Ống lót cacbua vonfram are known for their exceptional độ cứng Và khả năng chống mài mòn.

However, one of the critical factors that determine their performance in various industrial applications is the coefficient of friction (CoF).

The CoF is an important measure of how much frictional resistance occurs when two materials interact, and it directly affects the efficiency, lifespan, and operation of tungsten carbide bushings.

In this blog, we will explore what the coefficient of friction is, how it impacts tungsten carbide bushings, and how to optimize it for different applications.

What is the Coefficient of Friction (CoF)?

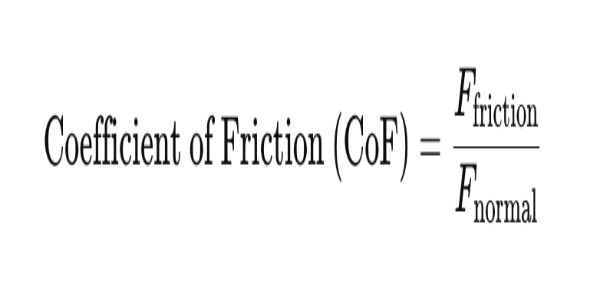

The coefficient of friction is a number that represents the frictional force between two surfaces in contact.

It’s defined as the ratio of the force of friction (the resisting force) to the normal force (the force pressing the surfaces together). Mathematically, it’s expressed as:

There are two main types of friction to consider:

Static Friction: The friction that resists the initiation of motion between two surfaces.

Kinetic Friction: The friction that occurs once the surfaces are already in motion relative to each other.

Vì ống lót cacbua vonfram, kinetic friction is often more relevant as these bushings are typically in motion when in use.

Why is CoF Important in Tungsten Carbide Bushings?

The CoF plays a crucial role in the performance of tungsten carbide bushings. It directly affects:

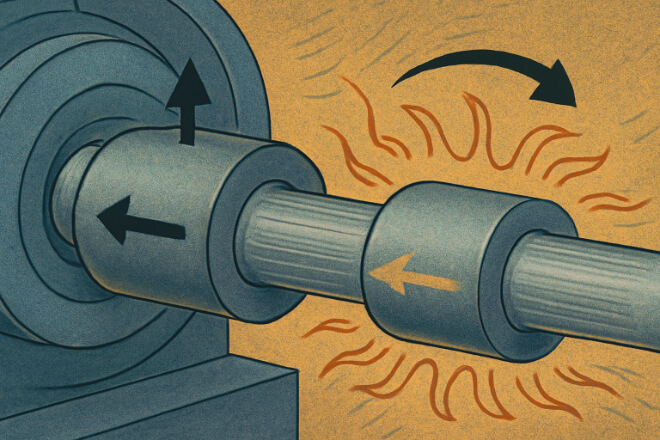

Wear Rate:

Higher CoF means more resistance between the bushing and the shaft, leading to higher wear and tear.

Conversely, a lower CoF reduces wear, prolonging the life of both the bushing and the shaft.

Heat Generation:

Increased friction causes heat, which can damage the materials over time.

Managing CoF helps minimize heat generation, improving the operational efficiency of the system.

Hiệu quả năng lượng:

The lower the friction, the less energy is lost to heat. In high-speed machinery, reducing the CoF can result in better energy efficiency, contributing to overall system performance.

Tải trọng:

The CoF also affects the load capacity of the bushing. In systems where bushings are subjected to high loads.

Abalance between khả năng chống mài mòn and friction is needed to ensure that the bushing can withstand the forces without excessive wear.

Coefficient of Friction in Tungsten Carbide Bushings: A Closer Look

Tungsten carbide bushings generally have a low coefficient of friction, which is one of the reasons they are ideal for high-wear applications.

However, the exact CoF can vary depending on several factors:

1). Material Pairing

The CoF is influenced by the materials in contact with the tungsten carbide bushing. For example:

Tungsten Carbide on Steel: This combination typically has a low CoF, making it suitable for high-speed applications.

Tungsten Carbide on Ceramic: When paired with ceramic materials, the CoF may increase slightly due to the higher độ cứng of ceramics, but it still maintains low friction compared to many metals.

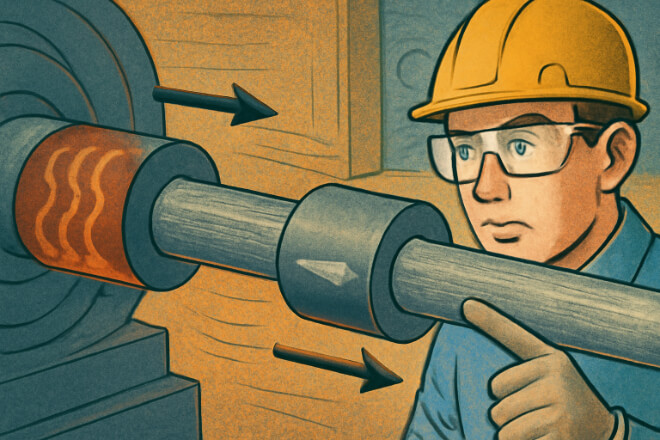

2). Hoàn thiện bề mặt

The surface finish of the bushing and the shaft also plays a major role in the CoF. A smoother surface reduces friction, while a rougher surface increases it.

