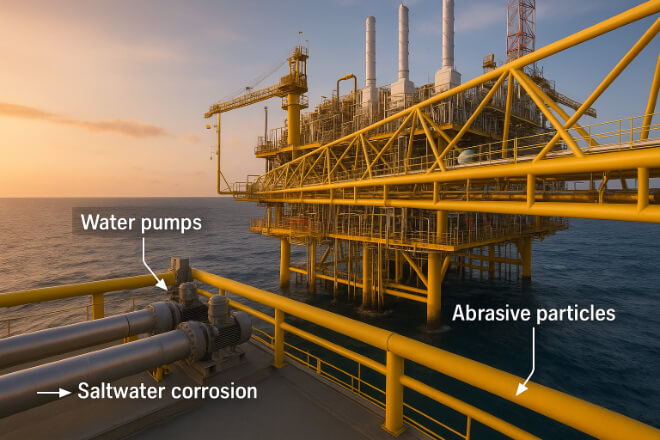

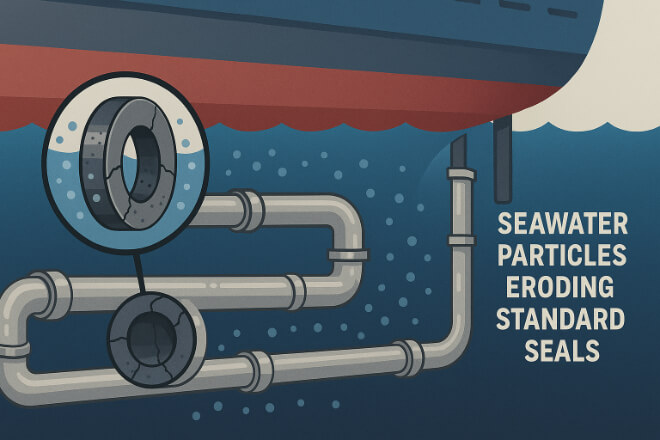

Tungsten Carbide Bushings for Desalination and Seawater Intake Pumps

Desalination plants and seawater intake stations operate in some of the toughest environments in the world. Pumps in these systems must handle constant exposure to seawater, sand, silt, and corrosive ions. To keep these pumps running reliably, many engineers choose tungsten carbide bushings. This article explains why tungsten carbide is widely used in desalination, what […]

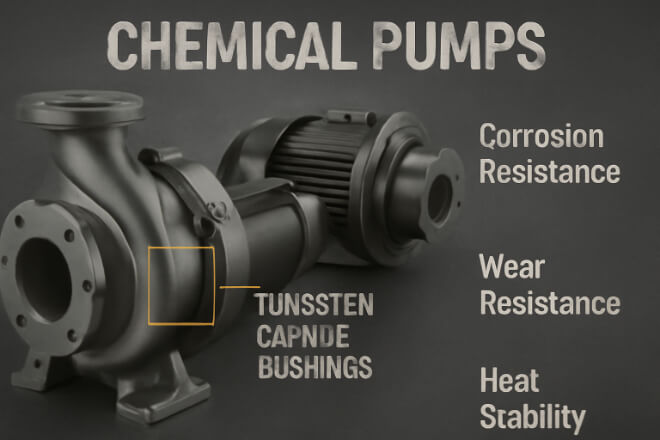

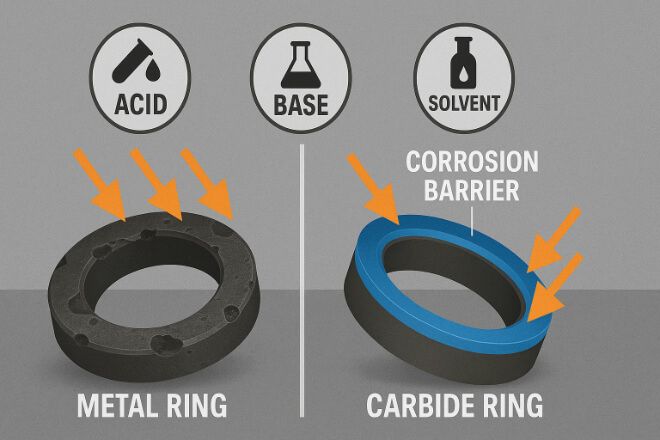

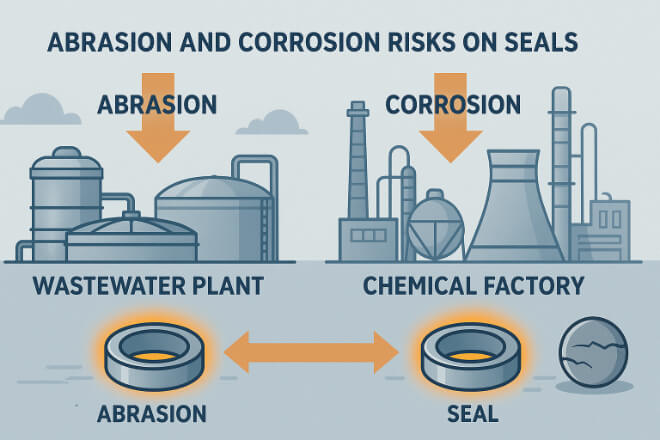

Why Chemical Plants Specify Tungsten Carbide Bushings for Corrosive Media

Chemical plants operate in environments where pumps, mixers, compressors, and rotating equipment must handle highly corrosive fluids. These conditions require components that can survive both chemical attack and mechanical wear. For this reason, many chemical plants choose tungsten carbide bushings as their first option for shaft support and protection. This article explains why tungsten carbide […]

Tungsten Carbide Bushings in Dredging and Slurry Handling Systems

Dredging and slurry handling systems work in extremely harsh environments where sand, gravel, mud, and abrasive minerals constantly attack equipment. Pump shafts and rotating parts face rapid wear if they are not protected by strong, durable components. Tungsten carbide bushings are one of the most effective solutions for extending equipment life in dredging and slurry […]

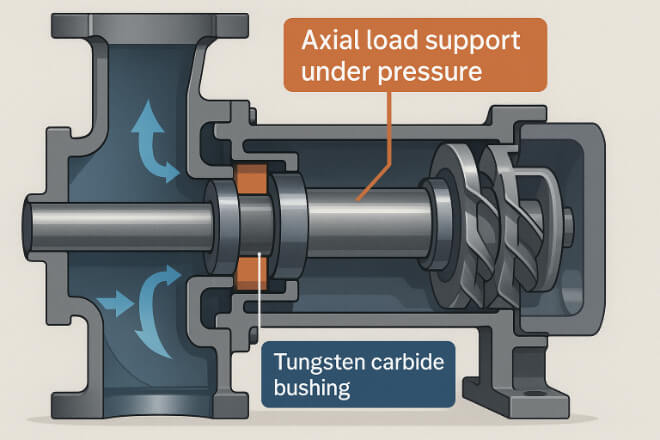

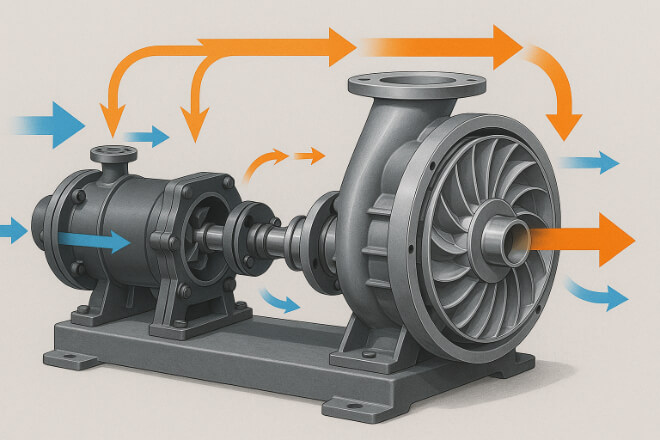

Best Tungsten Carbide Bushings for Centrifugal Pump Shafts

Centrifugal pumps are used across many industries, from chemical plants to power stations and water treatment facilities. Their shafts rotate at high speed and face continuous friction, load, and fluid exposure. Tungsten carbide bushings play an essential role in protecting the shaft and ensuring smooth, long-term operation. This article explains the best tungsten carbide bushing […]

Tungsten Carbide Bushings for Electric Submersible Pumps (ESP)

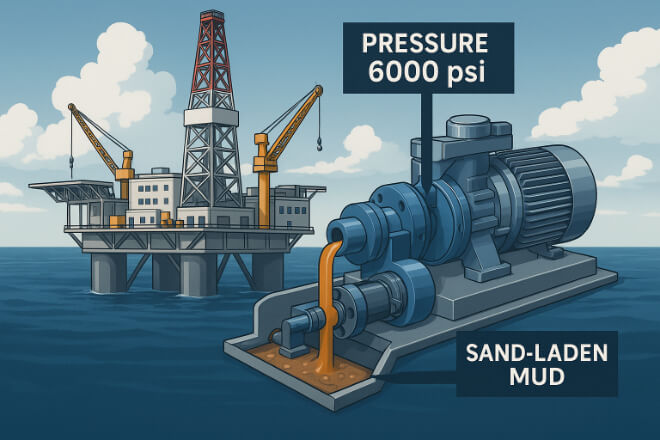

Electric Submersible Pumps (ESP) work in some of the harshest environments in the oil and gas industry. High pressure, abrasive solids, corrosive fluids, and continuous operation make reliability essential. Tungsten carbide bushings play a key role in supporting the pump’s rotating shaft and ensuring long service life. This article explains why tungsten carbide bushings are […]

Packaging and Shipping Best Practices for Tungsten Carbide Bushings

Tungsten carbide bushings are hard, heavy, and brittle. Even though they offer excellent wear resistance, they can still chip, crack, or deform during transport if the packaging is not correct. This guide explains the best practices for packaging and shipping tungsten carbide bushings so OEMs and industrial users can reduce damage, protect quality, and ensure […]

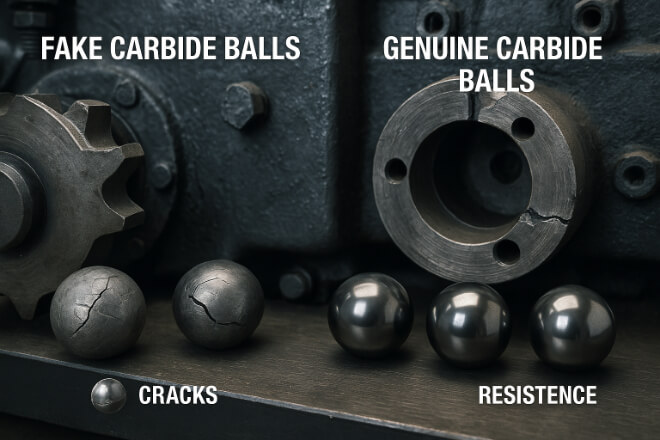

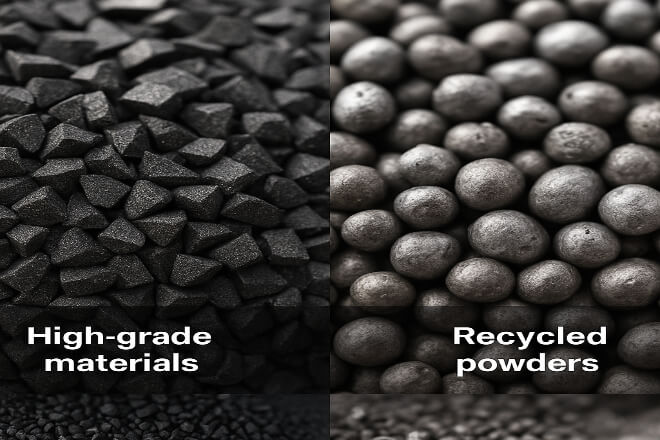

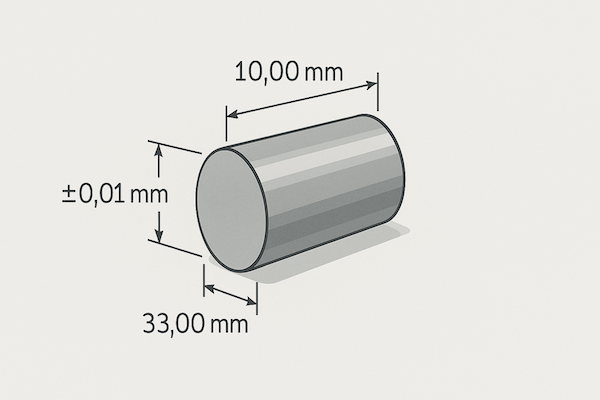

How to Verify Material Authenticity in Tungsten Carbide Bushings

For OEMs and industrial companies, the quality of a tungsten carbide bushing depends heavily on the authenticity of its material. Poor-quality or mixed-grade carbide can lead to early wear, cracking, leakage, and unexpected downtime. This guide explains practical methods to verify whether a tungsten carbide bushing is made from true, high-grade materials. It is written […]

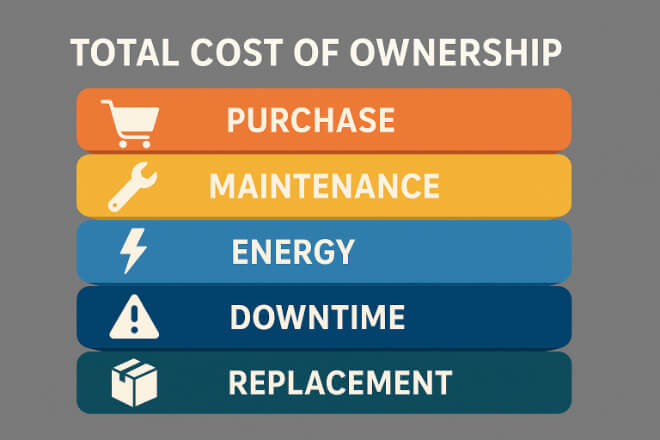

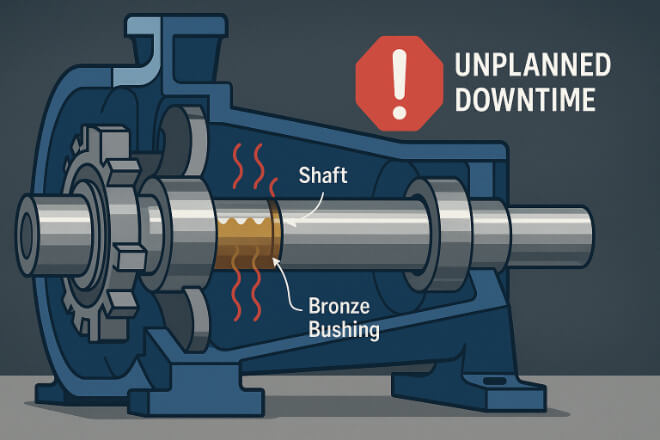

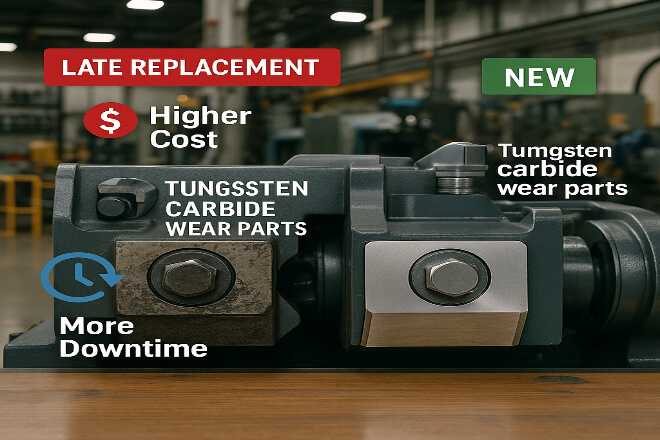

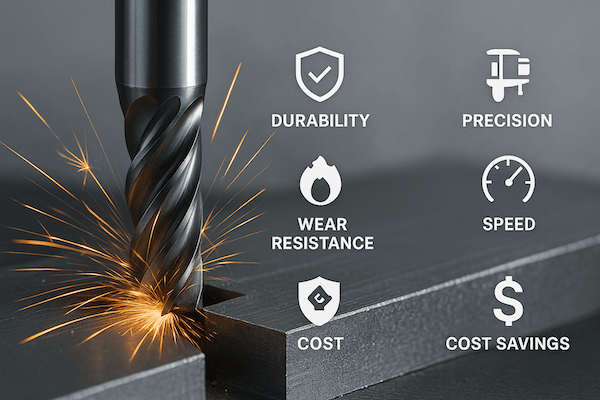

Total Cost Comparison: Tungsten Carbide vs Conventional Bushings

For many OEMs and industrial companies, the first question when choosing bushings is not only performance, but total cost. Tungsten carbide bushings have a higher purchase price than bronze, steel, polymer, or ceramic bushings. But the total cost over the full life cycle often tells a very different story. This guide compares both options using […]

