Tungsten carbide has been a trusted material for các bộ phận hao mòn for decades. Its hardness, toughness, and wear resistance make it a top choice in industries like khai thác mỏ, dầu khí, tạo hình kim loại, and manufacturing.

However, the technology behind tungsten carbide is not standing still. New developments in materials science, manufacturing processes, and coatings are changing how các bộ phận hao mòn cacbua vonfram are made and how they perform.

For decision-makers, understanding these emerging technologies is important.

It can help you improve product performance, reduce downtime, and make better purchasing decisions. This article looks at the latest innovations shaping the future of tungsten carbide wear parts.

Advances in Tungsten Carbide Powder Production

The performance of tungsten carbide parts starts with the powder. Better powder means better end products.

1). Ultra-Fine Grain Powders

- New pro

duction methods create finer grains, often below 0.5 microns.

Finer grains improve toughness and wear resistance.

Best for applications that require precision and durability.

2). Spray-Dried Powders

Uniform particle shapes improve packing density.

This leads to more consistent sintering results.

Helps reduce porosity and improve final strength.

Impact for Businesses: These powders help make stronger, longer-lasting wear parts, lowering replacement rates.

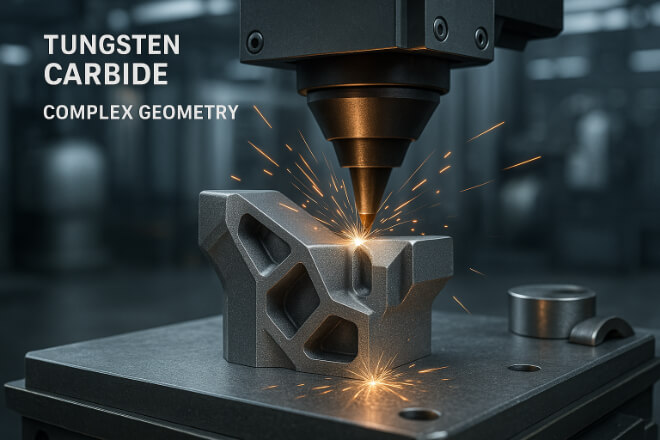

Additive Manufacturing (3D Printing) of Tungsten Carbide

3D printing is no longer just for plastics and lightweight metals. Advanced additive manufacturing methods can now process tungsten carbide-based materials.

1). Benefits:

Complex geometries that are hard to make with traditional machining.

Faster prototyping for custom wear parts.

Reduced waste compared to traditional cutting and grinding.

2). Limitations:

Still slower than mass production.

Requires advanced printers and binders.

Impact for Businesses: Ideal for custom, low-volume, high-performance parts where design flexibility is important.

Improved Sintering Technologies

Sintering is the process that bonds tungsten carbide powder with binders, usually cobalt or nickel.

1). Spark Plasma Sintering (SPS)

Uses electric pulses to speed up the sintering process.

Creates dense, uniform structures with fewer defects.

Can produce parts with better grain control.

2). Hot Isostatic Pressing (HIP)

Applies high pressure and heat from all directions.

Eliminates pores, improving độ dẻo dai and reliability.

Impact for Businesses: Sintering improvements mean more consistent part quality and fewer failures in the field.

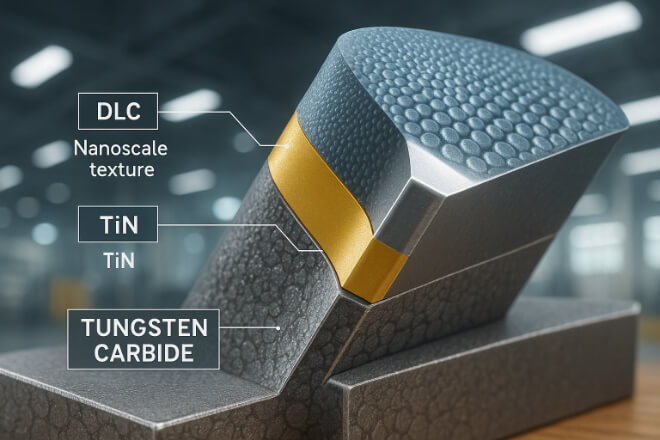

Advanced Coating Technologies

Coatings extend the life of tungsten carbide parts by reducing wear, friction, and heat damage.

