In pumps, turbines, and compressors, seal rings are essential. They stop leaks, protect equipment, and keep operations safe.

But not all vòng đệm cacbua vonfram are the same. They come in different grades, each designed for a specific condition.

For decision-makers, choosing the correct grade can make the difference between smooth performance and costly breakdowns.

This guide explains how to select the right tungsten carbide seal ring grade based on environment, binder type, pressure, and chemical exposure.

What Is a Tungsten Carbide Seal Ring Grade?

A grade refers to the specific formula of tungsten carbide and binder used to make the seal ring.

By changing binder type or percentage, the ring’s properties also change.

Cobalt binder → higher độ dẻo dai

Nickel binder → better khả năng chống ăn mòn

Mixed or coated grades → designed for special conditions

Selecting the right grade ensures longer life and better performance.

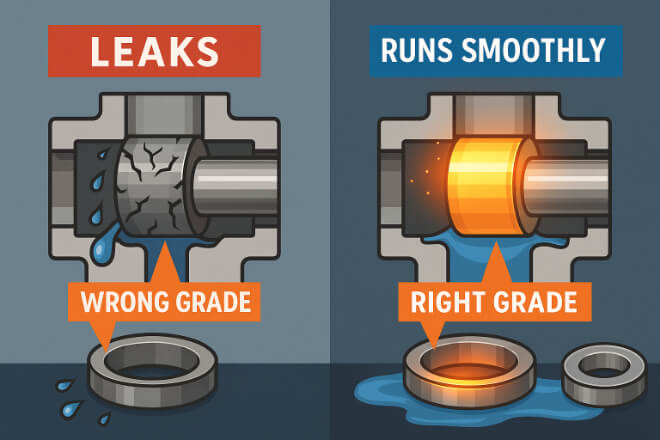

Why Grade Selection Matters

The wrong grade can lead to:

Cracks or wear under high load

Fast corrosion in chemical plants

Seal failure in high-temperature systems

Increased replacement costs

The correct grade matches environment, fluid type, and load conditions, giving decision-makers peace of mind and cost savings.