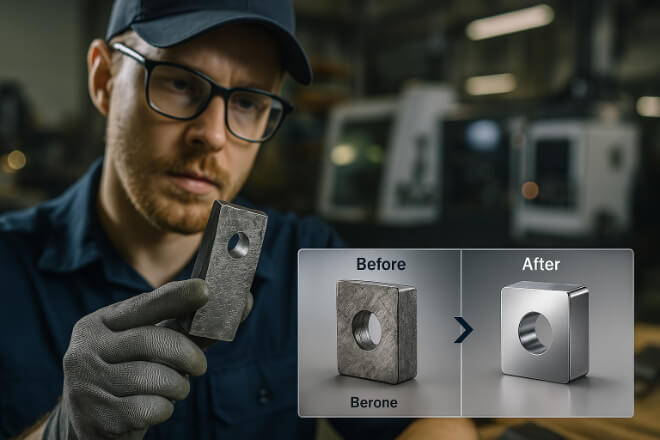

OEM Replacement Guide for Tungsten Carbide Bushings

Replacing tungsten carbide bushings is a key task for OEMs that run pumps, compressors, motors, or rotating equipment. A correct replacement process ensures stable performance, low downtime, and long service life. This guide explains how OEMs can evaluate old bushings, select the right replacements, and work with suppliers to ensure accuracy and quality. When OEMs […]

Factors That Influence the Export Cost of Tungsten Carbide Bushings

Exporting tungsten carbide bushings in 2025 involves more than material and machining cost. For OEMs and global buyers, the final export price depends on many hidden factors—logistics, regulations, currency, packaging, and regional supply changes. This article explains the key cost drivers in simple, clear language to help decision-makers understand how export prices are built and […]

Global Price Trends of Tungsten Carbide Bushings in 2025

In 2025, the steel-hard compound used for bushings — tungsten carbide — is seeing significant price shifts. For companies sourcing tungsten carbide bushings, understanding global price trends is vital to managing cost, supply risk and contract timing. This article outlines major price movements across regions, key drivers behind change, and what decision-makers should do when […]

Evaluating Supplier Capability for Tungsten Carbide Bushings

Choosing the right supplier for tungsten carbide bushings is a critical step for OEMs and industrial companies. A strong supplier can help you reduce downtime, improve product performance, and ensure stable long-term supply. This guide explains how to evaluate supplier capability using clear and practical criteria that match real industrial needs. Why Supplier Capability Matters […]

How MOQ and Lead Time Affect Bushing Cost

When sourcing tungsten carbide bushings, the final price is not only determined by the material grade or size. Two factors—MOQ (Minimum Order Quantity) and lead time—play a major role in shaping the total cost. Understanding how these two elements influence pricing helps decision-makers control budgets, avoid delays, and build a more stable supply chain. Why […]

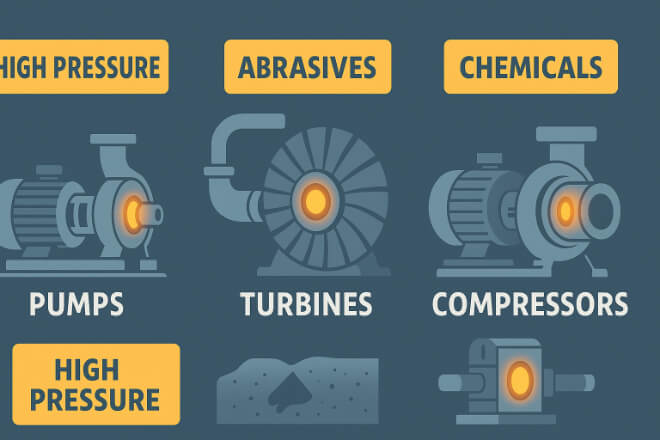

Tungsten Carbide Bushing Sourcing Guide for OEMs

For OEMs in the pump, compressor, turbine, and industrial machinery sectors, choosing the right supplier for tungsten carbide bushings is a critical decision. A reliable supplier helps reduce downtime, increase product life, and ensure long-term performance. This guide explains the key sourcing steps every OEM should follow to select the best material grade, evaluate manufacturers, […]

How to Order Custom Tungsten Carbide Bushings

Ordering custom tungsten carbide bushings can be challenging, especially when the application involves pumps, compressors, turbines, high pressure, or abrasive fluids. To get the right part, you must provide clear technical details and understand the key factors that influence design, performance, and cost. This article guides decision-makers through each step of the ordering process to […]

Troubleshooting Bearing Clearance Issues in Tungsten Carbide Bushings

Bearing clearance is one of the most important factors in the performance of tungsten carbide bushings. If the clearance is too tight or too loose, problems such as friction, vibration, heat, noise, or even full pump failure can occur. This article explains the common causes of clearance problems, how to detect them, and the best […]

Why Some Tungsten Carbide Bushings Fail Prematurely

Tungsten carbide bushings are known for their strength, hardness, and long service life. They are widely used in pumps, compressors, turbines, and other rotating equipment. But in real industrial environments, some bushings fail much earlier than expected. Early failure means unplanned downtime, higher maintenance costs, and possible damage to shafts or seals. This article explains […]

Detecting Erosion and Cavitation Damage in Pump Bushings

Pump bushings made of tungsten carbide work under high speed, high pressure, and aggressive fluids. In these harsh conditions, two common failure modes appear again and again: erosion and cavitation damage. Both can cause early wear, vibration, leakage, and even shutdown of the pump. This article explains how to detect these problems early, why they […]

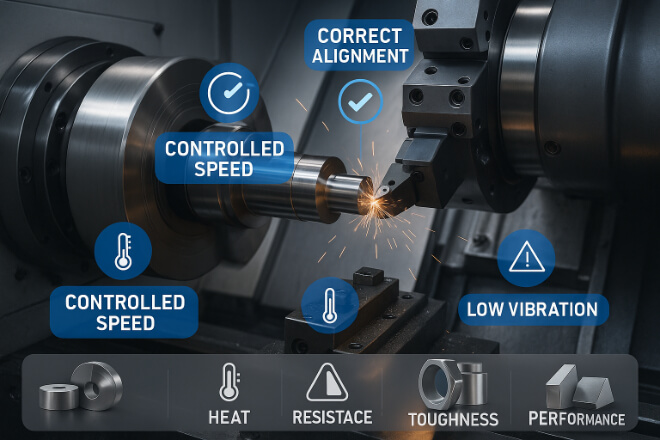

How to Improve Shaft Alignment for Longer Bushing Life

Good shaft alignment is one of the most important factors for achieving long service life in tungsten carbide bushings. When the shaft is not aligned well, the bushing faces extra stress, heat, and wear. This leads to early failure and higher maintenance costs. This article explains how to improve shaft alignment using simple steps, practical […]

Noise and Vibration Problems in Tungsten Carbide Bushing Assemblies

Noise and vibration are early warning signs of problems inside equipment that uses tungsten carbide bushings. If these issues are ignored, they can lead to higher wear, reduced efficiency, and unexpected downtime. This article explains why noise and vibration occur, the risks they bring, and how to prevent failures in tungsten carbide bushing systems. Why […]

Common Reasons for Leakage Around Tungsten Carbide Bushings

Tungsten carbide bushings are widely used in machinery and pumps due to their exceptional hardness, wear resistance, and strength. However, even the most durable materials can face issues in demanding industrial applications. Leakage around tungsten carbide bushings is a common problem that can cause significant operational issues, including reduced efficiency, increased maintenance costs, and potential […]

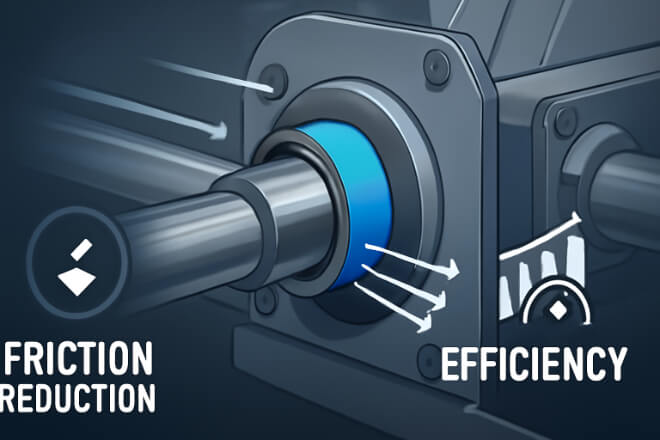

Reducing Friction and Galling with Proper Tungsten Carbide Pairing

Tungsten carbide is renowned for its exceptional hardness, wear resistance, and durability, making it a popular choice for industrial applications such as bushings, bearings, and seals. However, even tungsten carbide can face issues like friction and galling when paired improperly with other materials. These issues can result in excessive wear, damage, and ultimately failure of […]

Temperature Limits for Tungsten Carbide Bushings in Service

Tungsten carbide bushings are known for their outstanding wear resistance and strength, making them ideal for a wide range of industrial applications. However, like all materials, tungsten carbide has temperature limits that must be considered to ensure optimal performance. Understanding these temperature limits is crucial for industries such as mining, oil and gas, and aerospace, […]

How to Detect Misfit or Out-of-Round Bushings Early

In the world of industrial machinery, tungsten carbide bushings are essential components that help reduce wear, improve performance, and extend the life of equipment. However, misfit or out-of-round bushings can lead to significant issues like increased wear, vibration, and early failure of the machinery. Detecting these issues early on is crucial to prevent costly repairs […]

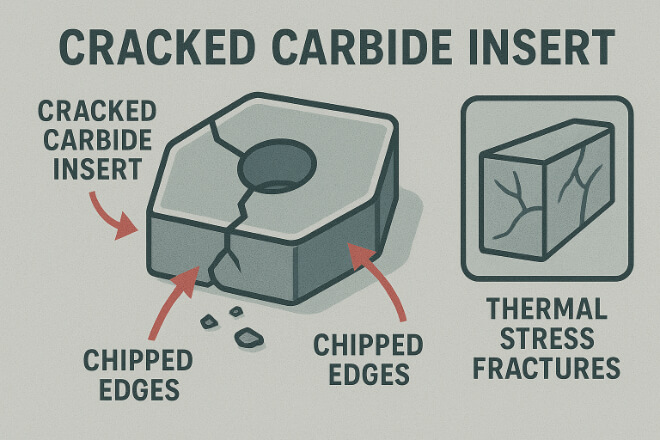

Diagnosing Cracks in Tungsten Carbide Bushings

Tungsten carbide bushings are widely used in industrial machinery due to their superior hardness, wear resistance, and strength. However, even the most durable materials are susceptible to damage under certain conditions. Cracks in tungsten carbide bushings can occur due to various factors, and diagnosing them early is essential to prevent further damage, costly repairs, and […]

The Future of Additive Manufacturing in Tungsten Carbide Bushings

Additive manufacturing (AM), also known as 3D printing, has revolutionized several industries, including the production of tungsten carbide bushings. Tungsten carbide is already known for its high wear resistance, strength, and durability, making it ideal for industrial applications. However, traditional manufacturing methods for tungsten carbide bushings are often limited by complexity, cost, and production time. […]

How Hot Isostatic Pressing Improves Tungsten Carbide Bushing Density

Tungsten carbide bushings are widely used in industrial applications due to their outstanding wear resistance, hardness, and durability. However, to maximize their performance, the density of the tungsten carbide must be optimized during the manufacturing process. Hot Isostatic Pressing (HIP) is one of the most effective methods used to enhance the density of tungsten carbide […]

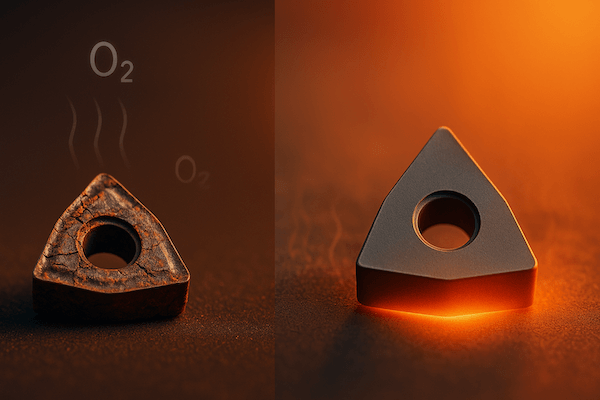

Anti-Corrosion Treatments for Tungsten Carbide Bushings

Tungsten carbide bushings are known for their incredible hardness, wear resistance, and toughness, making them ideal for demanding industrial applications. However, when exposed to harsh environments—especially those involving chemicals, salts, and moisture—tungsten carbide can suffer from corrosion, leading to reduced performance and premature failure. To combat this, various anti-corrosion treatments have been developed to improve […]

Tungsten Carbide Composite Bushings for Extreme Conditions

Tungsten carbide is a well-known material for its exceptional hardness and wear resistance, making it a top choice for manufacturing bushings. However, when operating under extreme conditions—such as high temperatures, heavy loads, or corrosive environments—tungsten carbide composite bushings offer enhanced properties that make them suitable for even the harshest industrial applications. This article explores the […]

Grain Size Optimization in Tungsten Carbide Bushing Production

Tungsten carbide bushings are crucial components used in a wide variety of industrial applications due to their exceptional hardness, wear resistance, and durability. However, the properties of tungsten carbide, especially its hardness and wear resistance, are significantly influenced by the grain size of the tungsten carbide particles. Optimizing grain size during production is essential for […]

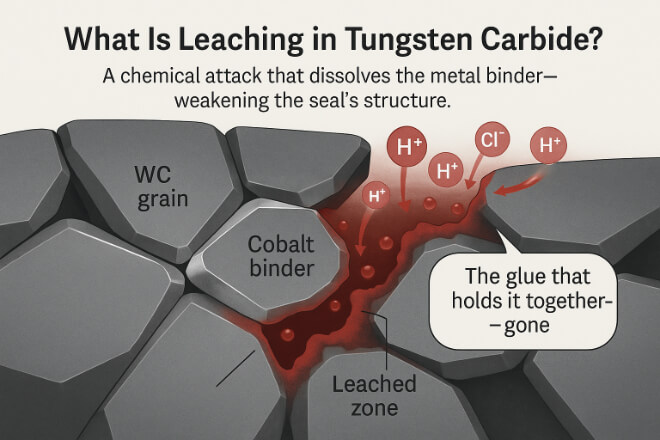

Comparing WC-Co and WC-Ni Bushings in Corrosive Environments

Tungsten carbide (WC) bushings are widely used for their exceptional hardness, wear resistance, and durability. However, in corrosive environments, the binder material used to bond the tungsten carbide grains—cobalt (Co) or nickel (Ni)—plays a crucial role in determining the performance and longevity of the bushing. This article will compare WC-Co and WC-Ni bushings in corrosive […]

Advances in Binderless Tungsten Carbide for Bushings

Tungsten carbide is known for its superior hardness, wear resistance, and durability, making it a popular material for bushings in a variety of industrial applications. Traditionally, tungsten carbide is combined with metal binders such as cobalt or nickel to improve toughness and machinability. However, recent advancements in binderless tungsten carbide technology have made it possible […]

When to Use Silicon Carbide Instead of Tungsten Carbide Bushings

Tungsten carbide bushings are known for their excellent wear resistance, hardness, and durability, making them a popular choice for a wide range of industrial applications. However, in certain environments, silicon carbide (SiC) bushings may offer better performance, especially in situations that involve extreme temperatures, abrasive conditions, or aggressive chemical exposure. This article will explore the […]

