Ống lót cacbua vonfram are designed for extreme khả năng chống mài mòn and high load performance.

They are widely used in pumps, compressors, turbines, and heavy-duty industrial machinery.

However, after long periods of use, even carbide bushings begin to lose dimensional accuracy and surface quality.

Instead of immediate replacement, regrinding or refurbishing can often restore their performance — saving time and cost.

This article explains how to evaluate, regrind, and refurbish tungsten carbide bushings effectively, including inspection steps, grinding parameters, and post-refurbishment testing.

When to Consider Regrinding or Refurbishment

Not every worn bushing needs replacement. If the core material is intact and the damage is limited to surface wear, regrinding is often the smarter choice.

You should consider regrinding when:

The inner or outer surface shows minor wear but no cracks.

The dimensional deviation is within 0.1 mm.

Surface roughness has increased but remains even.

There are no fractures or binder leaching marks.

Refurbishment helps restore the original geometry, surface finish, and clearance tolerance — extending service life by 50–80%.

Initial Inspection and Damage Assessment

Before any regrinding process, a detailed inspection must be done to assess the bushing’s condition.

Step 1: Visual Inspection

Check for visible wear, grooves, or discoloration. Cracks or deep pitting usually mean replacement, not repair.

Step 2: Dimensional Check

Use micrometers or bore gauges to measure inner diameter (ID), outer diameter (OD), and concentricity. Compare with design drawings.

Step 3: Hardness and Microstructure

Measure Rockwell độ cứng (HRA scale). Typical tungsten carbide bushings should read 87–91 HRA. Lower hardness suggests binder degradation.

Step 4: Magnetic and Dye Penetrant Testing

Used to detect subsurface cracks before regrinding.

Typical Damage Types Suitable for Regrinding

Below is a quick guide to help determine if a bushing can be refurbished.

| Damage Type | Severity Level | Repair Feasibility |

|---|---|---|

| Minor Scoring or Polishing Marks | Thấp | Easily repaired by fine regrinding |

| Moderate Pitting or Corrosion Spots | Trung bình | Repairable with deep grind and lapping |

| Thermal Cracks or Binder Leaching | Cao | Not recommended; replace the bushing |

Refurbishment is most successful when damage is shallow and evenly distributed.

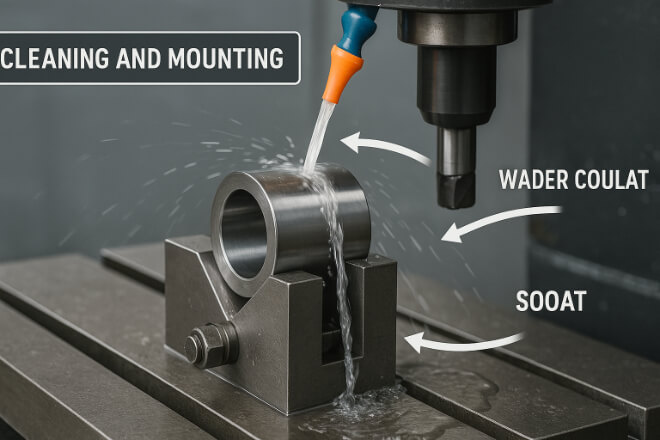

Preparation Before Grinding

To achieve precision, cleaning and fixturing are key steps before regrinding.

1). Cleaning:

Remove oil, grease, and oxide film using ultrasonic cleaning.

Avoid aggressive acids that attack cobalt or nickel binders.

2). Mounting:

Secure the bushing concentrically using a precision V-block or soft jaw chuck.

Ensure stable alignment to prevent taper or eccentric wear.

3). Marking Reference Points:

Mark axial and radial orientation to maintain geometry consistency.

Proper preparation ensures the bushing can be ground evenly and within tolerance.

Grinding Process Parameters

Tungsten carbide’s độ cứng demands diamond or cubic boron nitride (CBN) grinding wheels.

The process must balance material removal rate, temperature, and surface finish.

| Parameter | Recommended Range | Notes |

|---|---|---|

| Wheel Type | Resin-bonded diamond | Provides smooth finish with low stress |

| Wheel Speed | 20–30 m/s | Too high speed increases surface heat |

| Feed Rate | 0.01–0.05 mm/rev | Use smaller feed for fine finish |

| Coolant | Water-soluble oil or synthetic emulsion | Avoid dry grinding to prevent cracking |

Always monitor coolant flow to control grinding zone temperature below 60°C to prevent microcracks.

Lapping and Polishing

After regrinding, lapping and polishing restore surface smoothness and dimensional precision.

1). Lapping Steps:

Use a cast-iron or copper lap plate.

Apply diamond slurry (1–3 µm) with consistent motion.

Rotate both lap plate and bushing to achieve uniformity.

2). Polishing Steps:

Use colloidal silica or alumina slurry on a soft pad.

Aim for a mirror finish of Ra 0.05–0.1 µm.

This final step improves friction behavior and enhances khả năng chống mài mòn.

Dimensional Verification After Regrinding

After machining and polishing, check all dimensions to confirm precision.

| Parameter | Tolerance | Inspection Tool |

|---|---|---|

| Inner Diameter (ID) | ±0.003 mm | Air gauge or bore micrometer |

| Roundness | < 0.005 mm deviation | CMM or roundness tester |

| Surface Finish (Ra) | 0.05–0.1 µm | Surface profilometer |

Proper verification ensures the bushing meets the same standards as new components.

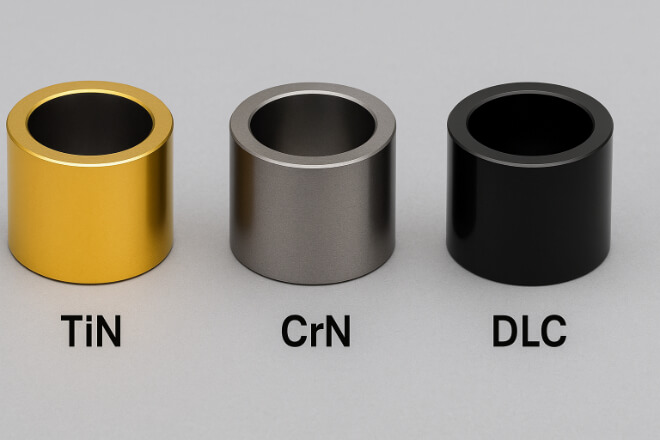

Coating and Surface Protection (Optional)

In high-corrosion or abrasive environments, consider applying protective coatings after refurbishment.

Common coatings include:

Titanium Nitride (TiN): Improves độ cứng and oxidation resistance.

Chromium Nitride (CrN): Provides excellent khả năng chống ăn mòn.

Diamond-like Carbon (DLC): Reduces friction and extends wear life.

These coatings help delay future wear, making regrinding a longer-lasting investment.

Economic and Environmental Benefits

Refurbishing tungsten carbide bushings is both cost-efficient and eco-friendly:

Cost Savings: 40–70% compared to new bushings.

Shorter Lead Time: Refurbishment takes days, not weeks.

Reduced Waste: Minimizes scrap carbide and energy use.

Sustainability: Supports circular manufacturing principles.

Many companies now include regrinding programs as part of their maintenance strategy.

Phần kết luận

Regrinding and refurbishing tungsten carbide bushings is an effective way to restore performance and reduce operating costs.

When done with precision and proper inspection, refurbished bushings can perform nearly as well as new ones.

By following structured steps — inspection, grinding, lapping, verification, and protection — you ensure reliable performance and a longer service life for your critical machinery.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.