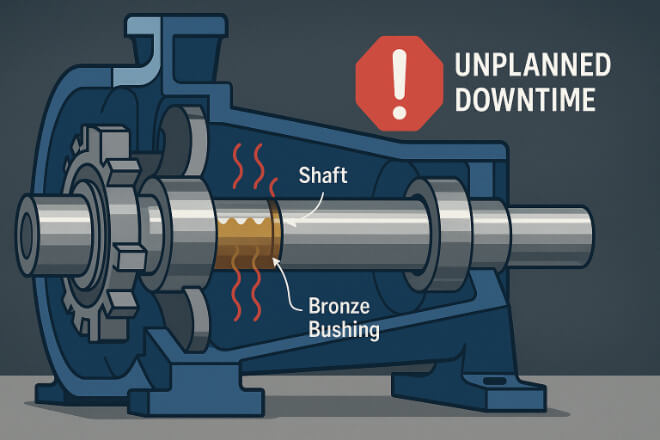

In industrial environments, downtime is expensive. Every hour a pump, compressor, or turbine stops working costs time, money, and sometimes even production losses.

Many of these failures start with small components — like bushings — wearing out faster than expected.

Ống lót cacbua vonfram have become the industry standard for reducing maintenance frequency and unplanned shutdowns.

Their exceptional độ cứng, khả năng chống mài mòn, and stability make them ideal for extending equipment life and minimizing downtime.

This article explains how tungsten carbide bushings help companies achieve better reliability, lower maintenance costs, and higher operational efficiency.

Why Downtime Happens in Rotating Equipment

Downtime often begins with minor mechanical failures. Bushings are key elements that guide shafts and reduce friction in moving parts.

When they wear out or lose alignment, the entire system can suffer.

Common causes of downtime include:

Abrasive wear from particles in fluids

Shaft misalignment due to bushing deformation

Corrosion in chemical or marine environments

Thermal expansion causing clearance loss

Vibration fatigue or cracking

Ống lót cacbua vonfram are designed to solve all of these issues at once — by resisting wear, maintaining shape, and enduring harsh conditions.

The Role of Tungsten Carbide Bushings in Uptime Improvement

A tungsten carbide bushing acts as a precise interface between the rotating shaft and the housing. It must hold tight tolerances while operating under load, friction, and temperature.

Tungsten carbide provides three main advantages:

Cao độ cứng prevents rapid wear and scoring.

High compressive strength maintains shape under pressure.

Thermal and chemical stability ensures reliable long-term operation.

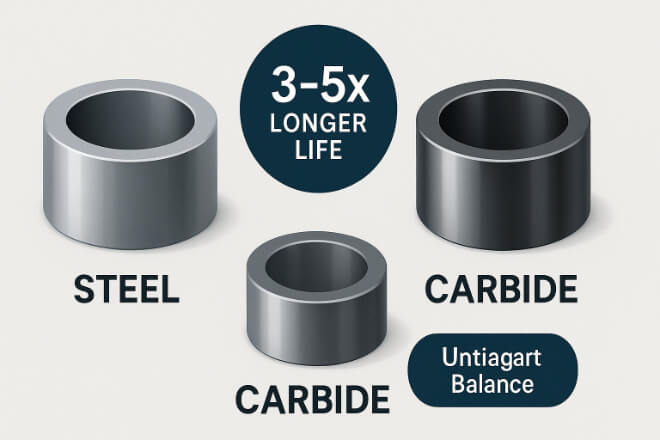

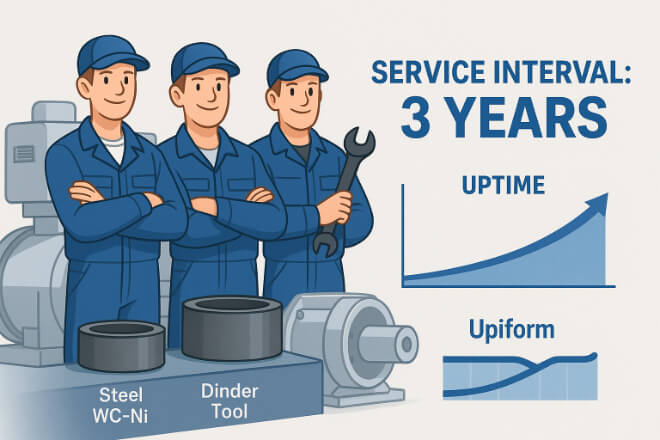

When used properly, carbide bushings can extend service intervals by 3–5 times compared to traditional steel or bronze components.