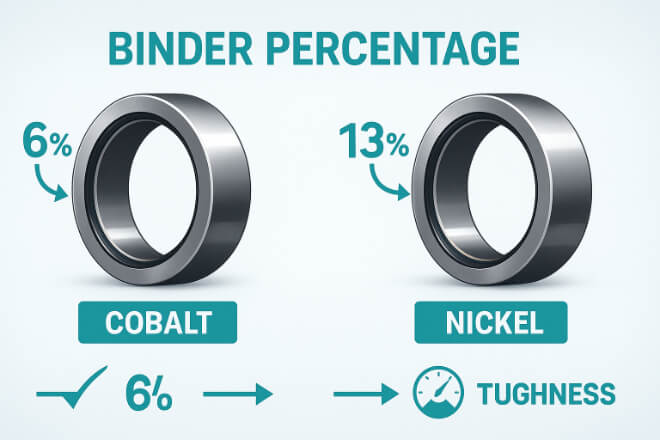

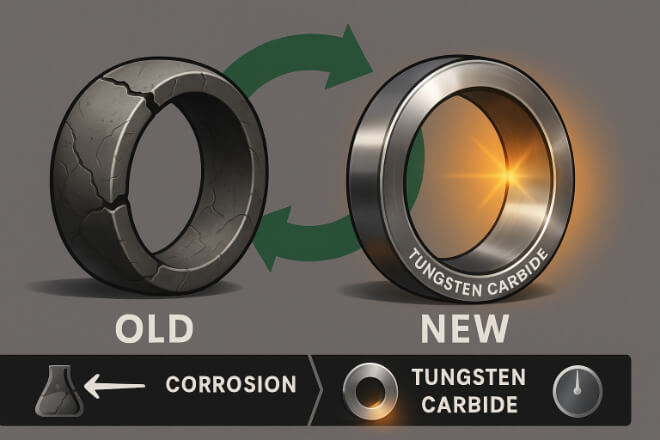

Binder Choice: Nickel vs Cobalt

1). Cobalt-Bonded Grades

Tougher and stronger under heavy pressure

Best for dầu, khí đốt, Và khai thác mỏ industries

Less resistant to acids and seawater

2). Nickel-Bonded Grades

Xuất sắc khả năng chống ăn mòn

Safer in chemical and marine applications

Slightly lower độ dẻo dai than cobalt grades

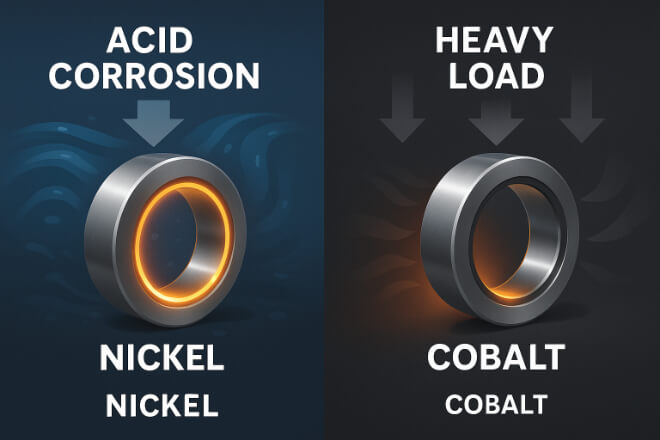

Tip for buyers: If corrosion is the main risk → choose nickel. If load and shock are higher → choose cobalt.

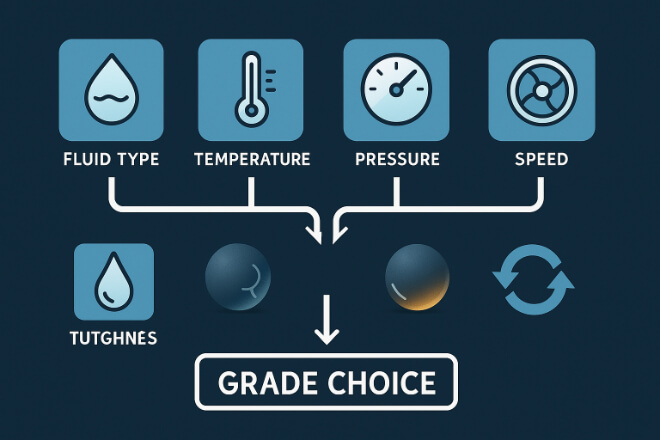

Operating Conditions That Affect Grade Selection

1). Fluid Type

Acids, solvents, seawater → nickel-bonded grades

Abrasive slurry or drilling mud → cobalt-bonded grades

2). Temperature

Standard tungsten carbide works in hot environments

Thermal shock grades are better for systems with sudden heat changes

3). Pressure

High-pressure pumps and turbines → cobalt binder preferred

Moderate pressure with corrosive media → nickel binder

4). Speed

- High-speed compressors and mixers need smoother, low-friction grades

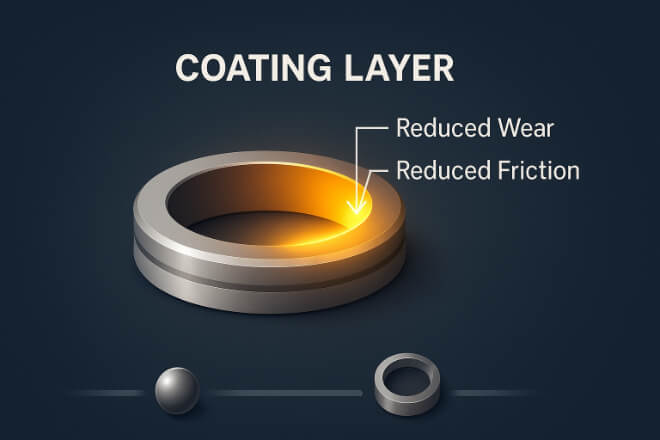

Special Coatings and Composite Grades

In some cases, standard nickel or cobalt grades are not enough.

Diamond-like coatings (DLC): extra protection against friction

Composite grades: tungsten carbide mixed with ceramics for unique needs

Polished surfaces: reduce heat and wear in high-speed systems

Decision-makers should ask suppliers if coated or composite grades are needed for special applications.

Industry Examples of Grade Selection

1). Dầu khí

Cobalt-bonded grades are used in downhole pumps and compressors because they resist impact and abrasion.

2). Nhà máy hóa chất

Nickel-bonded grades are preferred for acids and corrosive solvents.

3). Marine and Offshore

Nickel-bonded grades perform better in seawater, preventing premature failures.