1). Nanostructured Coatings

Ultra-thin layers with nanoscale structures.

Improve hardness without making the part brittle.

2). Multi-Layer Coatings

Combine different materials (e.g., TiN + AlTiN).

Each layer addresses different wear mechanisms.

3). Diamond-Like Carbon (DLC) Coatings

Reduce friction to near zero.

Great for non-ferrous material machining.

Impact for Businesses: Coatings can double or triple part life in demanding environments, saving costs over time.

Hybrid Tungsten Carbide Composites

New materials combine tungsten carbide with other hard phases to create tailored performance.

Examples:

WC + TiC (Titanium Carbide): Better resistance to high-temperature wear.

WC + Cr3C2 (Chromium Carbide): Improved corrosion resistance.

WC + Ceramics: Lower density while keeping độ cứng.

Impact for Businesses: Allows parts to be designed for specific environments, reducing premature failures.

Digital Manufacturing and Quality Control

Industry 4.0 is making its way into tungsten carbide production.

1). In-Line Quality Sensors

Monitor grain size, density, and binder distribution during production.

Detect defects before parts leave the factory.

2). AI-Driven Process Control

Uses machine learning to adjust sintering and grinding parameters in real time.

Ensures consistent part quality batch after batch.

Impact for Businesses: Reduces risk of receiving defective parts and improves predictability in part lifespan.

Recycling and Sustainable Tungsten Carbide Production

Tungsten is a critical raw material. Many countries now encourage recycling to reduce reliance on mining.

1). Closed-Loop Recycling

End-of-life parts are collected, crushed, and processed into new powders.

Maintains high material quality.

2). Eco-Friendly Binder Alternatives

Research into cobalt-free binders to reduce toxicity and environmental risks.

Impact for Businesses: Helps meet sustainability goals while keeping costs down.

Application-Specific Customization

Emerging technology allows tungsten carbide parts to be optimized for individual industries.

Examples:

Mining: Extra-thick coatings for drilling in abrasive rock.

Oil & Gas: Corrosion-resistant carbides for saltwater exposure.

Metal Forming: Ultra-smooth surfaces to improve sheet metal flow.

Impact for Businesses: More targeted solutions improve performance and reduce downtime in specific operating conditions.

Cost vs. Performance Considerations

While these new technologies often come at a higher initial cost, they can deliver a better return on investment (ROI) by extending part life and improving efficiency.

| Technology | Performance Gain | Initial Cost | Best Use Case |

|---|---|---|---|

| Ultra-fine grain powders | Cao | Vừa phải | Precision machining, wear-critical parts |

| 3D printing | Trung bình | Cao | Custom, low-volume production |

| Nanostructured coatings | Rất cao | Vừa phải | High-speed, abrasive environments |

| Vật liệu composite lai | Trung bình | Vừa phải | Specialized wear and corrosion resistance |

| Recycling processes | Low to Medium | Thấp | Cost and sustainability focus |

The Future of Tungsten Carbide Wear Parts

The combination of materials science, digital manufacturing, and sustainable practices means tungsten carbide will continue to evolve. Decision-makers should:

Stay informed about new coating and sintering methods.

Work with suppliers that invest in advanced powder technology.

Consider total lifecycle costs, not just purchase price.

Phần kết luận

Tungsten carbide wear parts are becoming stronger, more efficient, and more specialized thanks to emerging technologies.

From ultra-fine powders to AI-driven production and sustainable recycling, these innovations help industries reduce downtime, improve product quality, and extend part life.

For business leaders, the key is to match the right technology with the right application. Investing in advanced tungsten carbide solutions can give your company a competitive advantage in performance and cost efficiency.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.