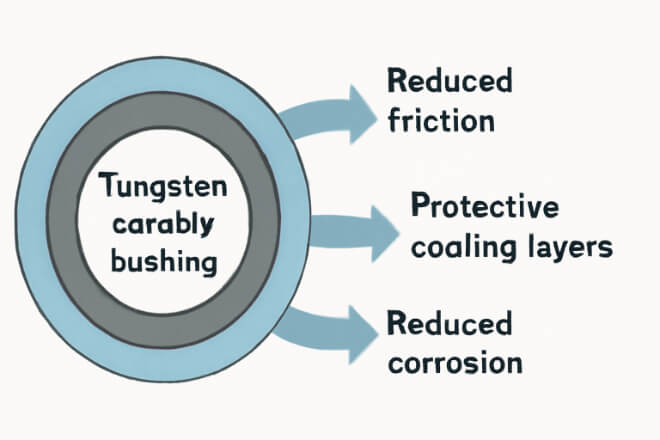

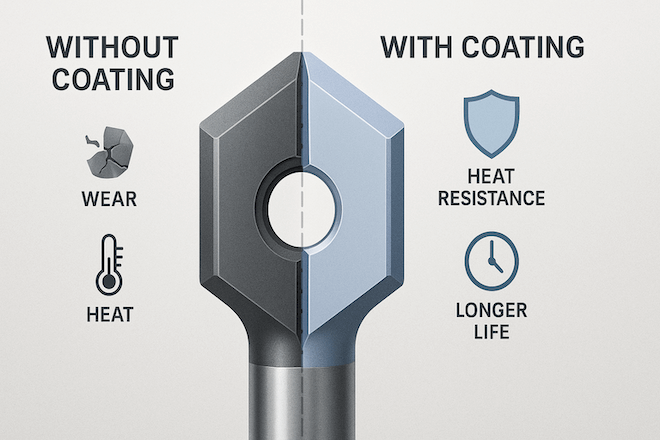

How Coatings Like TiN and DLC Improve Tungsten Carbide Bushings

Tungsten carbide bushings are widely used in industries such as oil and gas, chemical processing, and machinery because of their excellent wear resistance and hardness. However, even the best tungsten carbide surfaces can experience friction, corrosion, or premature wear under extreme conditions. This is where advanced coatings such as TiN (Titanium Nitride) and DLC (Diamond-Like […]

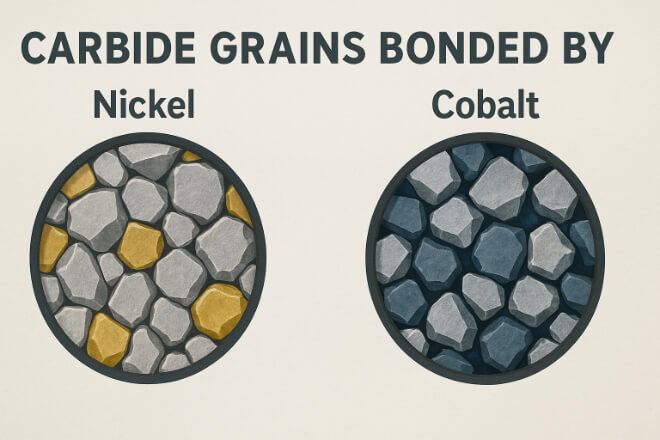

Nickel-Bonded vs Cobalt-Bonded Tungsten Carbide Bushings

Tungsten carbide bushings are essential components in many industrial systems, valued for their hardness, wear resistance, and durability. The performance of these bushings depends not only on the tungsten carbide (WC) itself but also on the type of metal binder used—most commonly nickel (Ni) or cobalt (Co). The binder holds tungsten carbide grains together, influencing […]

Field Repair Options for Worn Tungsten Carbide Bushings

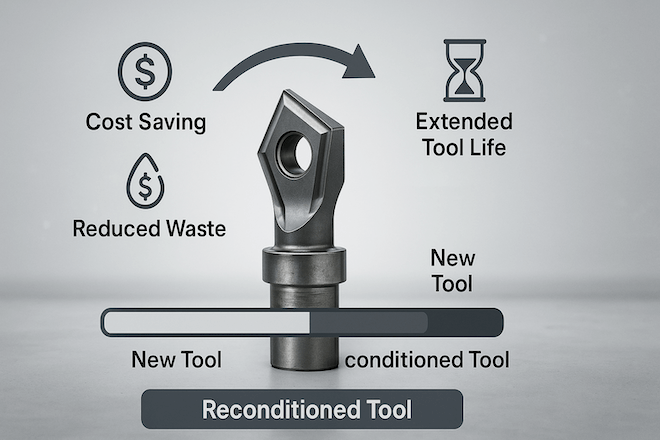

Tungsten carbide bushings are designed to handle extreme wear, friction, and pressure in pumps, compressors, and rotating machinery. However, even the most durable bushings eventually wear down after long service. When this happens, replacing the bushing is not always the fastest or most cost-effective option. In many cases, field repair can restore worn tungsten carbide […]

Proper Handling and Storage of Tungsten Carbide Bushings

Tungsten carbide bushings are vital components in various industrial applications, known for their exceptional durability, wear resistance, and hardness. These properties make them ideal for use in high-load, high-speed environments. However, proper handling and storage are essential to maintain the integrity and performance of tungsten carbide bushings. Mishandling or improper storage can lead to cracks, […]

How to Measure Internal and External Clearance of Bushings

Accurate measurement of the internal and external clearance of bushings is essential for ensuring that these components function properly and efficiently in machinery. Bushings are critical for reducing friction, supporting rotating shafts, and preventing wear in various industrial applications. When the clearance between the bushing and its mating components is not properly measured or maintained, […]

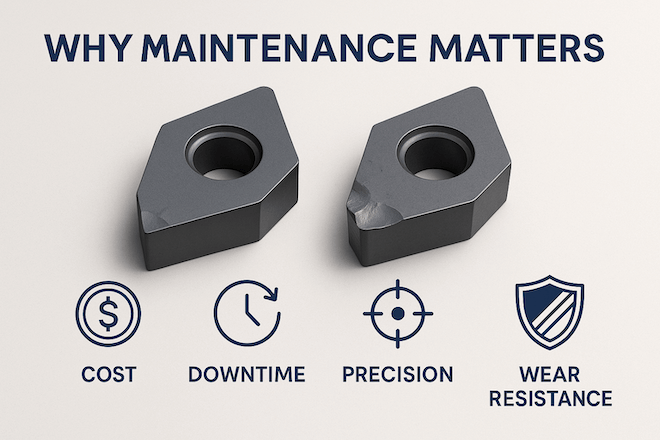

Maintenance Checklist for Pump Bushings Made of Tungsten Carbide

Tungsten carbide bushings are essential components in pumps, offering high resistance to wear, heat, and corrosion. They are used in various industries, including oil and gas, chemical processing, and water treatment. However, even the toughest materials require regular maintenance to ensure optimal performance and longevity. In this blog, we will outline a simple and effective […]

How Lubrication Affects Tungsten Carbide Bushing Life

Tungsten carbide bushings are widely used in industrial applications for their exceptional wear resistance, hardness, and durability. However, even the toughest materials can experience premature failure if not properly maintained. One of the most important factors that influence the lifespan of tungsten carbide bushings is lubrication. Proper lubrication reduces friction, prevents wear, and ensures that […]

Preventing Misalignment and Vibration in Tungsten Carbide Bushing Systems

Tungsten carbide bushings are highly durable and widely used in various industrial applications that demand high wear resistance and toughness. However, even the toughest materials can experience performance issues if not properly installed and maintained. Misalignment and vibration are two common problems that can significantly impact the performance of tungsten carbide bushing systems. In this […]

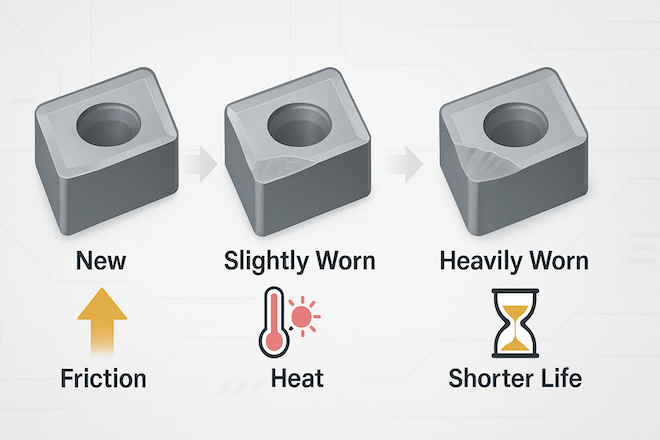

Causes of Premature Wear in Tungsten Carbide Bushings

Tungsten carbide bushings are essential components in many industrial applications due to their excellent wear resistance and durability. However, despite their toughness, tungsten carbide bushings can experience premature wear if not properly maintained or installed. In this blog, we will explore the common causes of premature wear in tungsten carbide bushings, how these issues can […]

Aligning Shaft and Housing for Tungsten Carbide Bushings

Tungsten carbide bushings are integral components in various industrial applications, particularly where high wear resistance, toughness, and durability are required. These bushings are often subjected to harsh conditions, such as high loads, high speeds, and extreme temperatures. To ensure optimal performance and longevity, proper alignment of the shaft and housing during installation is crucial. Misalignment […]

Common Installation Mistakes with Tungsten Carbide Bushings

Tungsten carbide bushings are highly valued for their exceptional wear resistance, toughness, and longevity. However, improper installation can lead to premature failure or reduced performance, even in these durable components. In this blog, we will explore the most common installation mistakes made with tungsten carbide bushings and offer practical solutions to avoid these pitfalls. By […]

How to Press-Fit Tungsten Carbide Bushings Without Cracking

Tungsten carbide bushings are widely used in industries that require exceptional wear resistance, durability, and toughness. These bushings play a critical role in high-performance machinery, from pumps to heavy equipment. However, one common challenge during installation is the risk of cracking the bushing during the press-fit process. This blog will explore how to press-fit tungsten […]

The Role of Polishing and Lapping in Tungsten Carbide Bushing Performance

Tungsten carbide bushings are highly valued for their durability, wear resistance, and hardness, making them ideal for use in demanding applications like pumps, machinery, and aerospace components. However, to ensure optimal performance and lifespan, the surface finish of the bushings plays a crucial role. Two key processes that significantly impact the performance of tungsten carbide […]

Common Machining Tolerances for Tungsten Carbide Bushings

Tungsten carbide bushings are widely used in industries that require high durability and resistance to wear, such as automotive, aerospace, and manufacturing. To ensure that these bushings perform optimally, it is crucial to adhere to specific machining tolerances during their manufacturing process. In this blog, we will explore the common machining tolerances for tungsten carbide […]

Understanding Micrograin vs Submicron Tungsten Carbide Bushings

Tungsten carbide bushings are essential components in industries that require high wear resistance and durability, such as automotive, mining, and aerospace. One critical factor in the performance of these bushings is the grain size of the tungsten carbide material used to manufacture them. In this blog, we will explore the differences between micrograin and submicron […]

Surface Roughness Values That Extend Bushing Lifespan

Surface roughness plays a crucial role in the performance and lifespan of bushings, particularly in demanding industrial applications. Tungsten carbide bushings, known for their exceptional wear resistance and hardness, require specific surface roughness values to ensure optimal functioning over time. In this blog, we will discuss how surface roughness affects the lifespan of bushings, the […]

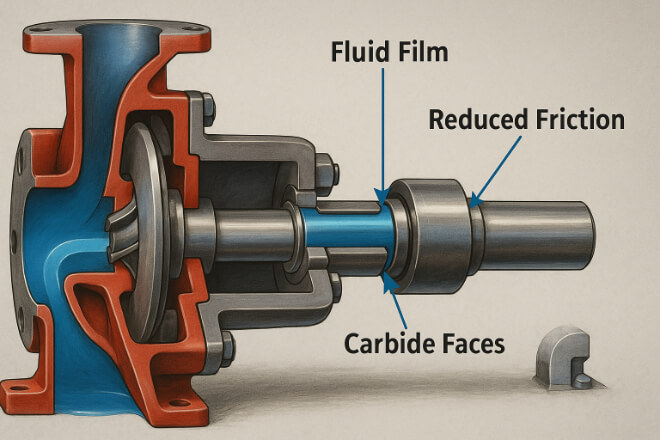

Coefficient of Friction in Tungsten Carbide Bushings Explained

Tungsten carbide bushings are known for their exceptional hardness and wear resistance. However, one of the critical factors that determine their performance in various industrial applications is the coefficient of friction (CoF). The CoF is an important measure of how much frictional resistance occurs when two materials interact, and it directly affects the efficiency, lifespan, […]

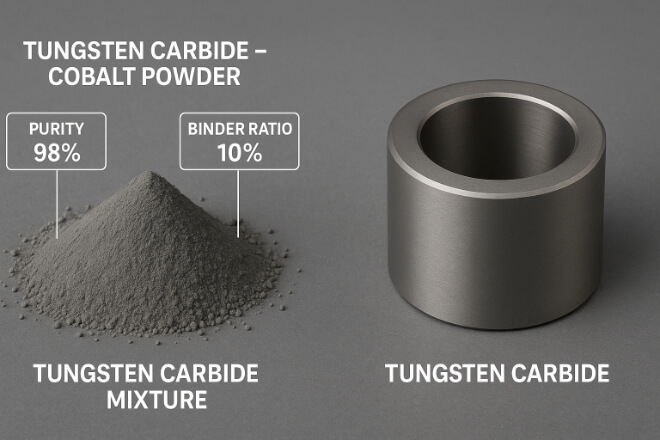

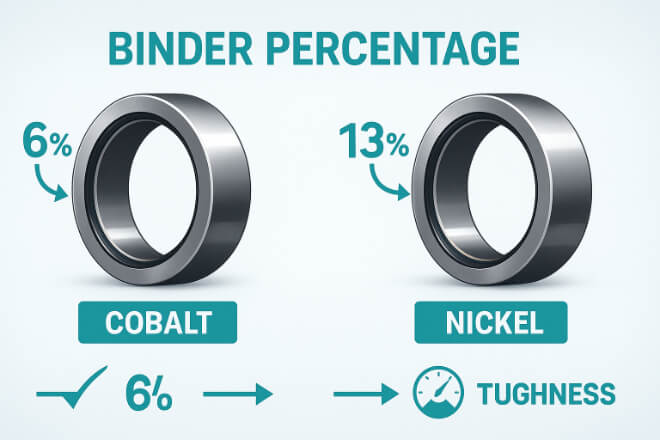

The Effect of Binder Percentage on Tungsten Carbide Bushings

Tungsten carbide bushings are widely used in industries requiring high wear resistance, durability, and toughness. The performance and longevity of these bushings depend heavily on their composition, particularly the binder percentage. The binder, typically cobalt or nickel, plays a crucial role in the mechanical properties and performance of the bushing. In this blog, we will […]

Recommended Shaft Hardness for Tungsten Carbide Bushings

Tungsten carbide bushings are renowned for their wear resistance and durability, making them ideal for high-performance applications. However, to ensure optimal performance and lifespan, the hardness of the shaft that interacts with the bushing plays a critical role. In this blog, we will discuss the recommended shaft hardness for tungsten carbide bushings, the factors influencing […]

How to Control Thermal Expansion in Tungsten Carbide Bushings

Tungsten carbide bushings are known for their durability and resistance to wear, but one challenge in high-performance applications is controlling thermal expansion. When exposed to varying temperatures, materials expand and contract, which can affect the fit, function, and longevity of components like bushings. In this blog, we will explore why thermal expansion matters in tungsten […]

Optimal Surface Finish for Tungsten Carbide Bushings

The surface finish of tungsten carbide bushings plays a crucial role in their performance, longevity, and efficiency in various applications. Achieving the optimal surface finish can reduce wear, lower friction, and improve the overall functioning of the machinery. In this blog, we will explore the importance of surface finish for tungsten carbide bushings, factors that […]

Clearance Fit Guidelines for Tungsten Carbide Bushings

Selecting the right clearance fit for tungsten carbide bushings is critical for ensuring the efficiency and longevity of machinery. The proper fit ensures smooth operation, reduces friction, and minimizes wear. This blog will guide you through the key considerations when choosing the appropriate clearance fit for tungsten carbide bushings. Its impact on performance, and how […]