4). Sản xuất điện

Cobalt-bonded grades work in turbines and steam systems, where pressure and heat are very high.

Steps to Select the Right Grade

1). Identify the Environment

Is it corrosive, abrasive, or clean?

2). Check Temperature and Pressure

High stress → cobalt grades

Corrosive + moderate stress → nickel grades

3). Consider Speed and Friction

Fast-moving systems may need polished or coated grades

4). Review Industry Standards

Follow ISO and safety requirements

5). Work With Trusted Suppliers

Ask for recommendations based on proven case studies

Common Mistakes to Avoid

Choosing based on cost alone

Ignoring chemical compatibility

Forgetting to plan for maintenance cycles

Not checking supplier certifications

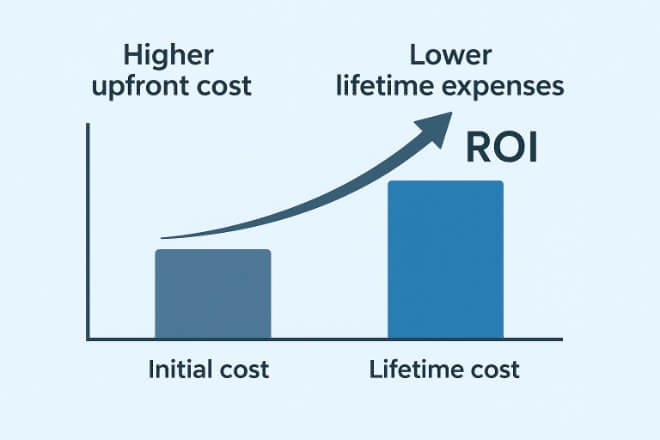

Correct grade choice lowers lifetime cost, even if initial price is higher.

Maintenance and Replacement Planning

Even with the right grade, regular care is needed.

Inspection: Every few weeks in critical systems

Warning Signs: Leaks, noise, cracks, or corrosion marks

Replacement: Always match the original grade and dimensions

Recycling: Old tungsten carbide rings can be recycled, saving money

Cost and ROI of Correct Grade Selection

The upfront cost of nickel-bonded or cobalt-bonded grades is higher than steel or graphite. But for decision-makers, the return is clear:

5–10x longer lifespan

Fewer failures and shutdowns

Safer operations in critical plants

Stronger long-term savings

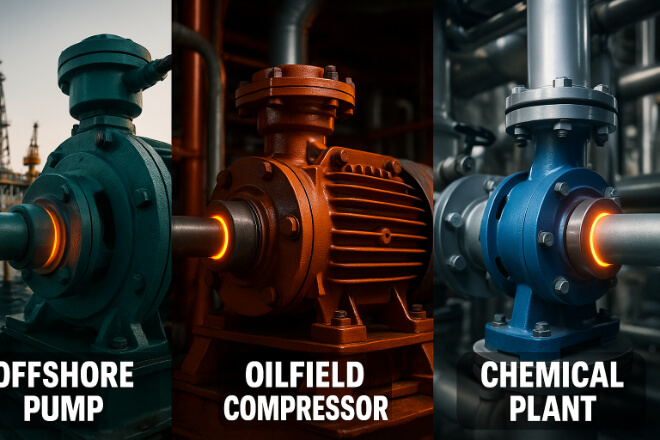

Nghiên cứu điển hình

1). Offshore Pump Manufacturer

Switched from cobalt to nickel-bonded grades for seawater pumps. Result: longer service life, lower warranty claims.

2). Oilfield Compressor

Used cobalt grades for high-pressure drilling. Result: fewer cracks and better uptime.

3). Chemical Plant

Replaced stainless steel seals with nickel-bonded tungsten carbide. Result: reduced corrosion failures and safer operations.

How to Source the Right Grade

When buying tungsten carbide seal rings:

Confirm binder type (nickel or cobalt)

Ask for grade recommendations based on your fluid and pressure

Check ISO and industry certifications

Choose suppliers with local stock for quick delivery

Phần kết luận

Choosing the right tungsten carbide seal ring grade is not just technical—it’s a business decision.

Nickel-bonded → better for corrosion resistance

Cobalt-bonded → better for toughness and load

By matching grade to operating conditions, decision-makers can improve reliability, reduce downtime, and secure stronger long-term ROI.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.