Trong các ngành công nghiệp như dầu khí, chemical processing, marine, and power generation, sealing systems face harsh and corrosive environments.

Equipment often operates under high pressure, heat, and exposure to aggressive fluids.

If seals fail, the result is leakage, downtime, and expensive repairs. For this reason, many companies rely on vòng đệm cacbua vonfram.

This article explores why tungsten carbide is valued for its chemical resistance, how it performs in harsh environments, and what decision-makers should consider when choosing seal rings.

What Makes a Seal Ring Chemically Resistant?

A chemically resistant seal ring is one that can withstand attack from corrosive fluids without losing strength or shape.

In harsh environments, seals must resist:

Acids and alkalis

Seawater and salt solutions

Hydrocarbons such as dầu khí

Aggressive chemical slurries

Without resistance, materials can corrode, swell, or crack, leading to early failure.

Tính chất của vòng đệm cacbua vonfram

Tungsten carbide is a hard compound of tungsten and carbon, usually bonded with cobalt or nickel. Its main properties for chemical resistance include:

Cao Tỉ trọng → Limits fluid penetration.

Khả năng chống ăn mòn → Especially with nickel binder in chemical or marine use.

Độ ổn định nhiệt → Maintains resistance under hot conditions.

Khả năng chống mài mòn → Protects against abrasive fluids with particles.

These features make tungsten carbide suitable for long-term sealing in chemical-rich environments.

Nickel-Bonded vs Cobalt-Bonded Tungsten Carbide

The binder material affects chemical resistance:

1). Cacbua vonfram liên kết coban

Cao độ dẻo dai và khả năng chống sốc.

Vừa phải khả năng chống ăn mòn, weaker against strong acids.

Best for oil and gas pumps under shock loads.

2). Cacbua vonfram liên kết niken

Excellent corrosion resistance in seawater and chemicals.

Less tough than cobalt-bonded.

Best for marine pumps and chemical processing plants.

Decision-makers must choose the grade that matches the operating fluid.

Performance in Harsh Environments

1). Dầu khí

Seal rings resist hydrocarbons, abrasive fluids, and pressure changes, reducing downtime in drilling and refinery pumps.

2). Nhà máy hóa chất

Nickel-bonded tungsten carbide seals resist acids, alkalis, and solvents, ensuring longer service life.

3). Hệ thống hàng hải

Exposure to seawater leads to corrosion in weaker materials. Tungsten carbide seals maintain performance in ballast and cooling pumps.

4). Sản xuất điện

High-temperature fluids and cooling water systems require both thermal stability and corrosion resistance, which tungsten carbide provides.

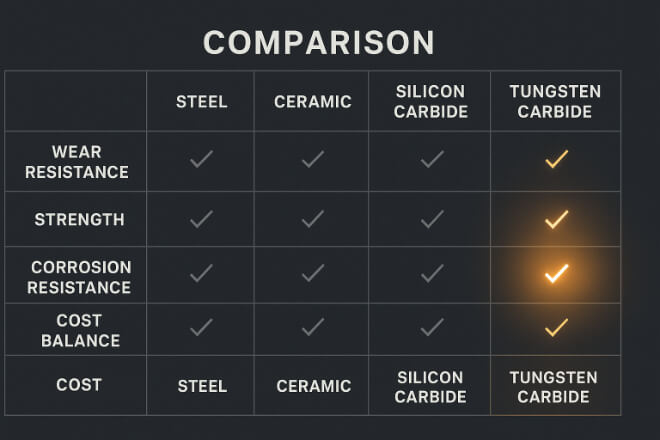

Ưu điểm so với các vật liệu bịt kín khác

Phớt thép → Corrode quickly in acids and seawater.

Con dấu gốm → Resist chemicals but brittle under shock.

Silic cacbua → Corrosion resistant but more fragile under impact.

Cacbua vonfram → Offers the best balance of độ dẻo dai, khả năng chống mài mònvà tính ổn định hóa học.

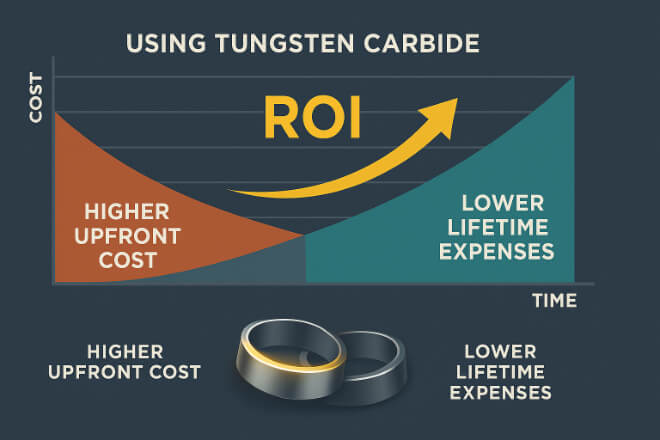

Chi phí so với Giá trị dài hạn

Tungsten carbide seal rings are more expensive upfront than steel or rubber seals. But in harsh environments, their longer life means:

Ít thay thế hơn

Chi phí bảo trì thấp hơn

Giảm thời gian chết

Higher return on investment

For companies where downtime costs thousands per hour, tungsten carbide’s value is clear.

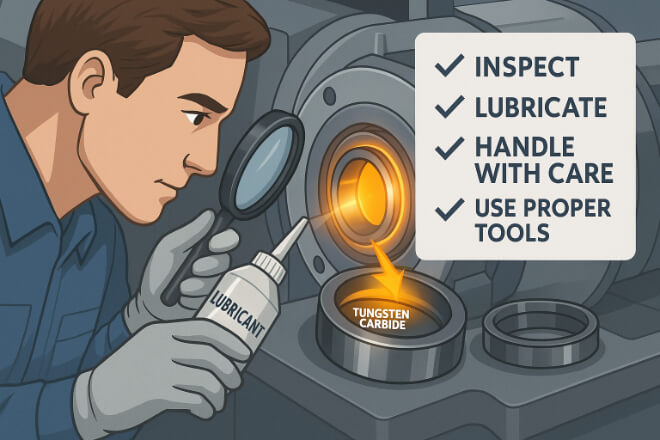

Best Practices to Maximize Chemical Resistance

To improve seal life in harsh environments:

Chọn đúng chất kết dính → Nickel-bonded for corrosive fluids, cobalt-bonded for high shock.

Đảm bảo cài đặt đúng → Avoid scratches that invite corrosion.

Sử dụng chất bôi trơn thích hợp → Prevents overheating and chemical attack.

Regular inspections → Phát hiện sớm các dấu hiệu hao mòn hoặc ăn mòn.

Tính bền vững và tái chế

Another advantage is recyclability. Worn tungsten carbide seal rings can be collected and processed into new materials. Recycling reduces demand for raw tungsten and lowers environmental impact.

Những điểm chính cần ghi nhớ cho người ra quyết định

Tungsten carbide seal rings provide strong chemical resistance in harsh environments.

Nickel-bonded grades are best for marine and chemical industries.

Cobalt-bonded grades are better in high-shock conditions.

Long-term ROI makes tungsten carbide the smarter investment.

Recycling adds sustainability value.

Phần kết luận

For industries facing harsh chemical environments, tungsten carbide seal rings are a proven solution.

They resist corrosion, wear, and heat better than most alternatives, helping mechanical seals perform reliably.

For decision-makers, tungsten carbide is not just a sealing material—it is a strategic choice for long-term efficiency, reliability, and sustainability.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.