Tungsten Carbide Bushings for High-Temperature Environments

Tungsten carbide bushings are well-known for their exceptional durability and wear resistance. In high-temperature environments, where many materials fail to perform reliably, tungsten carbide stands out as a preferred material. This blog will discuss why tungsten carbide bushings are an excellent choice for applications exposed to high heat. The factors to consider when selecting them, […]

How to Select Tungsten Carbide Bushings for Deepwell Pumps

Selecting the right tungsten carbide bushings for deepwell pumps is critical to ensuring the long-term reliability and efficiency of your pumping systems. Tungsten carbide offers outstanding wear resistance and toughness, making it an ideal material for high-stress environments like deepwell pumps. This guide will walk you through the key factors to consider when choosing tungsten […]

Tungsten Carbide Bushings for Aggressive Fluids and Corrosive Media

Tungsten carbide bushings are essential for industries that work with aggressive fluids and corrosive media. These bushings are highly valued for their wear resistance, corrosion resistance, and thermal stability, making them ideal for applications in chemical processing, oil and gas, and mining. Why Tungsten Carbide Bushings Excel in Harsh Environments 1). Superior Corrosion Resistance Tungsten […]

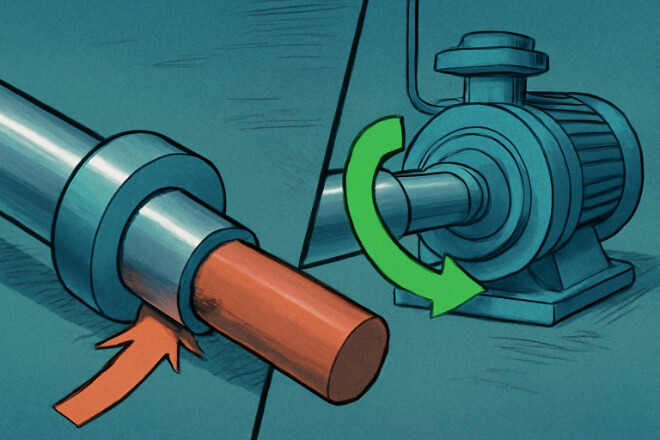

Why Tungsten Carbide Bushings Are Preferred in Chemical Pumps

Chemical pumps are crucial in many industries, from petrochemicals to pharmaceuticals, where they handle corrosive, abrasive, and high-temperature fluids. The materials used in these pumps need to be tough, wear-resistant, and able to withstand harsh chemical environments. Tungsten carbide bushings have become the preferred choice for chemical pumps due to their exceptional properties. In this […]

How Tungsten Carbide Bushings Perform in High RPM Conditions

High RPM (Revolutions Per Minute) applications are common in many industries, from pumps and motors to turbines and compressors. These systems often require components that can withstand extreme rotational speeds while maintaining performance and durability. Tungsten carbide bushings are an ideal solution for such conditions, offering superior wear resistance, thermal stability, and high strength. In […]

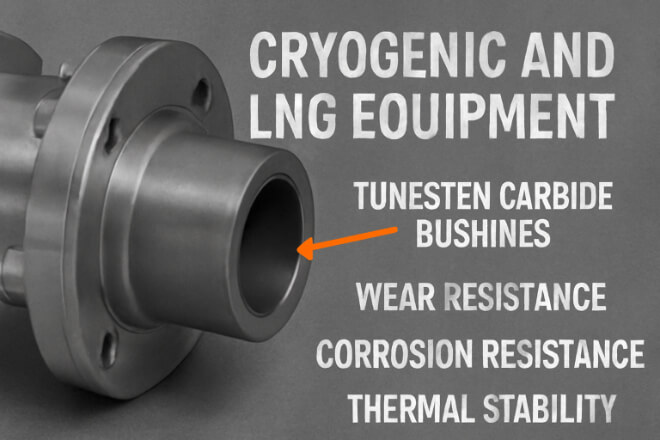

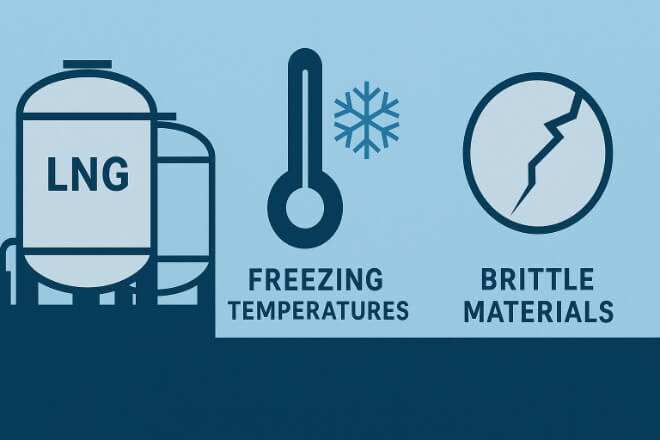

Using Tungsten Carbide Bushings in Cryogenic and LNG Equipment

Cryogenic and LNG (Liquefied Natural Gas) systems are designed to operate under extreme conditions. These systems often involve very low temperatures, high pressures, and corrosive environments. To ensure these systems run efficiently and reliably, the right materials are essential. Tungsten carbide bushings are one such material that provides superior performance in cryogenic and LNG applications. […]

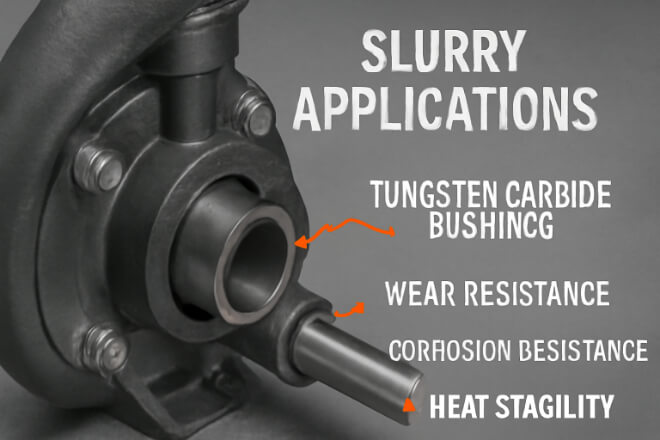

Best Materials for Tungsten Carbide Bushings in Slurry Applications

Slurry applications in industries like mining, wastewater treatment, and chemical processing require equipment that can handle abrasive, corrosive, and high-pressure conditions. Tungsten carbide bushings are an excellent choice for these environments due to their wear resistance, hardness, and ability to withstand corrosion. This guide explores the best materials for tungsten carbide bushings in slurry applications, […]

Tungsten Carbide Bushings for Submersible Pumps: A Complete Guide

Submersible pumps are essential in industries like oil and gas, mining, and water treatment. These pumps operate in extreme environments, submerged in harsh liquids under high pressure and temperatures. Tungsten carbide bushings are ideal for such conditions due to their exceptional wear resistance, corrosion resistance, and heat stability. This guide explains why tungsten carbide bushings […]

How Tungsten Carbide Bushings Improve Compressor Reliability

Compressors are essential in many industries, but they are often subject to wear and tear, leading to costly downtime. Tungsten carbide bushings improve compressor reliability by offering superior wear resistance, reducing maintenance, and extending service life. In this article, we’ll explore how these bushings contribute to smoother, more efficient compressor performance. What Are Tungsten Carbide […]

Tungsten Carbide Bushings for Centrifugal Pump Shafts

Centrifugal pumps are essential in industries such as water treatment, oil and gas, and chemicals. The pump shaft, which rotates at high speeds, is prone to wear. Tungsten carbide bushings offer an ideal solution for these shafts, providing durability, wear resistance, and performance in harsh conditions. In this article, we will explore why tungsten carbide […]

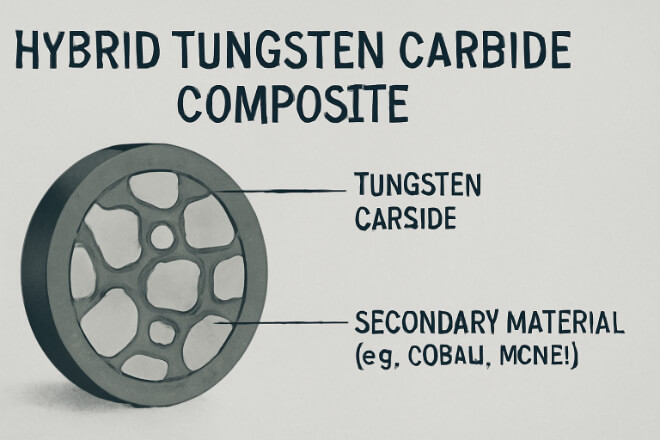

Hybrid Tungsten Carbide Composites for Extreme Conditions

In industries such as mining, oil & gas, and aerospace, machinery is often subjected to extreme conditions—high temperatures, pressures, and abrasive materials. To address these challenges, hybrid tungsten carbide composites are becoming increasingly popular. By combining tungsten carbide with other materials, these composites offer exceptional durability, wear resistance, and toughness. This article will explore the […]

Advances in Tungsten Carbide Bushing Coating Technology

Tungsten carbide bushings are crucial in many industrial applications due to their superior hardness and abrasion resistance. However, even the best materials require additional protection. Advanced coating technologies can significantly improve the performance, service life, and resilience of these bushings under harsh conditions. In this article, we will explore how coatings improve tungsten carbide bushings […]

3D Printing and Tungsten Carbide Bushings: Future of Manufacturing

In recent years, 3D printing has revolutionized many industries, particularly manufacturing. This advanced technology allows for precision, reduced waste, and quicker production timelines. When combined with tungsten carbide bushings, which are essential components in various machinery, the potential for innovation is vast. This article explores how 3D printing is shaping the future of manufacturing, specifically […]

How Nanostructured Tungsten Carbide Is Changing Bushing Design

Tungsten carbide bushings are widely used across industries such as mining, oil and gas, aerospace, and automotive for their unmatched wear resistance and durability. However, as demands for higher performance, longer life, and efficiency increase, the need for improved materials becomes ever more pressing. One of the cutting-edge innovations in tungsten carbide technology is nanostructured […]

Latest Innovations in Tungsten Carbide Bushing Materials

Tungsten carbide bushings are a vital component in many industries, offering high wear resistance and durability in demanding environments. However, as technology evolves, so do the materials used to make tungsten carbide bushings. With new innovations, manufacturers can now produce even more efficient, long-lasting, and eco-friendly bushings. In this post, we’ll explore some of the […]

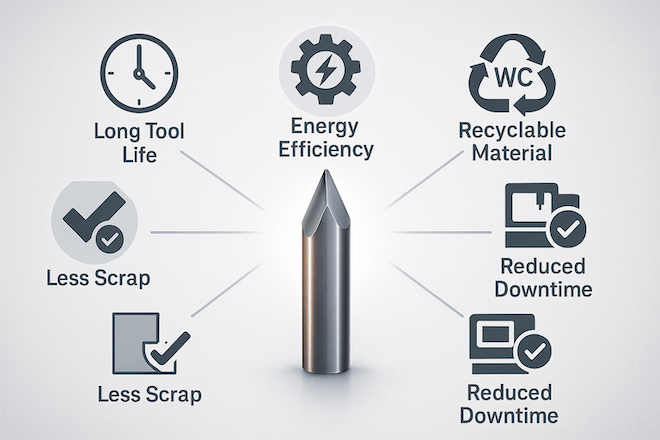

Energy Efficiency Benefits of Long-Life Tungsten Carbide Bushings

As industries strive to reduce energy costs and minimize environmental impact, tungsten carbide bushings have become a key component in achieving these goals. These high-performance bushings not only enhance the longevity of machinery but also offer significant energy savings. In this blog, we’ll dive into how long-life tungsten carbide bushings can help industries run more […]

Eco-Friendly Aspects of Using Tungsten Carbide Bushings

In industries worldwide, sustainability is becoming a key focus. As companies search for eco-friendly alternatives, tungsten carbide bushings have gained recognition for their environmental benefits. This article will explore the eco-friendly advantages of using tungsten carbide bushings, focusing on their durability, energy efficiency, recyclability, and low maintenance. Advantage 1: Durability and Longevity Tungsten carbide bushings […]

How Recycling Tungsten Carbide Bushings Reduces Waste and Cost

Tungsten carbide bushings are essential components used in various industrial applications, particularly in demanding environments like mining, pumps, and automotive systems. These bushings are known for their durability, wear resistance, and ability to handle high-pressure and high-temperature conditions. However, like any industrial material, tungsten carbide eventually wears out and needs to be replaced. The good […]

Can Tungsten Carbide Bushings Be Recycled?

Tungsten carbide bushings are well-known for their exceptional hardness, wear resistance, and long service life. They are used in critical applications — from pumps and compressors to drilling and automotive systems. But when these bushings reach the end of their service life, what happens next? Can they be reused or recycled? The good news is […]

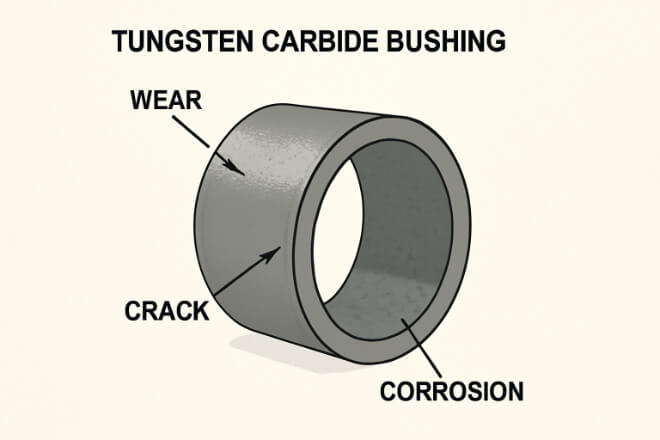

Common Failure Modes in Tungsten Carbide Bushings and How to Avoid Them

Tungsten carbide bushings are used in some of the toughest working conditions — inside pumps, compressors, turbines, and drilling tools. Their main job is to reduce friction and provide stable support for rotating shafts. Although tungsten carbide is extremely hard and durable, it is not indestructible. Improper use, poor lubrication, or incorrect fitting can lead […]