Mechanical Advantages That Prevent Failure

| Tài sản | Function | Downtime Reduction Impact |

|---|---|---|

| Hardness (88–92 HRA) | Prevents surface wear and scratching | Extends replacement intervals |

| Compressive Strength (>4000 MPa) | Maintains geometry under pressure | Prevents shaft misalignment |

| Độ dẫn nhiệt | Dissipates heat from friction | Avoids overheating and seizure |

Each of these properties plays a role in keeping machinery running longer with fewer interruptions.

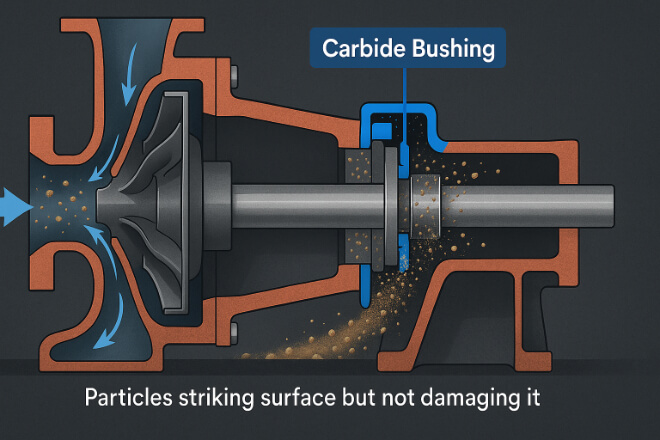

Wear Resistance in Harsh Conditions

In abrasive or particle-rich fluids, steel or bronze bushings wear out quickly.

Tungsten carbide’s extreme độ cứng allows it to resist micro-cutting and abrasive scoring.

Ví dụ:

In slurry pumps, ống lót cacbua vonfram survive months longer than steel ones.

In chemical plants, nickel-bonded carbide resists both corrosion and erosion.

TRONG dầu khí compressors, cobalt-bonded carbide handles shock loads without cracking.

By maintaining smooth surfaces and correct tolerances, these bushings reduce vibration, friction, and energy loss — all factors that shorten maintenance cycles.

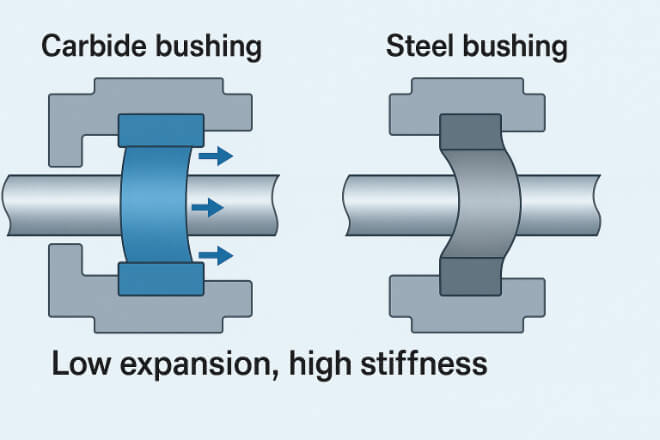

Dimensional Stability and Alignment

A key reason for downtime is shaft misalignment due to component deformation or thermal expansion.

Tungsten carbide’s elastic modulus (500–700 GPa) and low thermal expansion (≈4.5×10⁻⁶/K) prevent this from happening.

As a result:

Clearances remain constant at high speed.

Alignment is maintained through thermal cycles.

Bearings, seals, and shafts all experience less stress.

This mechanical stability directly translates into fewer shutdowns caused by vibration, imbalance, or seal failure.