Common surface finishes for tungsten carbide bushings include:

Polished Surface: Offers a very low CoF, ideal for high-precision applications where minimal friction is essential.

Ground Surface: While still low, a ground surface may have slightly higher friction compared to a polished surface.

3). Lubrication

Lubrication reduces the CoF by creating a thin film between the bushing and the shaft.

In dry conditions, the CoF can be higher, which leads to more wear and heat generation.

The type of lubricant used (oil, grease, solid lubricants) significantly impacts the CoF and the longevity of the bushing.

Oil Lubrication: Lowers friction and is suitable for high-speed operations.

Grease Lubrication: Ideal for low-speed or high-load conditions where consistent lubrication is needed.

Solid Lubricants: These are used in extreme conditions where liquid lubricants are ineffective, and can help maintain a low CoF.

4). Operating Conditions

Factors such as temperature, speed, and load all influence the CoF. At higher temperatures, the materials may expand, changing the CoF.

In high-speed applications, even small changes in CoF can lead to significant differences in performance and wear rates.

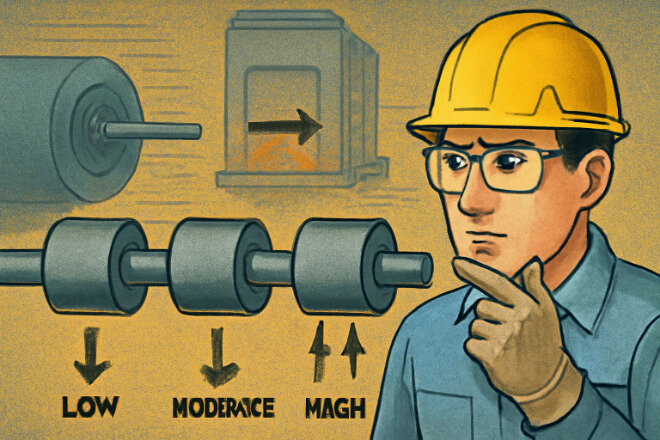

The Ideal CoF for Tungsten Carbide Bushings

The ideal CoF for ống lót cacbua vonfram depends on the specific application:

Low CoF (< 0.2):

In high-speed, low-load applications like precision machinery and pumps, a very low CoF is preferred to minimize wear and heat generation.

Moderate CoF (0.2 – 0.5):

For applications with moderate loads and speeds, such as automotive or industrial equipment, a slightly higher CoF may be acceptable.

High CoF (> 0.5):

In high-load applications where khả năng chống mài mòn is the primary concern, such as heavy machinery or mining equipment.

Ahigher CoF may be acceptable, as the focus shifts to toughness rather than friction reduction.

CoF Ranges for Different Applications

| Ứng dụng | Ideal CoF Range | Material Pairing |

|---|---|---|

| High-Speed Machinery | < 0.2 | Tungsten carbide on steel or ceramic |

| Industrial Equipment | 0.2 – 0.5 | Tungsten carbide on stainless steel |

| Heavy Machinery | > 0.5 | Tungsten carbide on hardened steel |

How to Control CoF in Tungsten Carbide Bushings

Controlling the CoF in tungsten carbide bushings involves several strategies, including:

1). Material Selection

Selecting the right material pairing for the bushing and the shaft is the first step in controlling the CoF.

Tungsten carbide, when paired with materials like stainless steel or ceramics, can result in an optimized low CoF, reducing friction and wear.

2). Surface Treatment

Applying a smoother finish or coating on the bushing and the shaft can significantly lower the CoF.

Polishing the bushing or using diamond-like carbon (DLC) coatings can further reduce friction, making them ideal for precision applications.

3). Proper Lubrication

Using the correct lubricant based on the application’s speed, temperature, and load will help reduce the CoF and protect the bushing from excessive wear.

4). Regular Maintenance

Regular monitoring of friction and wear can help identify changes in CoF over time, ensuring that any issues are addressed before they affect the performance of the system.

Phần kết luận

The coefficient of friction is a key factor in the performance and longevity of tungsten carbide bushings.

By understanding how the CoF is influenced by material pairing, surface finish, lubrication, and operating conditions, manufacturers can optimize their systems to achieve greater efficiency and wear resistance.

Whether for high-speed, high-load, or heavy-duty applications, managing the CoF in tungsten carbide bushings is essential for improving overall operational performance.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.