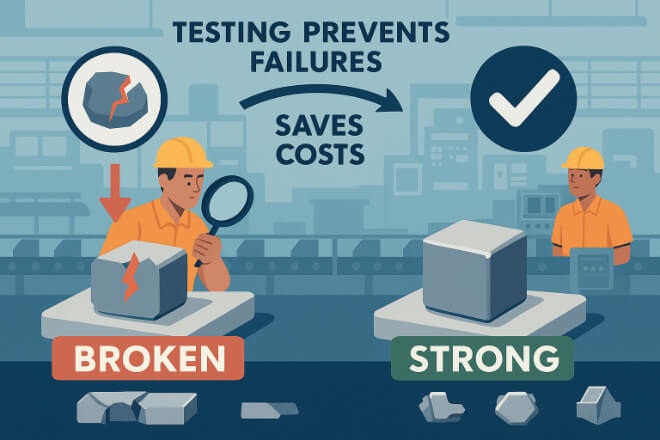

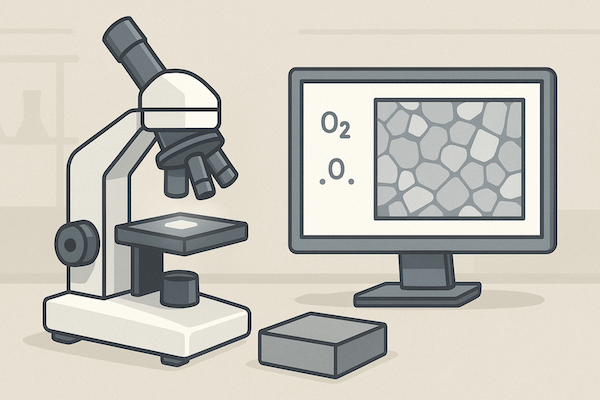

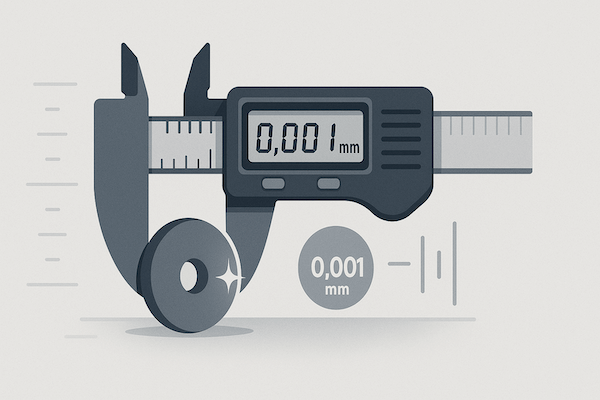

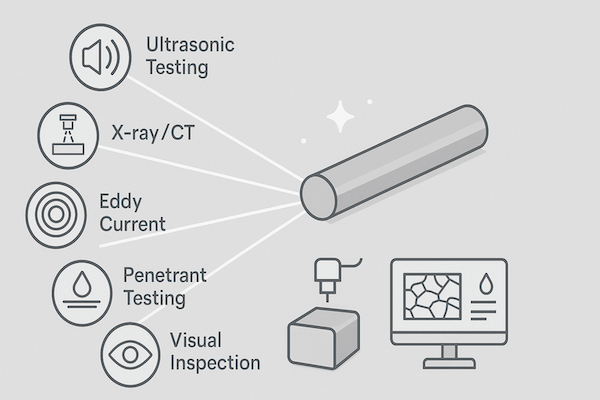

Testing and Quality Inspection Methods for Tungsten Carbide Bushings

Tungsten carbide bushings are critical components used in pumps, compressors, and industrial machinery where wear resistance, strength, and precision are essential. For decision-makers in manufacturing or maintenance, ensuring each bushing meets strict quality standards is not optional—it is vital for reliability and cost control. This article explains the main testing and quality inspection methods used […]

Coatings and Treatments That Enhance Tungsten Carbide Bushing Life

Tungsten carbide bushings are known for their high hardness, wear resistance, and durability. They are used in pumps, compressors, valves, and other heavy-duty machinery where precision and long life are essential. But even the best tungsten carbide will eventually wear out if it faces extreme friction, heat, or corrosion. To extend service life and reduce […]

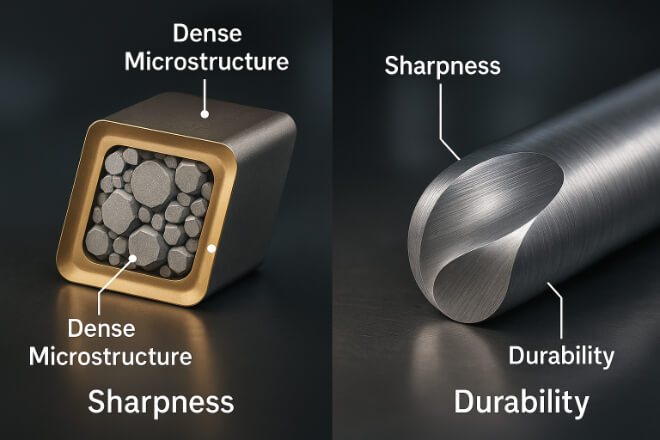

The Role of Grain Size in Tungsten Carbide Bushing Strength

When choosing tungsten carbide bushings, many buyers focus on binder percentage or overall hardness. However, one hidden factor defines how strong, tough, and reliable the part truly is — grain size. The grain size of tungsten carbide controls how the bushing reacts under stress, friction, and temperature. A change as small as a few microns […]

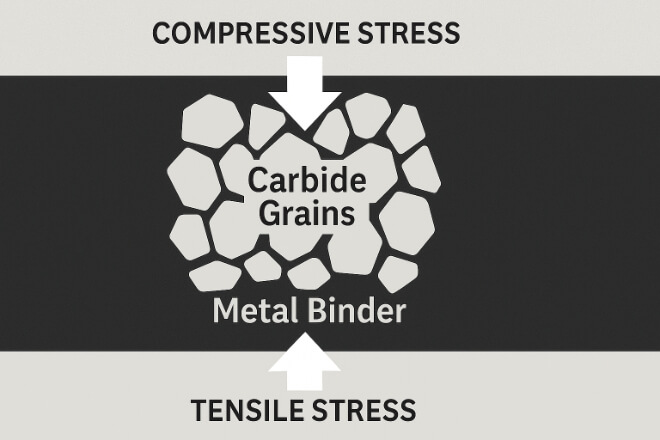

Stress, Load, and Thermal Expansion Analysis in Tungsten Carbide Bushings

Tungsten carbide bushings are widely used in pumps, compressors, turbines, and mechanical seals — where they must handle high pressure, speed, and temperature. To work reliably, these bushings must maintain their shape, strength, and fit under stress, load, and temperature changes. If not properly designed or analyzed, they may crack, deform, or seize, leading to […]

Tribology and Friction Behavior of Tungsten Carbide Bushings

In modern mechanical systems, friction control plays a key role in efficiency and durability. Whether in pumps, compressors, or turbines, every moving part relies on bushings or bearings to reduce wear and maintain stability. Among many materials used, tungsten carbide bushings stand out for their exceptional tribological performance — the science of friction, wear, and […]

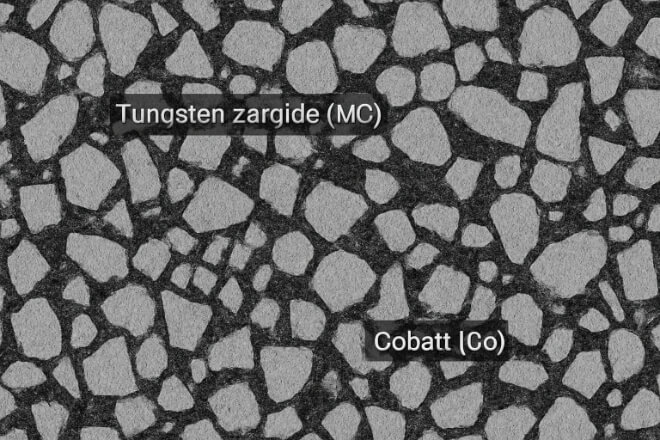

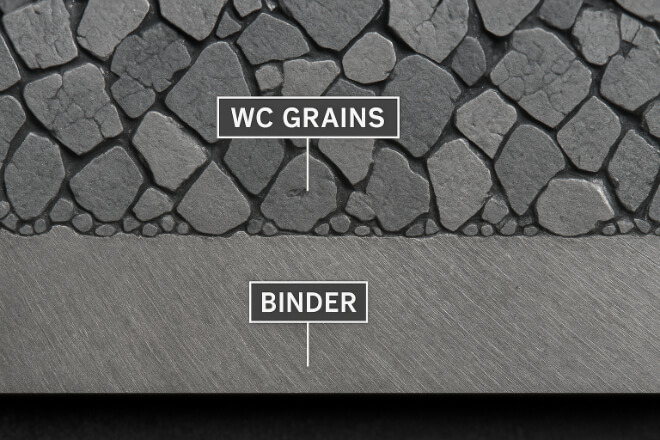

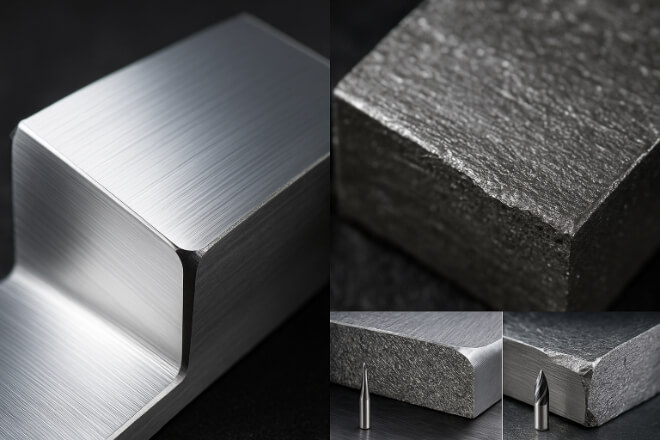

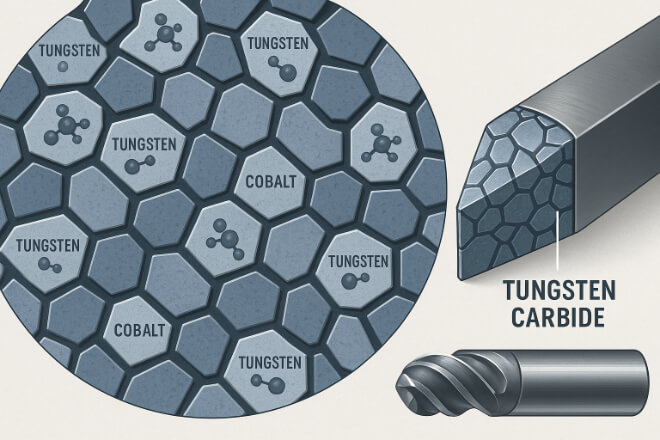

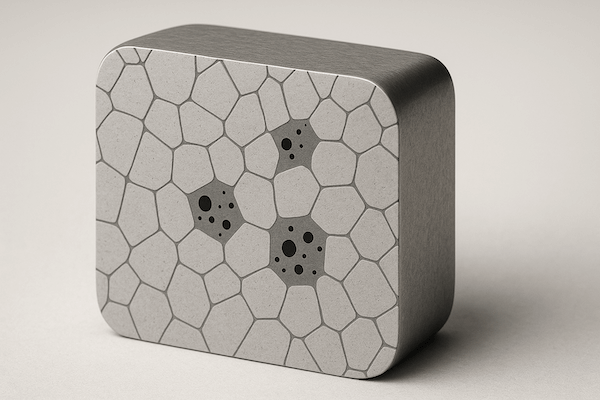

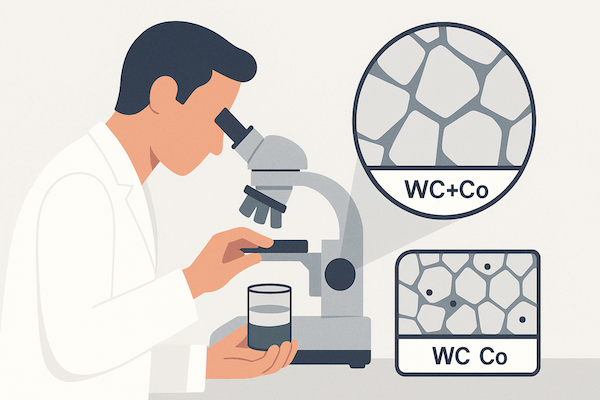

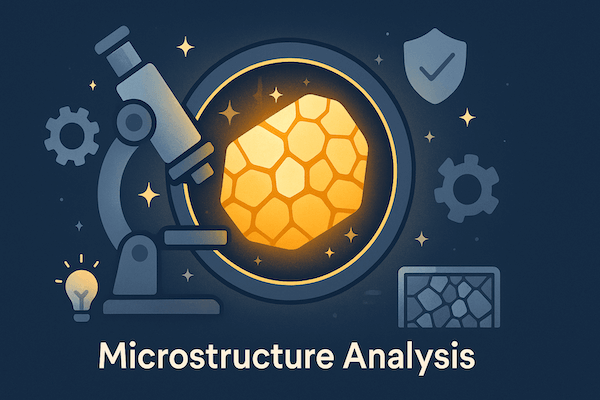

How Microstructure Affects the Performance of Tungsten Carbide Bushings

The microstructure of tungsten carbide bushings plays a key role in determining how well they perform under wear, heat, and pressure. While many buyers focus on grade codes like YG6 or YG8, the real story lies inside — in the arrangement of carbide grains and binder metal. For decision-makers in industries such as oil & […]

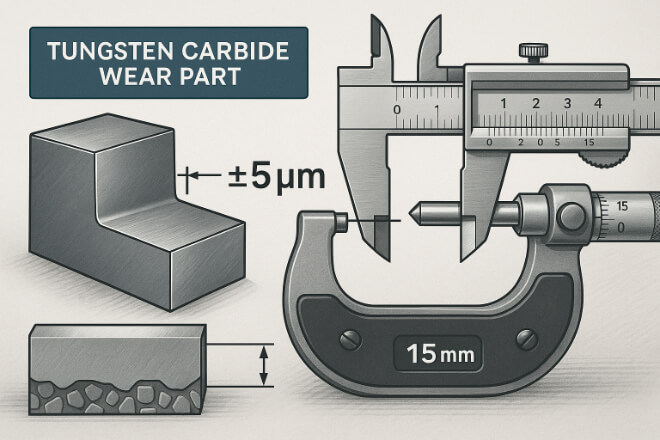

Dimensional Tolerances and Surface Finish in Tungsten Carbide Bushings

When engineers select tungsten carbide bushings for pumps, compressors, or turbines, they often focus on hardness and wear resistance. But two equally critical parameters are dimensional tolerance and surface finish. These two factors determine how well the bushing fits the shaft, how smoothly it operates, and how long it lasts. Even a small deviation — […]

How to Evaluate Supplier Quality for Tungsten Carbide Bushings

When sourcing tungsten carbide bushings, quality is not just about the product — it’s about the supplier behind it. A good supplier can ensure consistent performance, fast delivery, and long-term reliability. A poor supplier, on the other hand, can lead to production delays, early wear, or even equipment damage. For decision-makers in oil & gas, […]

Custom vs Standard Tungsten Carbide Bushings: Which Is Right for You?

When choosing tungsten carbide bushings for industrial equipment, one of the first questions buyers face is: Should I go with standard bushings or custom ones? At first, it may seem easier to pick a standard size — after all, it’s faster and cheaper. But in many high-performance machines, custom tungsten carbide bushings offer better fit, […]

Global Sourcing Guide: Top Tungsten Carbide Bushing Manufacturers

In today’s global manufacturing market, sourcing tungsten carbide bushings is not just about finding a supplier — it’s about finding the right partner. Tungsten carbide bushings are critical components in pumps, compressors, turbines, and drilling tools. Their reliability depends heavily on material purity, manufacturing precision, and quality control. As industries become more international, global sourcing […]

The Importance of Material Certification in Tungsten Carbide Bushings

In modern manufacturing, trust and traceability are everything. When it comes to tungsten carbide bushings, one missing document can mean serious trouble — machine failure, rejected batches, or even safety violations. That document is the material certification. Material certification proves that the bushings you receive were made using verified raw materials that meet required chemical […]

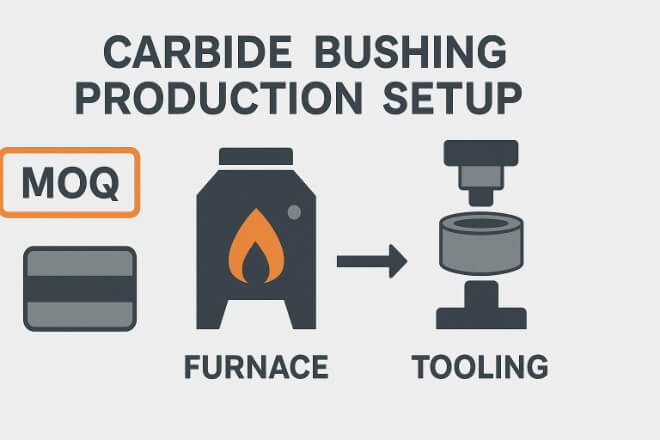

Understanding MOQ and Lead Time for Custom Tungsten Carbide Bushings

When sourcing custom tungsten carbide bushings, two terms often decide whether your project runs smoothly or faces costly delays: MOQ (Minimum Order Quantity) and lead time. For many decision-makers, these factors directly affect production schedules, procurement costs, and inventory strategies. Understanding how MOQ and lead time are set — and how to manage them effectively […]

How to Choose a Reliable Tungsten Carbide Bushing Supplier

Choosing the right tungsten carbide bushing supplier is one of the most important decisions for any manufacturer or plant operator. The quality of your bushings directly affects machine life, downtime, and maintenance cost. A reliable supplier is not just a vendor — it’s a long-term partner that helps you achieve consistent performance, cost control, and […]