Resistance to Corrosion and Chemical Attack

| Loại chất kết dính | Khả năng chống ăn mòn | Ứng dụng điển hình |

|---|---|---|

| Coban (Co) | Good; may oxidize in acids | Oilfield and power generation pumps |

| Niken (Ni) | Excellent; resistant to acids and seawater | Chemical and marine equipment |

By choosing the right binder, companies can prevent corrosion-related failure — a common cause of downtime in wet, hot, or chemically active environments.

Lower Maintenance Frequency

Ống lót cacbua vonfram significantly reduce the number of maintenance shutdowns.

Because they maintain surface finish and shape for long periods, inspections and replacements can be scheduled less often.

Điều này có nghĩa là:

Less labor spent on frequent servicing

Fewer spare parts required

More stable operating schedules

In many cases, equipment fitted with tungsten carbide bushings shows a service life increase of up to 300%.

Energy Efficiency and Smooth Operation

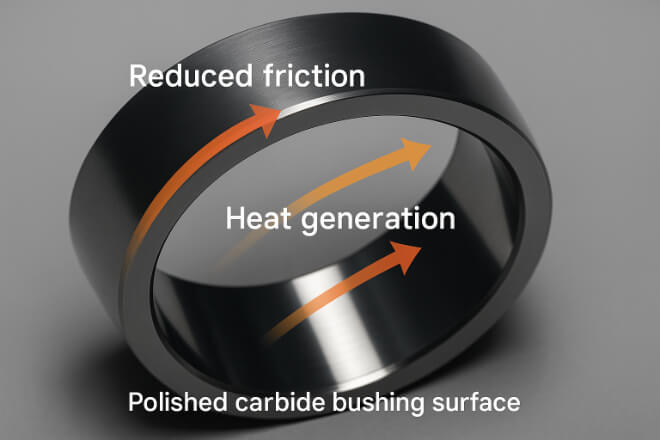

Friction is the enemy of both performance and reliability.

A well-polished carbide bushing (Ra ≤ 0.05 µm) reduces friction between the shaft and housing, improving energy efficiency and lowering operating temperature.

Lower friction also means:

Reduced lubricant degradation

Lower bearing load

Extended seal and shaft life

Together, these effects lower operational stress, minimizing unplanned downtime due to overheating or seizure.

Real-World Comparison

| Vật liệu | Typical Wear Life | Maintenance Frequency |

|---|---|---|

| Bronze Bushings | 3–6 months | Cao |

| Steel Bushings | 6–12 months | Trung bình |

| Tungsten Carbide Bushings | 2–3 years | Thấp |

This table clearly illustrates the difference in longevity and maintenance cost savings.

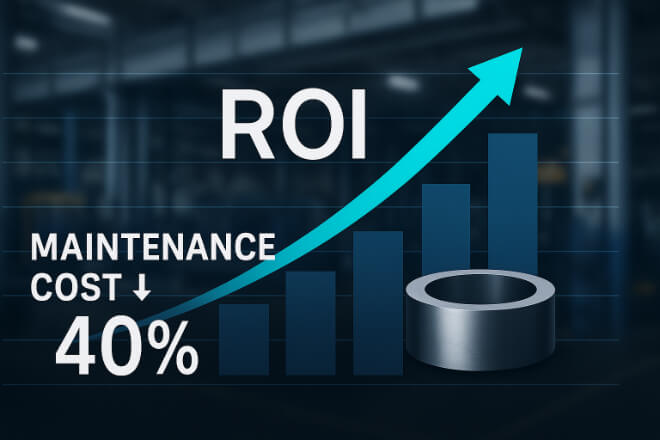

The ROI of Reduced Downtime

Switching to tungsten carbide bushings offers measurable financial returns.

Although the initial cost is higher, the total life-cycle cost is much lower due to reduced maintenance, spare parts, and energy consumption.

Typical ROI factors:

30–50% reduction in total maintenance cost

2–3× longer equipment service life

Improved system uptime and production output

Phần kết luận

Tungsten carbide bushings are one of the most effective ways to reduce equipment downtime.

Their combination of hardness, strength, corrosion resistance, and stability ensures machines keep running longer and more efficiently.

For decision-makers, this translates directly into lower operating costs, higher reliability, and greater ROI.

In critical systems where every hour of uptime counts, carbide bushings are not just a better option — they are a smart investment.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.