Total Cost of Ownership: Why Tungsten Carbide Bushings Pay Off Long Term

When choosing components for pumps, compressors, or turbines, many engineers focus only on the initial purchase price. But over time, the true cost is not what you pay upfront — it’s what you spend to keep your equipment running efficiently. This concept is called Total Cost of Ownership (TCO). It includes not just the purchase […]

Factors Affecting the Cost of Tungsten Carbide Bushings

Tungsten carbide bushings are widely used in pumps, compressors, turbines, and rotating machinery. They provide exceptional wear resistance, strength, and dimensional stability under harsh conditions. However, prices for tungsten carbide bushings vary greatly from one supplier to another. Understanding what drives these costs helps buyers make smarter procurement decisions — balancing performance, reliability, and long-term […]

How to Regrind or Refurbish Tungsten Carbide Bushings

Tungsten carbide bushings are designed for extreme wear resistance and high load performance. They are widely used in pumps, compressors, turbines, and heavy-duty industrial machinery. However, after long periods of use, even carbide bushings begin to lose dimensional accuracy and surface quality. Instead of immediate replacement, regrinding or refurbishing can often restore their performance — […]

Signs It’s Time to Replace Your Tungsten Carbide Bushings

Tungsten carbide bushings are known for their exceptional wear resistance and long service life. They protect rotating shafts, maintain alignment, and reduce friction in pumps, compressors, turbines, and other mechanical systems. However, even the most durable bushing will eventually reach its wear limit. Running equipment with a damaged or worn tungsten carbide bushing can lead […]

Lubrication and Cooling Best Practices for Tungsten Carbide Bushings

Tungsten carbide bushings are used in high-performance systems such as pumps, compressors, turbines, and rotating equipment. They are chosen for their hardness, wear resistance, and dimensional stability — even under heavy loads and extreme temperatures. However, their performance heavily depends on two key factors: proper lubrication and effective cooling. Without them, even the hardest material […]

How to Achieve Precision Fit Between Shaft and Tungsten Carbide Bushing

In high-performance machinery, the fit between the shaft and the tungsten carbide bushing determines how efficiently and reliably the system operates. A precision fit ensures correct alignment, minimizes friction, prevents vibration, and extends the lifespan of both the shaft and the bushing. Even if the bushing is made from high-quality tungsten carbide, poor fitting can […]

Understanding Tolerances and Surface Finishes in Tungsten Carbide Bushings

Tungsten carbide bushings are critical components in rotating machinery. They support shafts, control alignment, and minimize wear under high-pressure or high-speed conditions. While most engineers focus on material hardness and composition, tolerances and surface finishes often determine whether a bushing will succeed or fail in real operation. Small differences in dimensional accuracy or roughness can […]

How to Prevent Corrosion and Pitting in Tungsten Carbide Bushings

Tungsten carbide bushings are known for their hardness and wear resistance, making them vital in pumps, compressors, and high-load rotating systems. However, corrosion and pitting remain two major threats that reduce service life — especially in chemical, marine, or wet process environments. If corrosion is left unchecked, the binder phase (nickel or cobalt) begins to […]

Maintenance Tips to Extend the Life of Tungsten Carbide Bushings

Tungsten carbide bushings are among the most durable components used in pumps, compressors, turbines, and industrial machinery. Their hardness and wear resistance make them ideal for demanding environments. However, even the toughest materials need proper maintenance to deliver long-term performance. Regular inspection, correct lubrication, and suitable operating conditions can significantly extend the lifespan of tungsten […]

How to Inspect Tungsten Carbide Bushings for Wear or Damage

Tungsten carbide bushings are known for their exceptional hardness and wear resistance, but even the strongest materials can deteriorate over time. Regular inspection helps detect early signs of wear, cracking, or corrosion before they cause system failures. If inspection is ignored, bushings may seize, increase vibration, or damage shafts — all of which lead to […]

Installation Tips for Tungsten Carbide Bushings: Avoiding Common Mistakes

Even the best tungsten carbide bushings can fail early if they are installed incorrectly. These components are designed to handle extreme wear, high pressure, and temperature, but poor handling or improper fitting can cause cracks, misalignment, or performance loss. A correct installation ensures that the bushing achieves its full design life, maintains precise shaft alignment, […]

How to Specify the Right Tungsten Carbide Bushing for Your Equipment

Choosing the right tungsten carbide bushing is not just about picking a size or part number. It’s about making sure the bushing fits your equipment’s load, pressure, temperature, and medium — all while delivering maximum service life and minimal downtime. Tungsten carbide bushings are used in pumps, compressors, turbines, and rotating equipment where mechanical stress […]

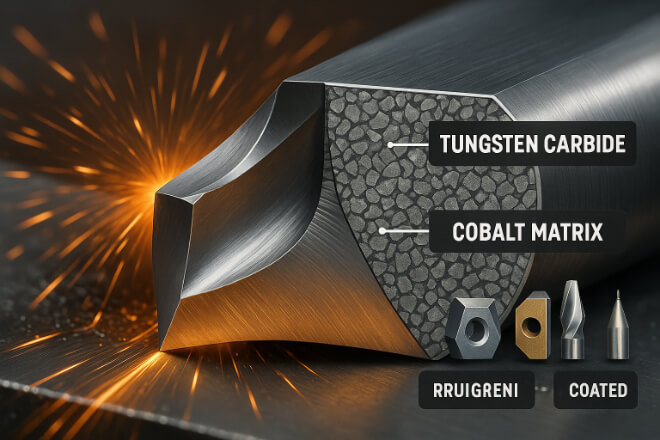

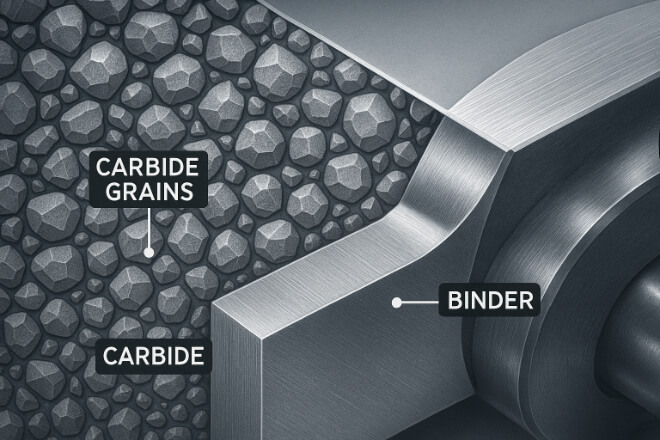

The Role of Cobalt Binder Content in Tungsten Carbide Bushings

Tungsten carbide bushings are known for their exceptional hardness, wear resistance, and durability. They are used in demanding industries — from oil and gas to chemical processing — where components must withstand friction, pressure, and corrosion. However, what truly defines the performance of a tungsten carbide bushing is not just the tungsten carbide itself, but […]

Comparing Different Grades of Tungsten Carbide Bushings

Tungsten carbide bushings are used in pumps, compressors, turbines, and many types of rotating machinery. Their job is simple — to reduce friction and wear between moving parts. But not all tungsten carbide bushings are the same. Different grades of tungsten carbide are designed for different working conditions. Choosing the right grade can affect your […]

Tungsten Carbide vs Silicon Carbide Bushings: Which Suits Your Process?

Selecting the right bushing material is one of the most important choices in designing pumps, compressors, or mixers. When a machine runs under high speed, pressure, or chemical exposure, the bushing material determines efficiency, wear life, and maintenance cost. Two of the most popular high-performance materials are tungsten carbide (WC) and silicon carbide (SiC). Both […]

So sánh ống lót phủ và ống lót cacbua vonfram nguyên khối

Bushings are essential parts in any system with rotating shafts — they guide, support, and reduce friction between moving components. In high-performance machinery, the type of bushing material you choose can determine the system’s reliability and lifespan. Two common types used in demanding industries are coated bushings and solid tungsten carbide bushings. Both aim to […]

Tại sao nên chọn ống lót cacbua vonfram thay vì ống lót kim loại thông thường?

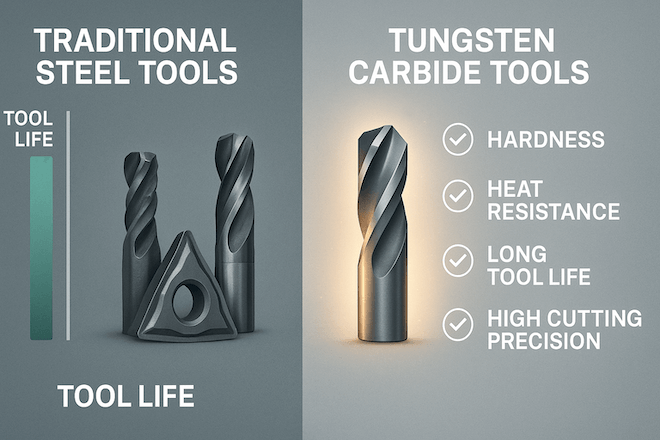

In many industrial machines — from pumps and compressors to drilling tools — bushings are critical parts that support shafts, reduce vibration, and prevent metal-to-metal contact. For decades, engineers relied on conventional metal bushings such as bronze, stainless steel, or brass. But as machines run faster and face harsher environments, these metals often wear out […]

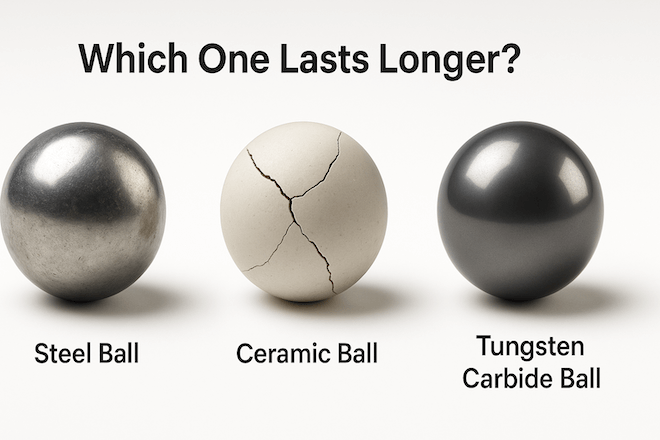

Ống lót cacbua vonfram so với ống lót gốm: Hiệu suất dưới áp lực

In demanding industrial systems — such as pumps, compressors, turbines, and chemical mixers — bushings play a key role in keeping shafts stable and reducing wear. When exposed to high pressure, temperature, and friction, material selection becomes critical to equipment reliability. Two materials often compared are tungsten carbide and ceramic bushings. Both are hard and […]

Ống lót cacbua vonfram so với ống lót đồng: So sánh thực tế

Bushings are essential in machines that involve movement — they reduce friction, guide shafts, and support rotating parts. The choice of bushing material has a big impact on reliability, performance, and maintenance cost. Two common materials used in demanding industrial systems are tungsten carbide and bronze. Both are strong and proven, but their performance characteristics […]

Ống lót cacbua vonfram so với ống lót thép không gỉ: Loại nào bền hơn?

When it comes to rotating equipment, pumps, and mechanical assemblies, bushings are the unsung heroes. They ensure smooth shaft movement, reduce vibration, and protect equipment from wear. But not all bushings perform equally under demanding conditions. Two of the most common materials are tungsten carbide and stainless steel. Both are durable, but their performance in […]

Ống lót cacbua vonfram trong máy móc thực phẩm và dược phẩm

In food and pharmaceutical manufacturing, every part of a machine must perform with precision, cleanliness, and long-term reliability. Equipment is constantly exposed to moisture, cleaning chemicals, and repetitive stress. Bushings — small but essential components that support rotating shafts — are often the first to fail if not made from the right material. When a […]

Ứng dụng của ống lót cacbua vonfram trong ngành công nghiệp ô tô

The automotive industry is constantly evolving. Modern vehicles demand higher performance, lighter materials, and longer-lasting components to stay competitive. Every part — from the engine to the transmission — must operate smoothly and reliably for thousands of hours. This pressure to improve efficiency and reduce maintenance has made tungsten carbide bushings an essential part of […]

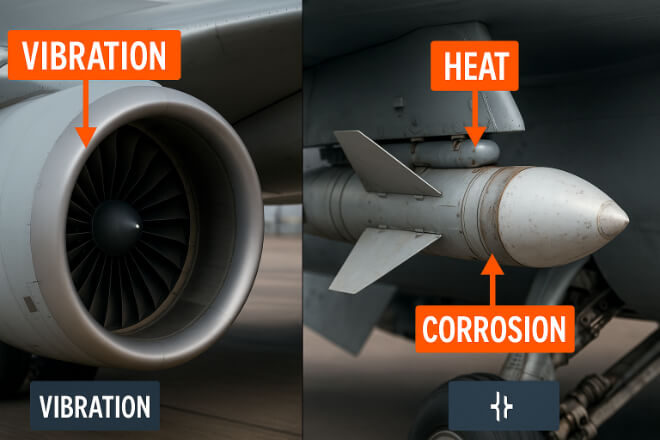

Why Aerospace and Defense Use Tungsten Carbide Bushings

The aerospace and defense industries demand absolute reliability. Every component—from turbines and landing gear to missile actuators—must perform perfectly under extreme stress, vibration, and temperature. In these sectors, failure is not an option. A single worn bearing or misaligned shaft can cause system damage or mission failure. That’s why tungsten carbide bushings have become essential […]

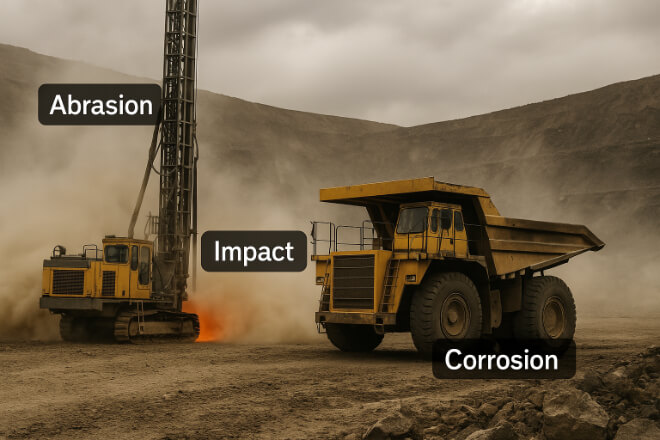

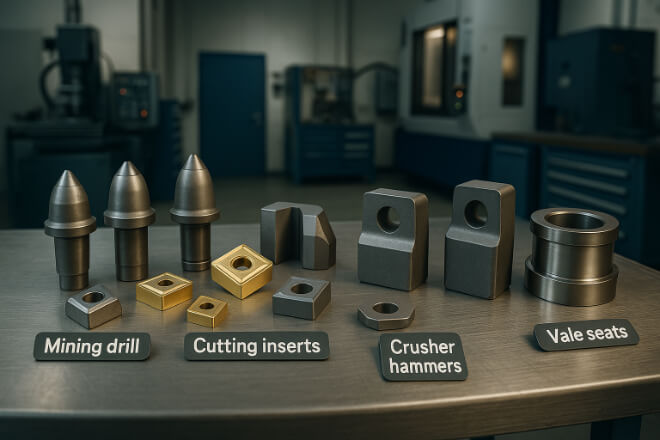

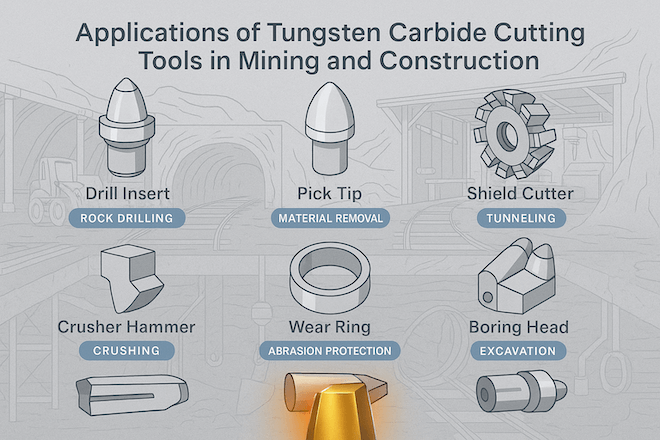

Tungsten Carbide Bushings for Mining and Drilling Applications

Mining and drilling are some of the toughest working environments in the world. Equipment used in these industries must endure abrasion, impact, vibration, and extreme pressure—often in dirty, wet, and dusty conditions. Every part of a machine that moves or rotates is under constant stress. Bearings, seals, and bushings face heavy wear from rock particles, […]

How Tungsten Carbide Bushings Enhance Chemical Processing Equipment

Chemical processing plants operate in some of the harshest industrial environments. Pumps, mixers, agitators, and compressors constantly face high pressure, temperature, and corrosive fluids. Every rotating component inside them must perform with precision and reliability. A small failure in a bearing or bushing can lead to leakage, contamination, or full equipment shutdown. This is why […]

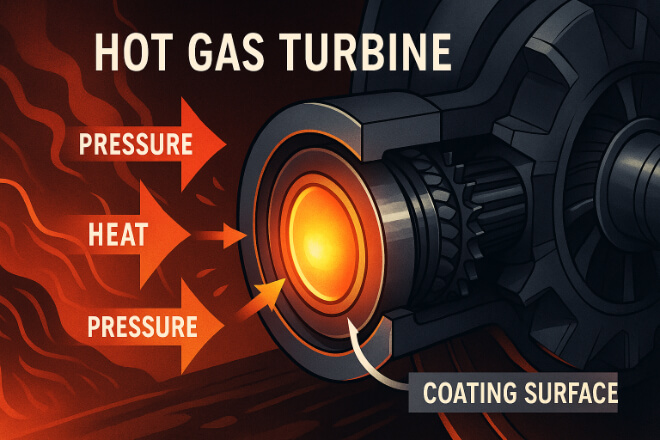

Tungsten Carbide Bushings for High-Temperature Industrial Operations

In high-temperature industrial operations, equipment faces extreme thermal stress, friction, and wear. Pumps, compressors, and rotating machinery often run at elevated temperatures for long periods, and even small material weaknesses can lead to failure. Tungsten carbide bushings are one of the few components that can perform reliably under such conditions. They provide excellent thermal stability, […]

Using Tungsten Carbide Bushings in Marine and Offshore Environments

Marine and offshore industries face some of the harshest working conditions on earth. Saltwater, pressure, vibration, and constant exposure to abrasive particles create extreme stress on machinery components. Pumps, compressors, and rotating equipment must operate continuously with little room for error. In such environments, tungsten carbide bushings play a vital role. They provide dimensional stability, […]

Tungsten Carbide Bushings in Water Pumps: Corrosion and Erosion Solutions

Water pumps are the backbone of modern industry and infrastructure — from power plants and desalination systems to irrigation and wastewater facilities. Yet, many pump failures begin with one small but important part: the bushing. Bushings support rotating shafts, maintain alignment, and reduce friction. However, in water and slurry environments, they are constantly attacked by […]

Why Tungsten Carbide Bushings Are Essential for Oil and Gas Equipment

The oil and gas industry operates in one of the toughest environments on Earth. Equipment used in drilling, pumping, and refining faces high pressure, abrasive fluids, extreme temperatures, and corrosive chemicals. To keep systems running safely and efficiently, every component must deliver exceptional reliability. Among these components, tungsten carbide bushings play a vital role. They […]

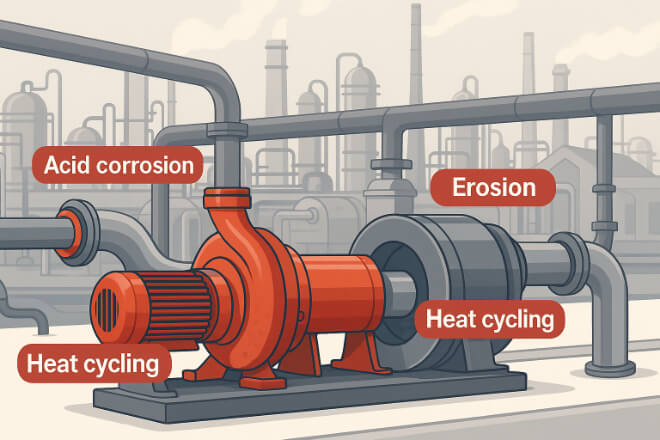

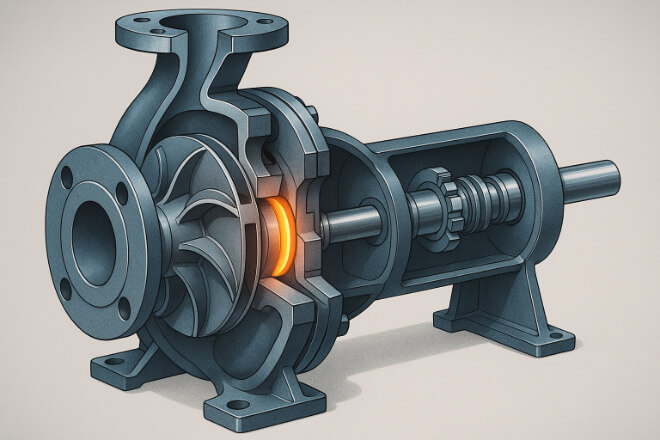

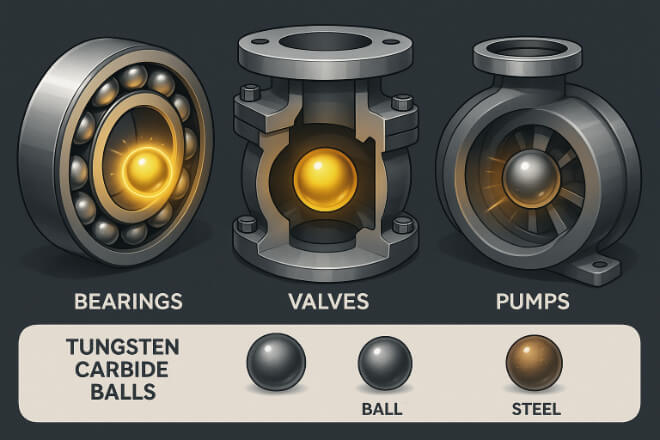

Applications of Tungsten Carbide Bushings in Pumps and Compressors

In many industries — from oil and gas to power generation and water treatment — pumps and compressors work non-stop under harsh conditions. Inside these machines, bushings play a small but critical role: they support rotating shafts, reduce friction, and maintain alignment. Among all materials used for bushings, tungsten carbide stands out for its exceptional […]

What Determines the Quality of Tungsten Carbide Bushings?

In modern industrial machinery, every small part affects the performance of the entire system. Among these parts, tungsten carbide bushings play a key role in reducing friction, supporting rotating shafts, and extending the life of pumps, compressors, and turbines. However, not all carbide bushings are made equal. The quality of a tungsten carbide bushing depends […]

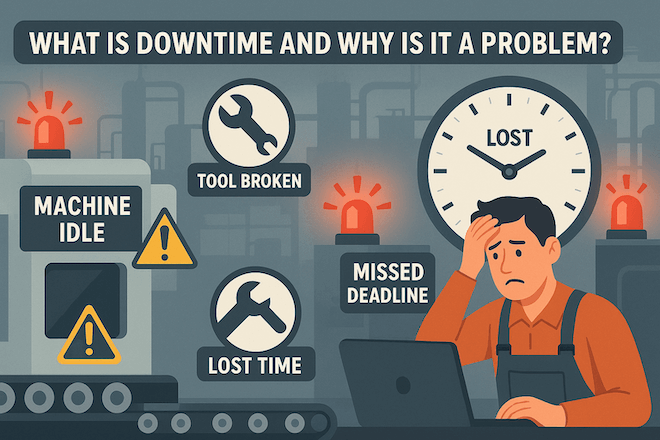

How Tungsten Carbide Bushings Reduce Equipment Downtime

In industrial environments, downtime is expensive. Every hour a pump, compressor, or turbine stops working costs time, money, and sometimes even production losses. Many of these failures start with small components — like bushings — wearing out faster than expected. Tungsten carbide bushings have become the industry standard for reducing maintenance frequency and unplanned shutdowns. […]

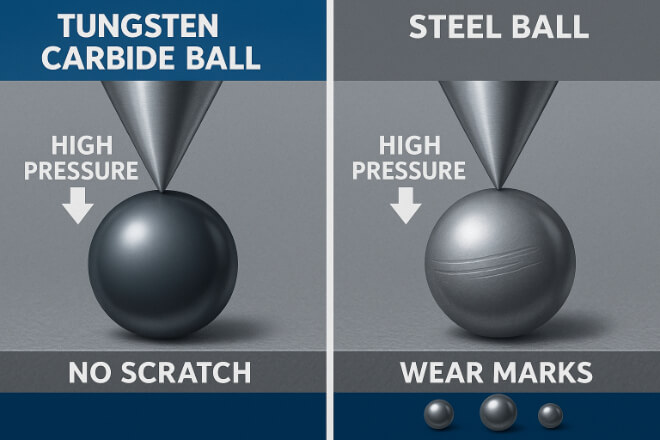

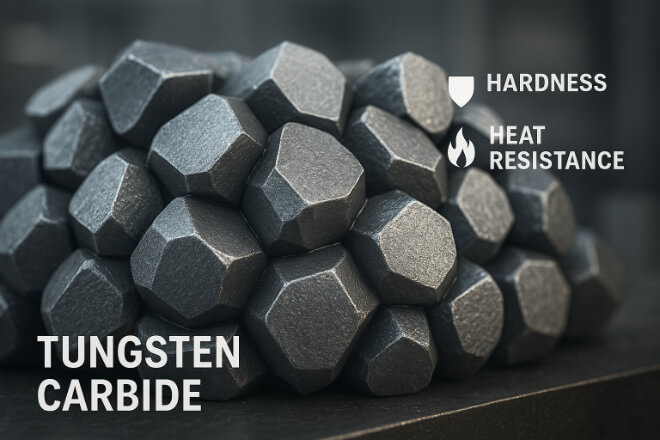

Why Tungsten Carbide Is Ideal for High-Pressure Bushings

In high-pressure machinery such as pumps, compressors, and hydraulic systems, every part must withstand extreme stress, friction, and temperature. Among all wear-resistant components, tungsten carbide bushings stand out as one of the most reliable materials for these demanding environments. The key lies in the science of strength. Tungsten carbide combines hardness, compressive strength, and thermal […]

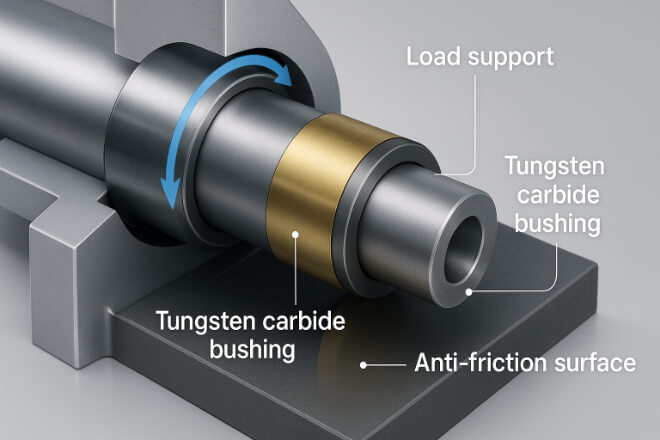

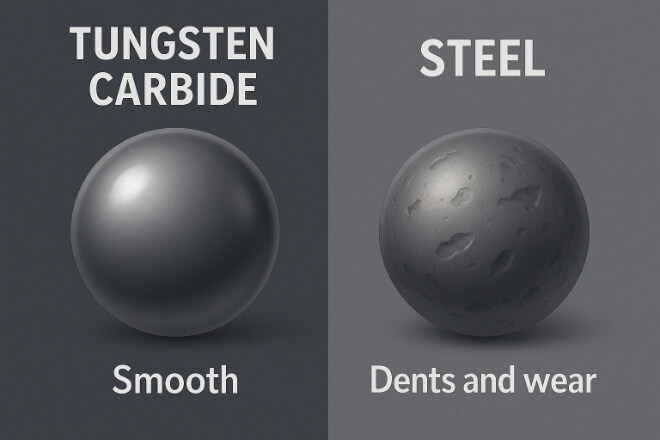

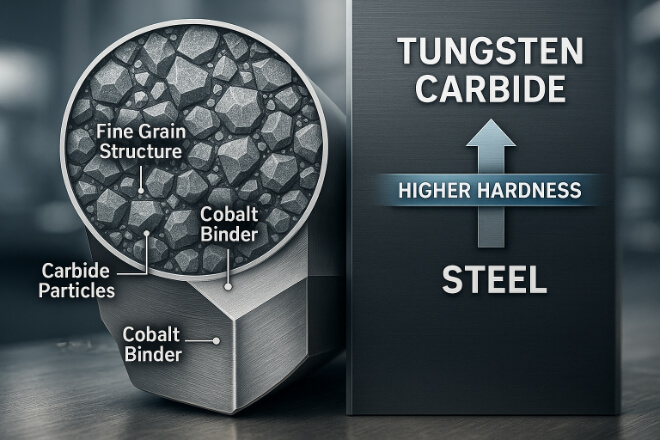

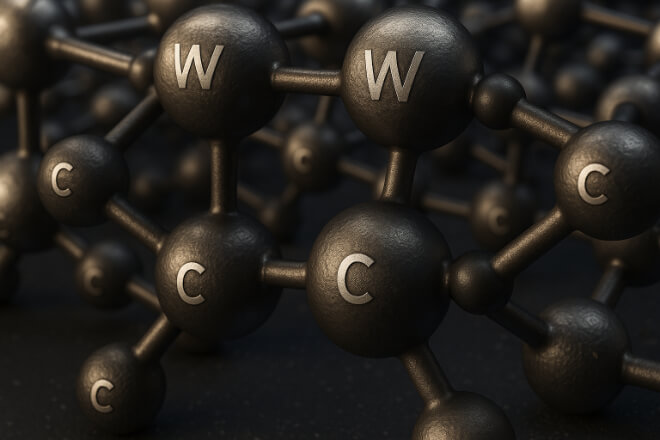

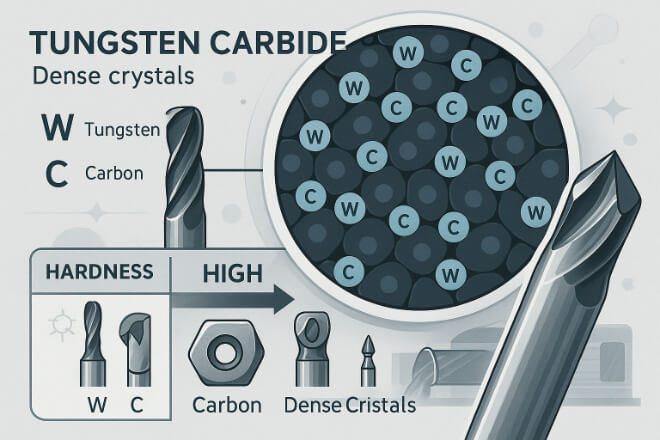

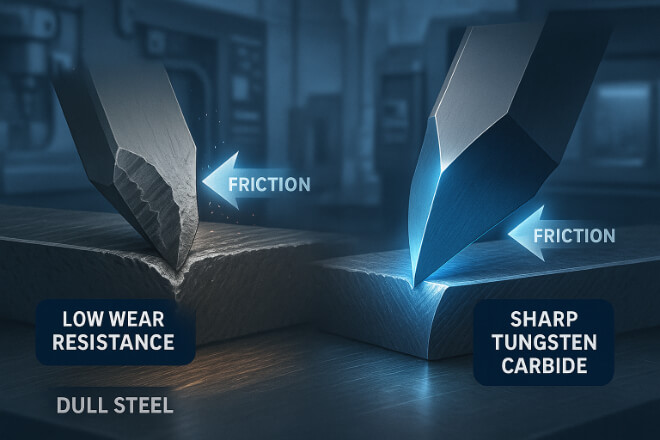

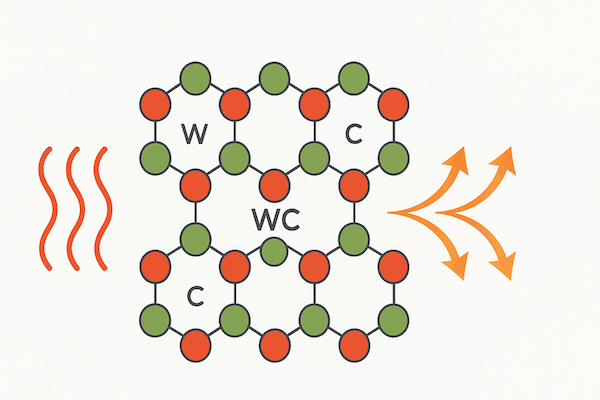

The Science Behind Wear Resistance in Tungsten Carbide Bushings

In modern industrial machines, parts are often exposed to friction, pressure, and harsh materials that cause wear. Once wear begins, efficiency drops, clearances increase, and failures become more frequent. To prevent this, engineers use materials that can withstand these demanding conditions — one of the most successful being tungsten carbide. Among its many uses, tungsten […]

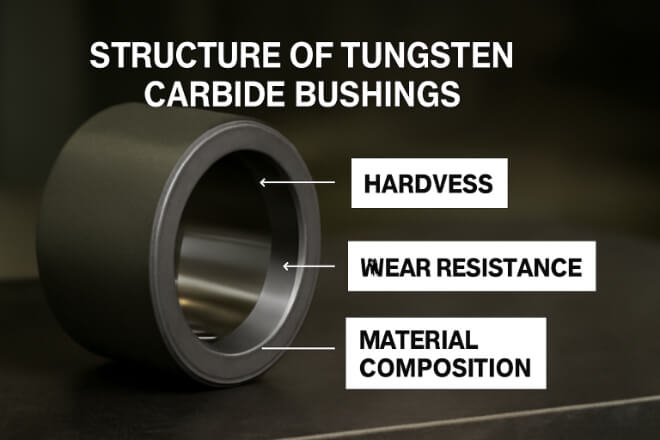

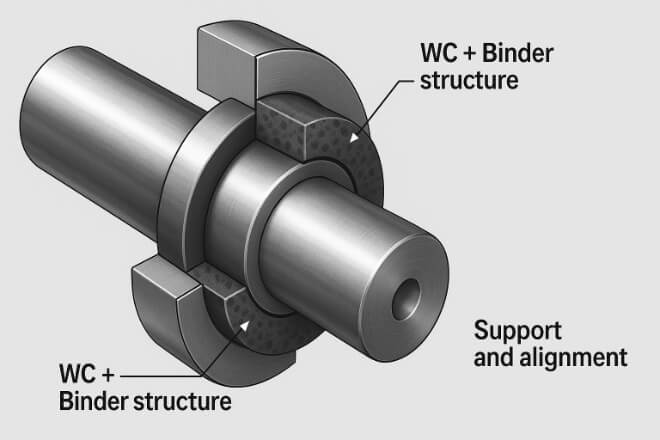

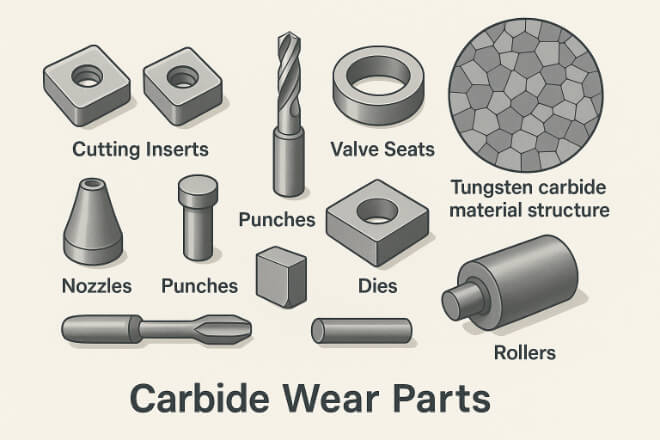

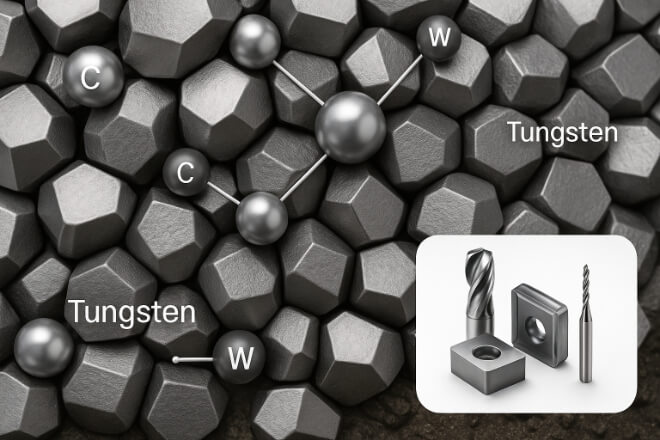

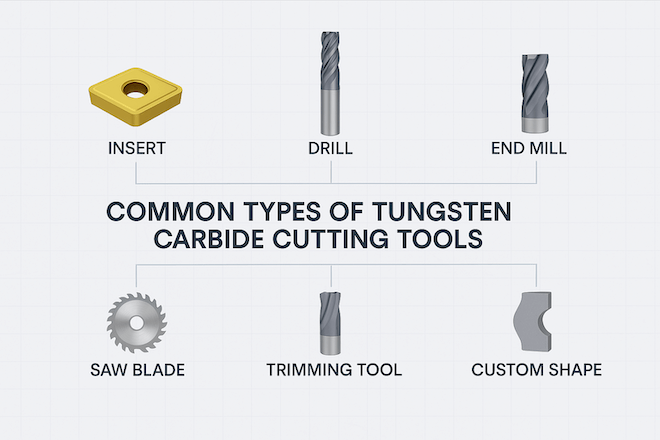

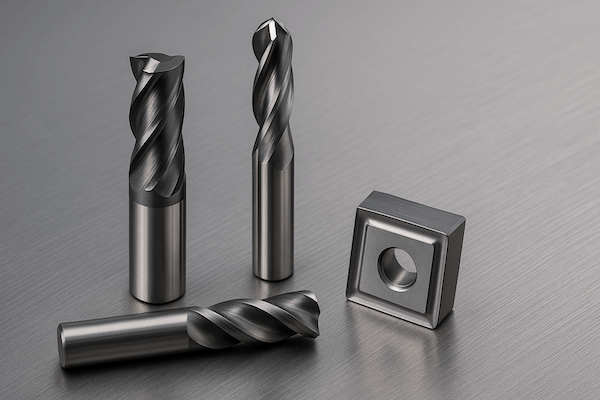

Tungsten Carbide Bushings: Structure, Composition, and Micrograin Types

In modern industrial equipment, precision and reliability depend heavily on materials that can handle extreme wear, pressure, and temperature. One such material is tungsten carbide, and one of its most important applications is in bushings. Tungsten carbide bushings play a key role in supporting rotating shafts, reducing friction, and extending the life of pumps, compressors, […]

How Tungsten Carbide Bushings Improve Machine Performance

In modern industry, machines are expected to run faster, longer, and under more demanding conditions than ever before. Reliability and uptime directly affect productivity and profitability. One small but essential component that makes this possible is the tungsten carbide bushing. These precision-made rings or sleeves are used to support shafts, reduce friction, and protect more […]

Understanding Hardness and Toughness in Tungsten Carbide Bushings

When it comes to mechanical parts that face constant wear, pressure, and friction, tungsten carbide bushings are among the most trusted materials. They are used in pumps, compressors, turbines, and other high-load systems where failure is not an option. Their outstanding durability comes mainly from two material properties — hardness and toughness. Both are vital, […]

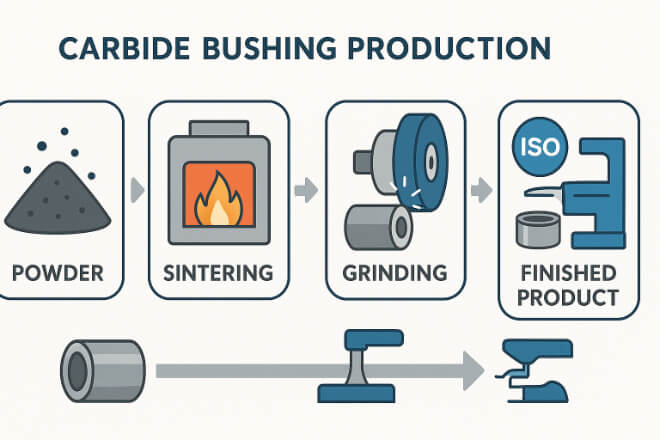

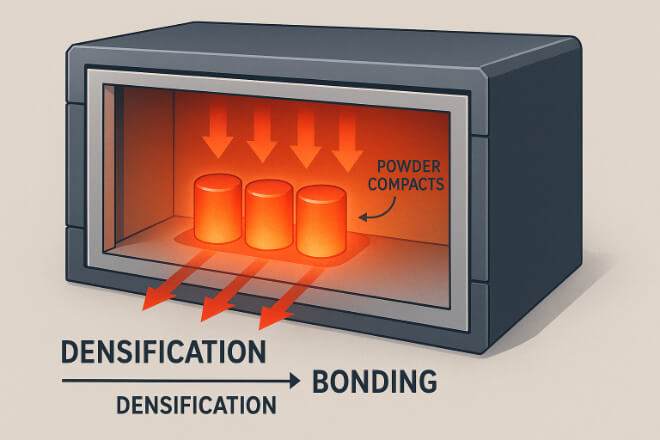

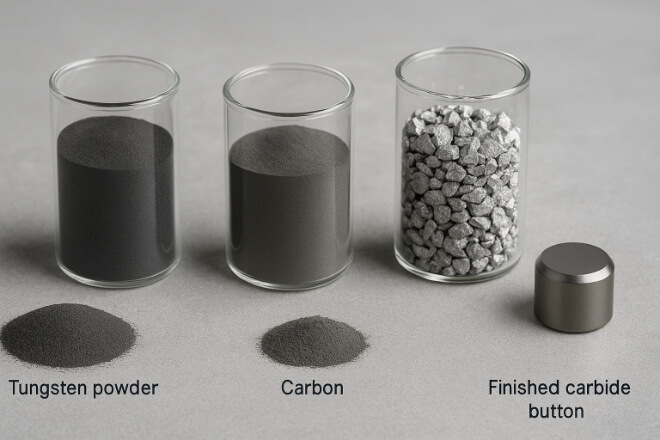

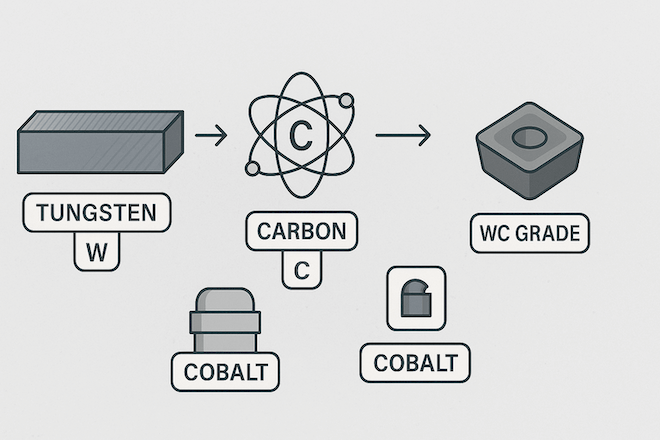

The Manufacturing Process of Tungsten Carbide Bushings Explained

Tungsten carbide bushings are small components with a big impact. They provide wear resistance, strength, and reliability in high-pressure and high-friction systems such as pumps, compressors, and turbines. Behind every finished bushing is a complex manufacturing process that turns fine tungsten and metal powders into a precision-engineered part. Each step — from powder preparation to […]

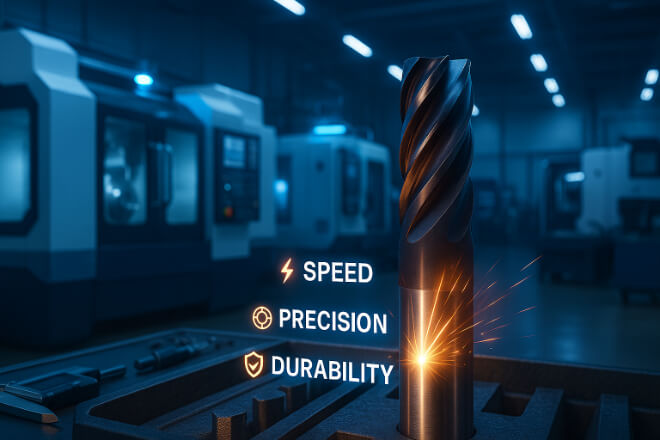

Key Properties That Make Tungsten Carbide Bushings Durable

In many industrial machines, small components decide the reliability of the whole system. Bushings, also known as bearing sleeves, play a quiet but essential role — they reduce friction and protect shafts from wear. When equipment runs under high load, abrasive media, or corrosive fluids, ordinary steel or bronze bushings cannot last long. This is […]

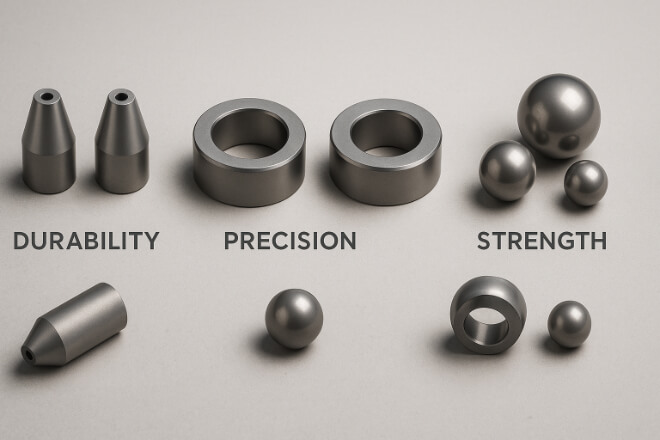

What Are Tungsten Carbide Bushings and How Do They Work?

In modern machinery, reliability often depends on the smallest components. Bushings, also called bearing sleeves or liners, are one such part. They reduce friction between moving parts and protect shafts or housings from wear. When high loads, abrasive fluids, or extreme temperatures are involved, standard steel bushings wear out quickly. That’s where tungsten carbide bushings […]

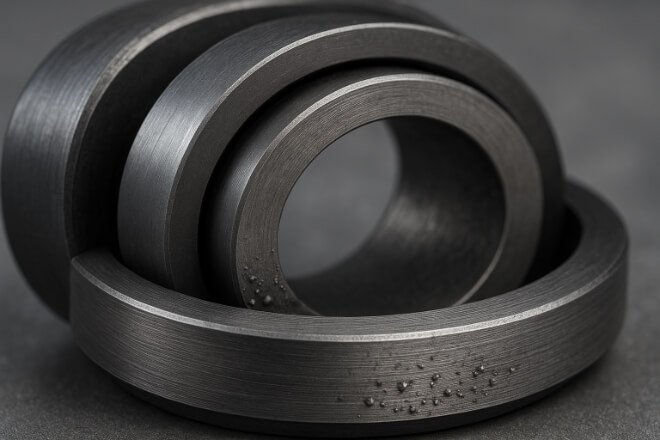

From Casting to Mirror Polish: End-to-End Workflow for Carbide Seal Rings

Producing a carbide seal ring that can survive high pressure, abrasive fluids, and corrosive chemicals is not just about material hardness—it’s about precision at every stage of manufacturing. From the casting of tungsten carbide powder to the final mirror-polished surface, each step determines how well the ring seals, resists wear, and maintains flatness in service. […]

Carbide Seal Rings for Semiconductor Wet Benches and Coaters: Cleanliness and Wear

In semiconductor manufacturing, wet benches and coating systems handle some of the world’s purest chemical processes. These tools rely on precise liquid control—using acids, bases, and cleaning solutions—to process wafers with nanometer-level precision. Any contamination, leakage, or wear in the mechanical seal system can cause defects, yield loss, or costly downtime. For this reason, carbide […]

Submersible Pump Seal Stacks: Why Carbide Faces Excel in Sand-Laden Water